Drying method and drying device for pole pieces in pole piece plating process of lithium battery

A battery pole piece and drying device technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of high energy consumption and low heating efficiency, so as to reduce radiant heat energy and reduce energy consumption. Consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

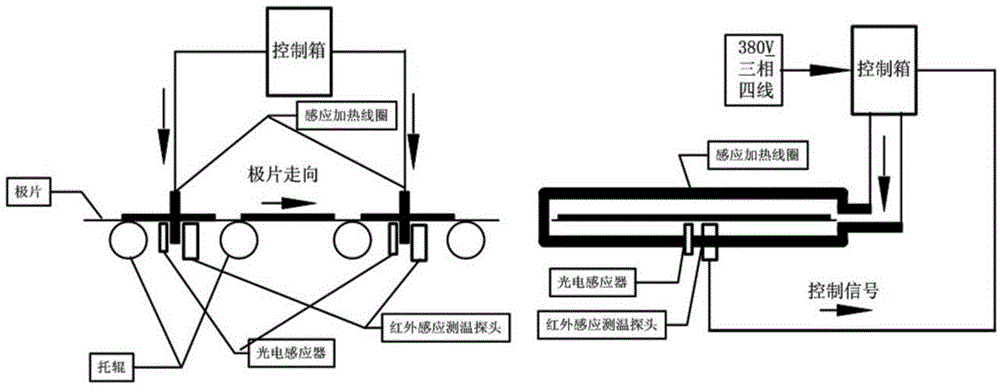

[0024] Example 1: Single-sided intermittent coating and drying (aqueous solvent, pole piece heating temperature range: 70-90°C)

[0025] Such as figure 1 As shown, the battery pole piece coated with electrode slurry intermittently on one side uses a roller to pass through the induction heating coil loaded with medium-frequency or high-frequency alternating current, thereby loading an alternating electromagnetic field on the pole piece. The metal foil of the pole piece is heated rapidly, and the temperature rises to the required drying temperature in a short time. A photoelectric sensor to determine whether an area of paste or blank foil passes through the temperature measuring cell. When the infrared measurement probe installed in the induction heating coil detects that the temperature of the metal foil on the uncoated surface reaches or exceeds the upper limit of the temperature set above, the infrared temperature controller outputs a control signal to the control box (con...

Embodiment 2

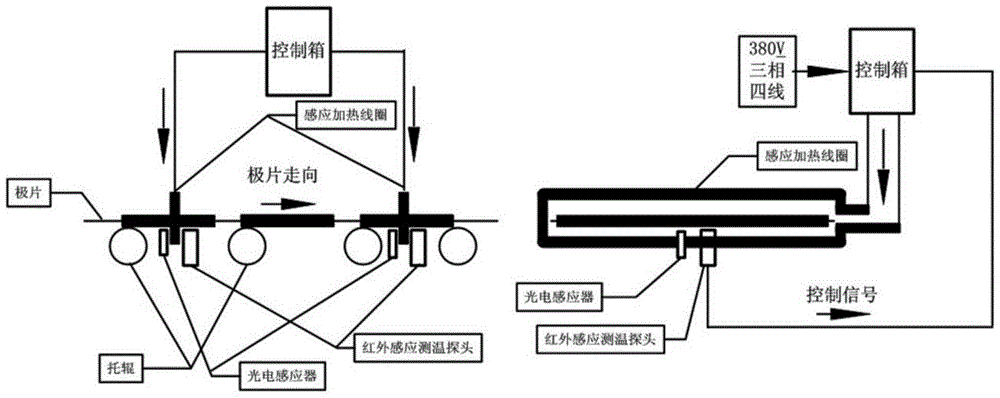

[0026] Embodiment 2: double-sided intermittent coating and drying (solvent is the pole piece of NMP solvent: 120~150 ℃)

[0027] as in figure 2 In the embodiment of double-sided intermittent coating induction heating and drying shown, the pole piece coated with electrode slurry on both sides passes through the induction heating coil loaded with medium-frequency or high-frequency alternating current, thereby applying an alternating electromagnetic field to the pole piece. The metal foil of the pole piece is heated rapidly, and the temperature rises to the required working temperature in a short time. A photoelectric sensor is provided, and when the photoelectric sensor detects that the slurry coating layer runs to the induction heating coil, the control box receives the temperature measurement control signal from the infrared temperature measuring probe. When the photoelectric sensor senses that the metal foil that is not coated with the electrode slurry runs to the induction...

Embodiment 3

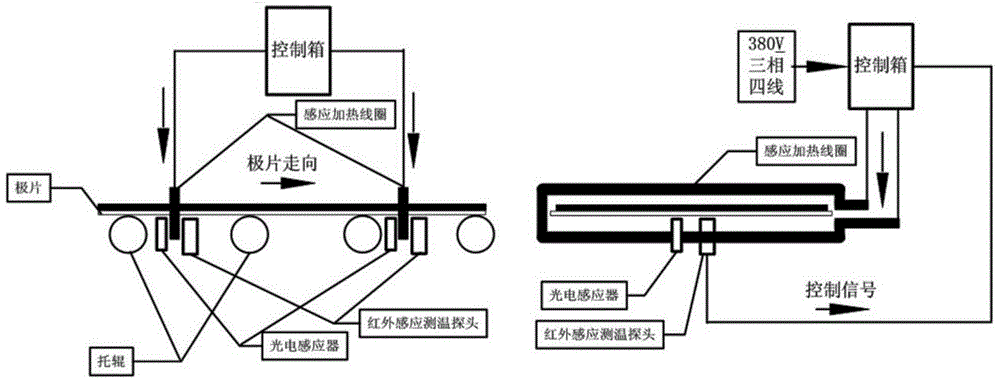

[0028] Embodiment 3: Continuous coating and drying on one side (the pole piece whose solvent is NMP solvent: 120~150° C.)

[0029] as in image 3 In the example of single-side continuous coating induction heating and drying shown in , the pole piece coated with electrode slurry on the first side passes through the induction heating coil loaded with medium-frequency or high-frequency alternating current, thereby loading an alternating electromagnetic field on the pole piece . The metal foil of the pole piece is heated rapidly, and the temperature rises to the required working temperature in a short time. When the photoelectric sensor senses that the slurry coating layer runs to the induction heating coil, the control box receives the temperature measurement control signal from the infrared temperature measuring probe. When the infrared temperature probe detects that the temperature of the metal foil reaches or exceeds the set temperature upper limit, the infrared temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com