Projected closed water-atomizing nozzle

A fine water mist, closed-type technology, applied in fire rescue and other directions, can solve the problems of affecting the effect of splashing fog, reducing fire extinguishing efficiency, and difficulty in forming fine water mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below with reference to the embodiments given in the drawings.

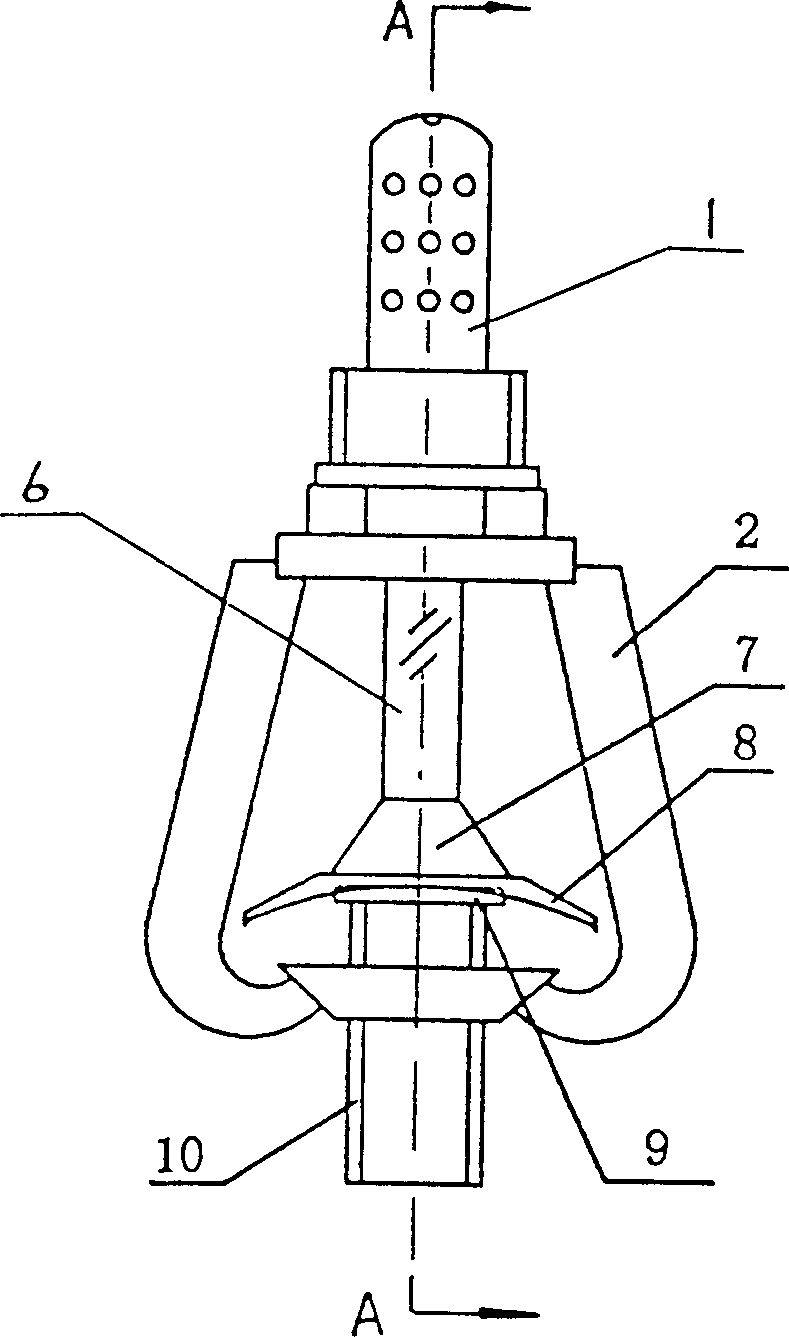

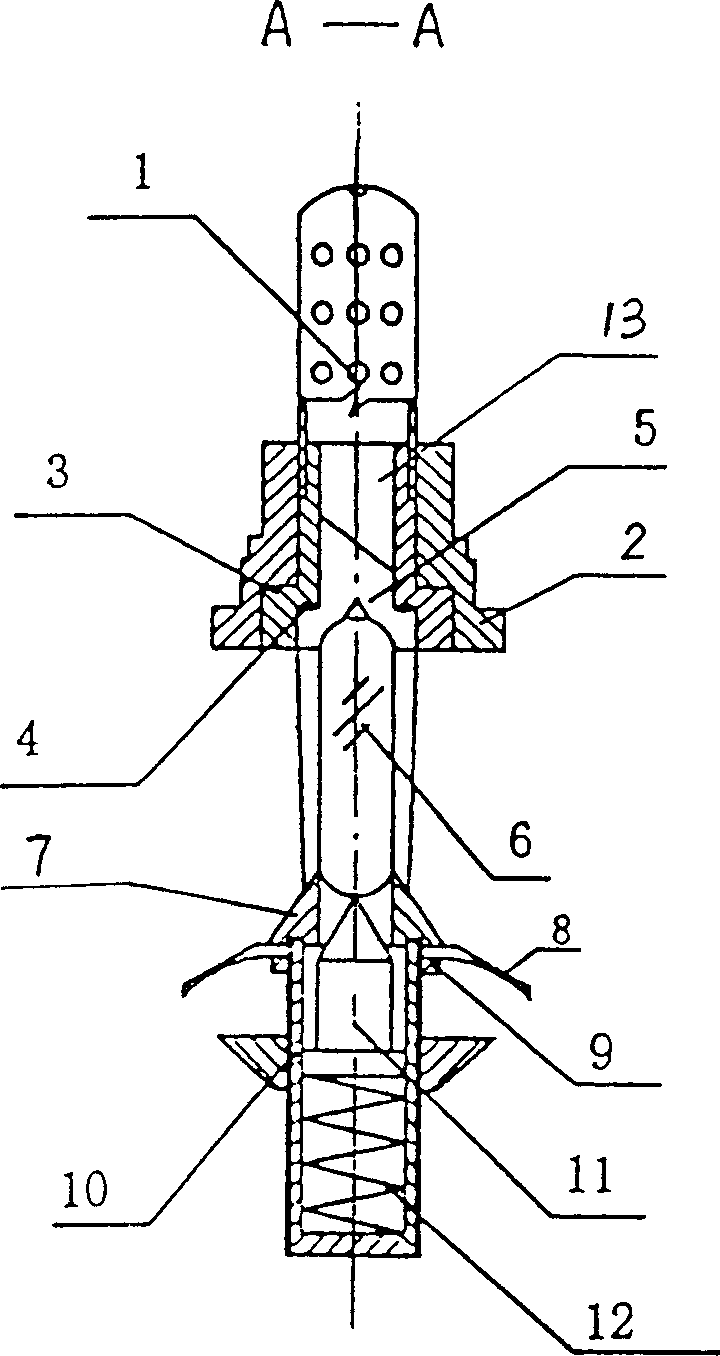

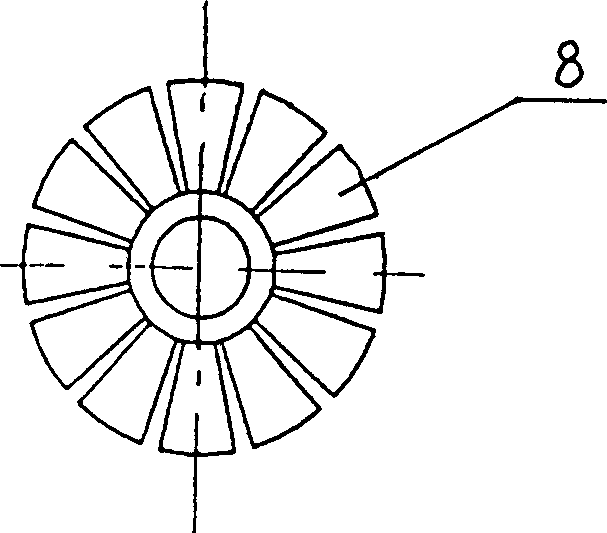

[0010] Such as figure 1 , 2 , 3, a top-out type water mist closed nozzle, including a water filter 1, a water diversion seat 3 with a water diversion hole 13, a sealing column 5, a sealing ring 4, a frame 2, a heat sensitive element 6, a spray mist The cone 7, the splash plate 8 and the solenoid 10, the inner cavity of the water filter 1 communicates with the water diversion hole 13 of the water diversion base 3. The water diversion base 3 is installed on the upper part of the frame 2, and the sealing column 5 is inserted into the water diversion hole of the water diversion base 3. In 13, the upper end of the heat-sensitive element 6 abuts on the sealing column 5, and the lower end abuts on the mist splash cone 7. The splash plate 8 is located below the mist splash cone 7 and is sleeved on the solenoid 10, inside the solenoid 10 A center 11 and a sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com