Encapsulation pulse power capacitor

A pulsed power, capacitor technology, applied in capacitors, fixed capacitors, multiple fixed capacitors, etc., can solve the problems of low reliability and safety, expansion breakdown high-voltage arcing, complicated welding process, etc., to improve product acceleration capability , improve reliability and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

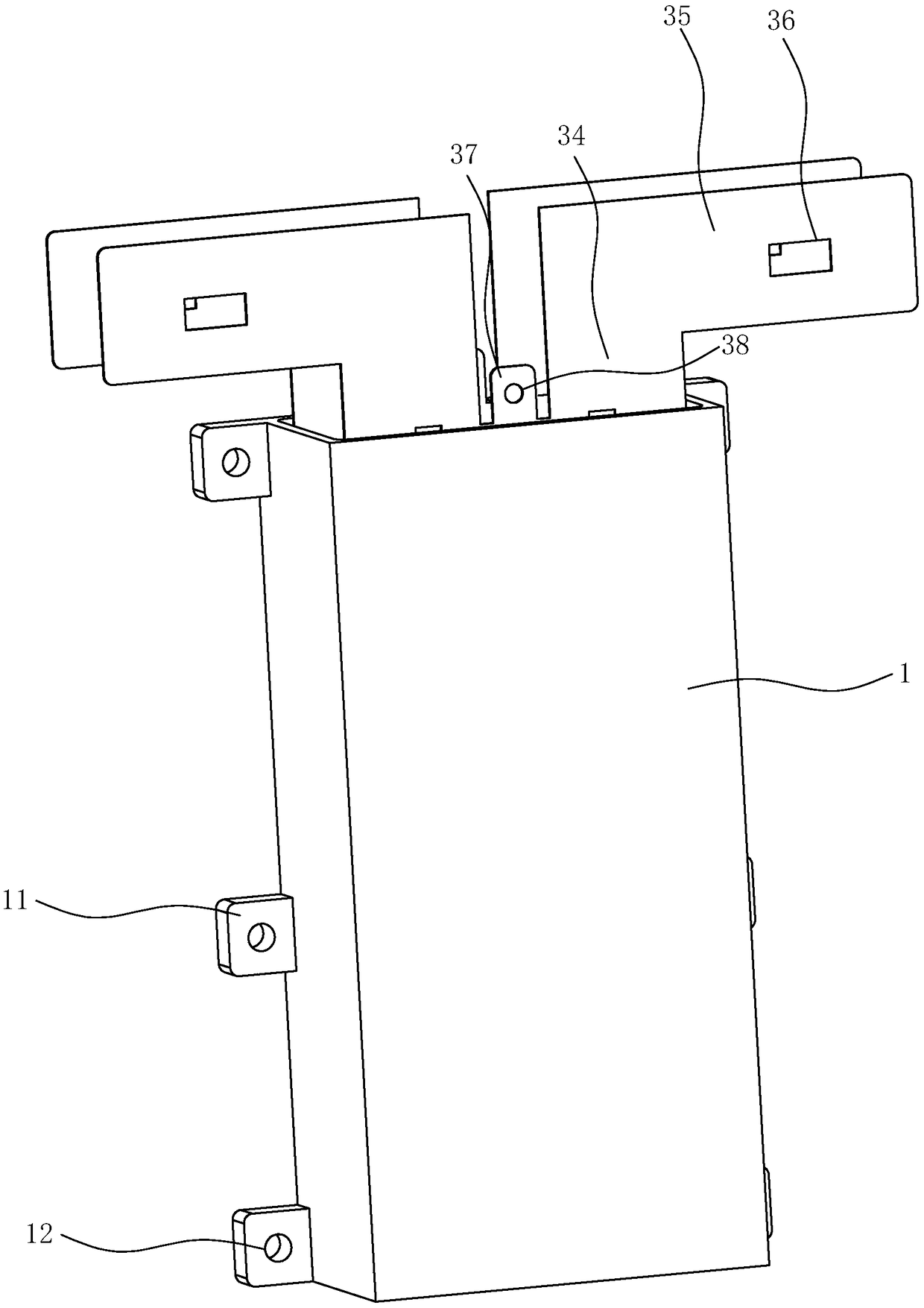

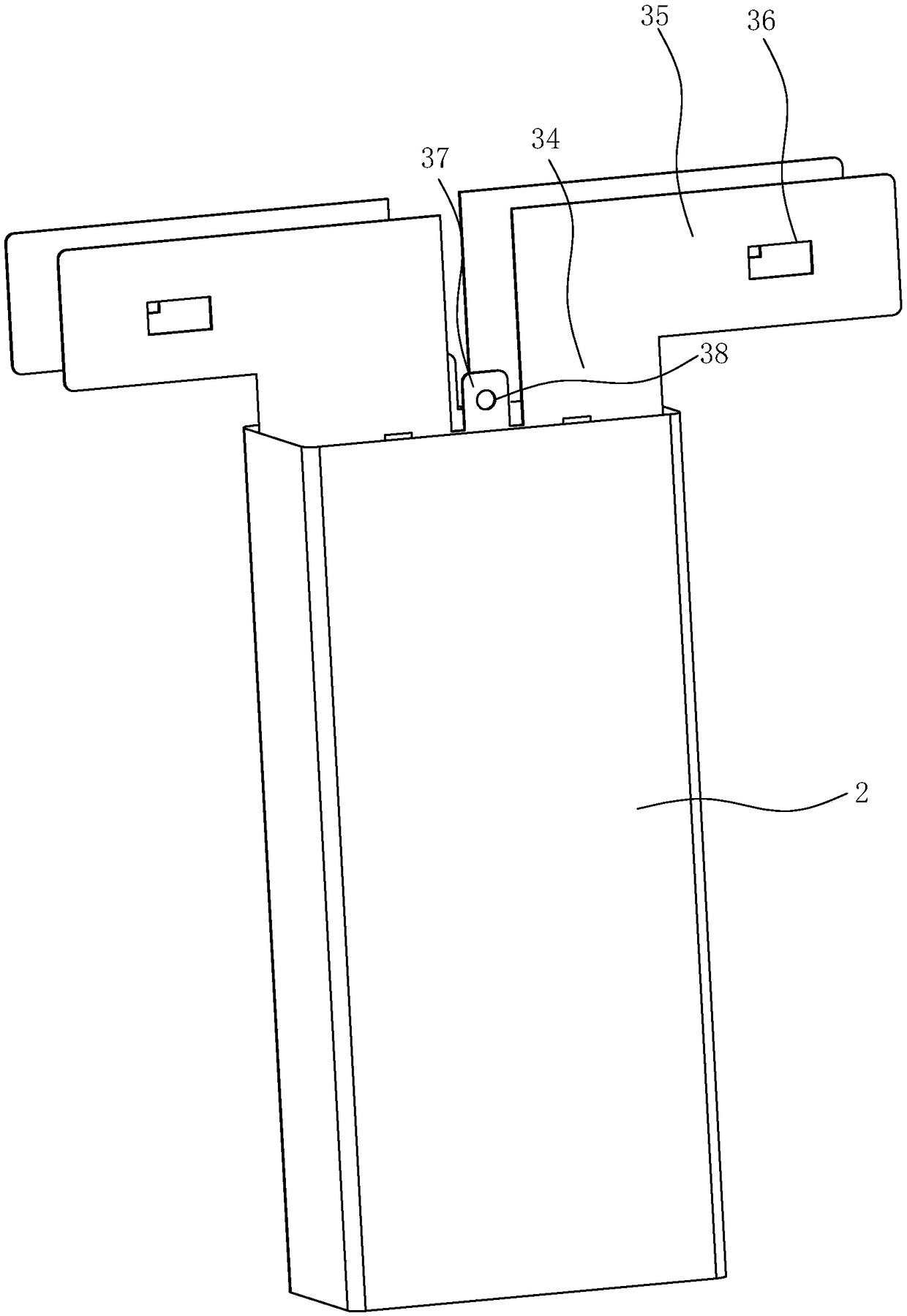

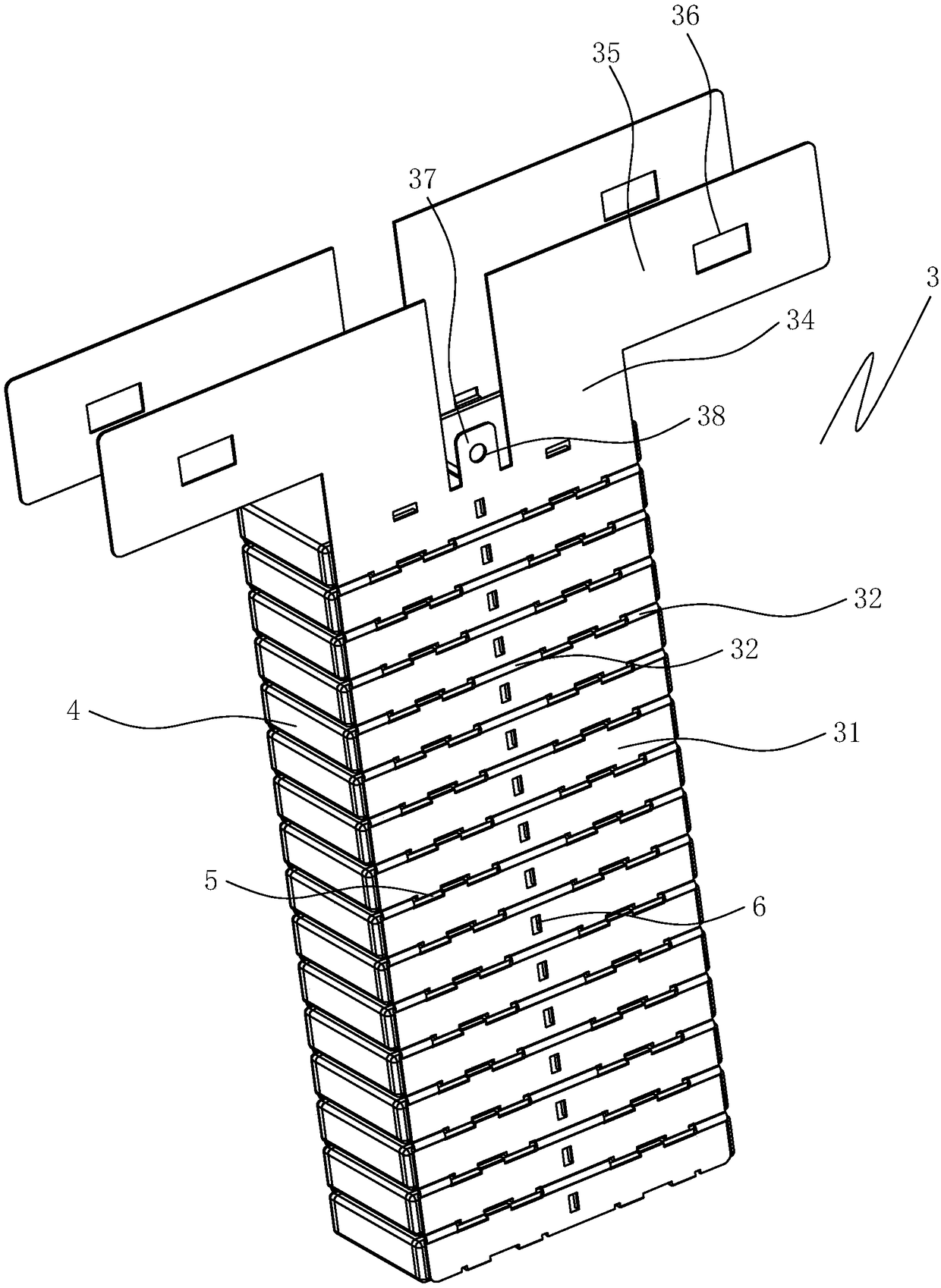

[0026] Such as Figure 1 to Figure 5 As shown, the potting pulse power capacitor includes a plastic casing 1, a potting adhesive layer 2, two metal electrode sheets 3 and several capacitors 4, and three mounting plates 11 are arranged on both sides of the plastic casing 1 at intervals, and a mounting plate 11 is provided on the mounting plate 11. The hole 12, the capacitor 4 is a pulse power capacitor 4, and several capacitors 4 are connected in parallel through two metal electrode sheets 3, and the metal electrode sheet 3 includes several electrode plates 31 arranged vertically at intervals, and expansion joints 32 are arranged between adjacent two electrode plates 31 , the electrode plate 31 is provided with two clamping mechanisms 5 at intervals, the number of the clamping mechanisms 5 is the same as the number of capacitors 4, the two metal electrode pieces 3 are arranged in the plastic casing 1 at intervals, and the clamping mechanisms 5 of the two metal electrode pieces 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com