Refractory material for steel-making RH refining furnace immersion tube

A technology for refractory materials and pipes, applied in the field of refractory materials, can solve the problems of decreased physical properties of refractory materials, defective SiC oxidation resistance, etc., and achieve excellent corrosion resistance, good adaptability and matching, long life and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment.

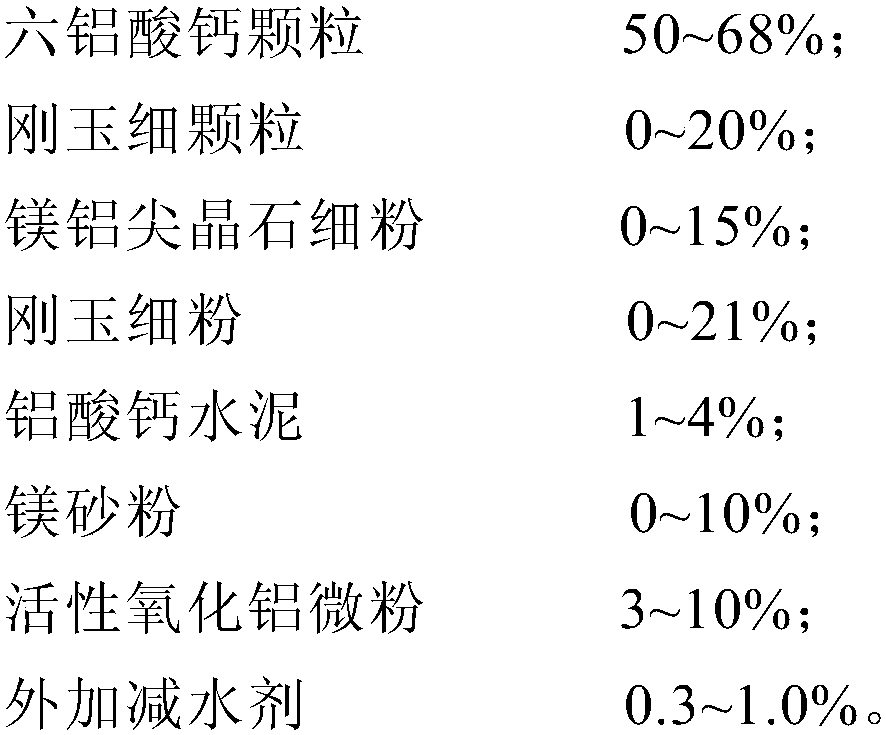

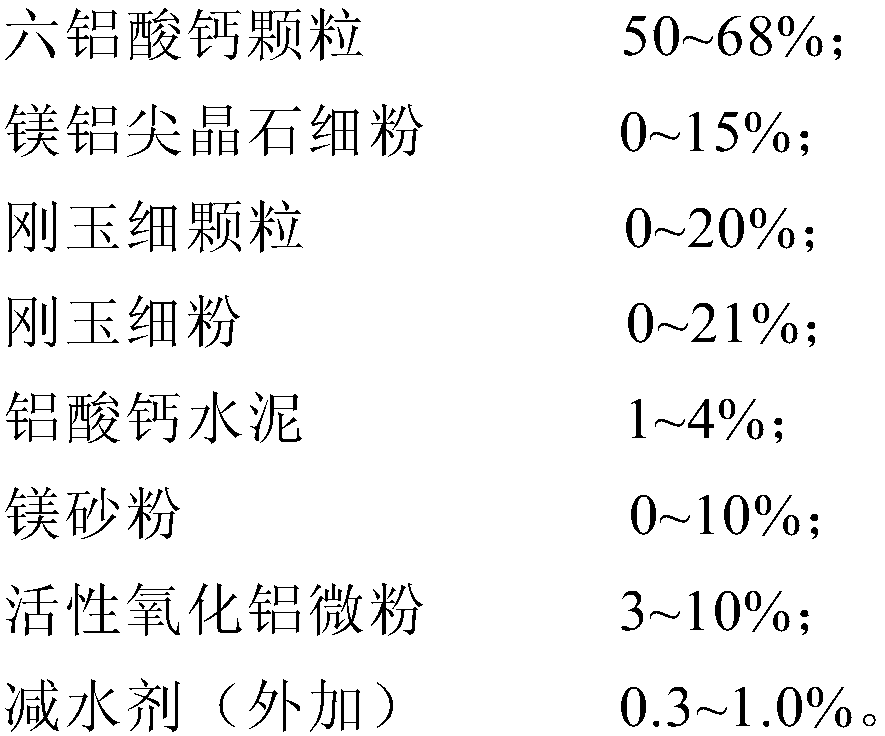

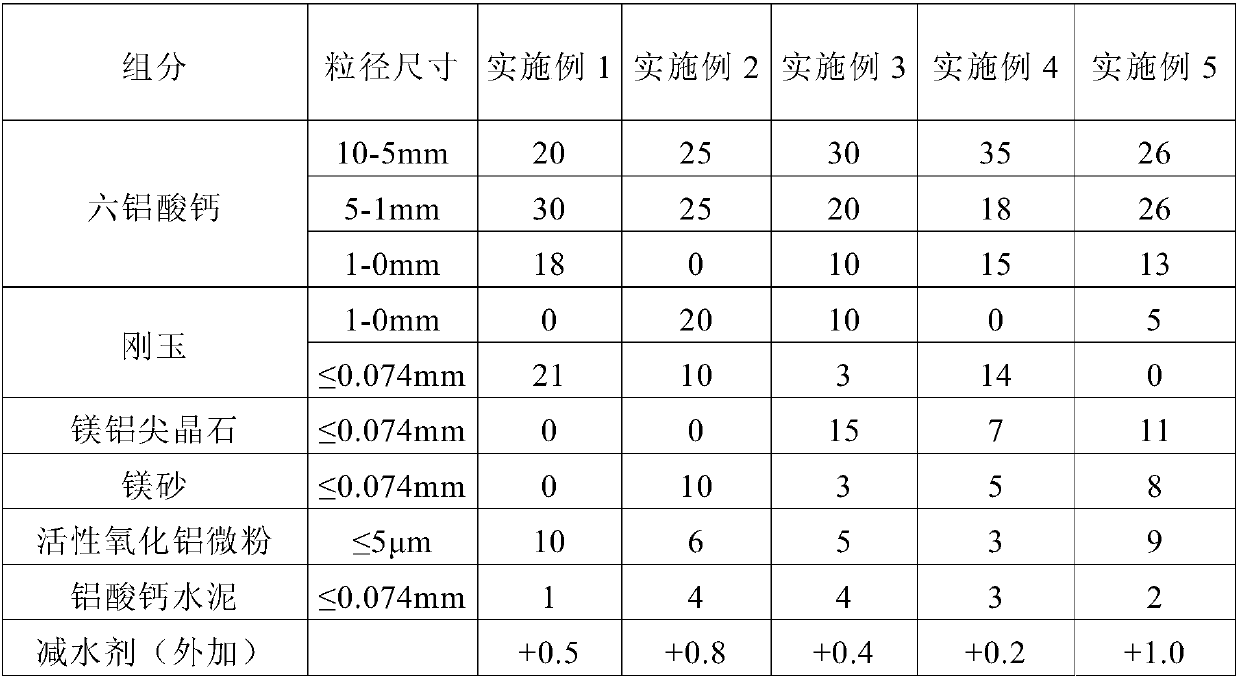

[0030] Table 1 is the material composition of the examples of the present invention, and Table 2 is the performance analysis and comparison of the examples. In Table 2, *CaO in ordinary refining slag is 15-32%, **CaO in test desulfurization slag is ≥ 35%, ** *CaO≥70% in the desulfurizer, the material of comparative example 1 is the existing corundum castable, and the material of comparative example 2 is the existing aluminum-magnesium castable.

[0031] It can be seen from Table 2 that the physical performance index of the RH dipped pipe refractory material of the present invention is: bulk density after baking at 1600°C×3h ≤ 2.9g / cm 3 , compressive strength ≥ 155MPa, flexural strength ≥ 27MPa, thermal conductivity at 500°C ≤ 0.6w / m·k, thermal shock resistance at 1600°C-cold water (normal temperature) ≥ 19 times, ordinary resistance after burning at 1600°C×3h Refining slag erosion i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com