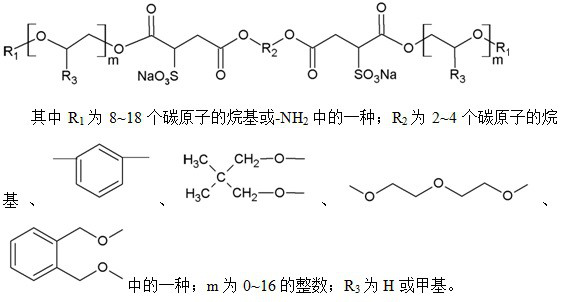

Twin-type concrete air-entraining agent and its preparation method

The technology of concrete and air-entraining agent is applied in the direction of sulfonate preparation, carboxylate preparation, chemical instruments and methods, etc. It can solve the problems of harsh reaction conditions and complex structure, and achieve simple and effective production process, good compound performance, The effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

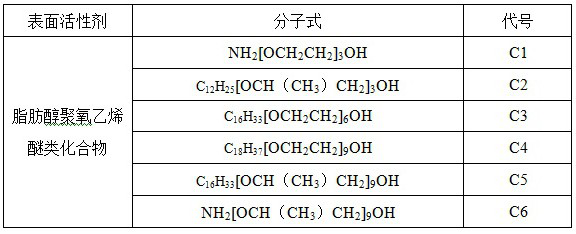

[0033] Embodiment 1: a kind of preparation method of twin type concrete air-entraining agent, it comprises the steps:

[0034] Step (1): Add 1.0mol (262g) C1 and 1.0mol (98g) maleic anhydride at 40°C, add 5.24g anhydrous sodium acetate, and stir for 3 hours to obtain maleic anhydride fatty alcohol polyoxyethylene ethers monoester.

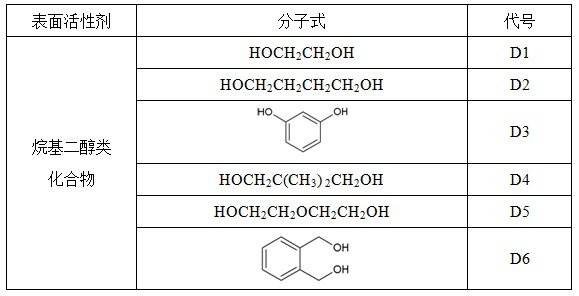

[0035] Step (2): Heat up to 130°C, add 0.50mol (31g) D1, continue to heat up to 150°C, keep the vacuum less than 0.2 MPa, and stir for 6 hours.

[0036] Step (3): Lower the temperature, control the temperature at 100°C, add 1.0mol (104g) sodium bisulfite, 8.82g octadecyltrimethylammonium bromide and water, and stir for 2 hours. The obtained product was dissolved in water and adjusted to a solution with a solid content of 50%. It is the twin-type concrete air-entraining agent of the present invention.

[0037] The air-entraining agent was diluted to 5%, and the surface tension of the solution was measured to be 31.2 mN / m.

Embodiment 2

[0038] Embodiment 2: a kind of preparation method of twin-type concrete air-entraining agent, it comprises the steps:

[0039] Step (1): Add 1.15mol (365.7g) of C2 and 1.0mol (98g) of maleic anhydride at 90°C, add 10.97g of p-toluenesulfonic acid, and stir for 2 hours to obtain maleic anhydride fatty alcohol polyoxygen Vinyl ether monoester.

[0040] Step (2): Heat up to 120°C, add 0.55mol (49.5g) D2, continue to heat up to 150°C, keep vacuum less than 0.2 MPa, and stir for 6 hours.

[0041] Step (3): Lower the temperature, control the temperature at 90°C, add 1.1mol (114.4g) of sodium bisulfite, 9.8g of cetyltrimethylammonium bromide and water, and stir for 1.5 hours to react. The obtained product was dissolved in water and adjusted to a solution with a solid content of 40%. It is the twin-type concrete air-entraining agent of the present invention.

[0042] The air-entraining agent was diluted to 5%, and the surface tension of the solution was measured to be 30.5 mN / m.

Embodiment 3

[0043] Embodiment 3: a kind of preparation method of twin-type concrete air-entraining agent, it comprises the steps:

[0044] Step (1): Add 1.2mol (607.2g) of C3 and 1.0mol (98g) of maleic anhydride at 80°C, add 24.29g of concentrated sulfuric acid, and stir for 1 hour to obtain maleic anhydride fatty alcohol polyoxyethylene ethers ester.

[0045] Step (2): Heat up to 125°C, add 0.60mol (66g) of D3, continue to heat up to 140°C, keep the vacuum less than 0.2 MPa, and stir for 4 hours.

[0046]Step (3): Lower the temperature, control the temperature at 85°C, add 1.2mol (124.8g) sodium bisulfite, 11.76g tetradecyltrimethylammonium bromide and water, and stir for 1 hour. The obtained product was dissolved in water and adjusted to a solution with a solid content of 30%. It is the twin-type concrete air-entraining agent of the present invention.

[0047] The air-entraining agent was diluted to 5%, and the measured surface tension of the solution was 30.8 mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com