Splashing-free resistance spot-welding method of galvanized steel plates for car

A technology of galvanized steel sheet and resistance spot welding, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as not mentioning the influence of spatter spot welding quality, reducing the strength of spot welding joints, etc., and achieving improved welding Safety, reduce welding energy consumption, improve the effect of solder joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

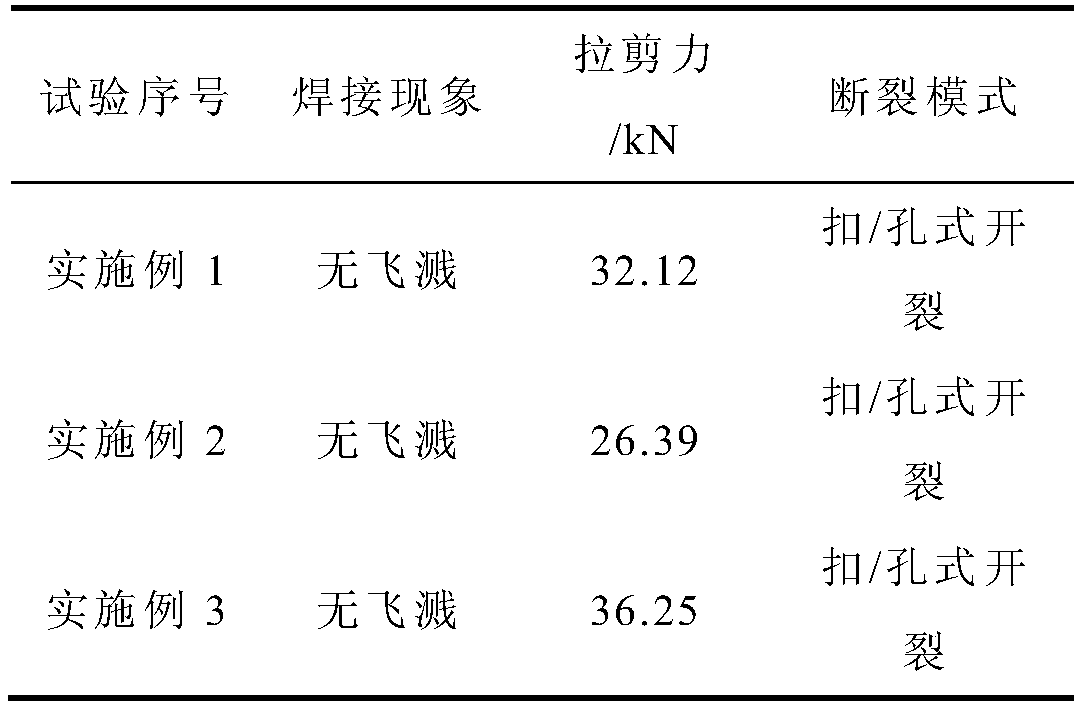

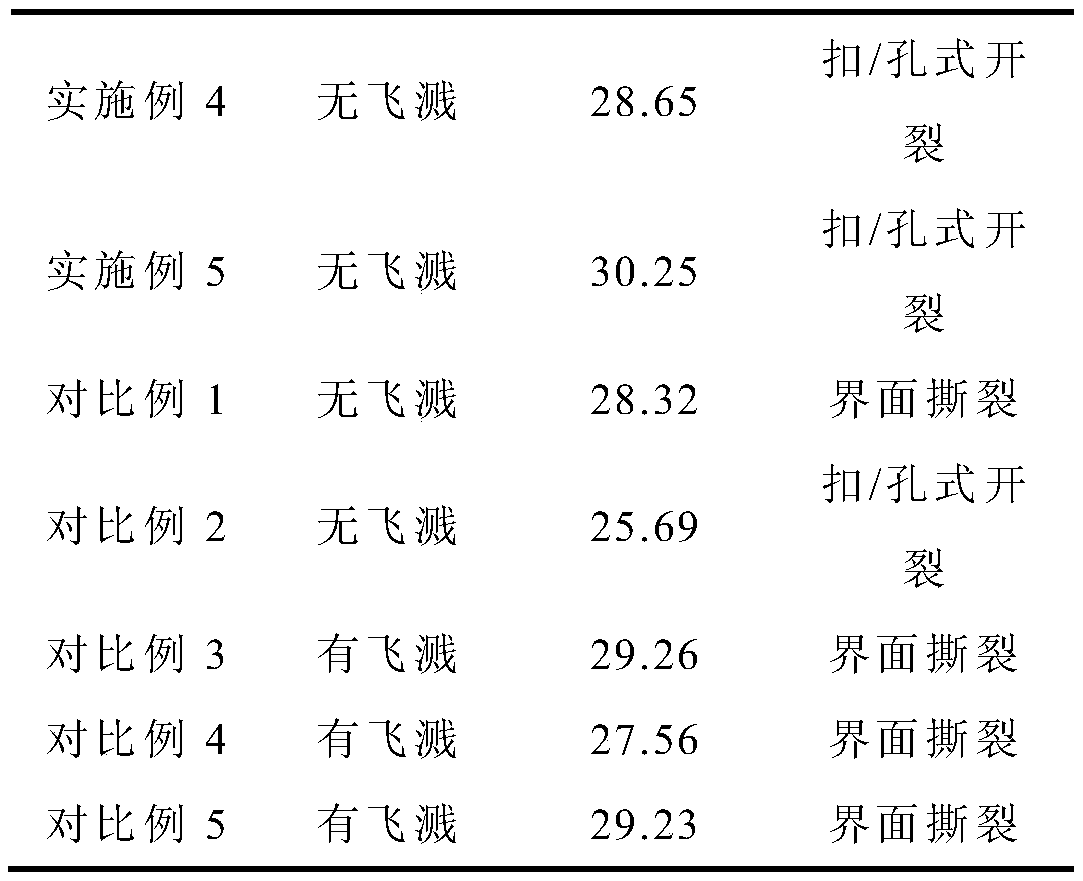

Embodiment 1

[0033] DP780 dual-phase steel hot-dip galvanized sheet, plate thickness 1.8mm, galvanized layer thickness 5μm; adding Cu intermediate layer thickness 0.02mm. The electrode is Cu-Al 2 o 3 , the end face of the electrode is concave, the diameter of the end face is 8mm, and the radius R of the concave surface is 30mm.

[0034] The Cu intermediate layer is placed between two galvanized steel sheets, and the composition is by mass percentage: 1.6% Mn, 10% Fe, O<0.02%, and the rest is Cu.

[0035] Set the preloading time to 2000ms, the welding current to 9.5kA, the welding time to 300ms, and the welding pressure to 3.0kN. Perform resistance spot welding and cool naturally after welding.

Embodiment 2

[0037] DP780 dual-phase steel electro-galvanized sheet, plate thickness 0.7mm, galvanized layer thickness 22μm; adding Cu intermediate layer thickness 0.2mm. The electrode is Cu-Cr-Zr, the electrode end surface is concave, the end surface diameter is 6mm, and the radius R of the concave surface is 55mm.

[0038] The Cu intermediate layer is placed between two galvanized steel sheets, and the composition is by mass percentage: 3% Mn, 1% Fe, O<0.02%, and the rest is Cu.

[0039] Set the preloading time to 1000ms, the welding current to 6.5kA, the welding time to 260ms, and the welding pressure to 1.5kN. Perform resistance spot welding and cool naturally after welding.

Embodiment 3

[0041] DP780 dual-phase steel hot-dip galvanized sheet, plate thickness 3mm, galvanized layer thickness 15μm; add Cu intermediate layer thickness 0.05mm. The electrode is Cu-Al 2 o 3 , The end face of the electrode is concave, the diameter of the end face is 8mm, and the radius R of the concave surface is 45mm.

[0042] The Cu intermediate layer is placed between two galvanized steel sheets, the composition: 2% Mn, 5% Fe, O<0.02%, and the rest is Cu.

[0043] Set the preloading time to 1600ms, the welding current to 11kA, the welding time to 400ms, and the welding pressure to 4.0kN for resistance spot welding, followed by natural cooling after welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com