Process for manufacturing rectangular box pipe

A production process and box tube technology, which is used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problem that the production process cannot meet the accuracy requirements, and achieve the effect of increasing strength, ensuring accuracy, and ensuring straightness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

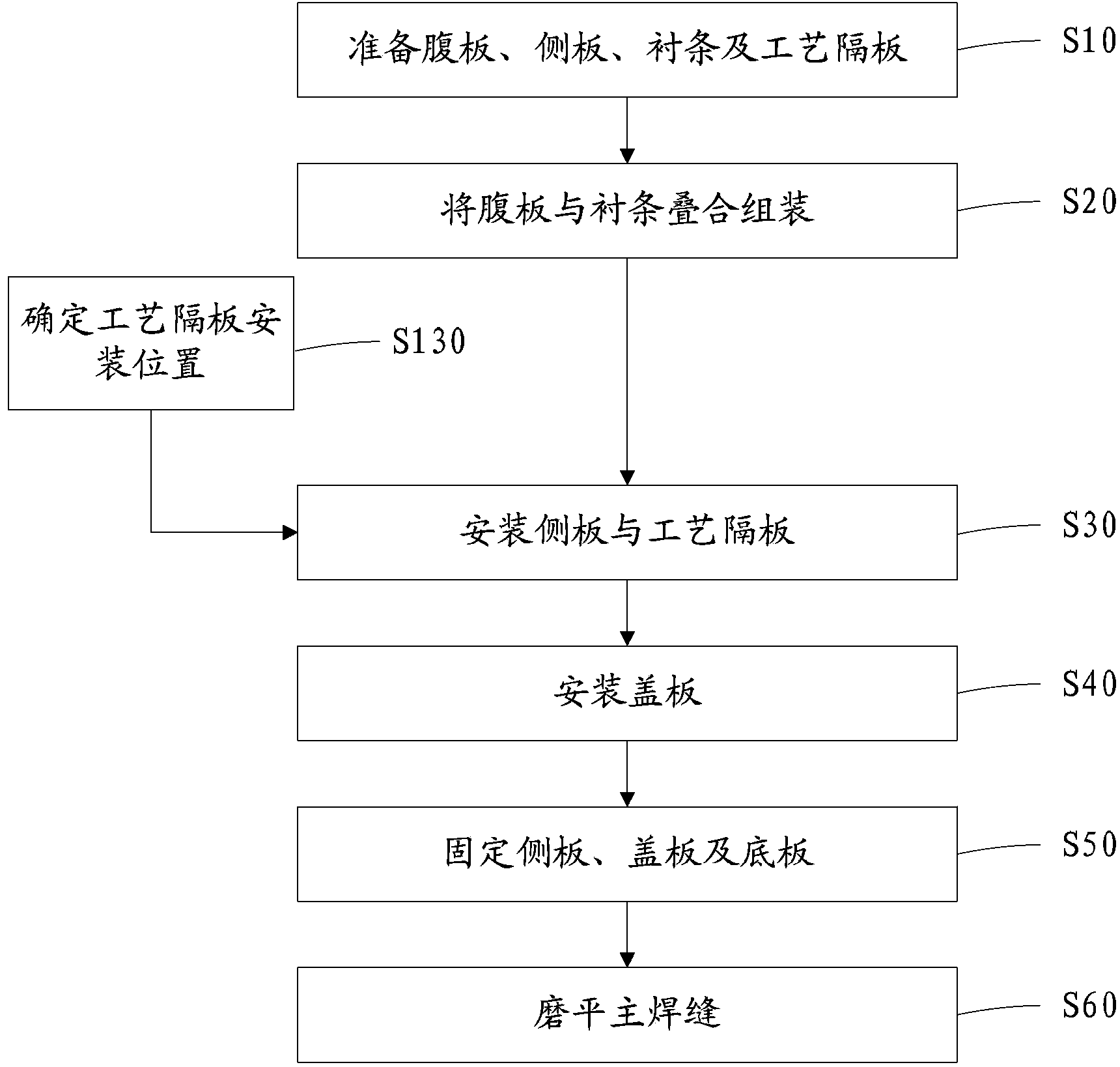

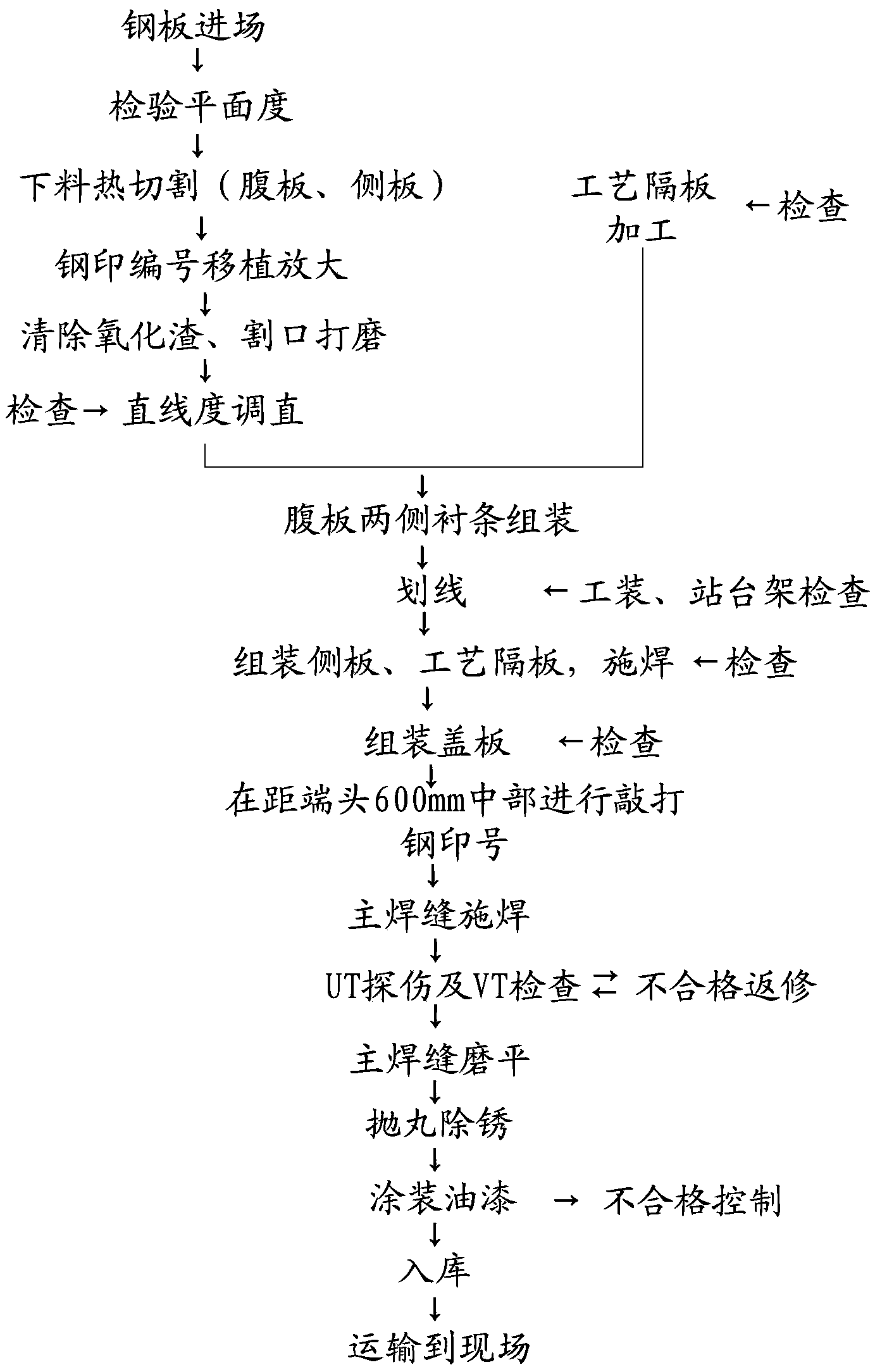

[0035] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

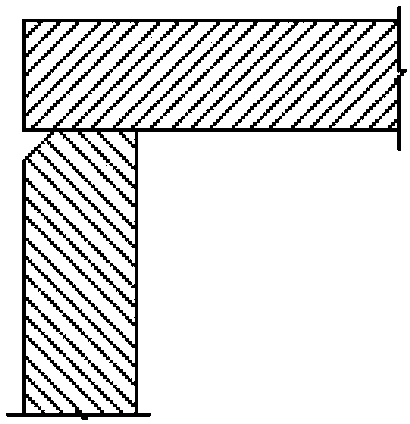

[0036] see Figure 2 to Figure 10 , the present invention provides a manufacturing process of a rectangular box tube, which is suitable for light and thin ultra-small rectangular box tube structure, the plate material used in this type of components is Q235B, generally by 6mm+6mm, 16mm+20mm, 12mm The +16mm plate is welded, and the main weld is full fusion level II. Due to the thinness of the plate, welding deformation and internal quality control are more difficult. In order to successfully meet the requirements of the process, the following is a detailed description of each step in the manufacturing process combined with the attached drawings. The breakdown is as follows:

[0037] Step S10: Prepare webs, side panels, lining strips and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com