Lime kiln barrel assembling and welding method

A technology for lime kiln cylinders and cylinders, which is applied to welding equipment, welding equipment, arc welding equipment, etc., to achieve the effects of controlling welding deformation, small welding current, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

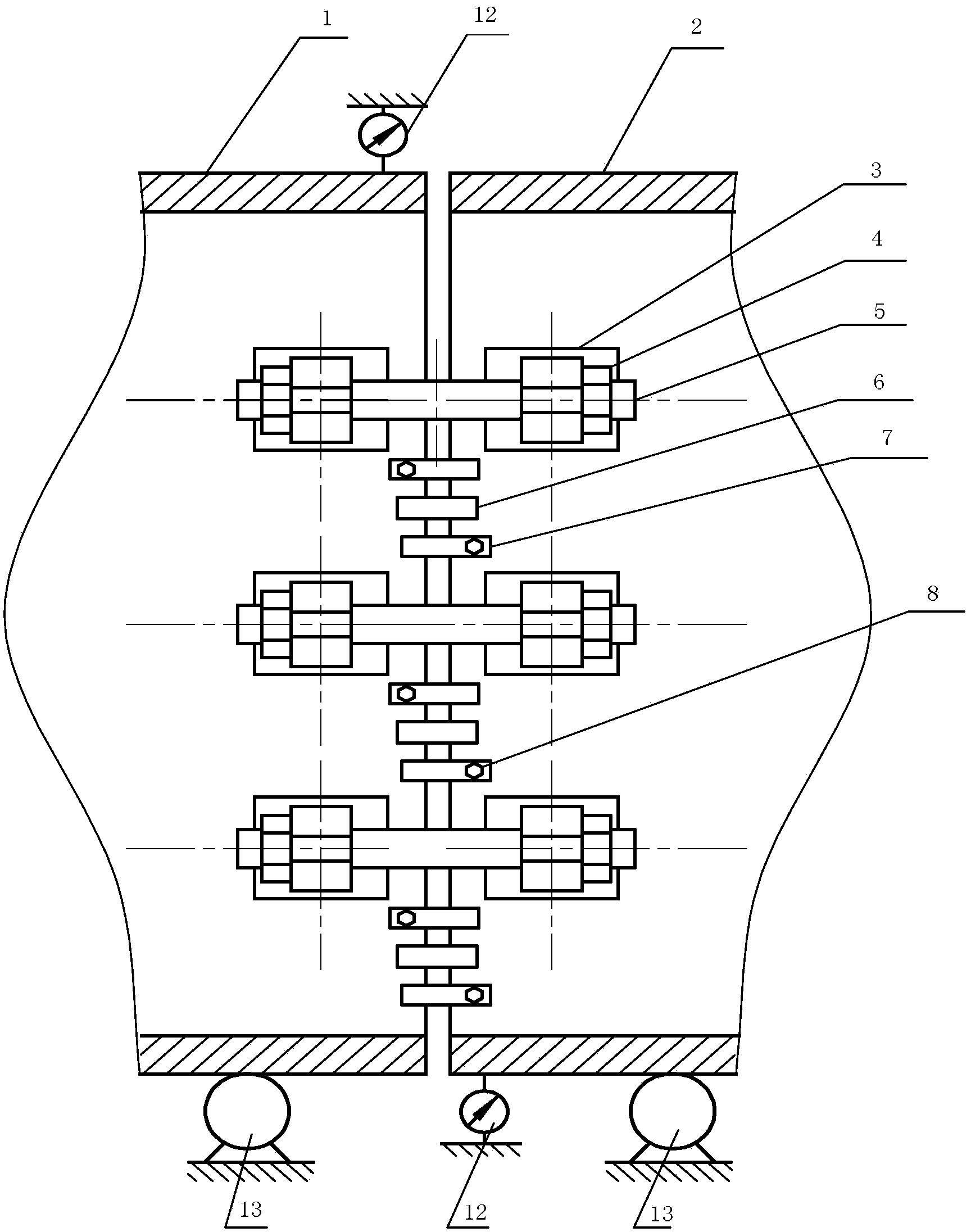

[0029] Such as figure 1 As shown, a lime kiln shell welding method adopts the following steps:

[0030] The lime kiln shell assembly welding method of the present invention adopts the following steps:

[0031] (a) Use a laser theodolite to measure the straightness of the first cylinder 1, the second cylinder 2... The circumference is aligned in the axial direction, and dial indicators 12 are respectively installed at symmetrical positions 180° apart on the outer circumference of the adjacent cylinder. Using a laser theodolite to measure straightness belongs to a conventional process method in the prior art;

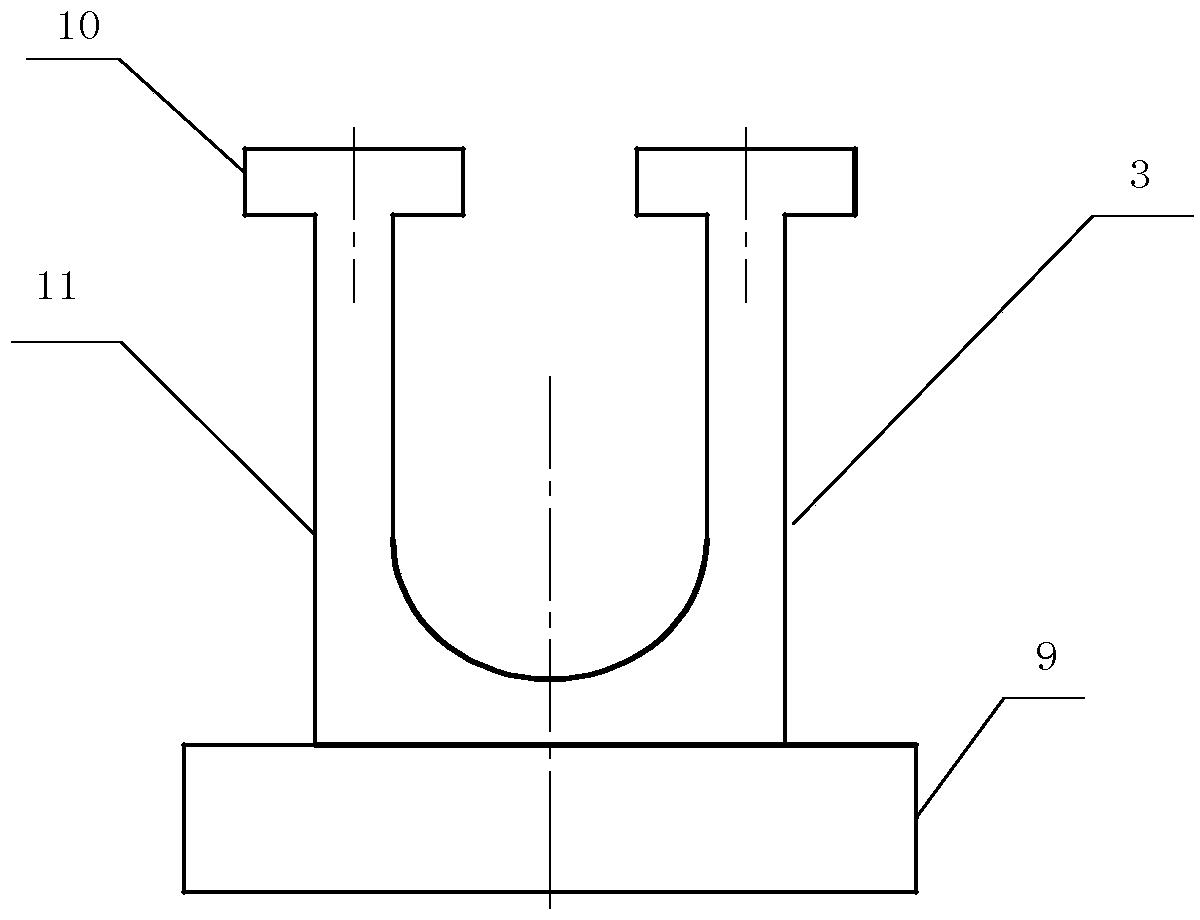

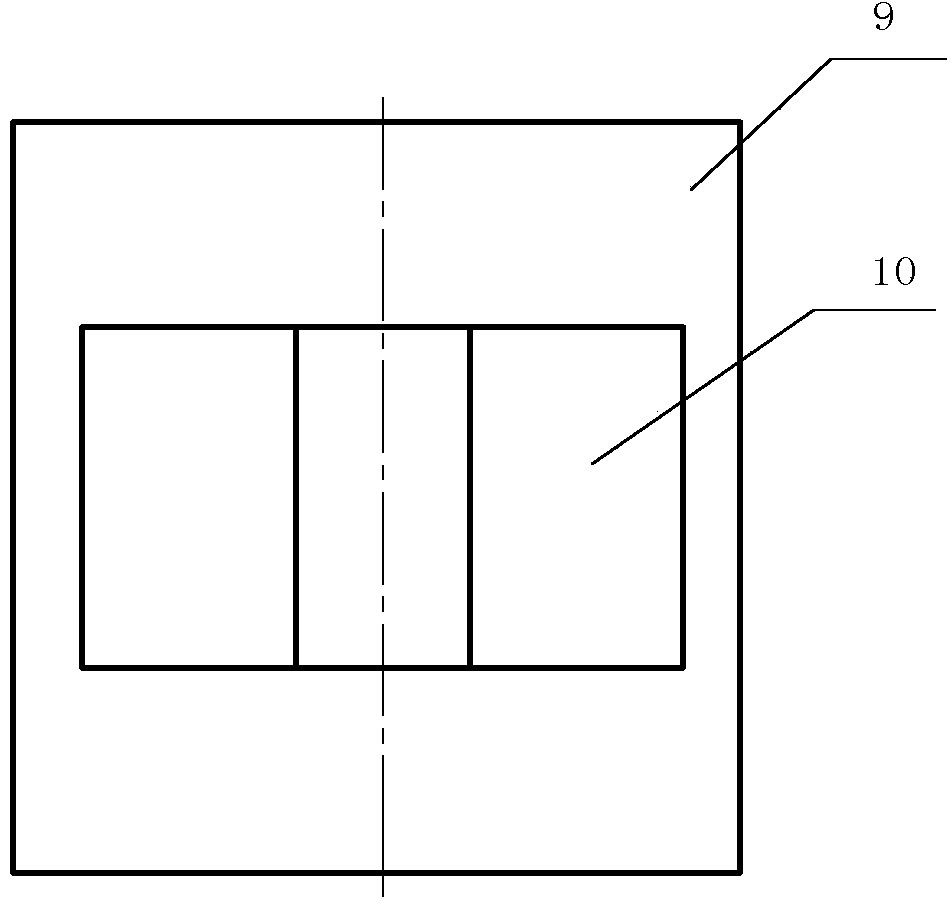

[0032] (b) On the inner peripheral surfaces of the butted first cylinder body 1 and the second cylinder body 2 at a distance of 100mm-300mm from the weld seam 16, several pairs of matching centering adjustment fixtures 3 are evenly welded, adjacent The distance between the centering adjustment jigs 3 is 200-400mm, centering bolts 5 are installed in several pairs of matc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com