Compressor protecting rack and welding method thereof

A welding method and protective frame technology, applied in the field of compressors, can solve problems affecting product quality and user satisfaction, low production efficiency, and shell welding penetration, so as to avoid mold repair adjustment and electrode replacement, high production efficiency, The effect of small welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

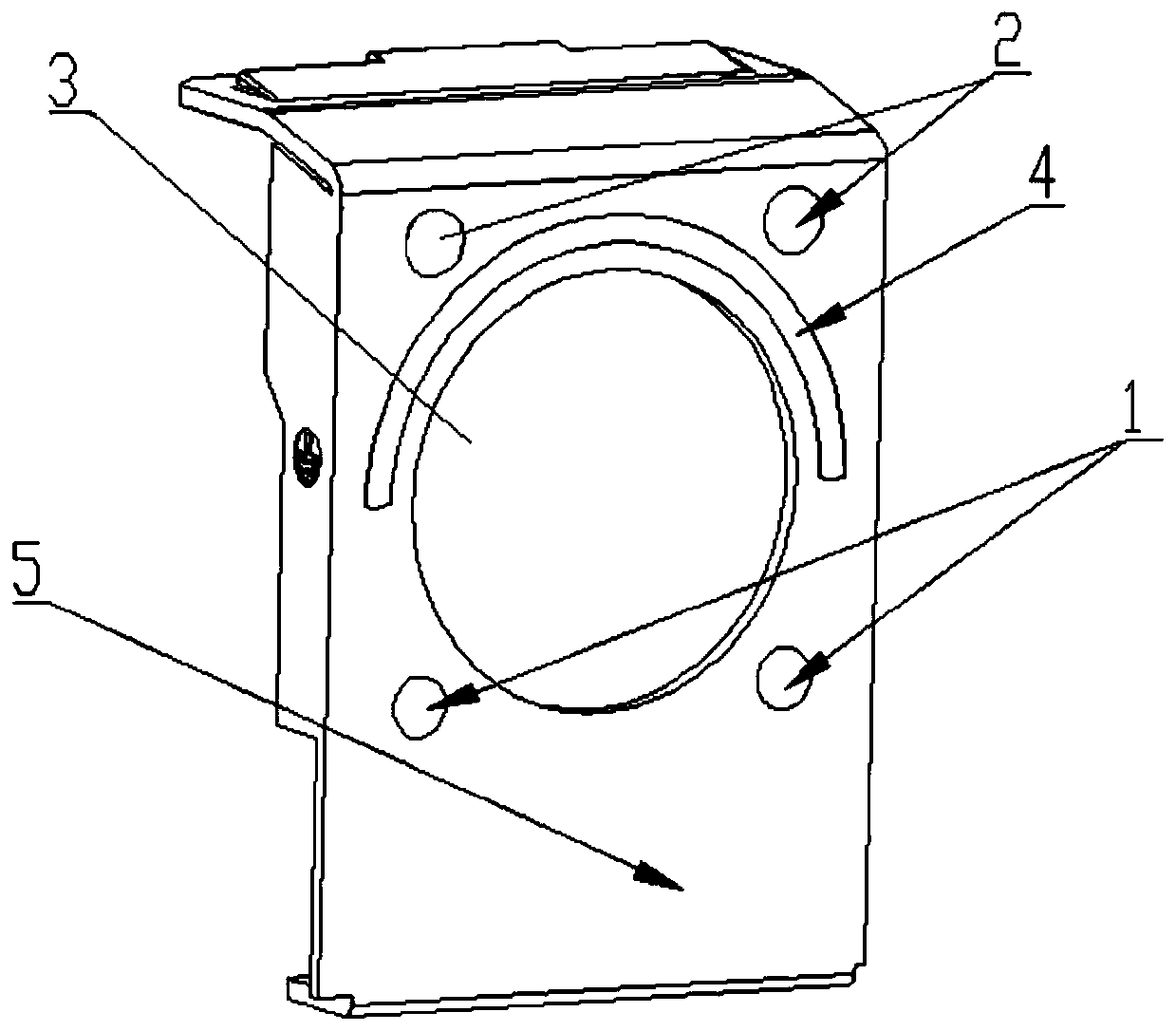

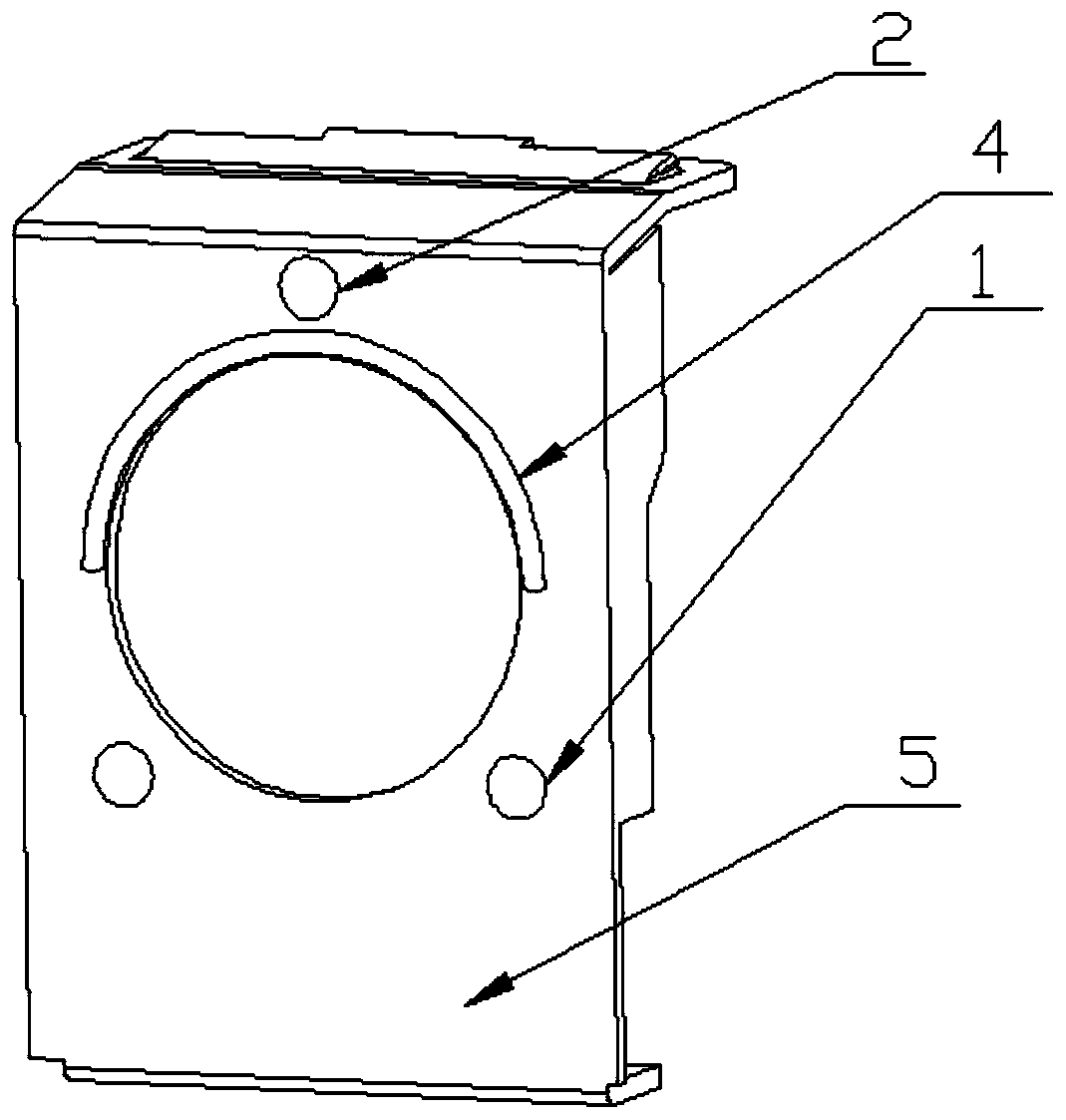

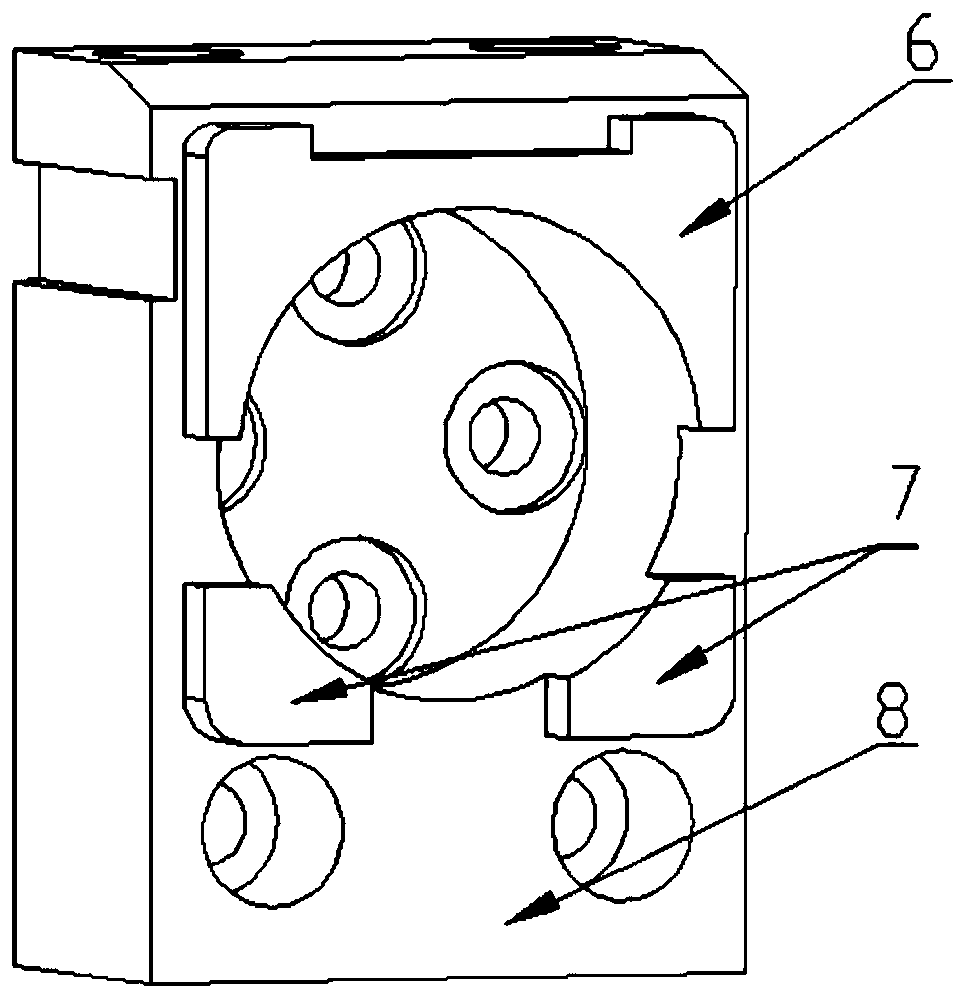

[0030] Such as Figure 1-Figure 2 As shown, the protection frame of this kind of compressor, the protection frame 5 is connected with the housing 11 of the compressor, the through hole 2 communicating with the housing 11 is provided on the protection frame 5, and the top of the through hole 2 on the protection frame 5 is connected with The waterproof rib 4, the upper welding point 3 and the lower welding point 1 are provided on the protective frame 5, and the protective frame 5 passes through the upper welding point 3 above the waterproof rib 4 and the lower welding point 1 below the through hole 2 and the shell 11 welding. The present invention adopts the method of spatial separation, and the welding points of the protective frame 5 are distributed above the waterproof rib 4 and below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com