Three-stage scroll rotor compressor

A rotor compressor and compressor technology, applied in the field of refrigeration compressors, can solve the problems of small adjustment range of internal pressure ratio, non-adjustable internal pressure ratio, large internal pressure ratio, etc., to expand the operating range and reduce the load of the whole machine , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

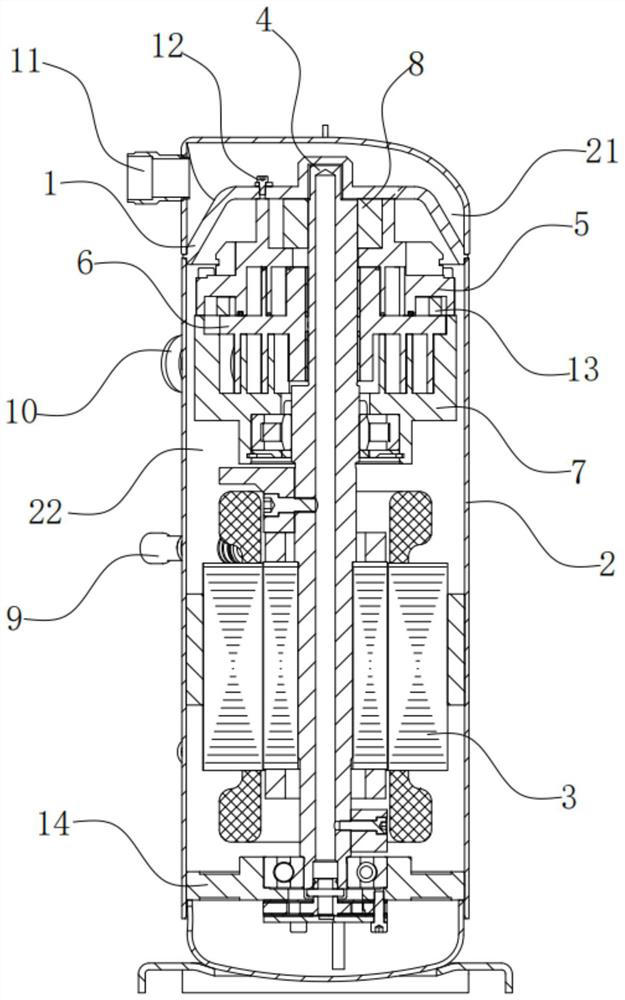

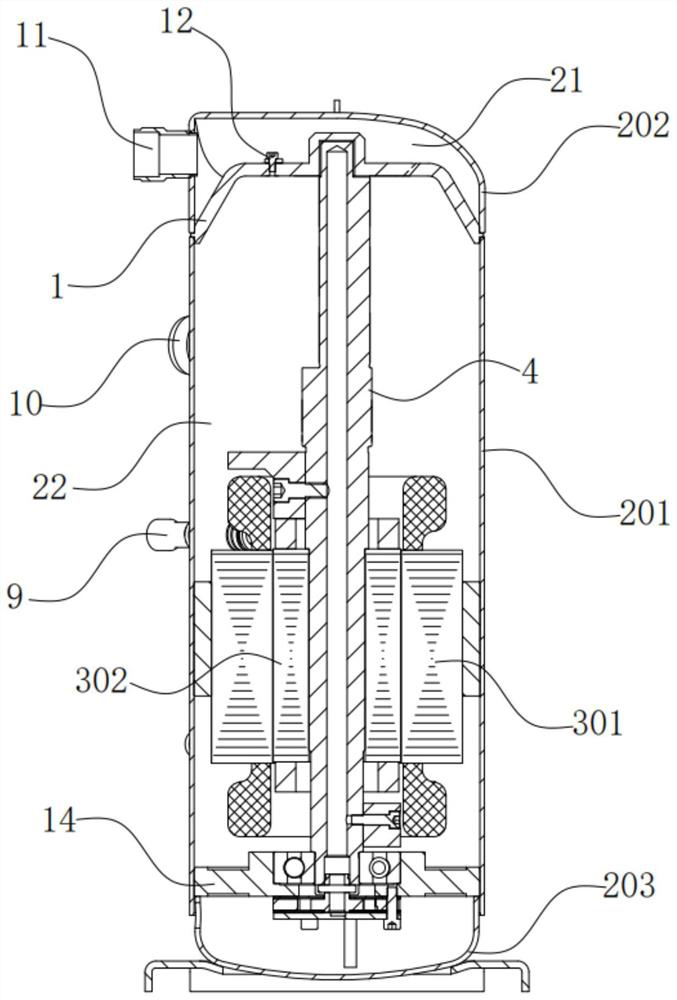

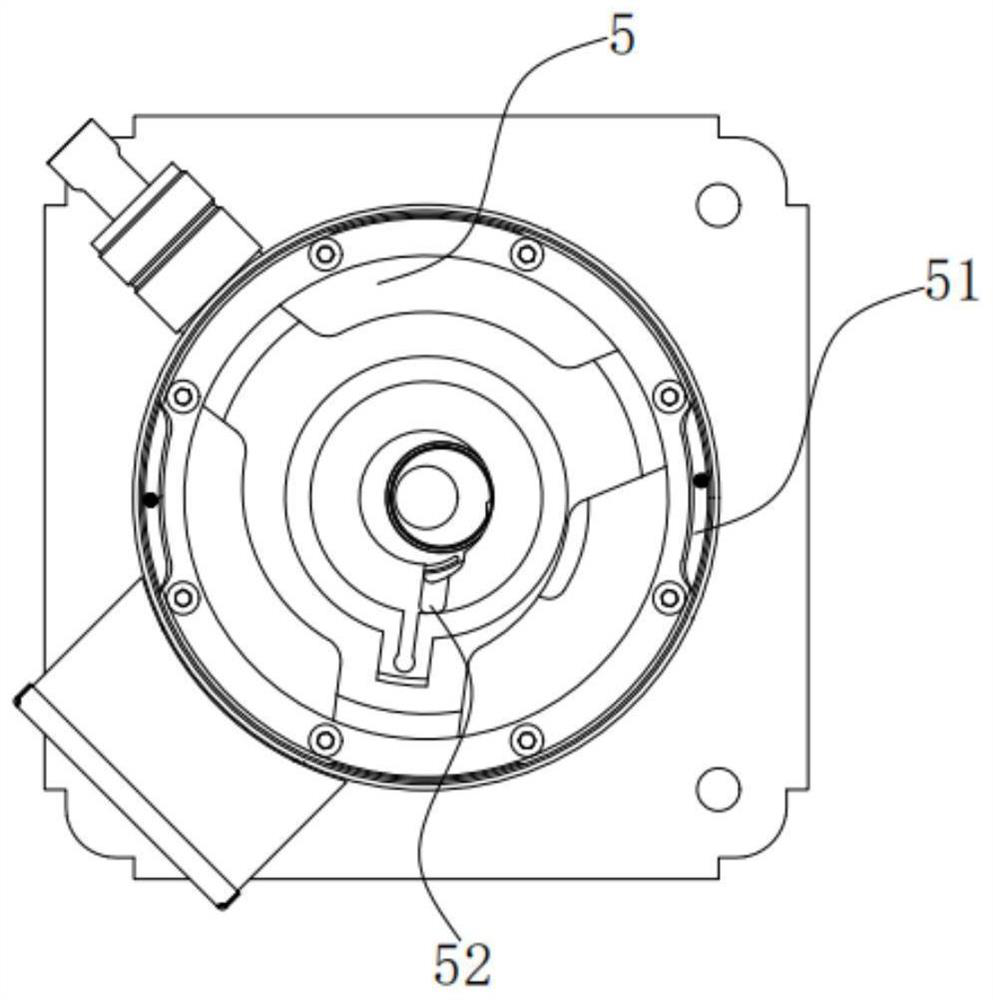

[0026] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0027] A three-stage scroll compressor, comprising a high-low pressure isolation plate 1, a sealed casing 2, a motor mechanism 3, a drive crankshaft 4, an upper fixed scroll 5, a movable scroll 6, a lower fixed scroll 7 and a rolling rotor 8, in:

[0028] The sealed casing 2 is composed of a casing 201, an upper cover 202 and a lower cover 203, and the upper cover 202 and the lower cover 203 are installed on the upper end and the lower end of the casing 201 respectively, and the inside of the upper cover 202 is fixed with a high The low-voltage isolation plate 1, the high-low-voltage isolation plate 1 divides the closed area formed by the housing 201, the upper cover 202 and the lower cover 203 into an upper chamber I21 and a lower chamber II22, and the chamber II22 is set There is a motor mechanism 3, a drive crankshaft 4, an upper fixed scroll 5, a movable scroll 6 and a lower fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com