Machining method for backstop blank

A blank processing and blank processing technology, which is applied in the field of rear block blank processing, can solve the problems of difficult machining, waste of raw materials, time-consuming, etc., and achieve the effects of saving machining time, reducing the wear and tear of machining equipment, and reducing the amount of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The invention relates to a method for processing a backstop blank. The specific steps are:

[0023] 1) Feed with bar stock, the size of the feed is Φ120×85 (mm), and remove the surface burr.

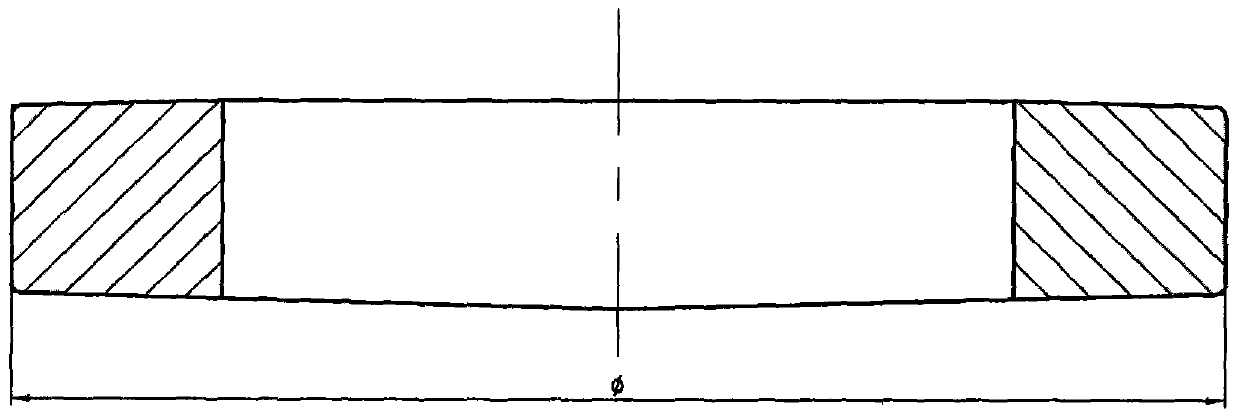

[0024] 2) Use a thyristor water-cooled static frequency converter to heat the placed bar, and use a portable infrared thermometer model PT300 to measure the furnace temperature every 30 minutes to ensure that there is no overheating or overburning of the billet during the heating process. When the temperature is above 1100°C, the blank can be forged, and the blank is flattened: the flattening is divided into axial and radial flattening, the axial flattening h=36, and the radial flattening=Φ185.

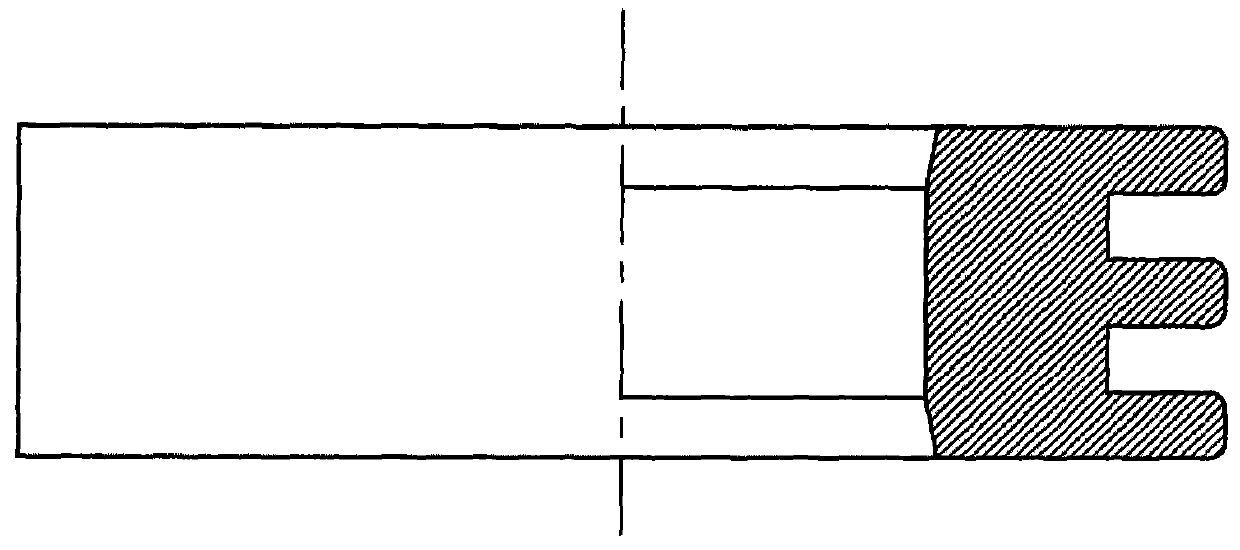

[0025] 3) Punch the flattened blank with a 750kg air hammer machine, and the punching size of this technical solution is Φ50.

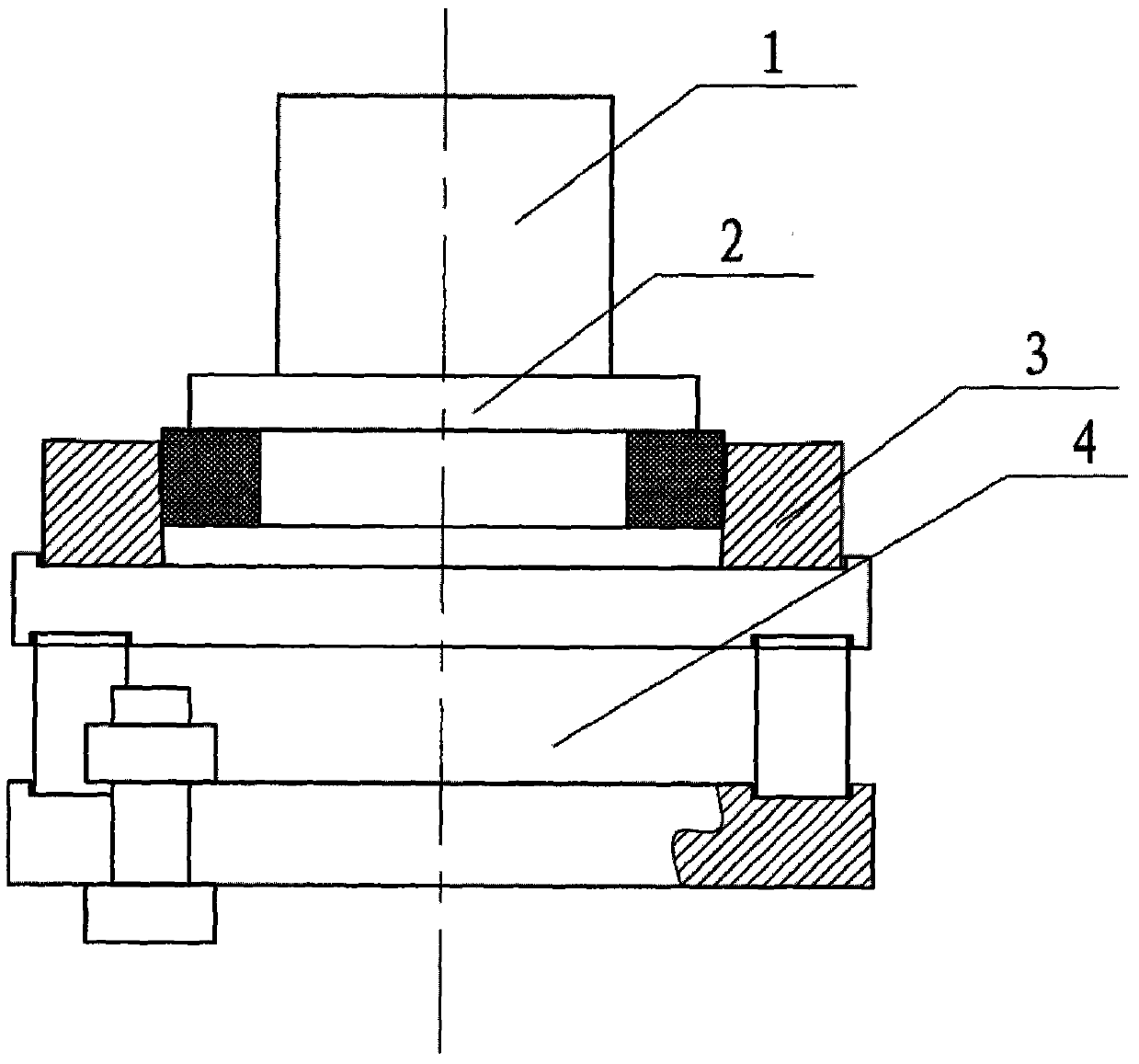

[0026] 4) first put such as figure 2 The rear block rolling forming die shown is preheated to 150°C, and then fixed on the fixture, put the punched blank into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com