Efficient half-portal double-row scraper reclaimer

A reclaimer, double-row technology, applied in the field of high-efficiency semi-gantry double-row scraper reclaimer, can solve the problems of resource waste, scraper size and reclaiming speed are not easy to be too large, and increase manufacturing costs, etc. Achieve the effects of small machine load, easy automation and centralized control, and large reclaiming capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

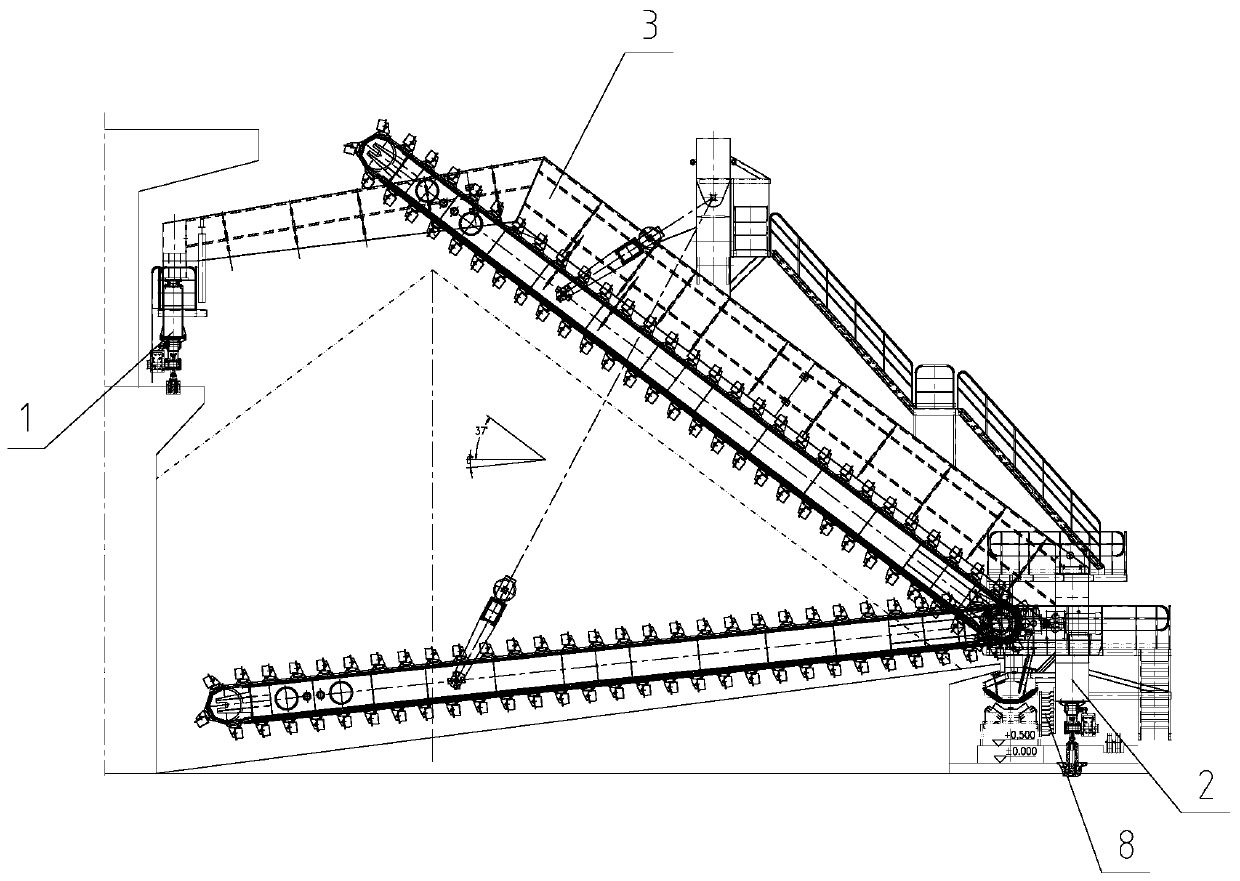

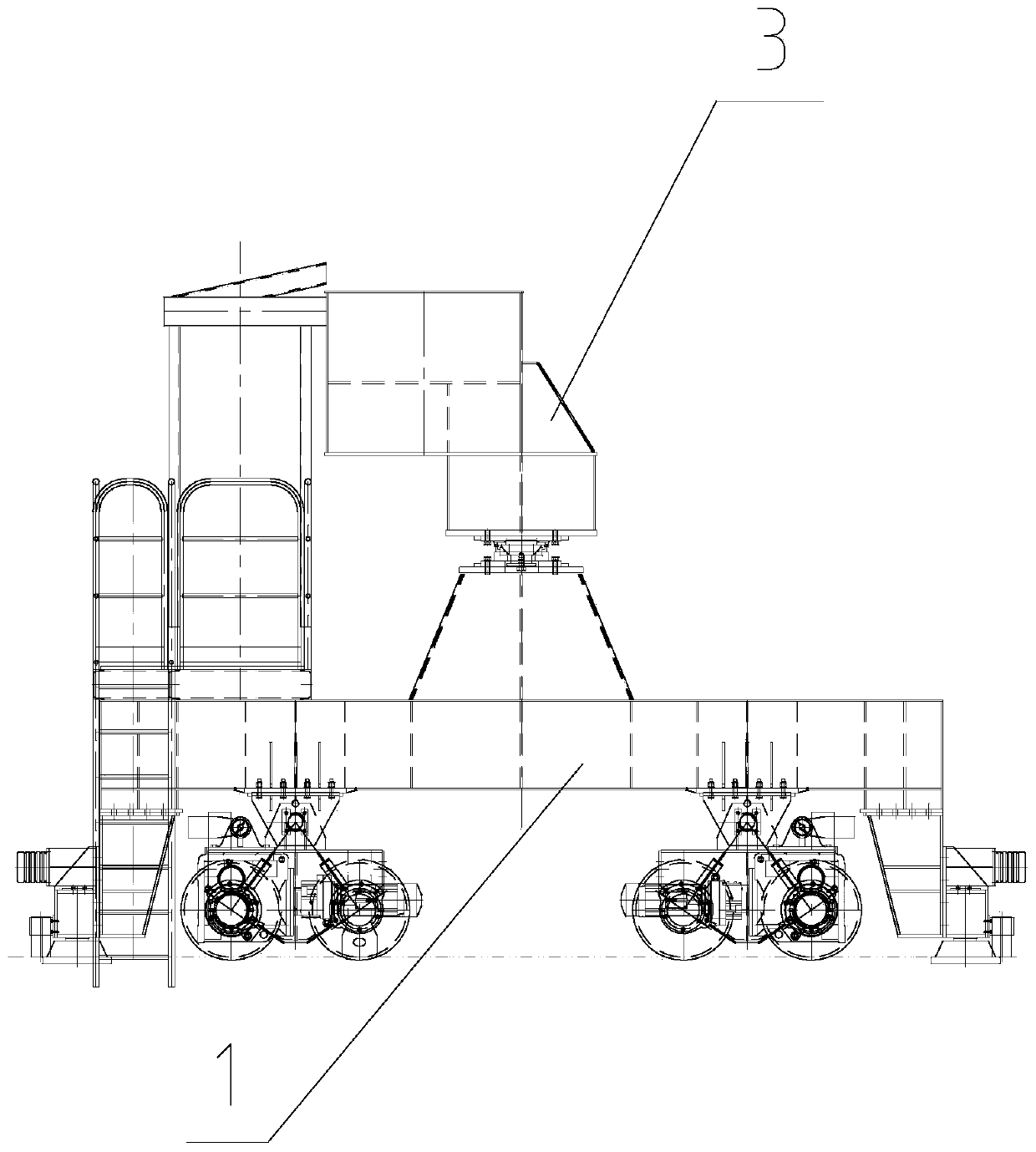

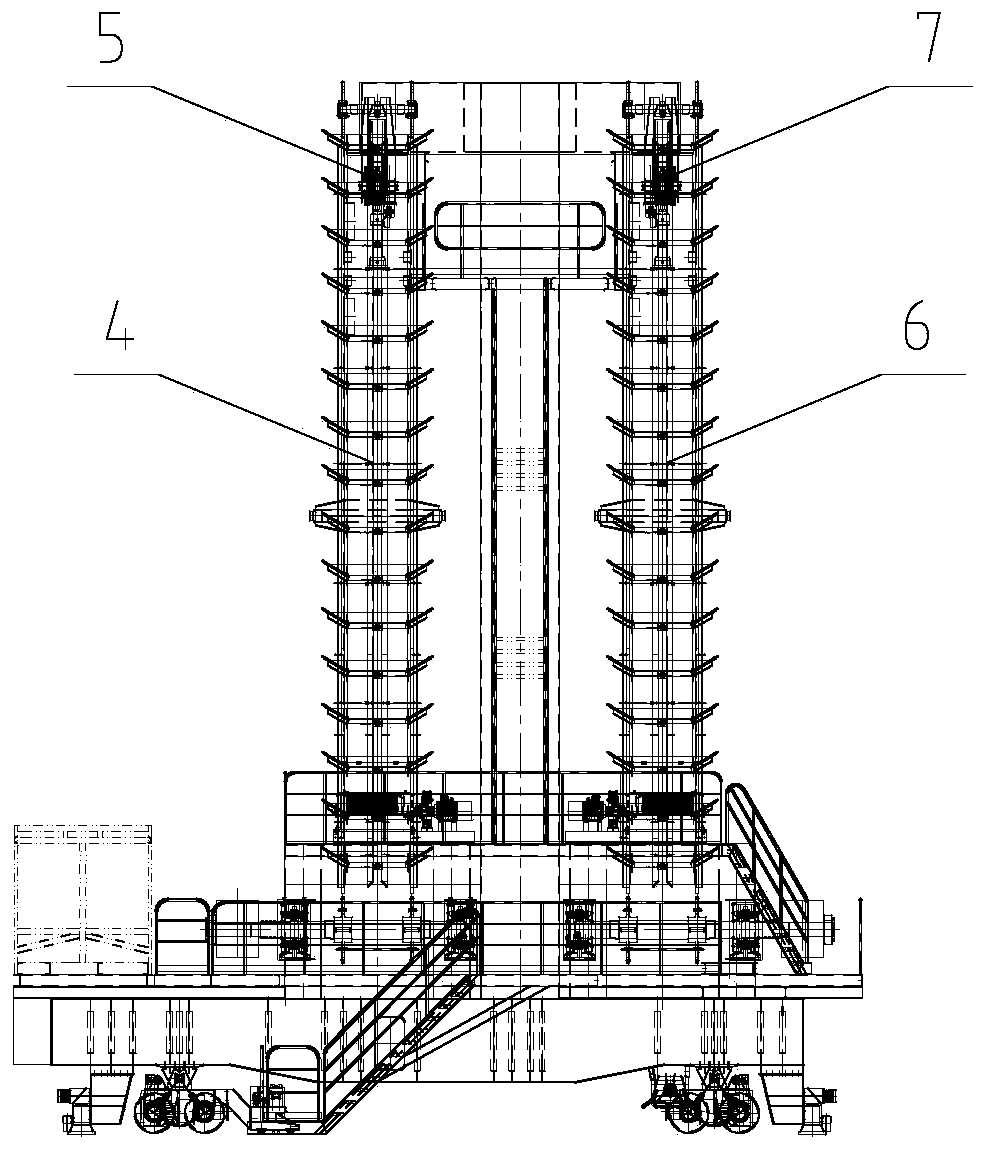

[0030] With reference to the drawings, a high-efficiency half-port frame double-row scraper reclaimer includes a hinged structure end beam 1, a fixed structure end beam 2, a half door frame 3, a first scraper reclaiming system 4, and a first wire rope hoisting system 5. The second scraper reclaiming system 6, the second wire rope hoisting system 7, the detection system 8. A half portal frame 3 is set on the end beam 1 of the hinged structure, and a detection system 8 is set on the side of the end beam 2 of the fixed structure. One end of the slab reclaiming system 4 is connected to the end beam 2 of the fixed structure, the other end of the first scraper reclaiming system 4 is connected to the half portal 3, and the first wire rope hoisting system 5 is provided on the first scraper reclaiming system 4. One end of the two scraper reclaiming system 6 is connected to the fixed structure end beam 2, the other end of the second scraper reclaiming system 6 is connected to the half por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com