Low-speed outer rotor permanent magnet drive device with rotating speed of outer cylinder being 0.001-30r/min

A permanent magnet drive, external rotor technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of large running vibration, high maintenance, poor stability, etc., to reduce the design load and operate safely. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

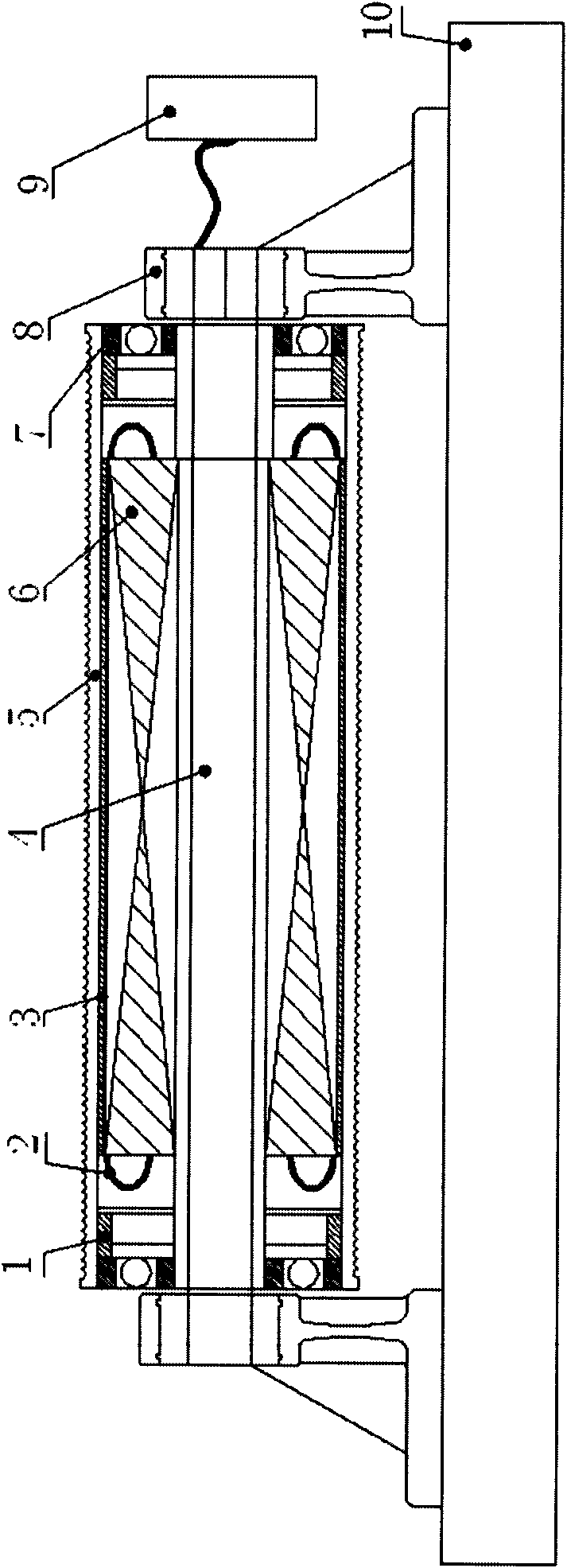

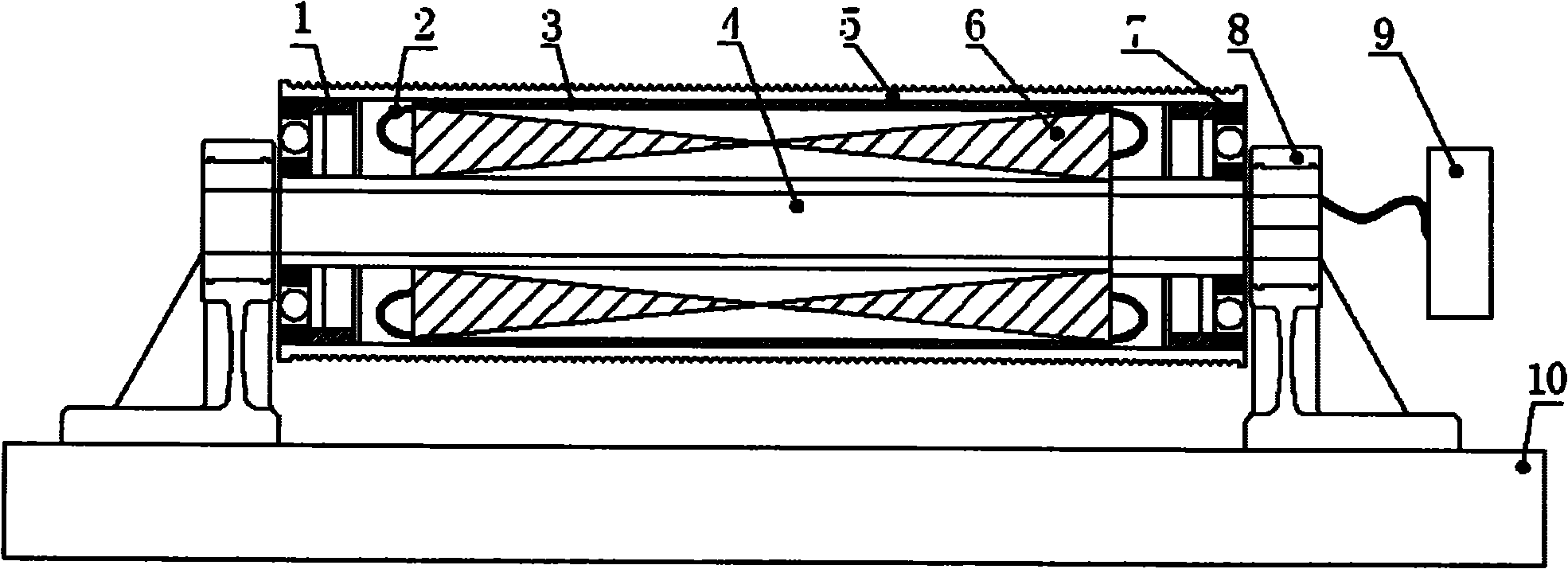

[0029] Embodiment 1. A low-speed outer rotor permanent magnet drive device with a rotating speed of the outer cylinder of 0.001r / min-30r / min, including a brake 1, a winding 2, a permanent magnet 3, a central shaft 4, an outer cylinder 5, an iron core 6, and a bearing 7. Fixed seat 8 and frequency converter 9; wherein: brake 1 is set at both ends of outer cylinder 5 and fixed on central shaft 4, permanent magnet 3 is installed on the inner wall of outer cylinder 5, and outer cylinder 5 is fixed in the center through bearing 7 On the shaft 4, the winding 2 is embedded in the iron core 6, and the iron core 6 is installed on the central shaft 4 to form a whole.

Embodiment 2

[0030] Embodiment 2, a low-speed outer rotor permanent magnet drive device with a rotating speed of the outer cylinder of 0.001r / min-30r / min, including a brake 1, a winding 2, a permanent magnet 3, a central shaft 4, an outer cylinder 5, an iron core 6, and a bearing 7. Fixed seat 8 and frequency converter 9; wherein: brake 1 is set at both ends of outer cylinder 5 and fixed on central shaft 4, permanent magnet 3 is installed on the inner wall of outer cylinder 5, and outer cylinder 5 is fixed in the center through bearing 7 On the shaft 4, the winding 2 is embedded in the iron core 6, and the iron core 6 is installed on the central shaft 4 to form a whole. Seat 8 is installed on the workbench 10.

Embodiment 3

[0031] Embodiment 3, a low-speed outer rotor permanent magnet drive device with a rotating speed of the outer cylinder of 0.001r / min-30r / min, wherein: the workbench 10 is a trolley of a crane. The trolley is the hoisting mechanism of the crane and undertakes the role of lifting heavy objects. All the other are with embodiment 1 or embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com