Oil-gas recovering system of storage tank and control method thereof

A technology of oil and gas recovery system and storage tank, which is applied in the field of oil and gas recovery of storage tanks, and can solve problems such as low operating efficiency, large design scale, and unreasonable processing capacity of the oil and gas recovery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

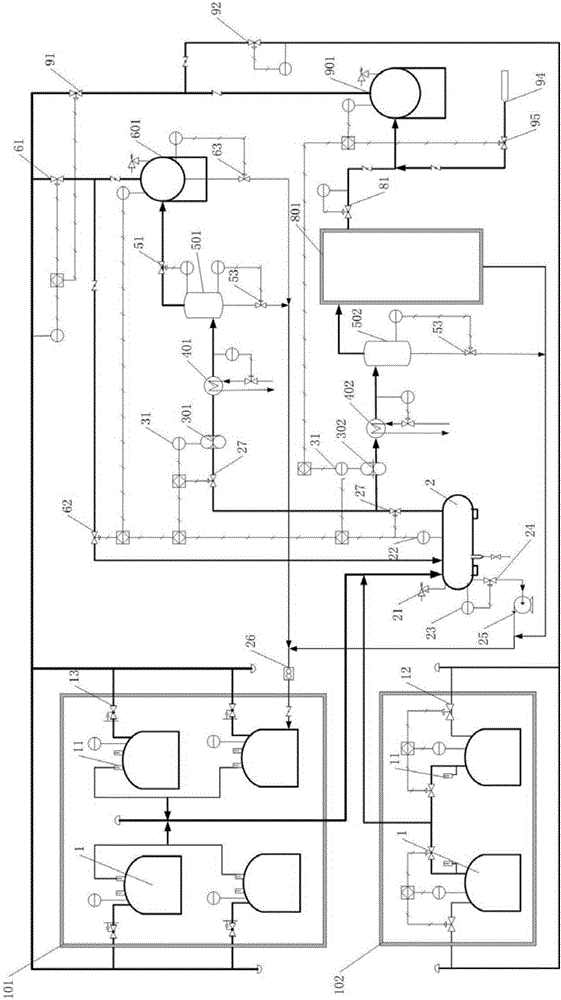

[0085] figure 1 A schematic diagram of the process flow of the storage tank oil gas recovery system provided by the embodiment of the present invention, as shown in figure 1 As shown, in this embodiment, the series oil and gas collection method is adopted.

[0086] This embodiment provides a storage tank oil and gas recovery system, including a storage tank 1, a liquid separation tank 2, a first compressor 301, a second compressor 302, a first separation tank 501, a second separation tank 502, a balance tank 601, The oil and gas recovery device 801 and the buffer tank 901, the storage tank 1 is connected with the nitrogen blanketing system; the oil and gas outlet of the storage tank 1 is connected with the inlet of the liquid separation tank 2, the first compressor 301, the first separation tank 501 and the balance tank 601 in sequence , the outlet of the balance tank 601 is respectively connected with the air inlet of the liquid separation tank 2 and the suction port of the ...

Embodiment 2

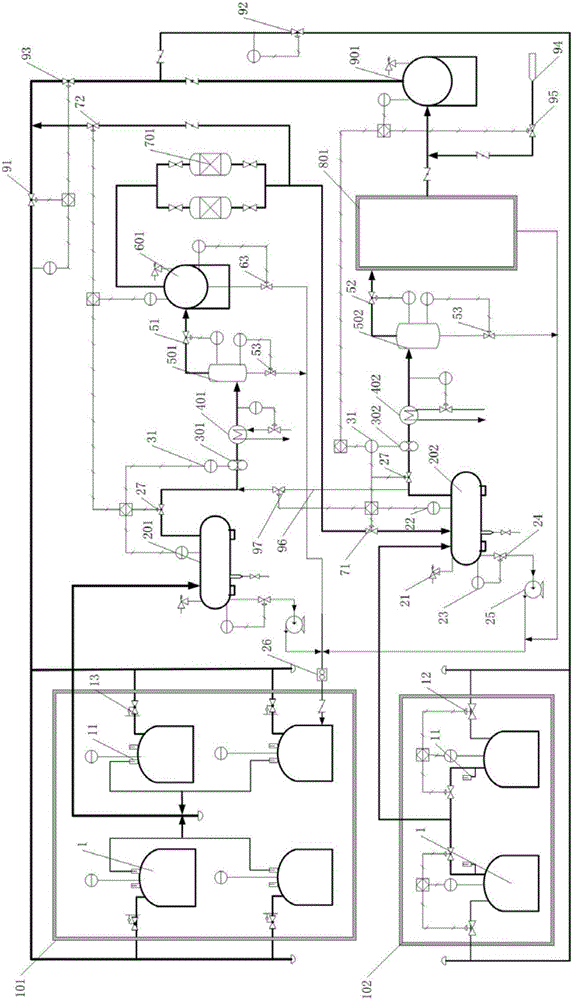

[0096] figure 2 Another schematic diagram of the process flow of the storage tank oil and gas recovery system provided by the embodiment of the present invention, such as figure 2 As shown, in this embodiment, the series oil and gas collection method is adopted.

[0097] This embodiment provides a storage tank oil and gas recovery system, including a storage tank 1, a liquid separation tank 2, a first compressor 301, a second compressor 302, a first separation tank 501, a second separation tank 502, a balance tank 601, The oil and gas recovery device 801 and the buffer tank 901, the storage tank 1 is connected with the nitrogen blanketing system; the oil and gas outlet of the storage tank 1 is connected with the inlet of the liquid separation tank 2, the first compressor 301, the first separation tank 501 and the balance tank 601 in sequence , the outlet of the balance tank 601 is respectively connected with the air inlet of the liquid separation tank 2 and the suction port...

Embodiment 3

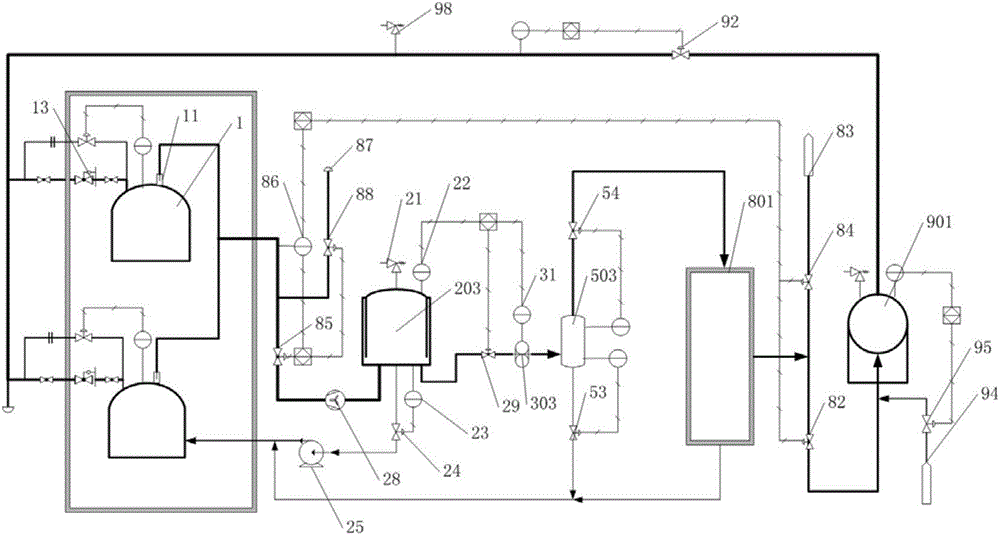

[0106] This embodiment provides a control method for the storage tank oil and gas recovery system as described in Embodiment 1 and Embodiment 2, which specifically includes:

[0107] (1) System pressure control:

[0108] The pressure of the oil and gas balance system is controlled by the pressure of the first separation tank 501, and the pressure of the oil and gas recovery system is controlled by the pressure of the second separation tank 502 or the outlet pressure of the oil and gas recovery device 801, specifically:

[0109] Set the pressure of the first separation tank 501 according to the large breathing volume of the storage tank 1, the total amount of small breathing gas and the floor area, and control the oil-gas balance system through the pressure control valve 51 on the gas phase outlet connection pipeline of the first separation tank 501 pressure;

[0110] Set the pressure of the second separation tank 502 according to the type of the oil vapor recovery device 801 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com