A bead screening device and a bead embroidery machine using the device

A technology for screening equipment and beads, applied in the direction of automatically controlled embroidery machines, embroidery machines, embroidery machine mechanisms, etc., can solve the problems of mixing beads, affecting the use of bead embroidery, and the aperture can not meet the needs of bead embroidery. Filter for effective, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

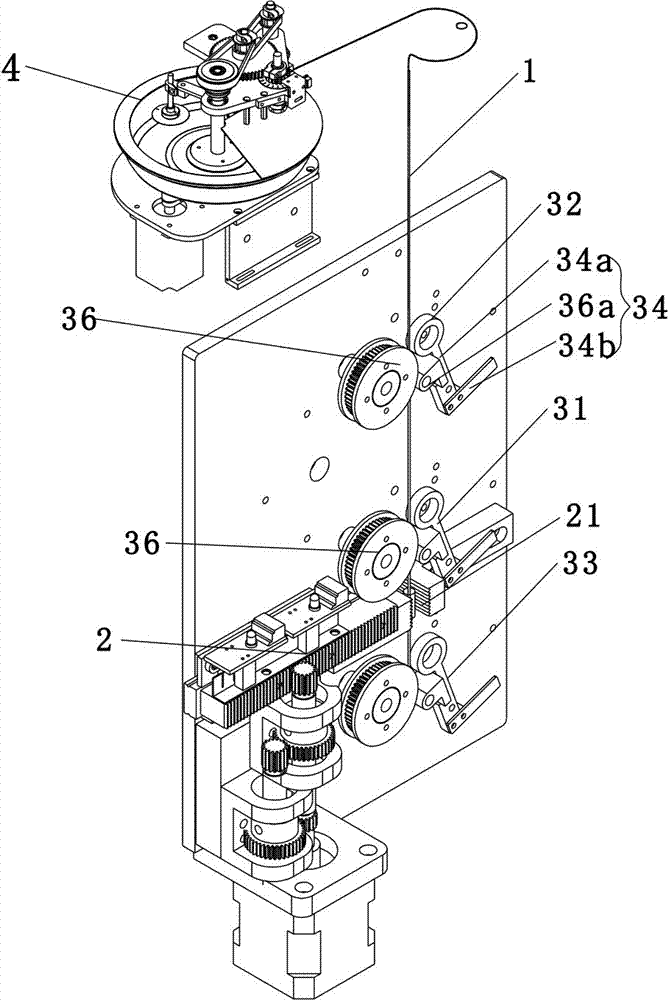

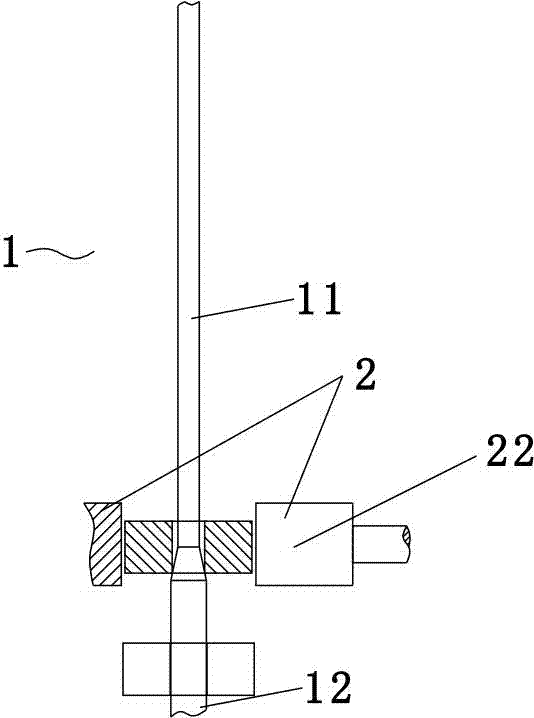

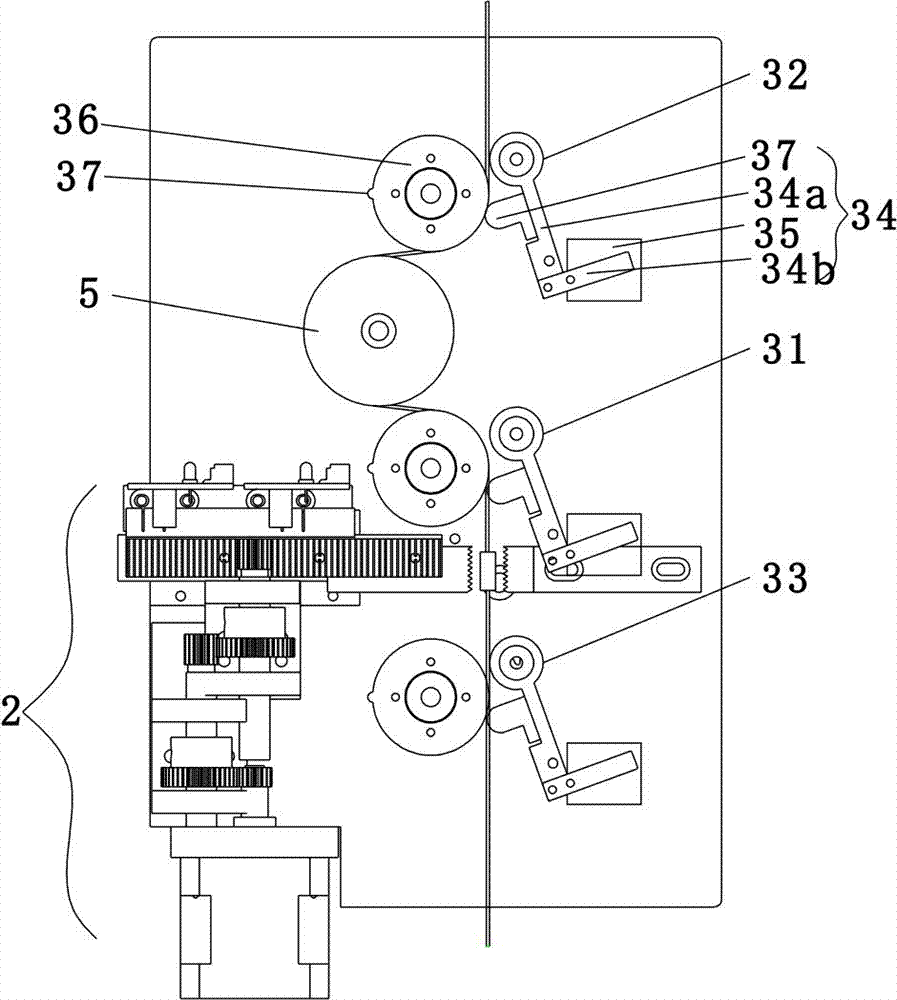

[0021] see Figure 1-3 , this implementation case includes a control device and a bead selection rod 1. In order to simplify the bead driving structure, the bead selection rod 1 is suspended, and the beads can slide by gravity. The bead selection rod 1 includes a thin diameter section 11 for stringing beads and a thick diameter section 12 for screening the inner diameter of beads, and the thick diameter section 12 can also be replaced by a thick diameter screening point. In this embodiment, the preferred thick-diameter section 12 is taken as an example. The thin diameter section 11 of the bead selection rod 1 is used for stringing beads, the thin diameter section 11 is connected with the thick diameter section 12 or the thick diameter screening point, and the bead selection rod 1 has a crushing inner diameter at the junction of the thick and thin diameters, which does not pass through the thick diameter section or the thick diameter screening The bead breaking mechanism 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com