Removal method and analysis method of impurities in lubricating oil sample in mining device oil fluid monitoring spectral analysis

A technology of oil monitoring and spectral analysis, which is applied in separation methods, chemical instruments and methods, color/spectral characteristic measurement, etc., can solve the problems of no pretreatment, etc., and achieve the effect of saving time and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

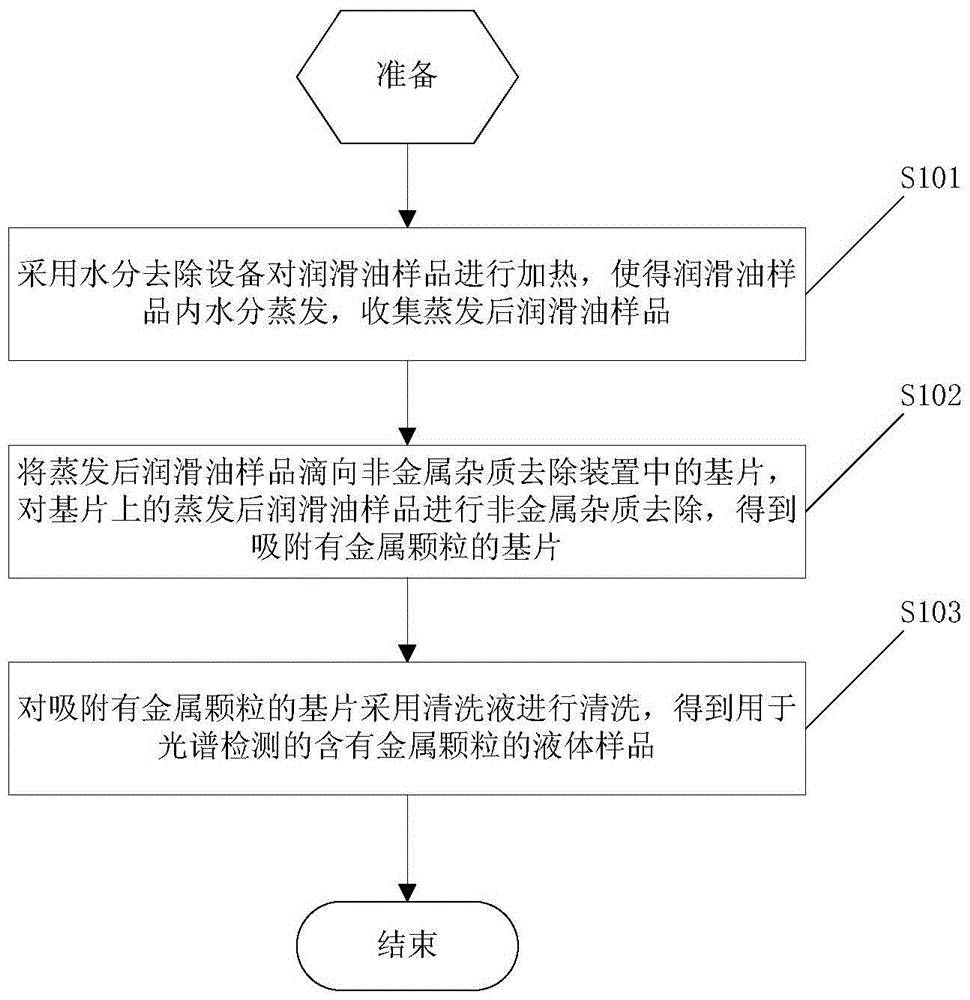

[0018] Such as figure 1 Shown is a flow chart of the method for removing impurities in lubricating oil samples in the oil monitoring spectrum analysis of mining equipment of the present invention, including:

[0019] Step S101, using a water removal device to heat the lubricating oil sample, so that the water in the lubricating oil sample evaporates, and collect the evaporated lubricating oil sample;

[0020] Step S102, drop the evaporated lubricating oil sample onto the substrate in the device for removing non-metallic impurities, remove non-metallic impurities from the evaporated lubricating oil sample on the substrate, and obtain a substrate with adsorbed metal particles;

[0021] Step S103, cleaning the substrate on which the metal particles are adsorbed with a cleaning solution to obtain a liquid sample containing metal particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com