Patents

Literature

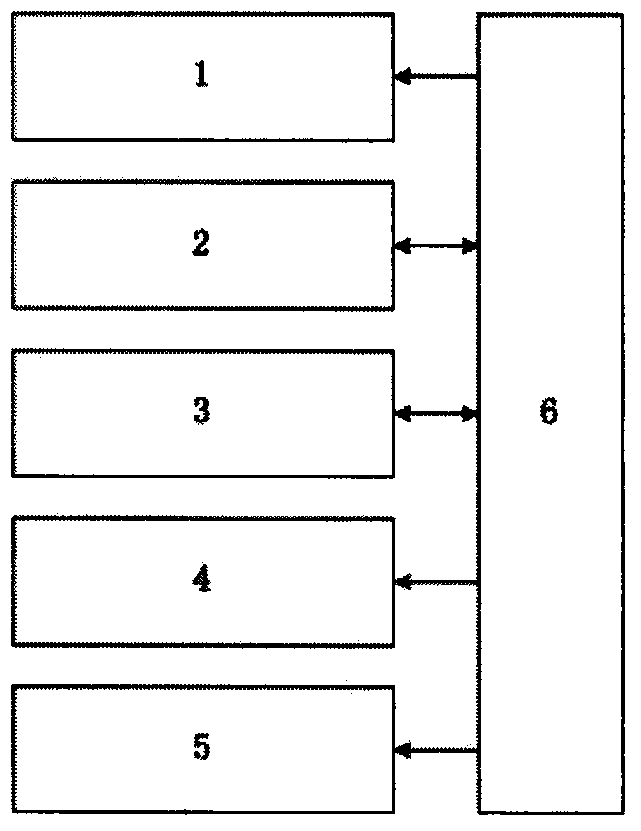

38results about How to "Realize continuous online detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

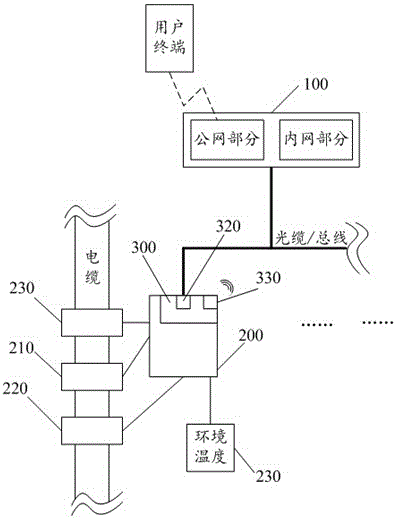

Cable online detection and fault diagnosis system

InactiveCN106093679AAccurate judgmentGood application prospectTesting dielectric strengthEngineeringGround current

The invention provides a cable online detection and fault diagnosis system, which comprises a background monitoring module, a plurality of acquisition terminals, a communication module, a grounding current sensor and a fault current sensor, wherein the grounding current sensor and the fault current sensor are respectively connected with the acquisition terminals for acquiring working electrical parameters of the cable and transmitting the parameters to the acquisition terminals; the communication module is arranged in the acquisition terminal, and the working electrical parameters are transmitted to the backstage monitoring module via the communication module; and the backstage monitoring module acquires the working electrical parameters and according to a preset condition, corresponding alarming information is sent to the user terminal. Thus, continuous online detection on the cable can be realized, a change state curve for each electrical parameter is acquired, the corresponding information can be timely sent to the user terminal via the communication module, and the insulation state of the cable can be judged more accurately.

Owner:顾鸿鸣

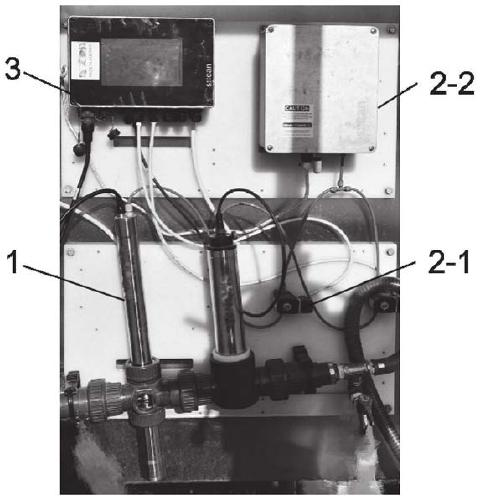

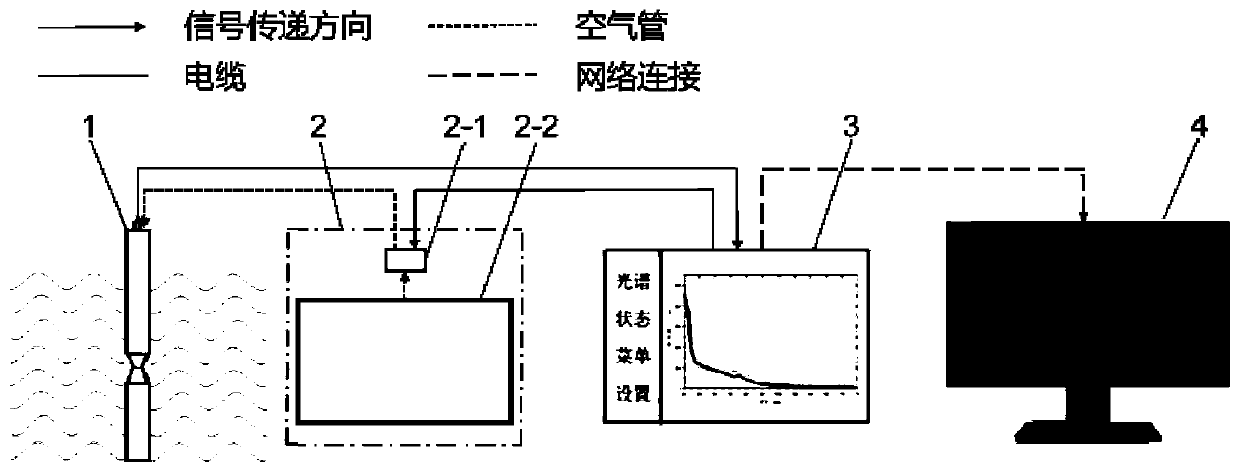

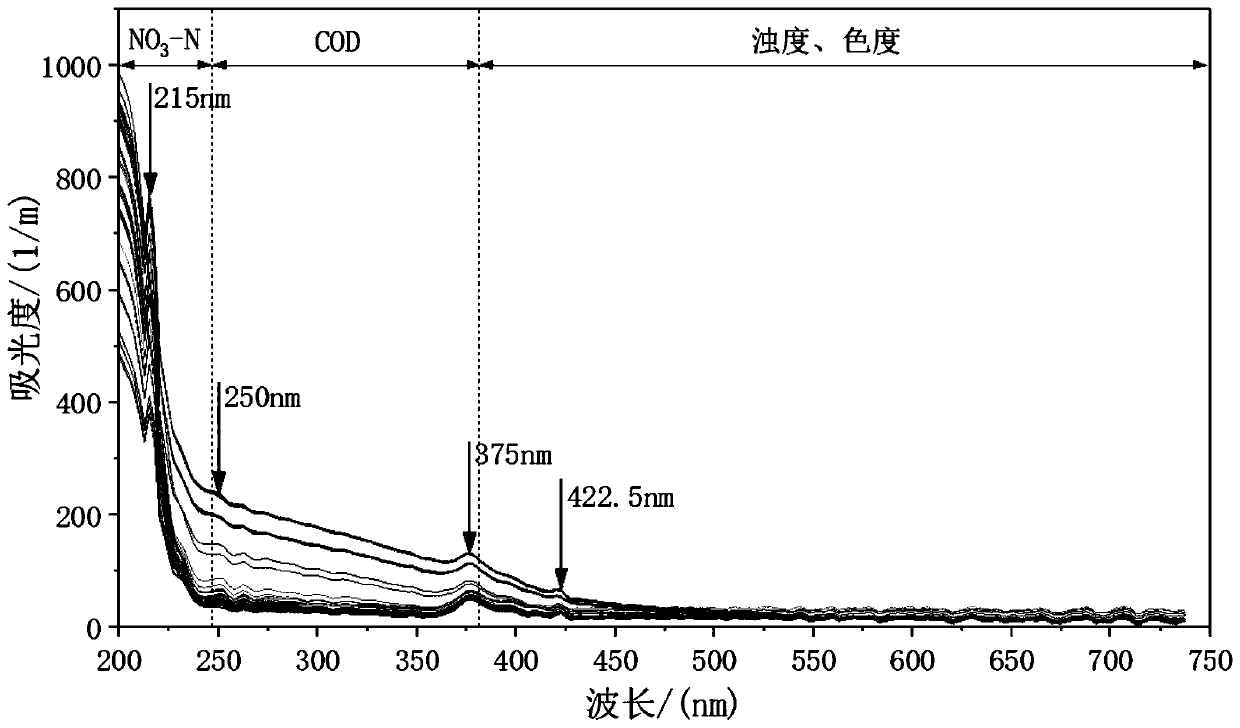

Ultraviolet-visible light full-wavelength scanning sewage quality online rapid detection method and application thereof

PendingCN111351762AAccurate Water Quality TestingShort detection timeGeneral water supply conservationTesting waterWater qualityPhysical chemistry

The invention relates to an ultraviolet-visible light full-wavelength scanning sewage quality online rapid detection method and an application thereof. A full-waveband spectrum detection system is used for carrying out full-waveband scanning on sewage, a water body is directly scanned in an immersion mode, and obtained spectral absorption information of the sewage is transmitted to the full-waveband spectrum detection system; an absorption full-spectrum chart of the sewage is calculated by utilizing the full-waveband spectrum detection system; a multiple regression equation of each to-be-detected substance is obtained by fitting through a multiple regression equation model by utilizing the full-waveband spectrum detection system, wherein the multiple regression equation model is as follows: Yn = A1 * x1 + A2 * x2 +... + A210 * x210 +... + An * xn (n = 215-217), Yn is a target parameter prediction value, and A1 to An are respectively a coefficient of a wavelength corresponding to each model. The full-waveband spectrum detection system is used for detecting water quality parameter values. The simultaneous detection of various substances is realized, the detection time is short and is15 seconds, and the result can be obtained.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

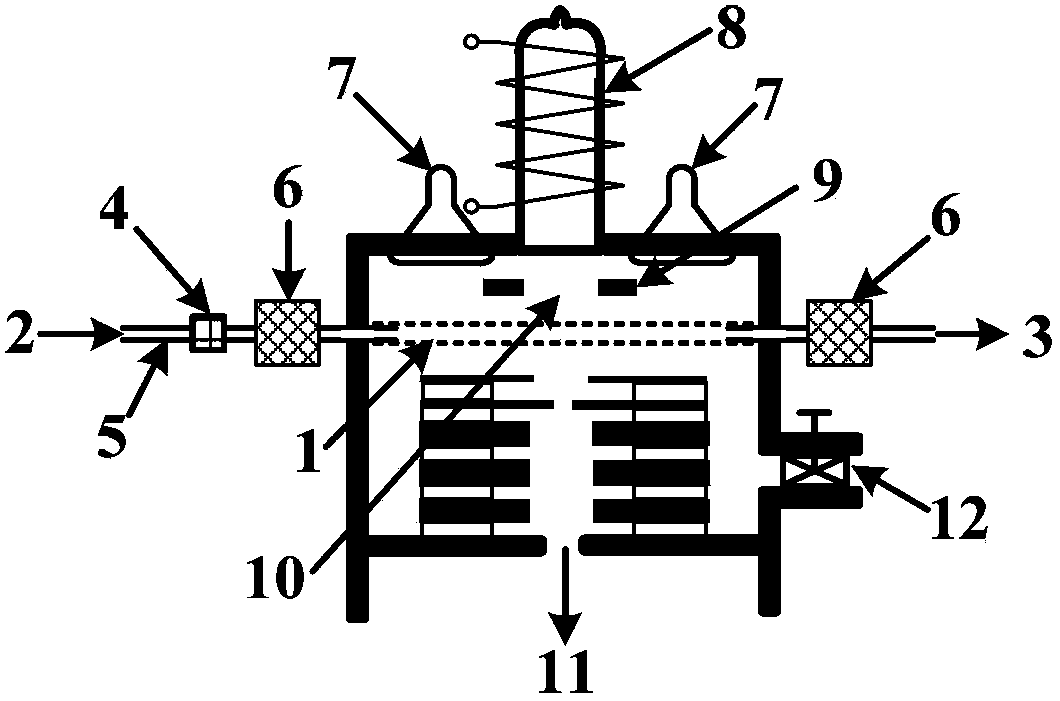

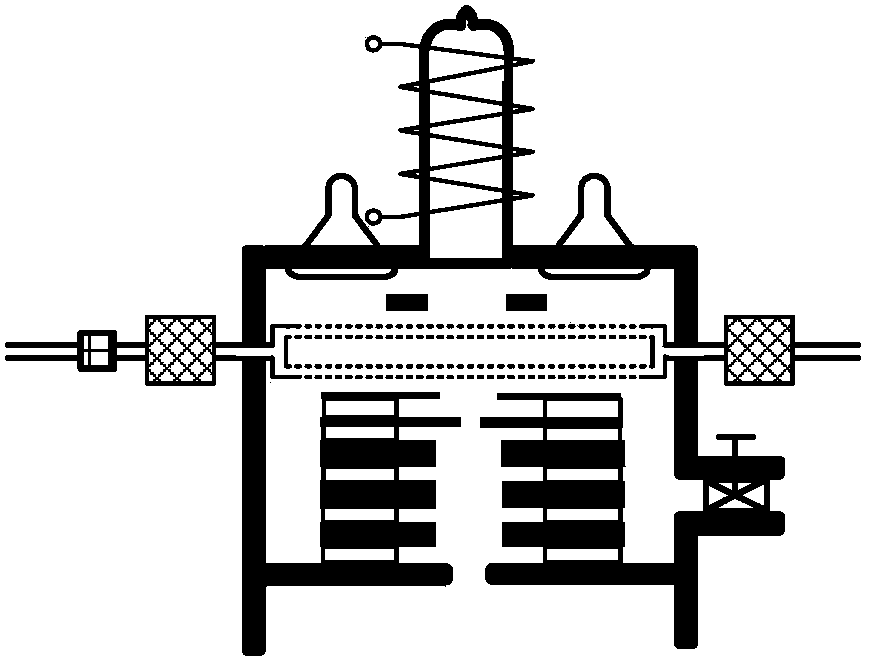

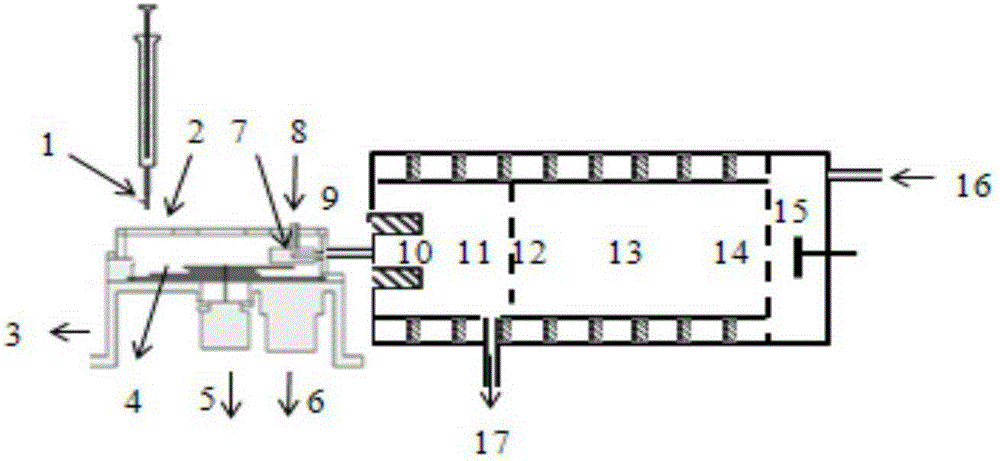

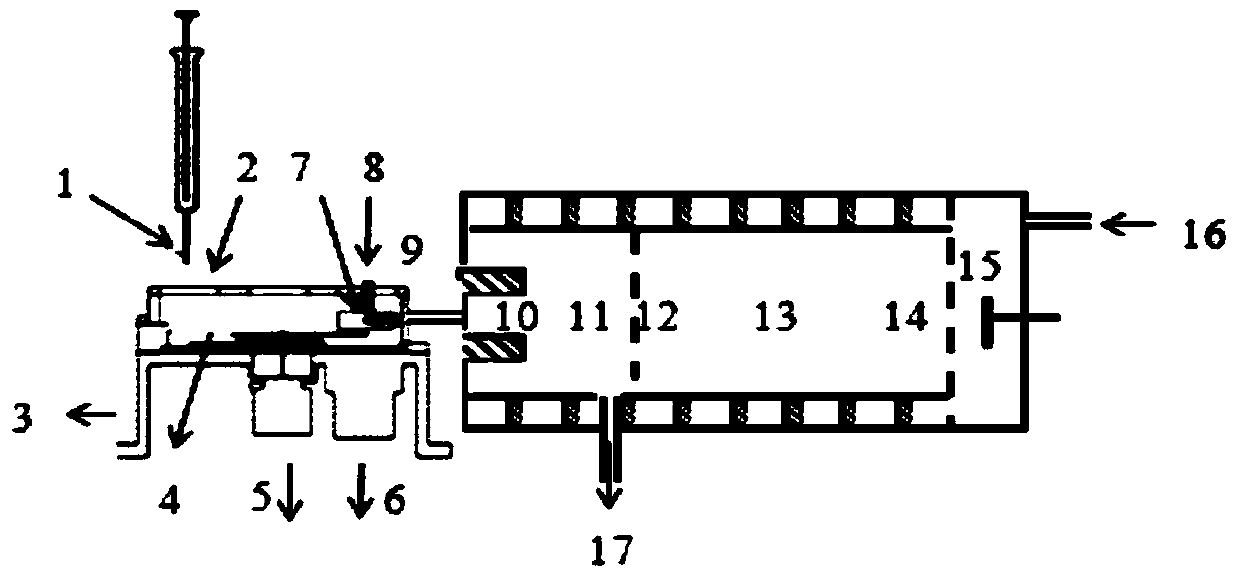

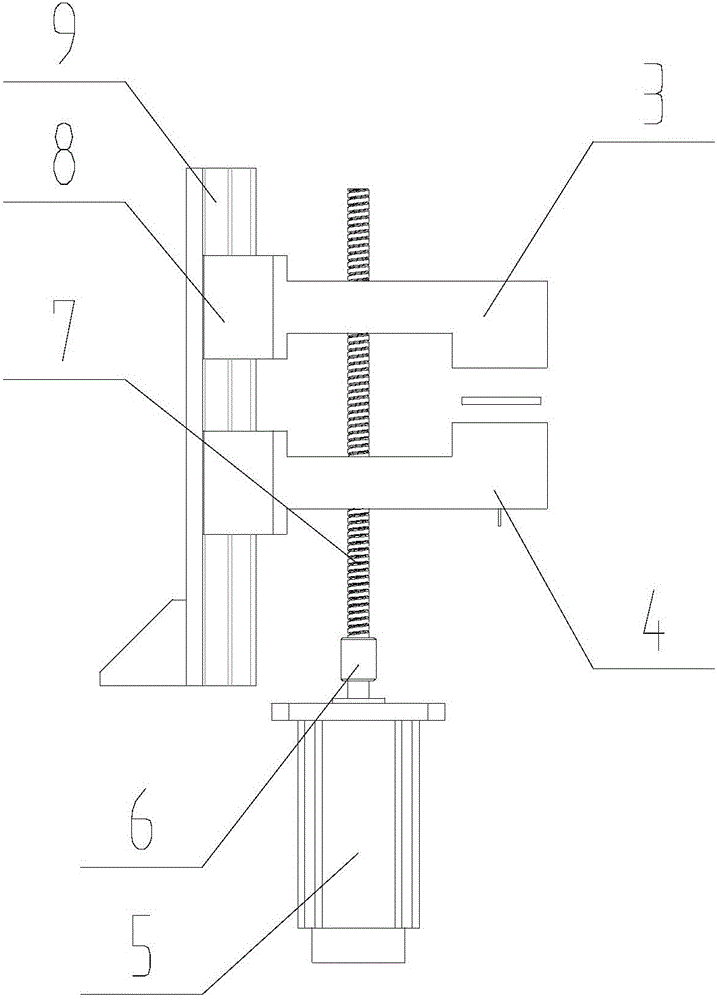

Online mass spectrum sample introduction device with tubular film inside ionization source

ActiveCN103531431AIncreased diffusion rateImprove ionization efficiencySamples introduction/extractionMass spectrometersSolenoid valveTransmittance

The invention designs an online mass spectrum sample introduction device with a tubular film inside an ionization source. The sample introduction device comprises the tubular film, heating lamps, a sample introduction metal tube, a particle filter screen and emergency cut-out solenoid valves. A nonporous compact polydimethylsiloxane tubular film serves as the tubular film. The tubular film is directly arranged in an ionized region. The heating lamps arranged on the outer sides of the tubular film are used as film heating devices. Metal capillary tubes are connected with two ends of the tubular film and are respectively used as a sample introduction inlet and a sample introduction outlet. An air exhausting opening is arranged on the side wall of the cavity of the ionized region. The air exhausting opening is provided with an adjustable valve to adjust the vacuum degree of the ionized region. Arrayed tubular films can be used in the ionized region to facilitate a large amount of sample introduction. The device improves the transmittance of samples in the film and ionization efficiency of the samples.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

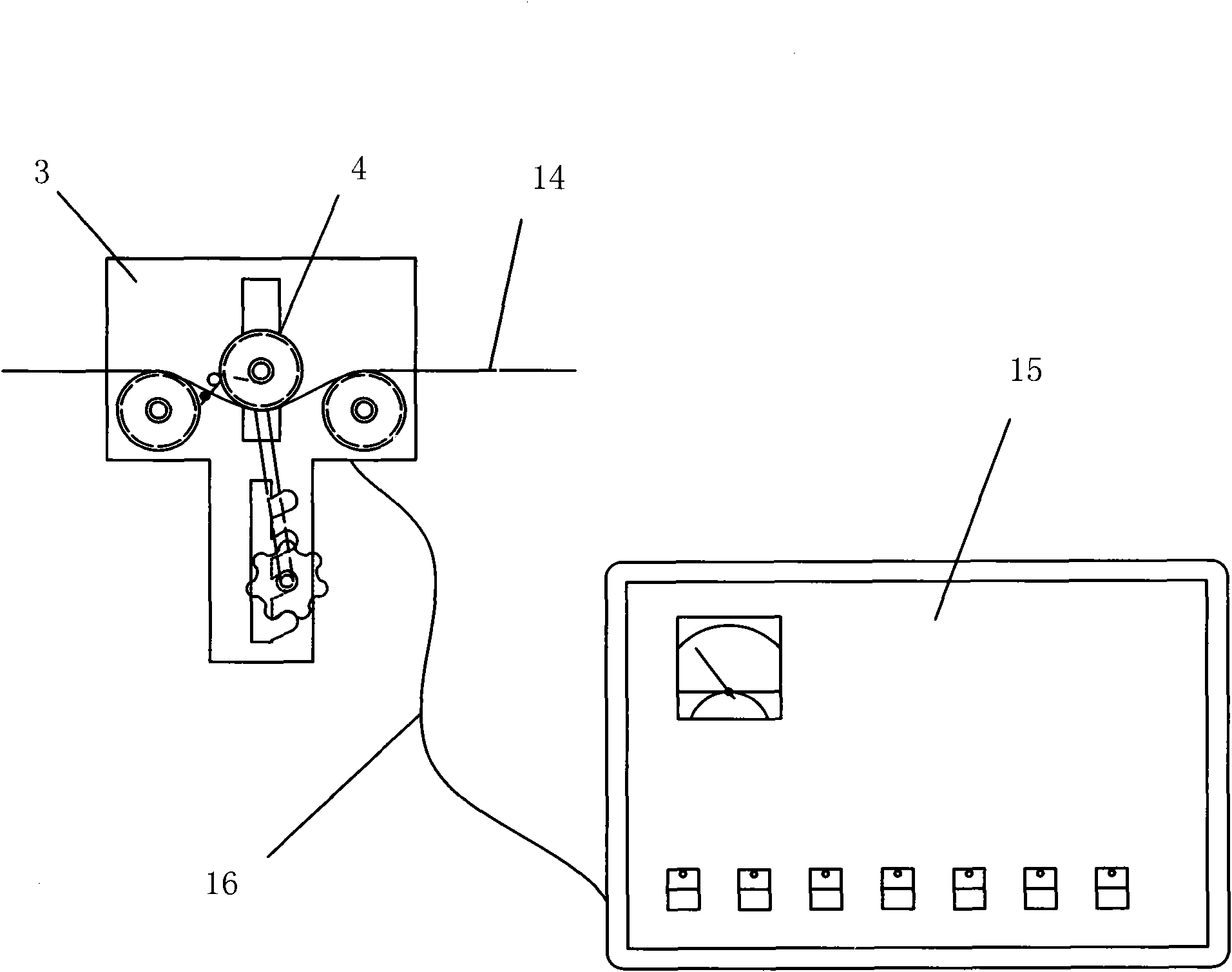

High-pressure paint film continuity tester

ActiveCN102033082AReduce test costSimple structureMaterial analysis by electric/magnetic meansEngineeringHigh pressure

The invention relates to a high-pressure paint film continuity tester, which comprises a high pressure test head, a direct-current high pressure generator, a signal detection circuit, a processing circuit and a counting instrument, wherein the high pressure test head consists of a bracket, left and right guide wheels fixed on the bracket, and a creaser wheel positioned in the middle of the left and right guide wheels; and the creaser wheel or the left and right guide wheels is / are fixed on the bracket through a vertical displacement adjusting device. The vertical position between the creaser wheel and the guide wheels on the high pressure test head is adjustable, so continuity online detection of enameled wires and paint films can be realized, detection materials are not dissipated, and the test cost is reduced; and the tester has a simple structure, and the positions of the creaser wheel and the guide wheels are convenient to set.

Owner:TONGLING JINGDA REA SPECIAL ENAMELED WIRE

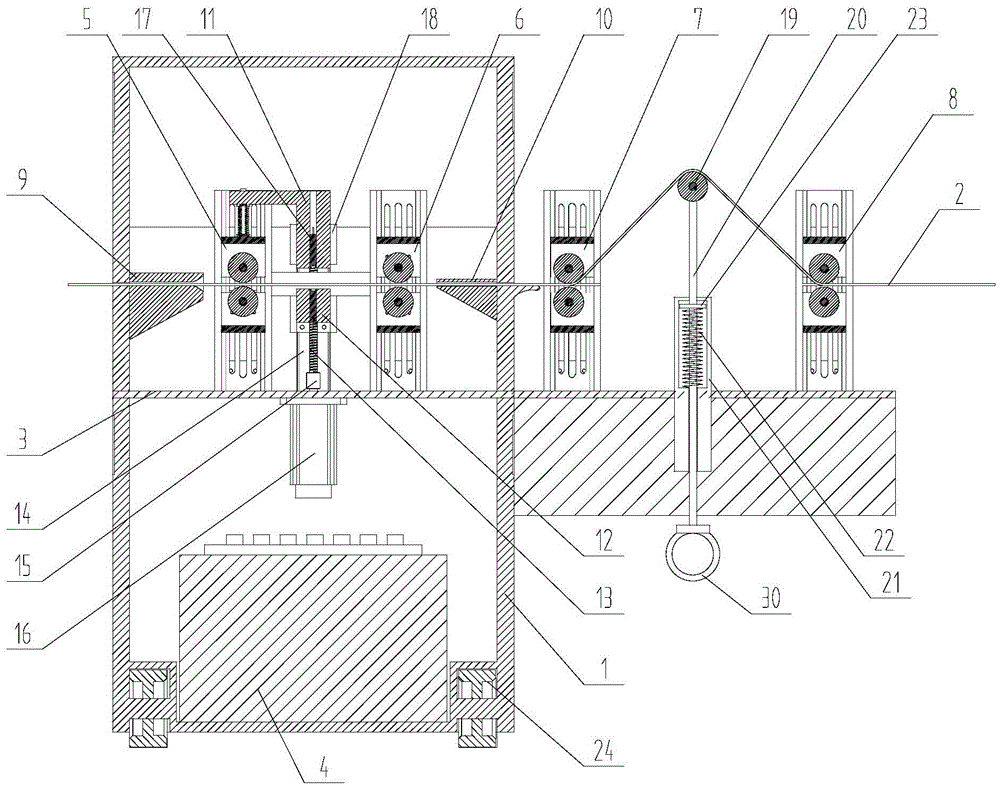

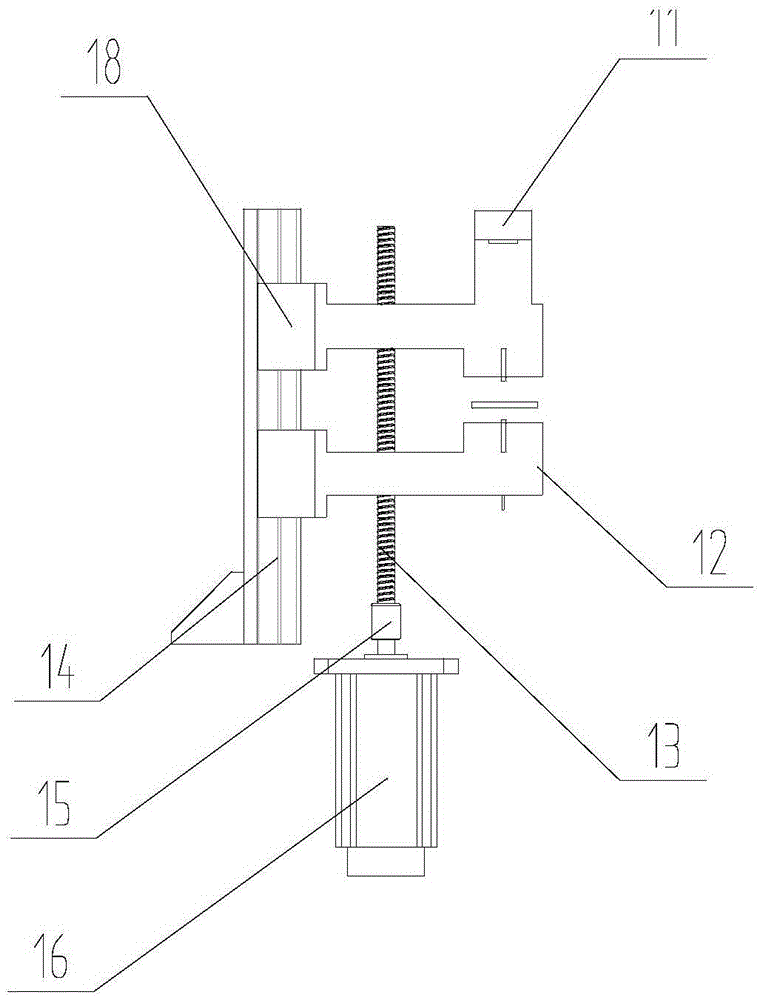

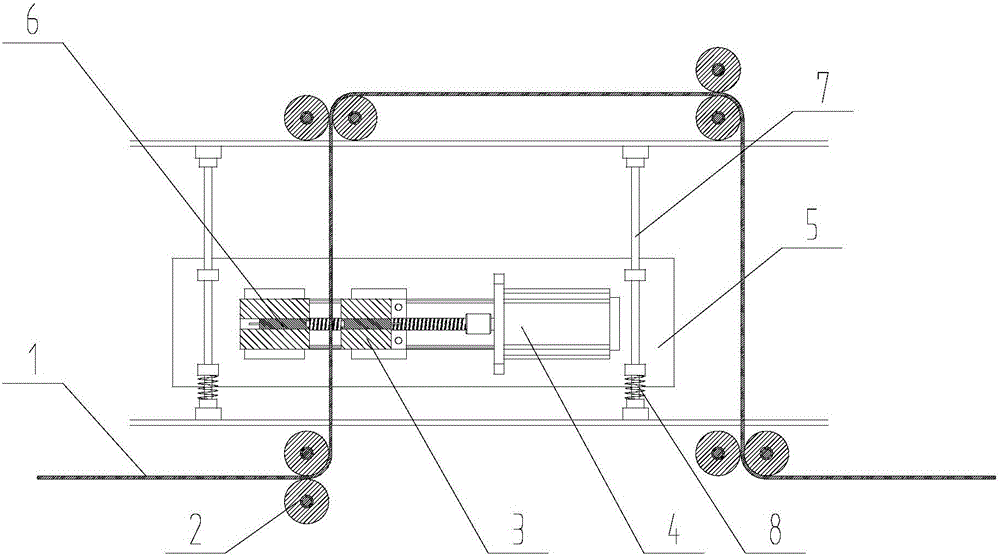

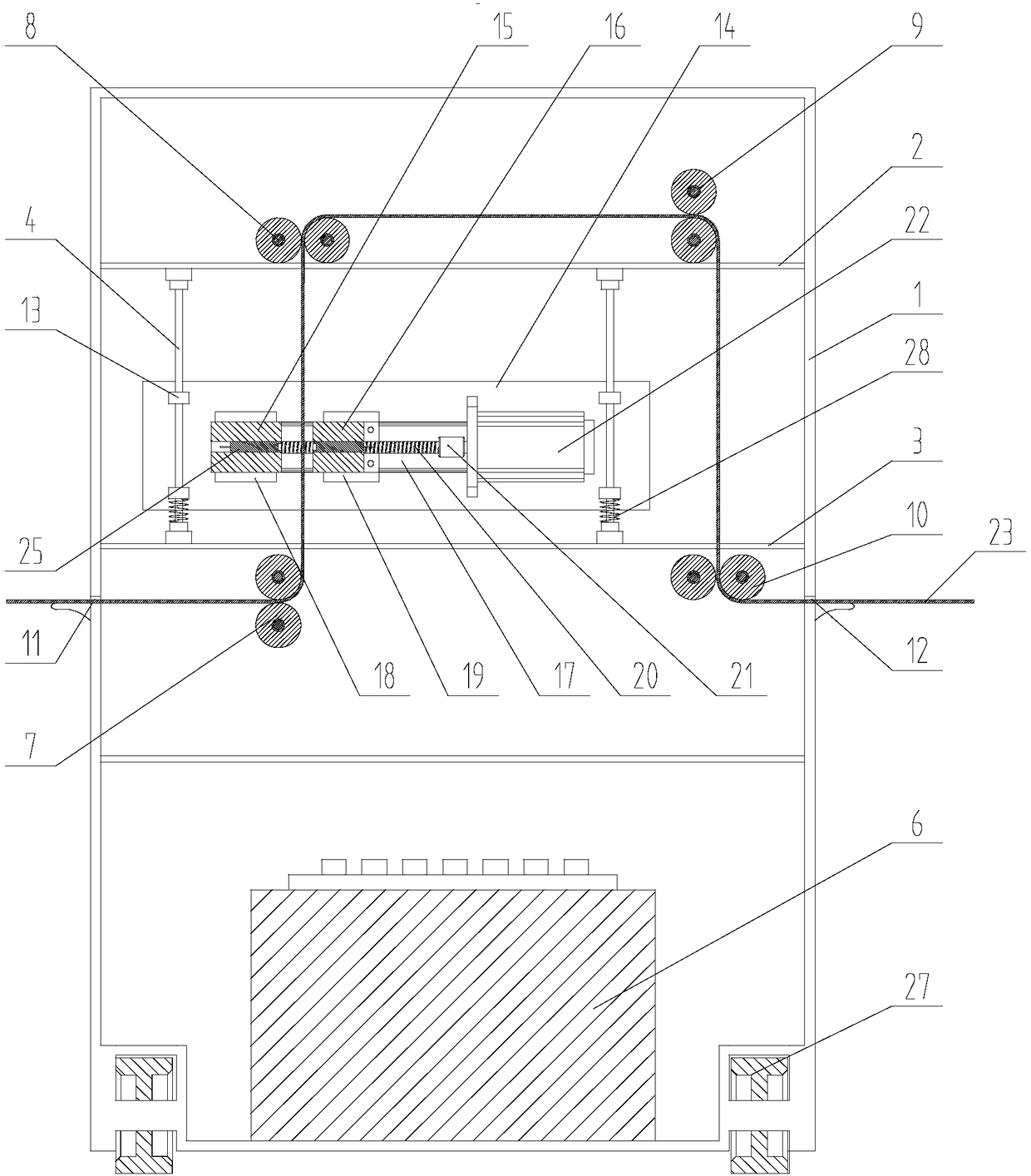

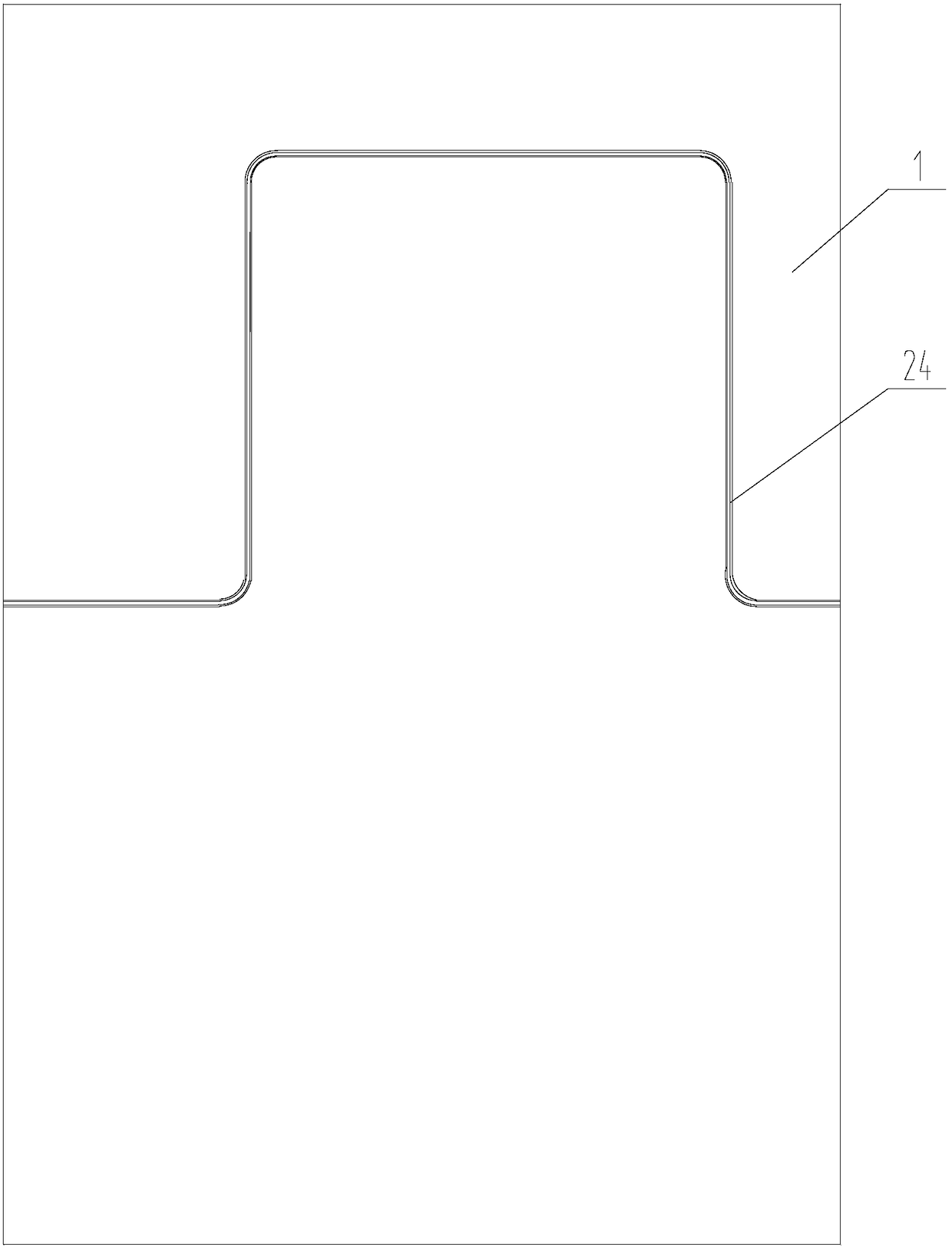

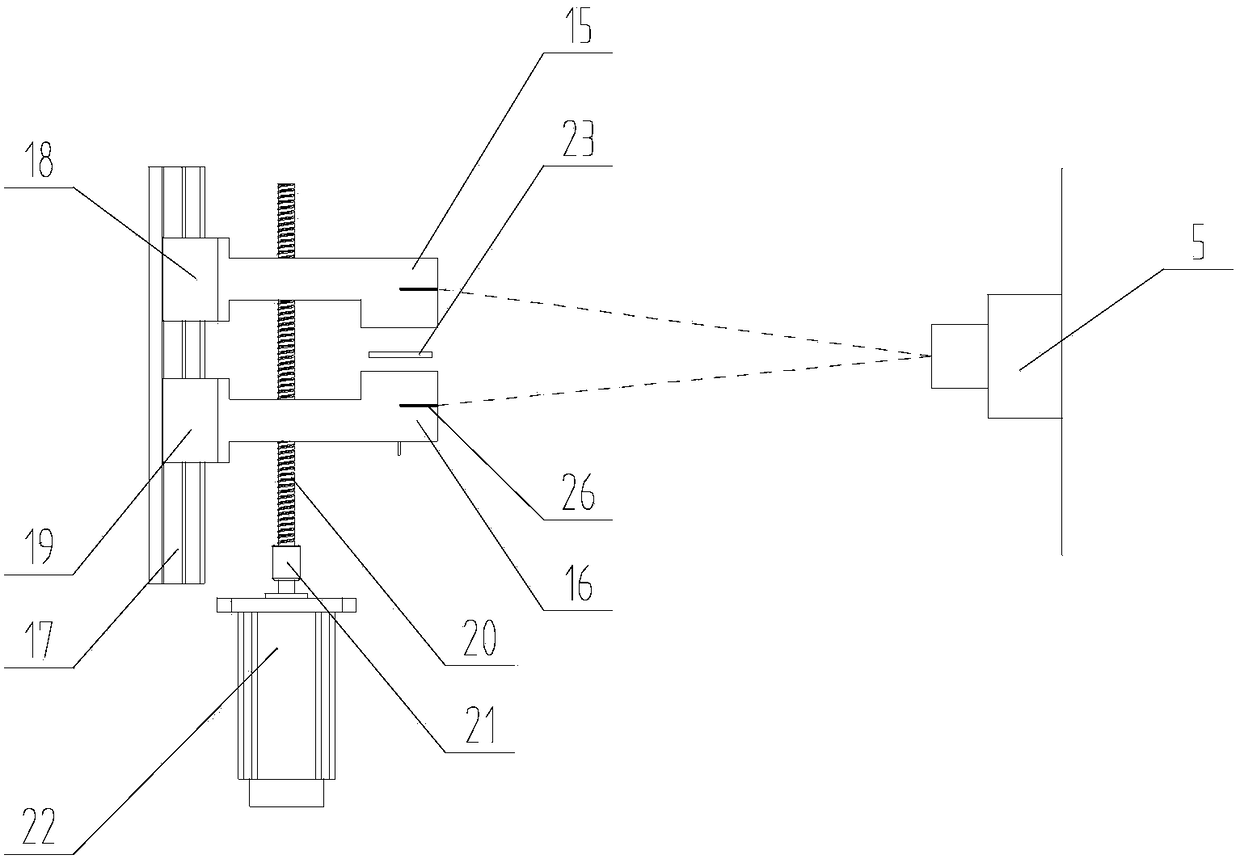

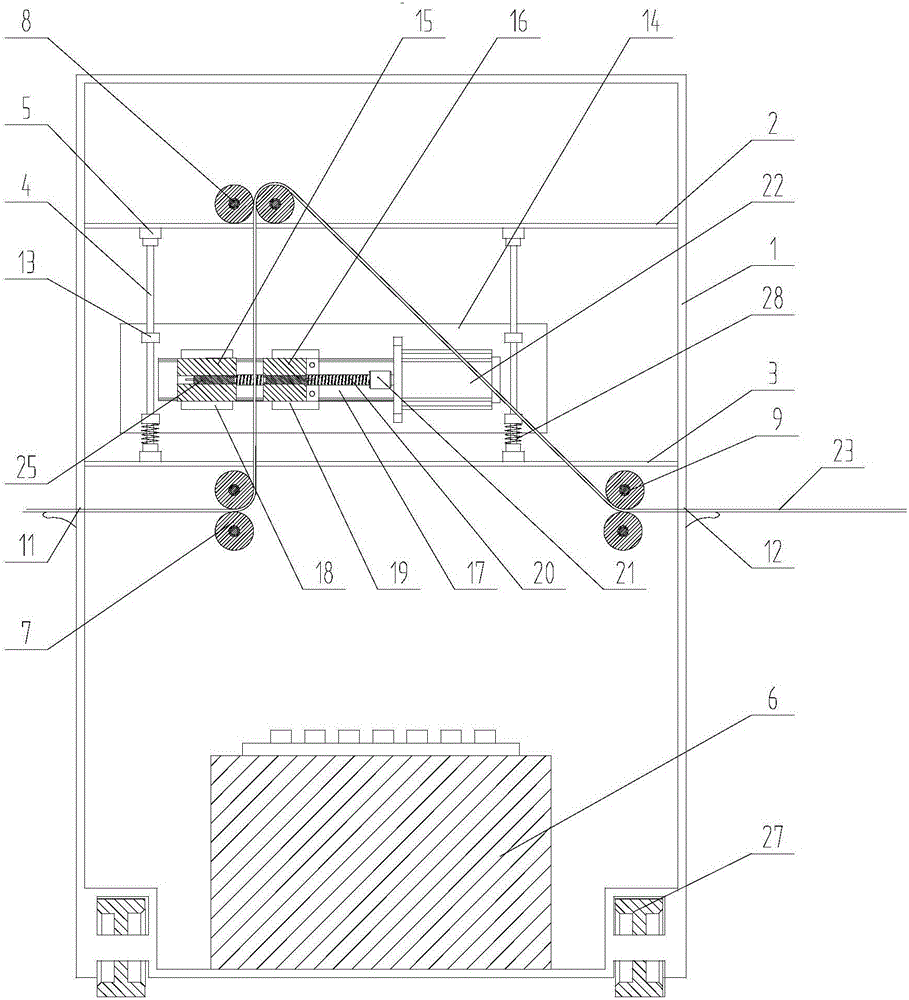

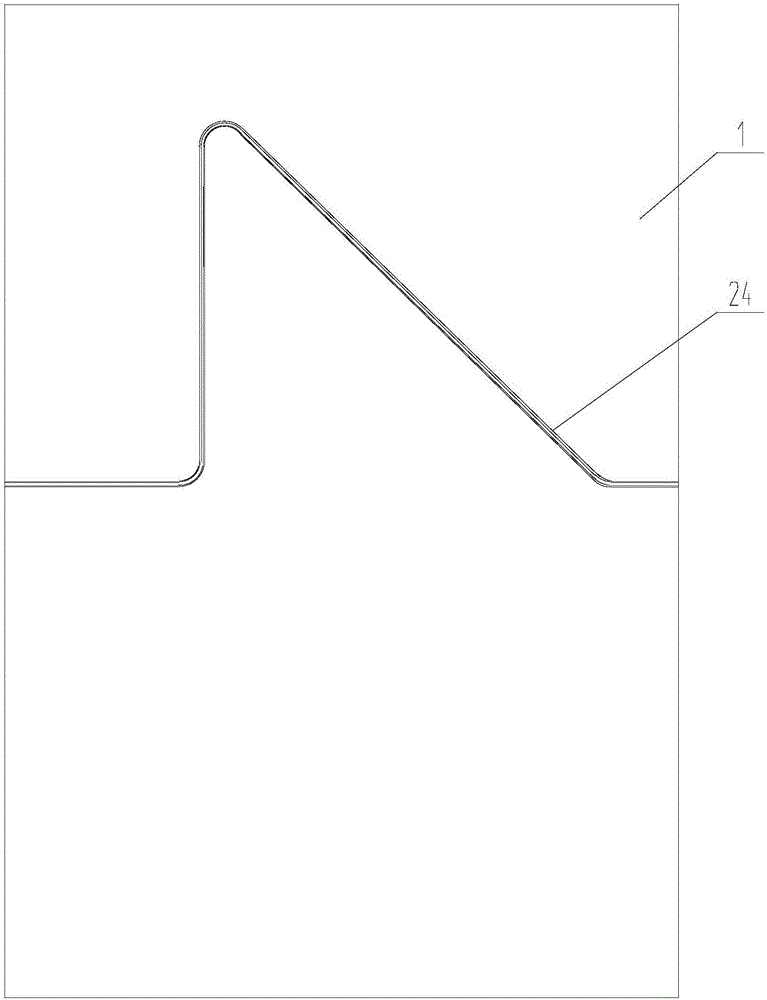

Device of measuring thickness of steel strip during production process by using distance sensor

ActiveCN105627966ARealize continuous online detectionCompact structureMeasurement devicesEngineeringDistance sensors

The invention discloses a device of measuring the thickness of a steel strip during a production process by using a distance sensor, which comprises a box-type shell, a supporting plate, a rechargeable battery, a flatting device, a distance sensor, four pairs of transmission roller groups, a steel strip buffer device and a pressure detection device, wherein the box-type shell, from inside to outside along the steel strip horizontal movement direction, is sequentially provided with a left limiting block, a first transmission roller group, the flatting device, a second transmission roller group, a right limiting block, a third transmission roller group, the steel strip buffer device and a fourth transmission roller group; the steel strip buffer device comprises an upper ejector roller, an upper ejector rod, a fixing block, a supporting seat and a reset spring; the upper ejector roller is fixed at the top part of the vertically-arranged upper ejector rod; and the upper ejector roller is contacted with the steel strip for lifting the steel strip. The device of the invention has the advantages that the moving is convenient; the operation is simple; the measurement process can be carried out in an online mode; the detection process is continuous; data calling is carried out conveniently; measurement on coiled steel strip is greatly facilitated; and mass promotion and use are facilitated.

Owner:浙江海宁经编产业园区开发有限公司

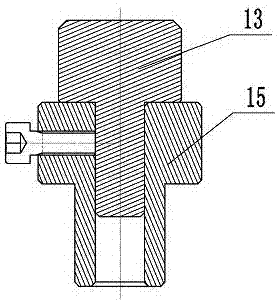

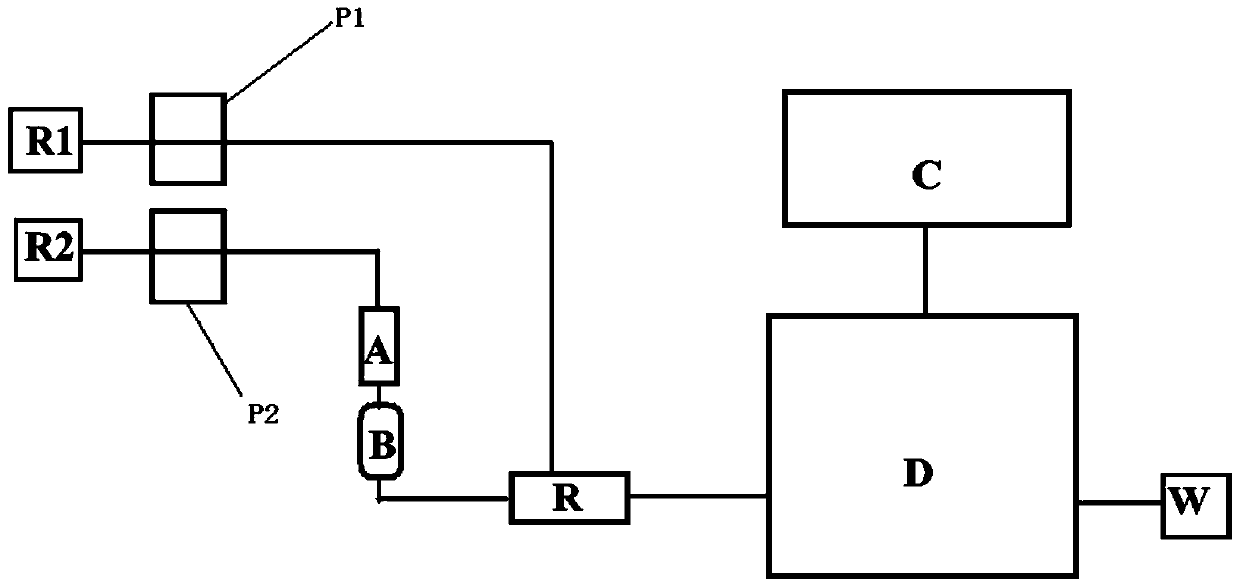

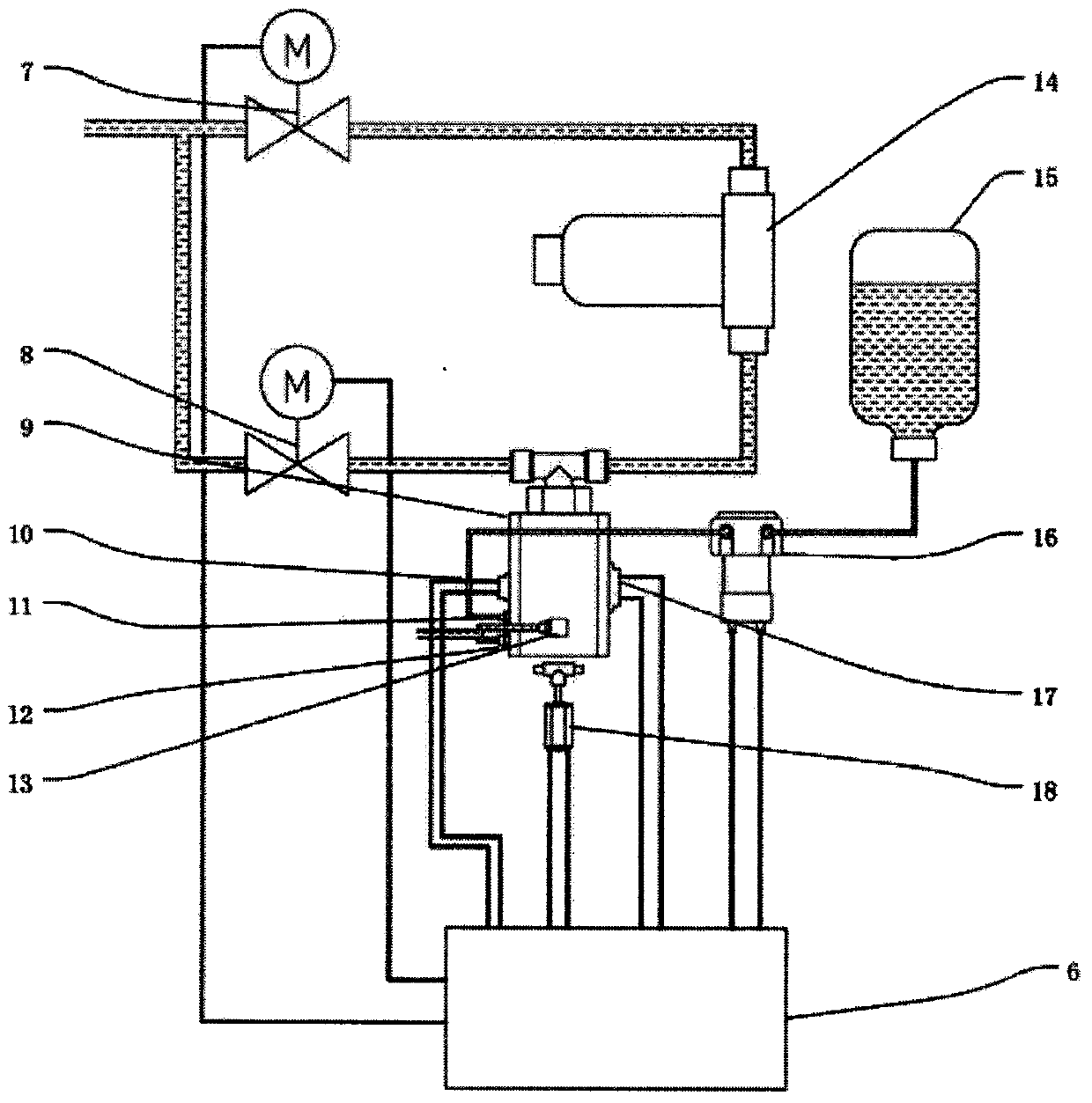

In-vitro simulated dissolution and continuous on-line detection device and method for nicotine in bagged oral tobacco products

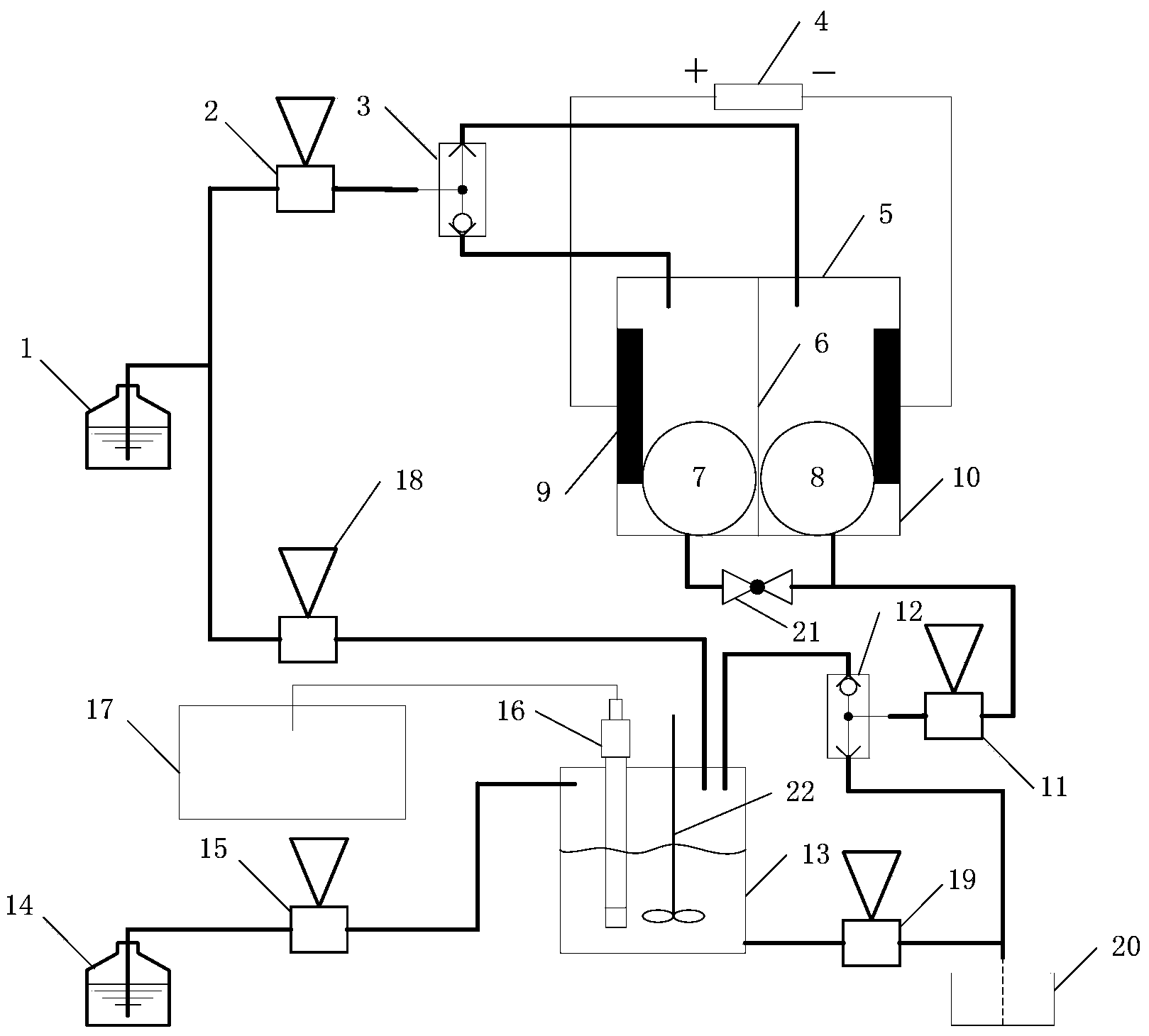

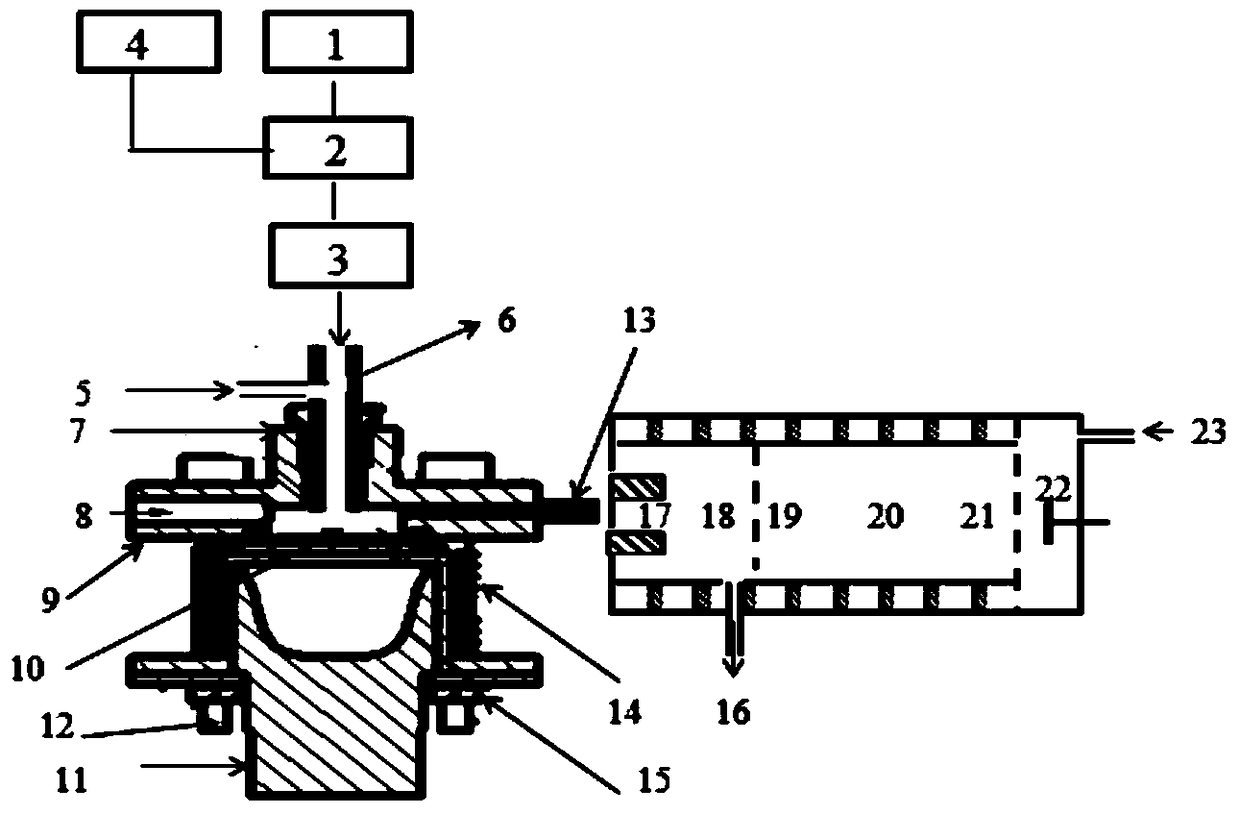

ActiveCN104833641ASimple structureEasy to disassembleColor/spectral properties measurementsPeristaltic pumpDissolution

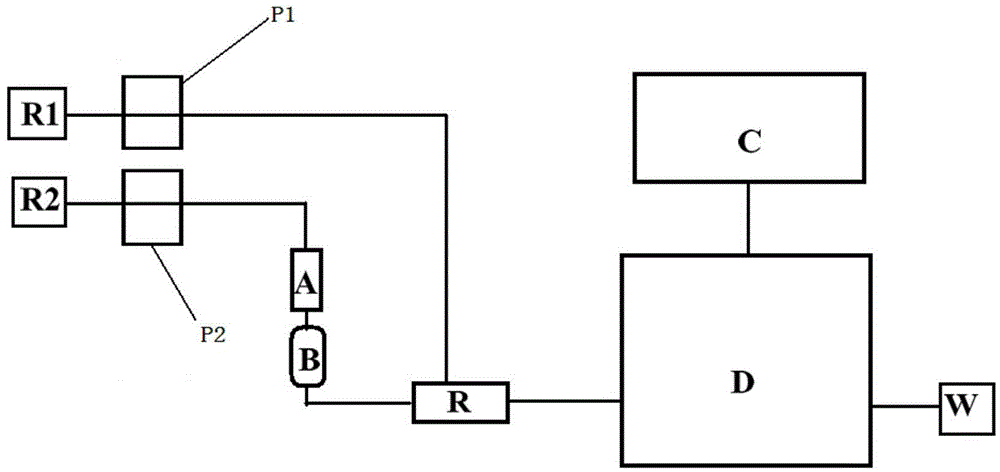

The invention relates to an in-vitro simulated dissolution and continuous online detection device for nicotine in bagged oral tobacco products. The device comprises a color developing agent containing device (R1), a dissolution agent containing device (R2), a first peristaltic pump (P1), a second peristaltic pump (P2), a dissolution pool (A), a decolorizing column (B), a reaction pool (R) and a spectrophotometer (D), wherein the first peristaltic pump (P1) is positioned at the downstream of the color developing agent containing device (R1) and is connected with the color developing agent containing device (R1) by virtue of a pipeline; the second peristaltic pump (P2), the dissolution pool (A), the decolorizing column (B), the reaction pool (R) and the spectrophotometer (D) are positioned at the downstream of the dissolution agent containing device (R2) and are sequentially connected with one another; the reaction pool (R) is positioned at the downstream of the first peristaltic pump (P1) and is connected with the first peristaltic pump (P1) by virtue of a pipeline; and the spectrophotometer (D) is connected with a data processing device (C). The invention also relates to an in-vitro simulated dissolution and continuous online detection method for the nicotine in the bagged oral tobacco products. According to the detection device and method disclosed by the invention, the continuous on-line detection of in-vitro dissolution for the nicotine can be realized, the operation is convenient, and the detection is rapid.

Owner:CHINA TOBACCO YUNNAN IND

Integrity detecting device for hollow fiber membrane component

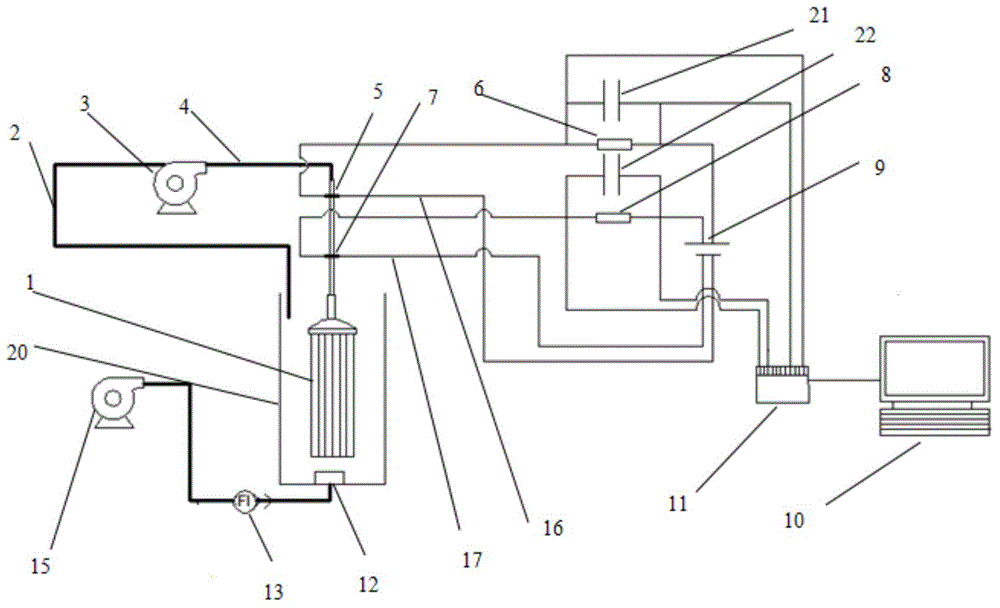

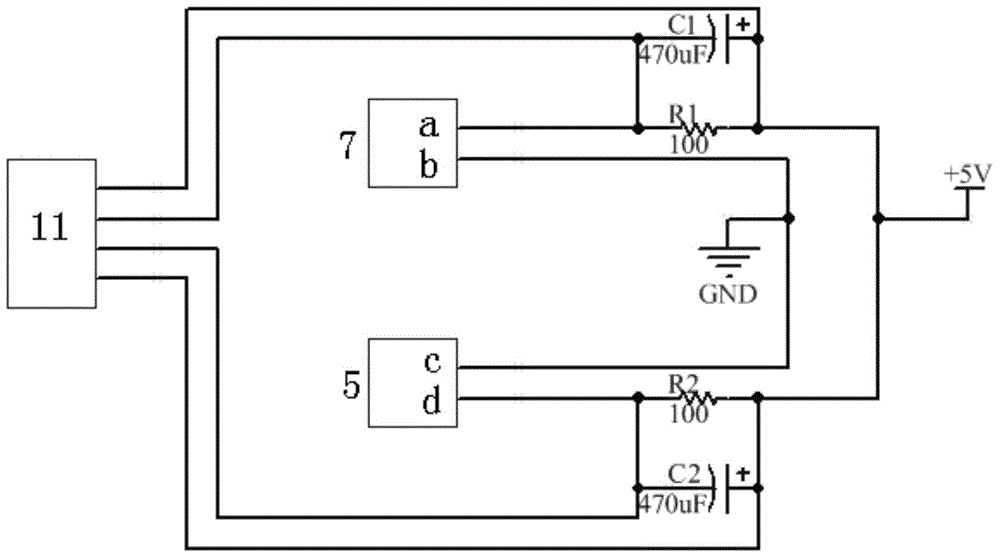

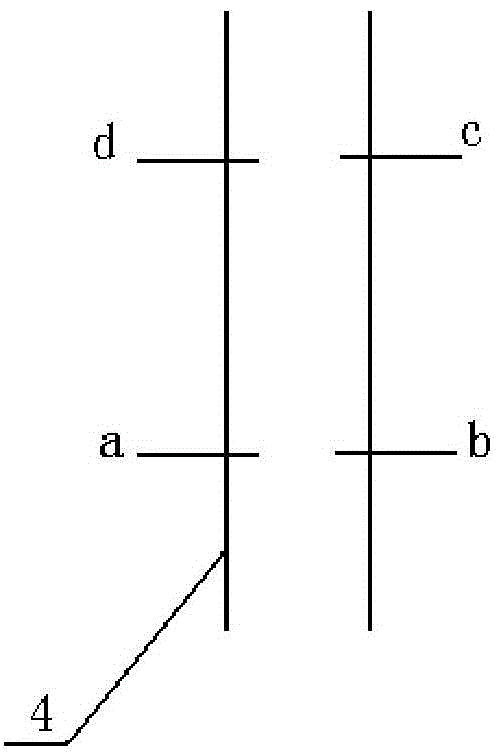

ActiveCN104888611AHigh sensitivityGuaranteed uptimeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisElectrical resistance and conductanceFixed capacitor

The invention discloses an integrity detecting device for a hollow fiber membrane component. The integrity detecting device comprises a reactor, an aerating device and a water pump, wherein two pairs of platinum wire probes are arranged on a water feeding pipe connected with the water pump, and two circuits are connected onto a 5V power supply in parallel; each pair of platinum wire probes and one fixed resistor are connected onto the circuits in series, each resistor is also connected with a fixed capacitor in parallel, the two ends of each fixed resistor are connected with an acquisition card by guide lines, the acquisition cards acquire voltages at the two ends of the fixed resistors, are connected with a computer by data lines and judge the integrity of the hollow fiber membrane component according to the change of on-line-displayed voltages. The integrity detecting device disclosed by the invention has the advantages that according to the electric principle, the change of the voltages of the two ends of the fixed resistors is acquired by utilizing the data acquisition devices, and the integrity of the membrane component is judged according to the change rule of voltage signals; continuous on-line detection can be realized, not only is the sensitivity relatively high and is the operation stable, but also the economy is relatively good.

Owner:TIANJIN POLYTECHNIC UNIV

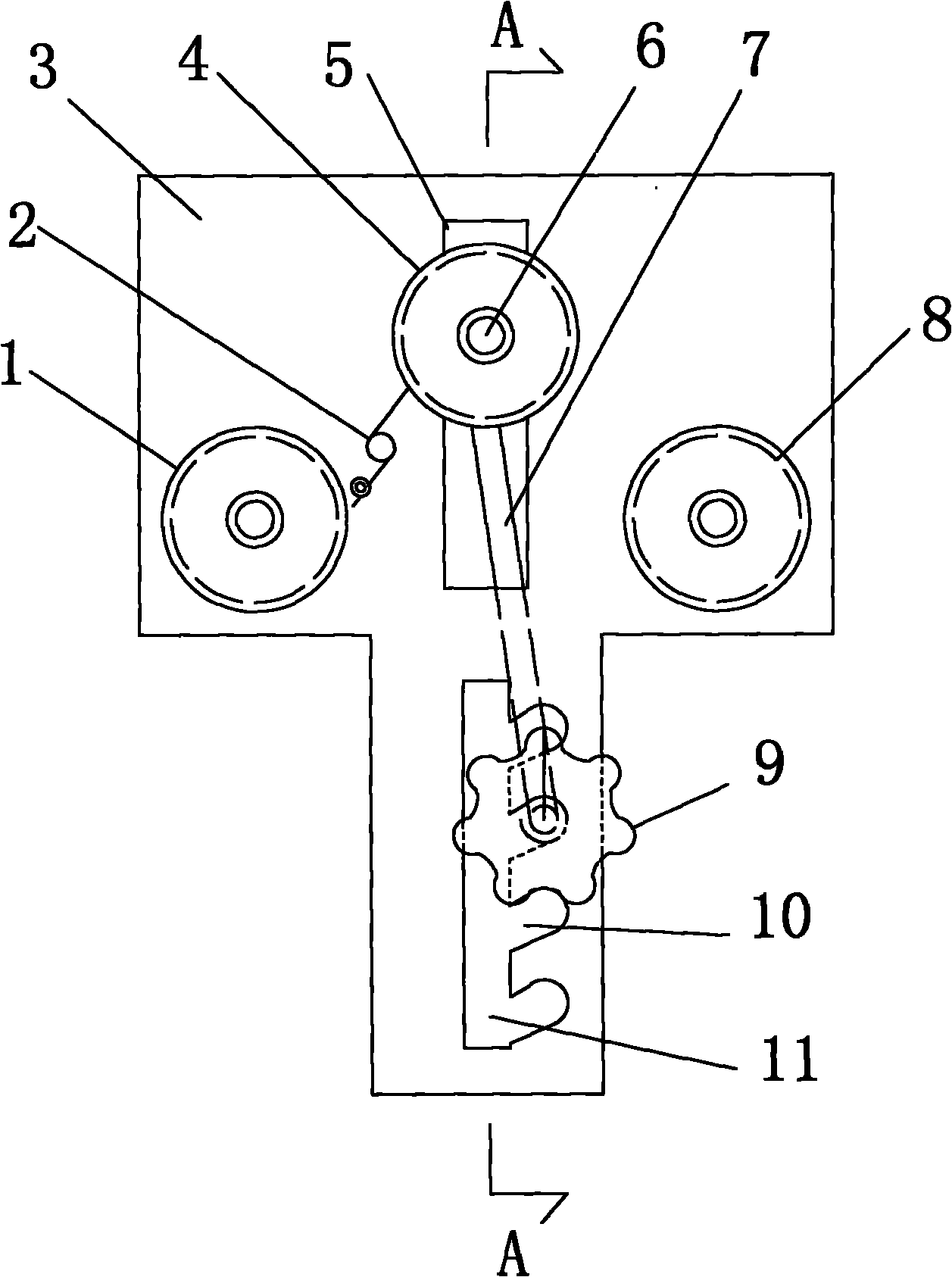

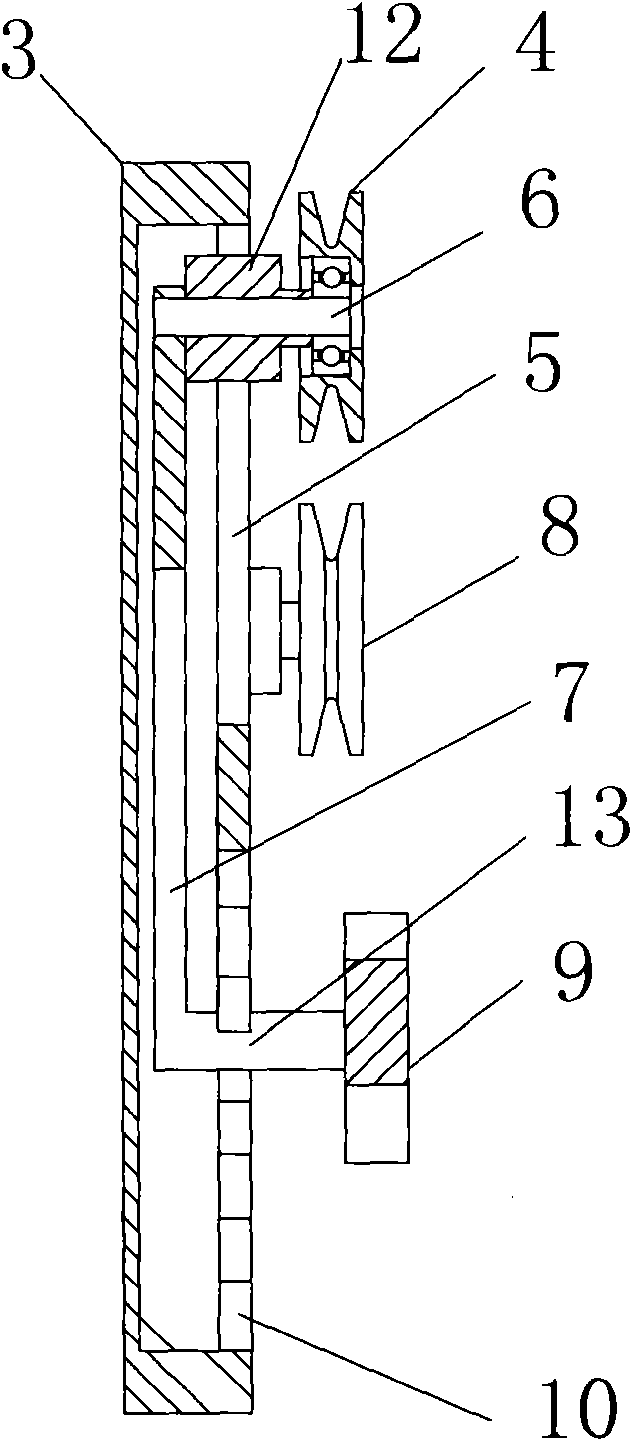

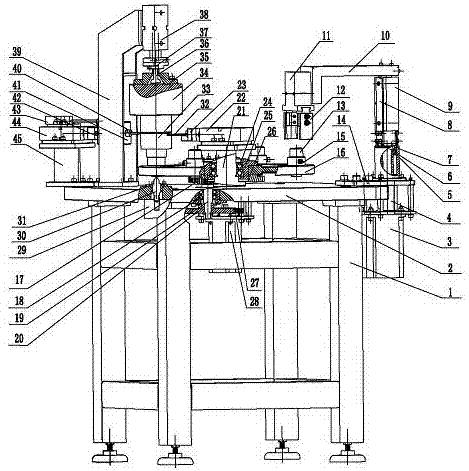

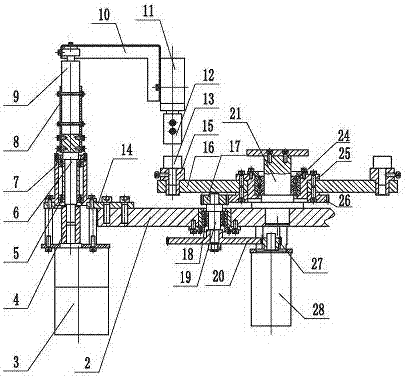

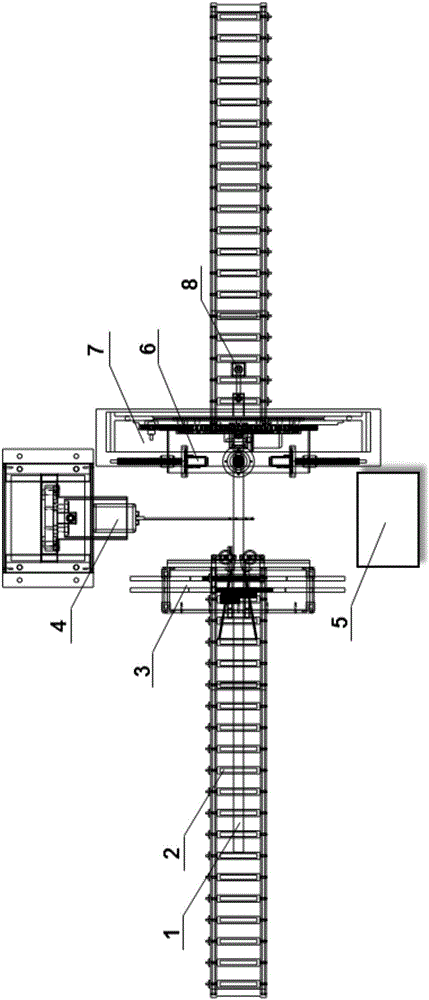

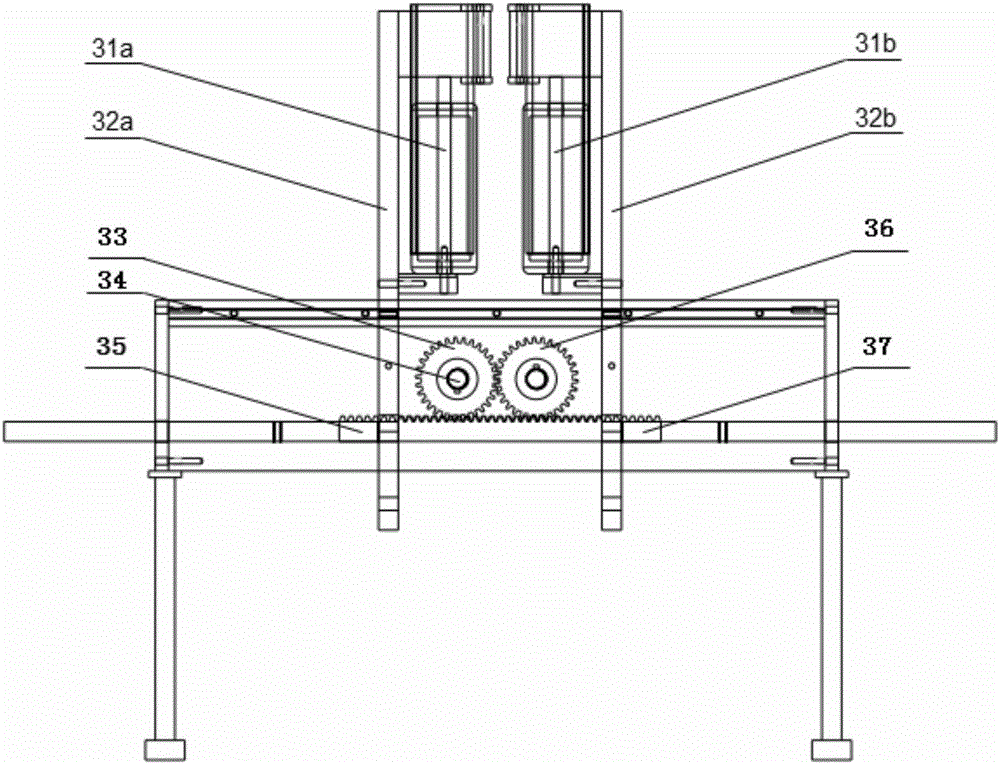

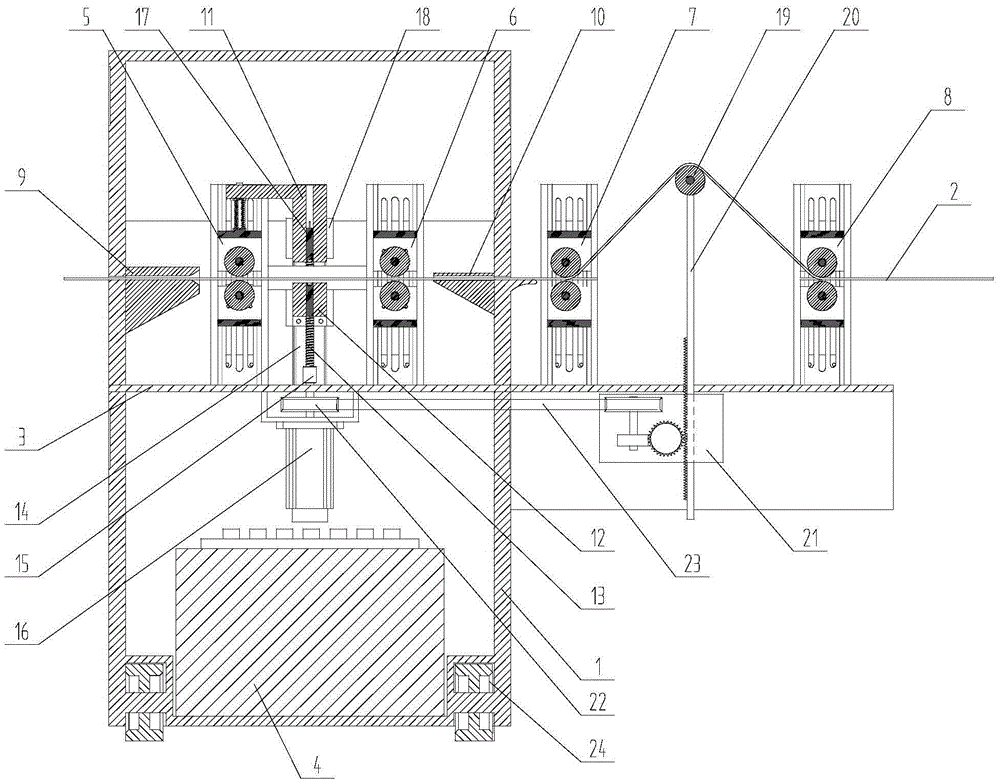

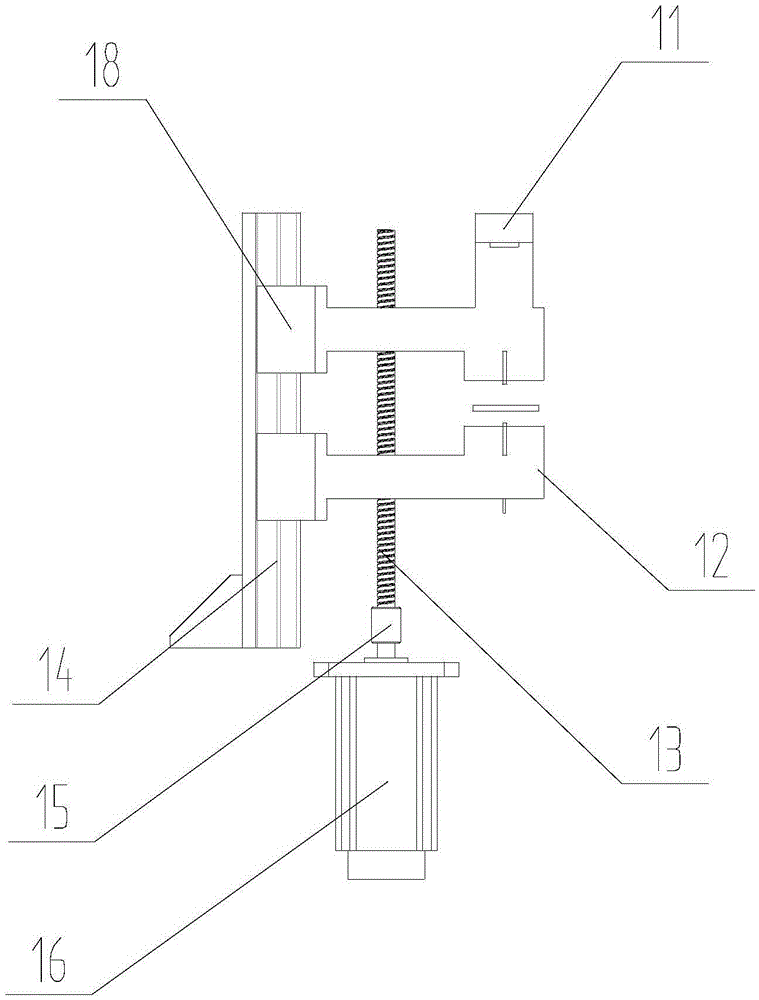

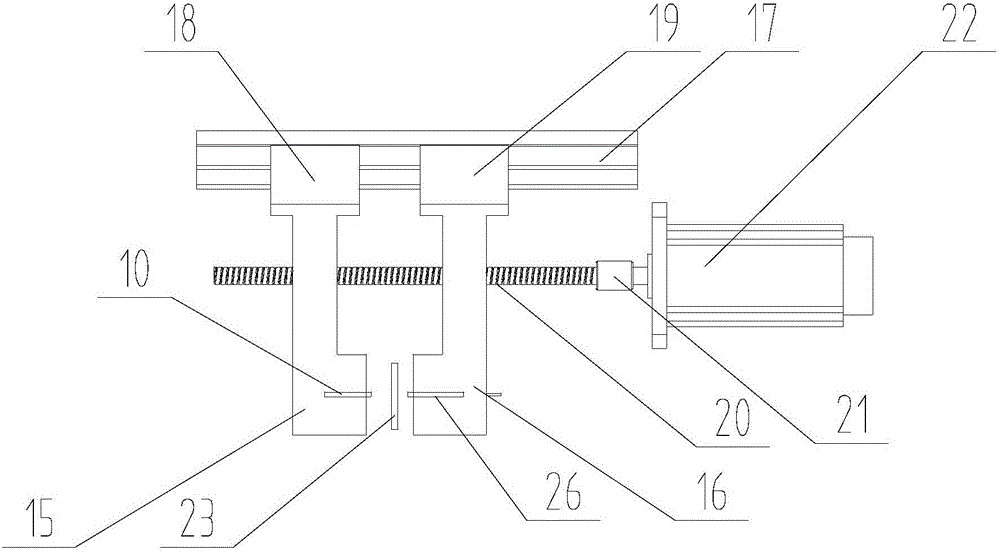

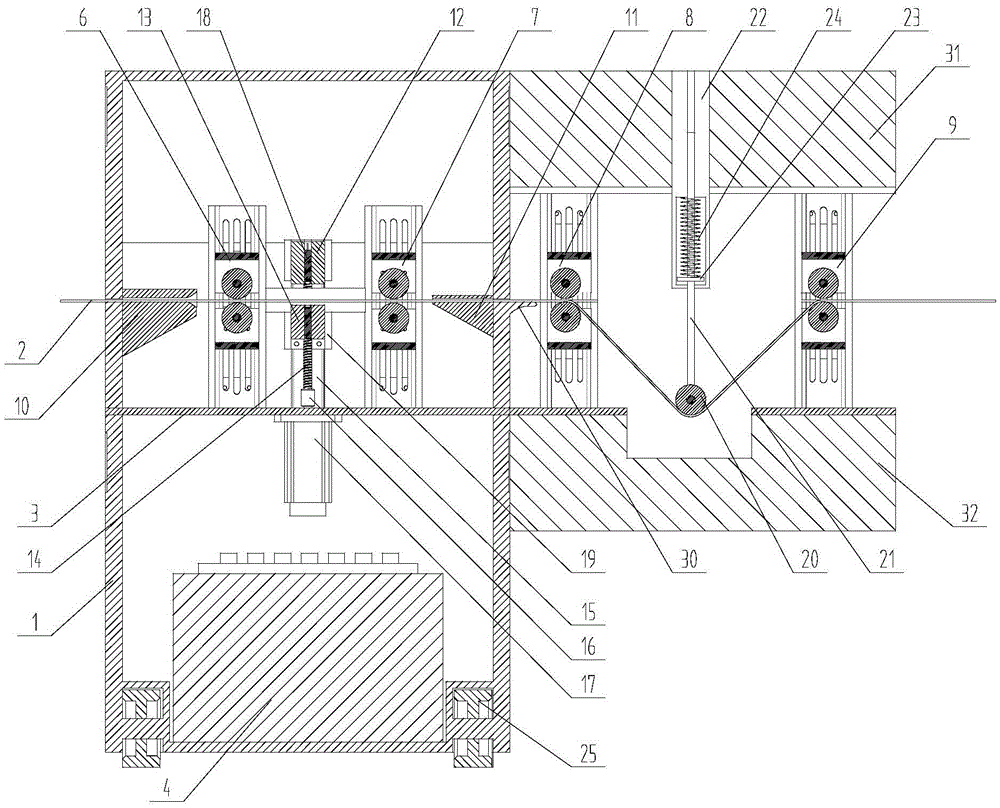

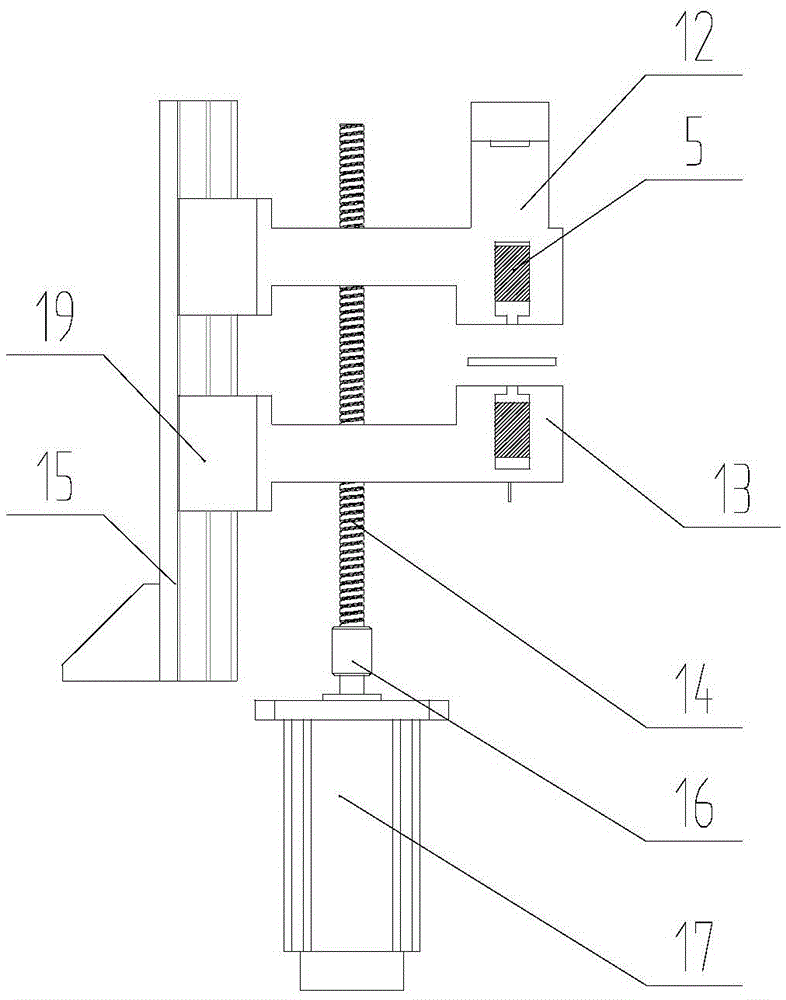

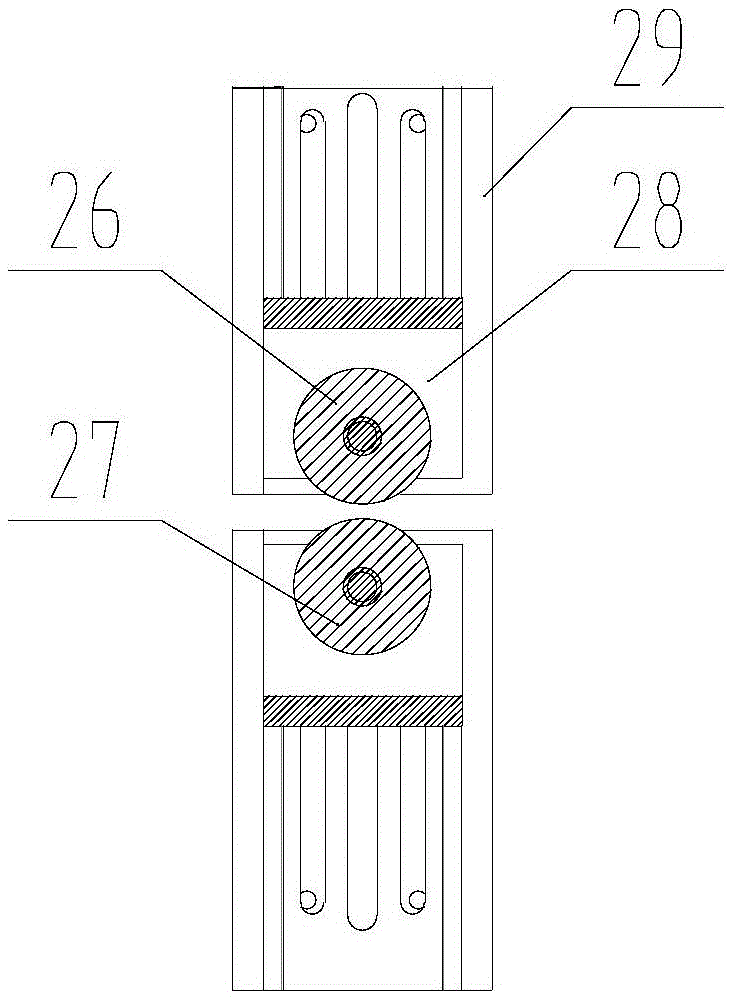

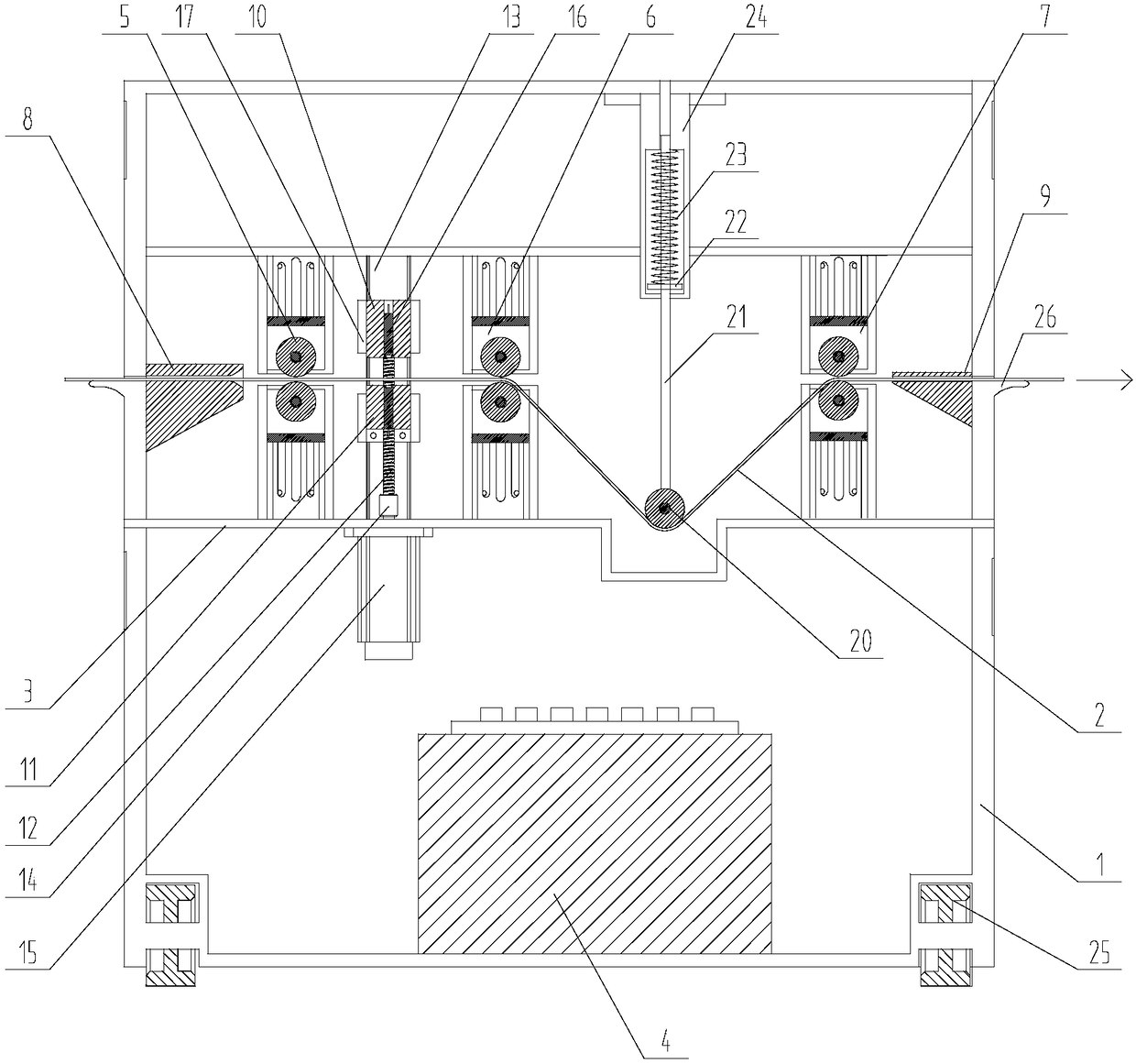

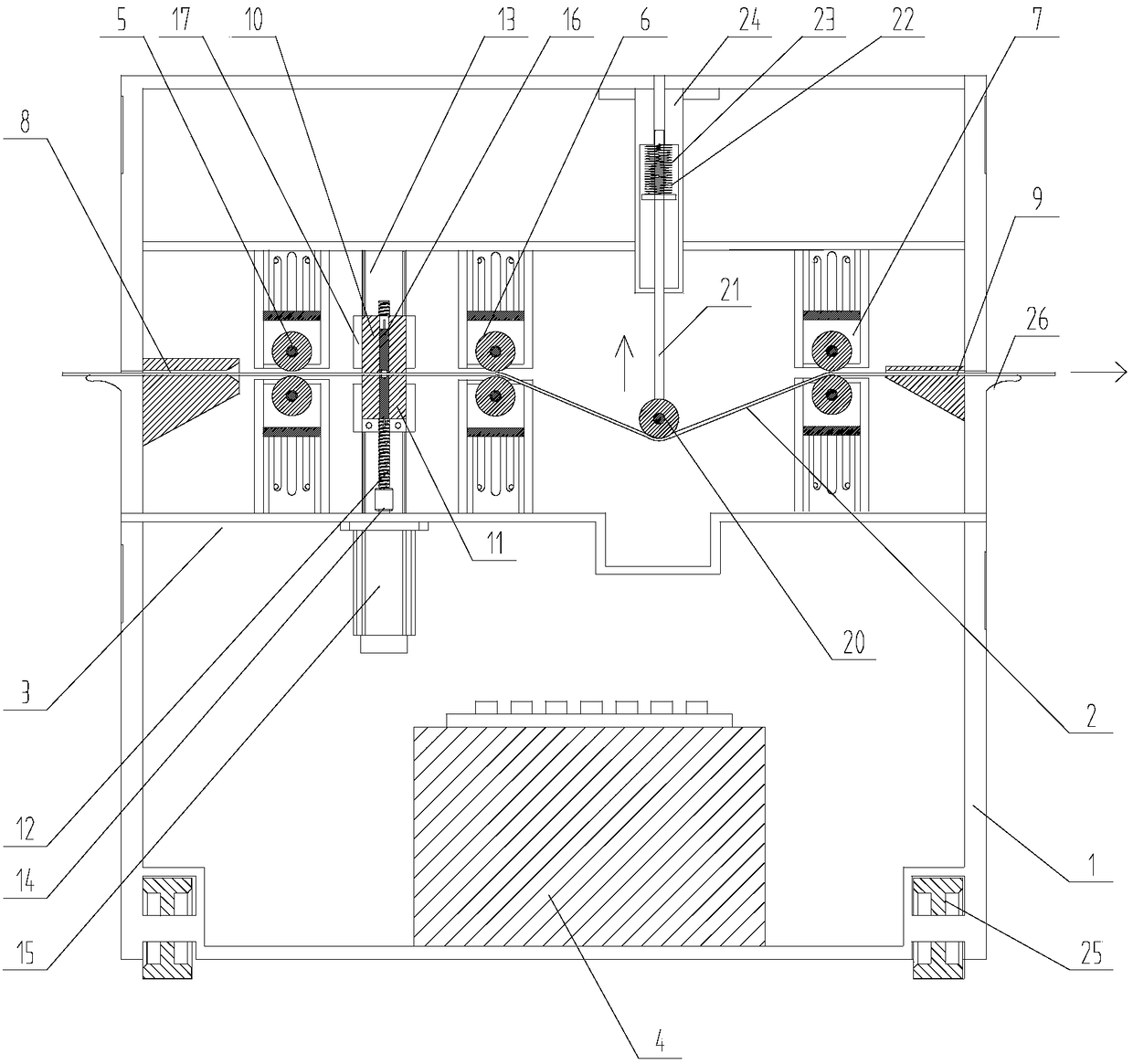

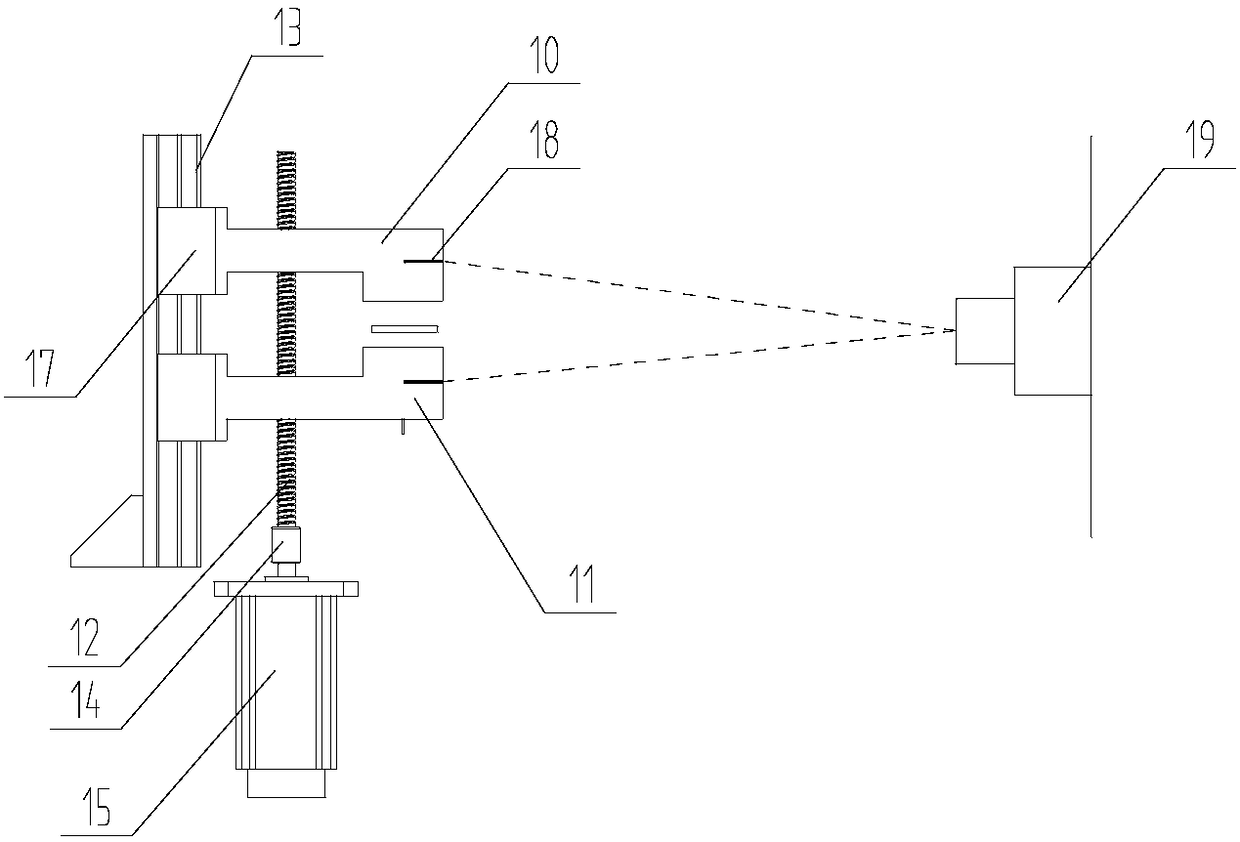

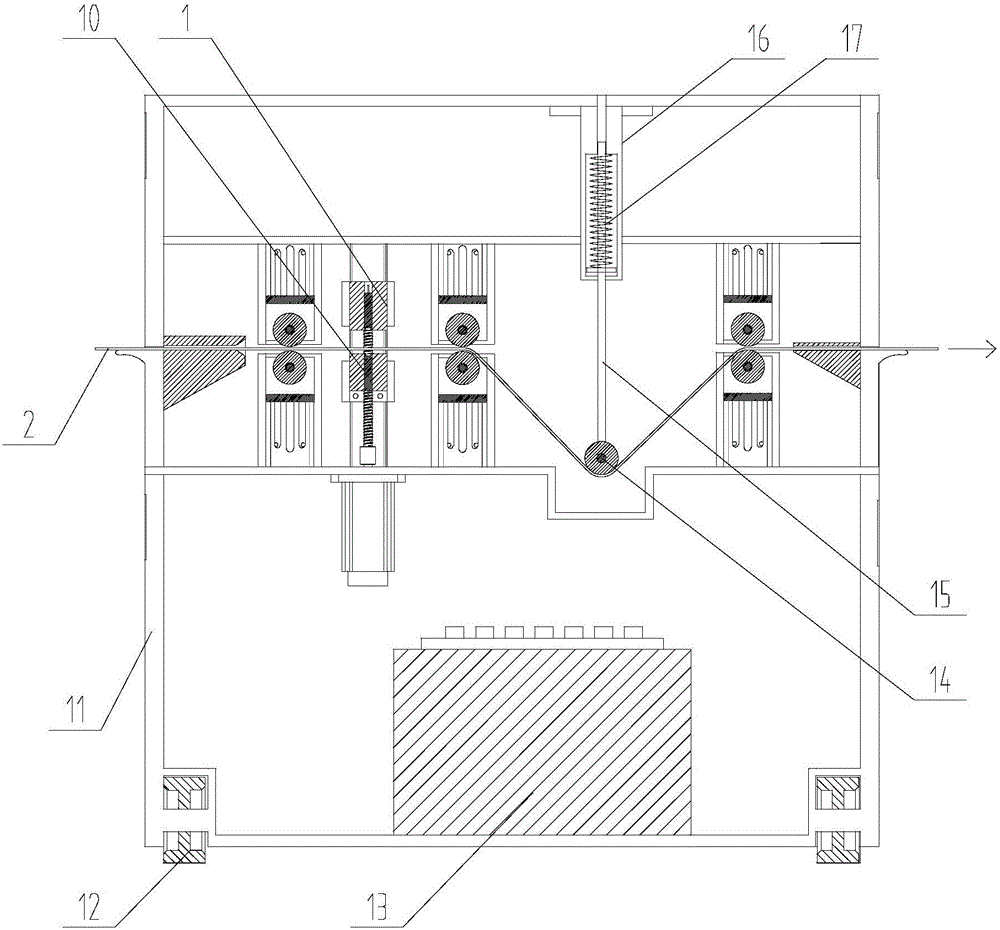

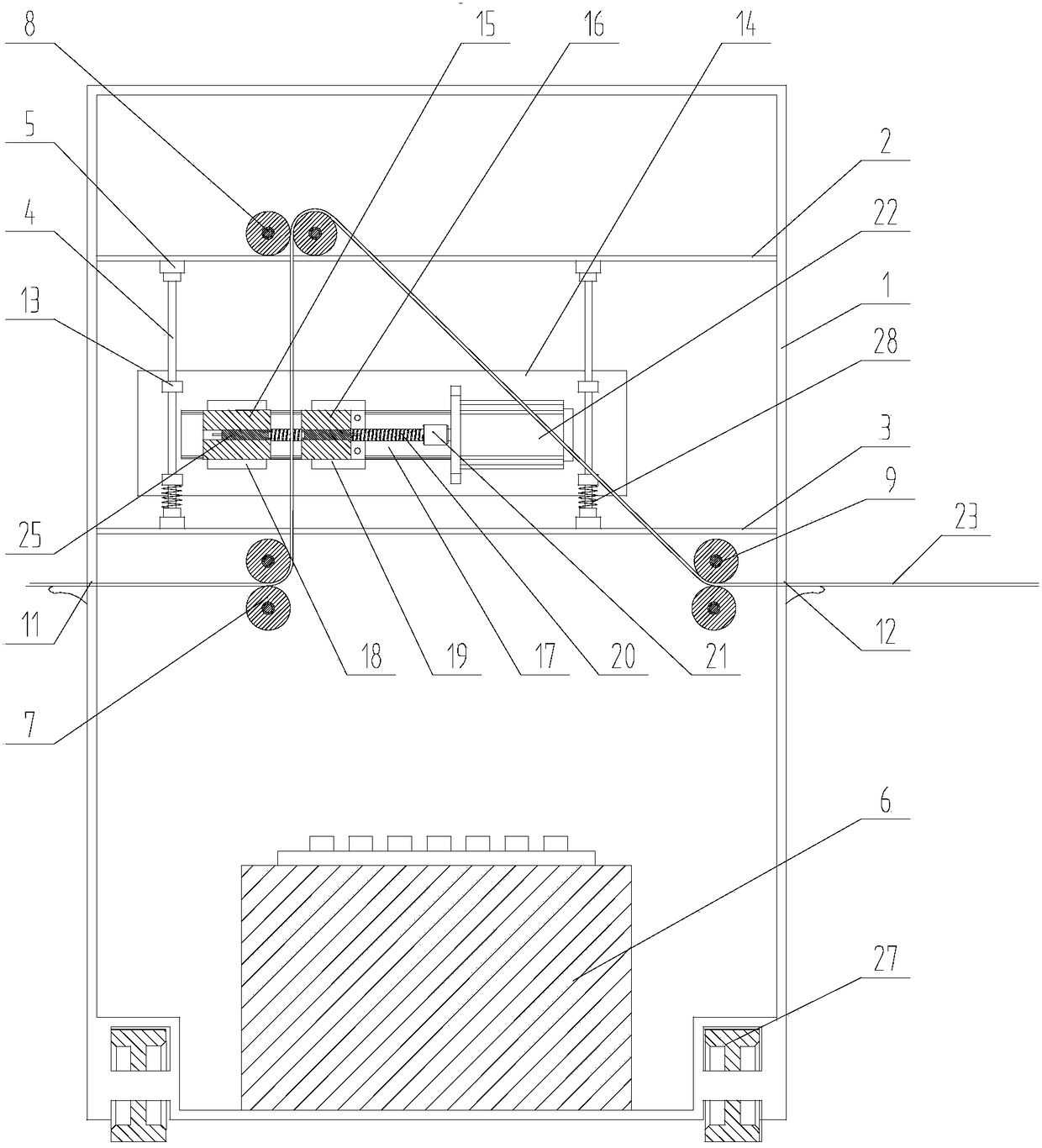

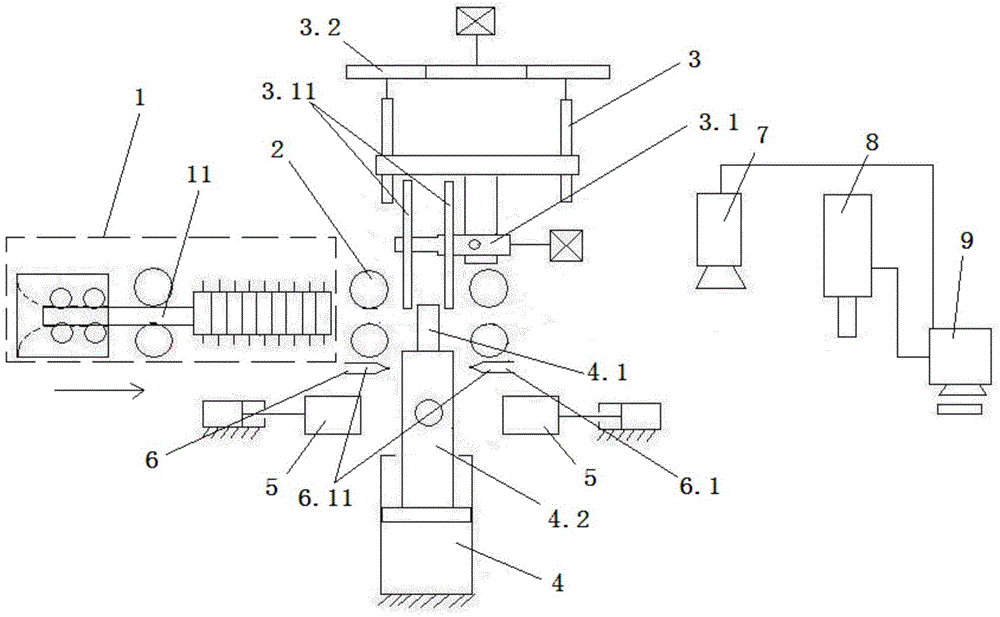

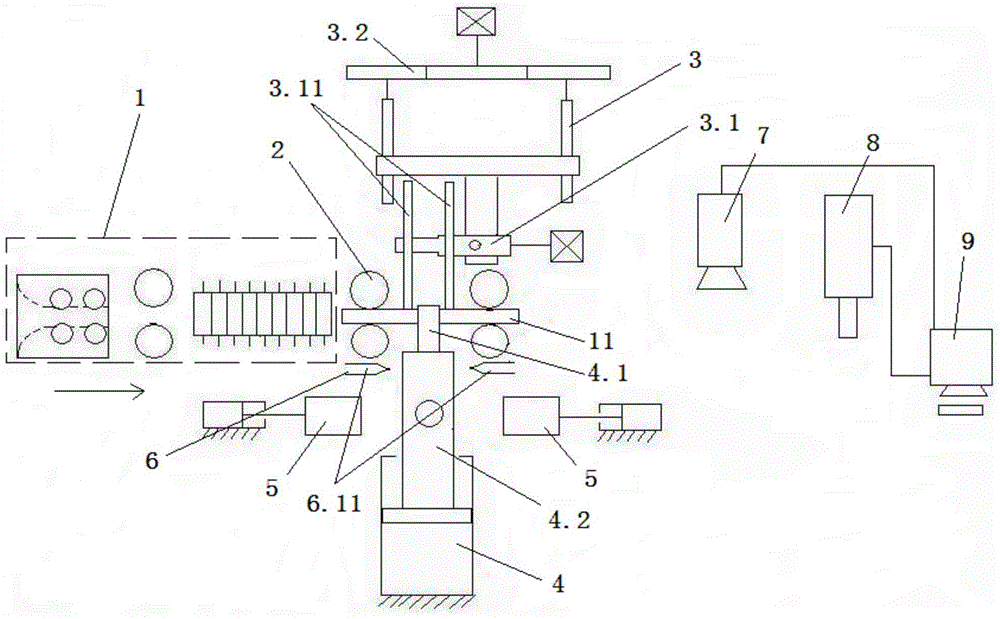

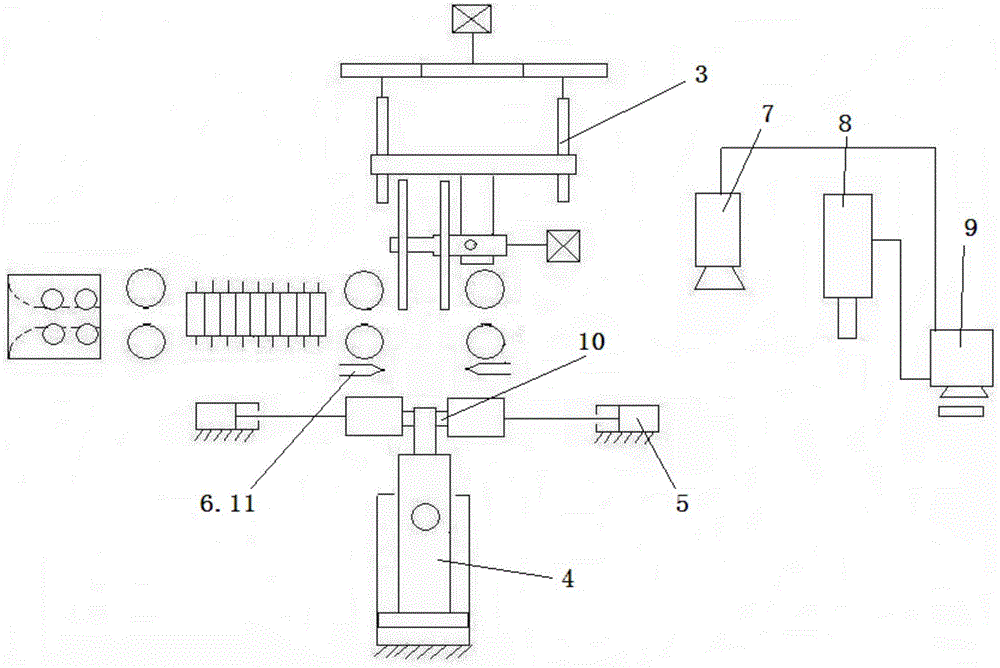

Automatic test bench for release bearing of automobile clutch

InactiveCN107044843ARealize continuous online detectionRealize automatic liftingForce sensorsTest efficiencyTest bench

The invention discloses an automatic testing platform for an automobile clutch release bearing, which comprises a frame, on which a vertical shaft is fixedly installed on the platform, and a rotatable turntable is installed on the vertical shaft; an offset cylinder is also fixedly installed on the vertical shaft; A detection cylinder is fixedly supported on the platen, and the detection cylinder is connected with a pressure sensor through a sensor seat, and a displacement sensor is fixedly installed on the detection cylinder, and a weight is suspended between the pressure sensor and the push plate; There is a positioning rod that can slide in the vertical direction. The positioning rod is driven by a positioning cylinder fixedly installed on the table. The positioning rod and the weight are on the same straight line; A loading and unloading cylinder is fixedly installed on the loading and unloading rotating shaft, and a loading and unloading swing arm is connected to the loading and unloading cylinder, and a pneumatic finger is installed on the loading and unloading swing arm. The automatic detection platform not only has high test efficiency and accurate data, but also realizes automatic online detection.

Owner:SOUTHEAST UNIV

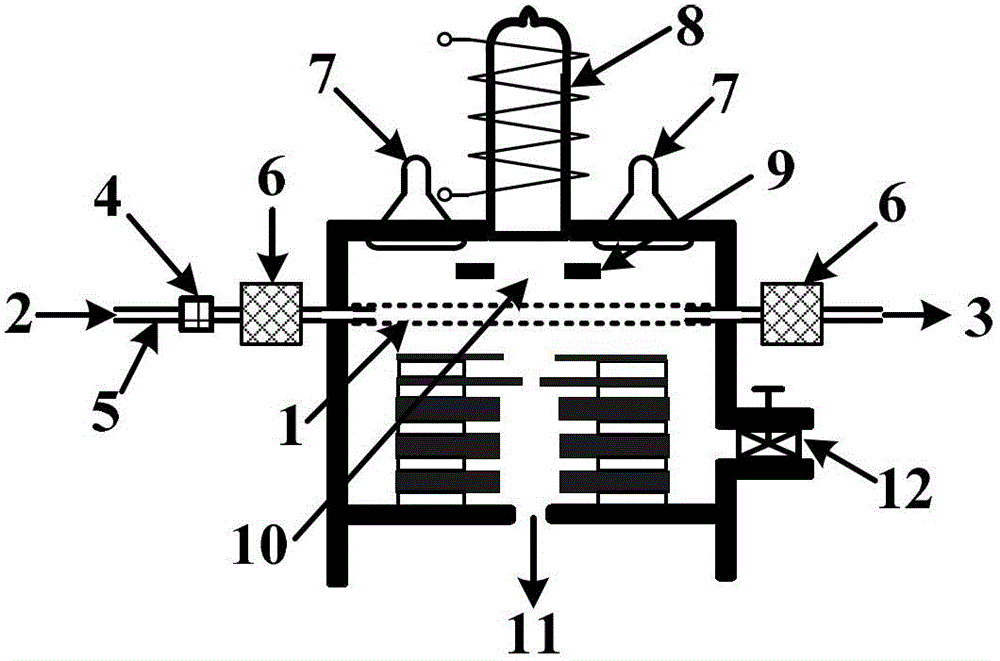

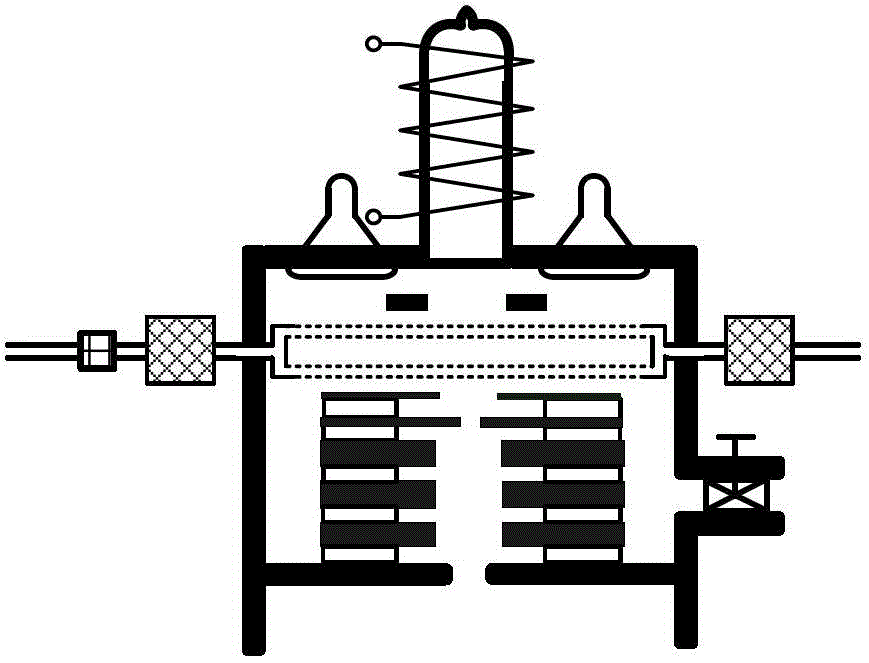

Field-eddy thermal imaging detection system and method for surface defect of steel product/billet

ActiveCN106770635ARealize continuous online detectionEqual distanceMaterial flaws investigationMaterial magnetic variablesProduction lineTemperature difference

The invention relates to a field-eddy thermal imaging detection system and a method for a surface defect of a steel product / billet. The system can be embedded into a steel product / billet forming production line as an automatic detection and marking module. The method comprises the following steps that a) a to-be-detected object enters an aligning device by a feeding rack; b) the surface temperature of the steel product / billet is transiently heated by high-frequency induction heating equipment in a heating area; c) a thermal infrared imager detection area is entered; d) a thermal infrared imager transmits a signal to a PC (Personal Computer) to obtain temperature difference data of an image and aftertreatment is performed on the image; and e) when the temperature difference of the image is greater than or less than a certain designated value, the PC gives an alarm and transmits a signal to an automatic spray gun for marking to realize automatic marking of a defect position. The method is high in detection speed and high in efficiency, avoids influences caused by nonuniform heating and environmental factors, and can accurately identify and mark the surface defect of the steel product / billet.

Owner:UNIV OF SCI & TECH BEIJING

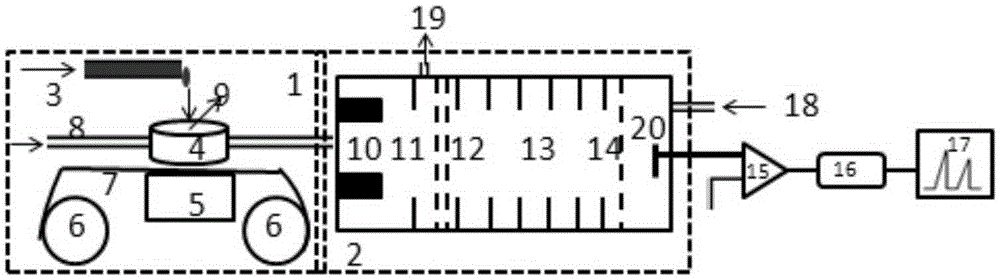

Online detector and applications thereof

ActiveCN106645369ARealize continuous online detectionRealize continuous detectionMaterial analysis by electric/magnetic meansSpectroscopyMotor control

The present invention relates to an online detector, wherein an ion mobility spectroscopy technology is adopted as a basic detection technology, a sample injection rotation disk is controlled by a rotation motor, sample thermal analysis and headspace injection technology are combined, a sample is not subjected to complex pretreatment and is collected to the surface of a sampling sheet, the rotation motor controls the sample injection rotation disk so as to make the sample on the sampling sheet be subjected to continuous sample injection thermal analysis, and the obtained sample enters the detector through carrying with carrier gas so as to be subjected to online detection analysis. According to the present invention, the online detector is used for the continuous online detection of propofol anesthetics in human blood during surgeries so as to guide physicians in clinical administration.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

An on-line detector capable of continuous sample injection and application thereof

InactiveCN106645770ADetection speedShort analysis timePreparing sample for investigationMaterial analysis by electric/magnetic meansPhysicsHuman blood

An on-line detector capable of continuous sample injection is designed in the invention. According to the detector, an ion-mobility spectrometry technique as a base detection technique is adopted and sample thermal desorption analysis and headspace sample feeding techniques are combined. A sample with a complex matrix does not need pretreatment and is collected to the surface of a sampling sheet, the sampling sheet allows volatile components of the sample to be gasified in a thermal desorption analysis sample injector through a belt type conveying manner, and then the sample vapor is carried by a carrier gas to enter the detector and subjected to on-line detection and analysis. The detector achieves on-line continuous detection of propofol in human blood during operations and is used for directing clinical administration by doctors.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ammonia nitrogen detection method and device based on electrodialysis ion transformation

ActiveCN103512932ARealize continuous online detectionRaise the pHMaterial electrochemical variablesEnvironmental resistanceIon-exchange resin

The invention relates to an ammonia nitrogen detection method and an ammonia nitrogen detection device based on electrodialysis ion transformation. Through a polarization principle of electrodialysis, pure water is electrolyzed to generate alkaline electrolytic water so as to replace the effect of a sodium hydroxide solution, thus achieving transformation of ammonium ions in a sample solution. The ammonia nitrogen detection device comprises an anode compartment electrodialysis cell, a cathode compartment electrodialysis cell, an electromagnetic valve, an injection pump and a detection tank, wherein two electrode compartments of the anode compartment electrodialysis cell and the cathode compartment electrodialysis cell are separated by a cation exchange membrane; cation exchange resin and an anode electrode are arranged inside the anode compartment; anion exchange resin and a cathode electrode are arranged inside the cathode compartment. The ammonia nitrogen detection method comprises the following steps: electrolyzing by the electrodialysis device by using an electrolytic cell with the two electrode compartments; after electrolysis, transferring a certain volume of alkaline electrolytic water to the detection tank, mixing the electrolytic water with a water sample to be detected according to a proportion, and ensuring that the pH of the mixed water sample is higher than 11 to meet an alkalization need; detecting by using an ammonia-sensitive electrode to obtain the ammonia nitrogen content value of the water sample to be detected. Chemical reagents are not required, and alkaline electrolytic water can be continuously generated only by using electrical energy and pure water, so that environment pollution and secondary pollution are avoided.

Owner:JIANGNAN UNIV

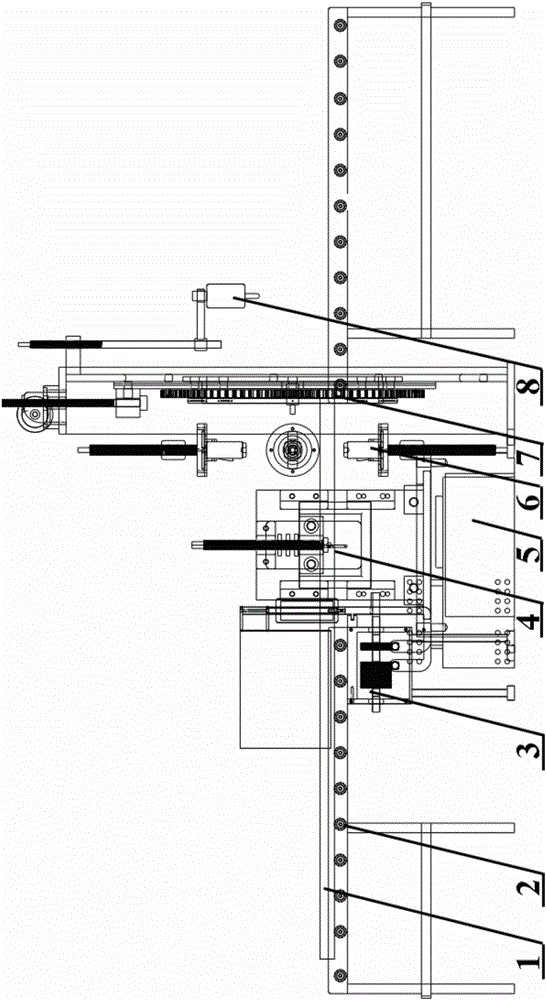

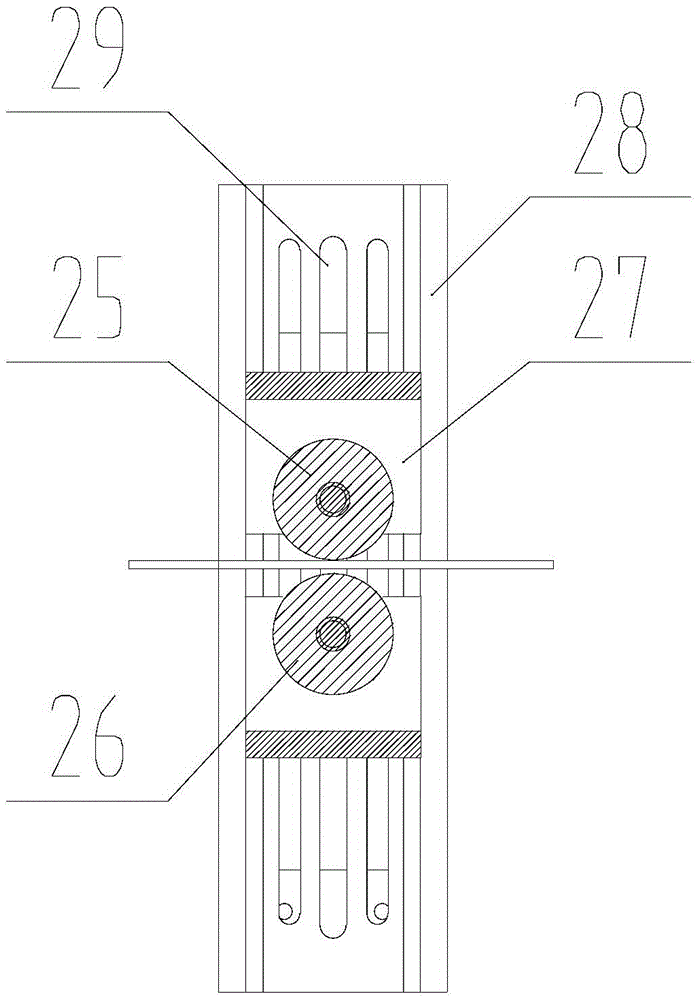

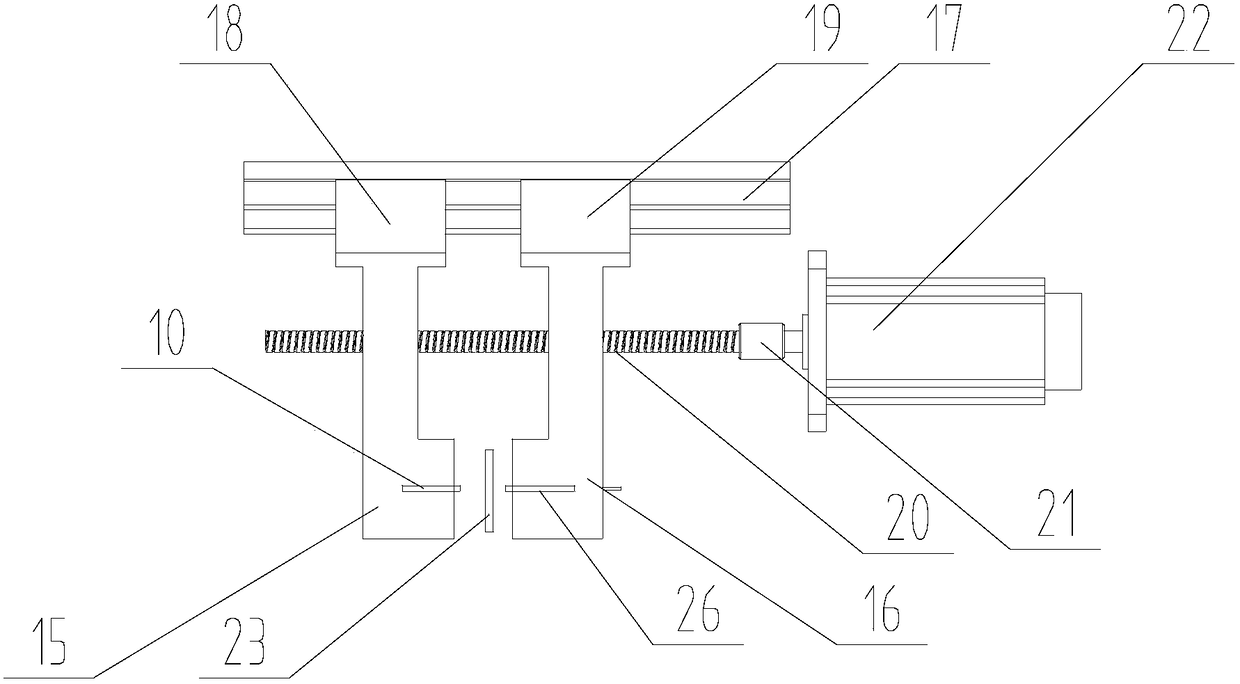

Device for detecting thickness in using process of rolled steel belt

ActiveCN105651214AMove without stoppingRealize continuous online detectionUsing subsonic/sonic/ultrasonic vibration meansEngineeringDistance sensors

The invention discloses a device for detecting the thickness in the using process of a rolled steel belt. The device comprises a box-type shell, a supporting plate, a rechargeable battery, a flattening device, a pair of ultrasonic distance sensors, four pairs of transmission roller sets, a steel belt buffering device and a pressure detecting device. A left limiting block, the first transmission roller set, the flattening device, the second transmission roller set, a right limiting block, the third transmission roller set, the steel belt buffering device and the fourth transmission roller set are sequentially arranged on the box-type shell from inside to outside in the horizontal movement direction of the steel belt. The steel buffering device comprises an upper ejecting roller, an upper ejecting rod and a transmission device. The upper ejecting roller is fixed to the top of the vertical upper ejecting rod. The lower end of the upper ejecting rod is connected with the transmission device and driven by the transmission device to reciprocate in the vertical direction. The device is simple and compact in structure, convenient to move and easy to operate, the measurement process can be performed online, data can be conveniently called, measurement work of the rolled steel belt is greatly facilitated, and the device is suitable for large-scale use and popularization.

Owner:浙江海宁经编产业园区开发有限公司

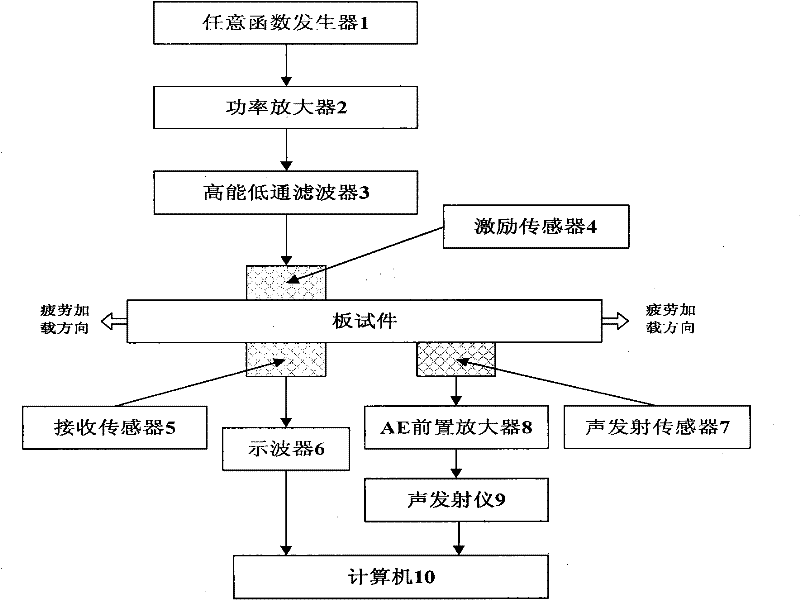

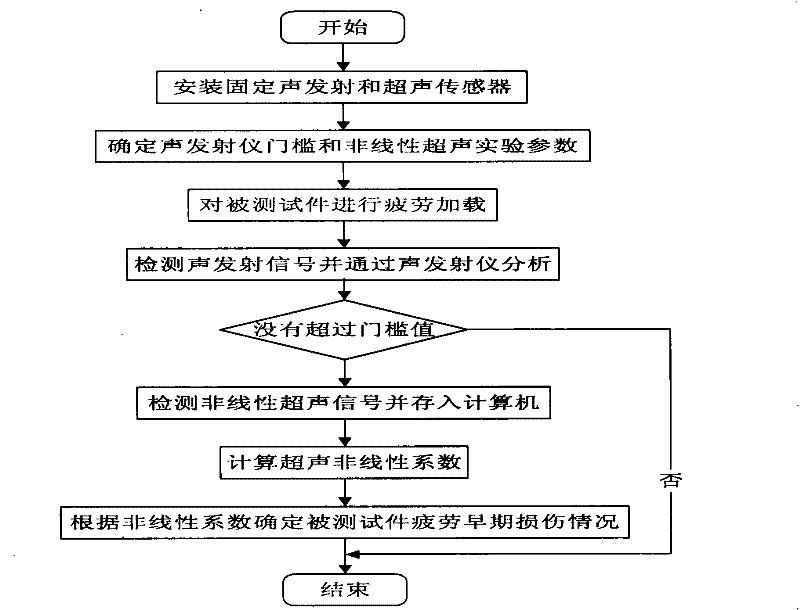

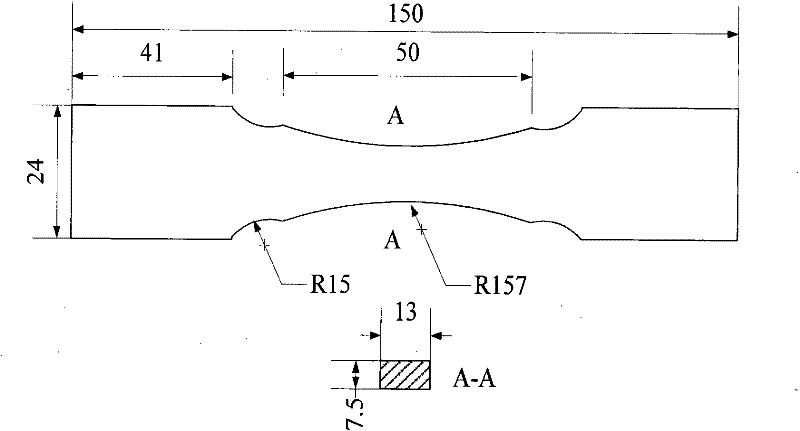

Method for non-linear ultrasonic online detection of early fatigue damage of metal material

InactiveCN101806778BRealize the whole process of fatigue detectionRealize continuous online detectionMaterial analysis using acoustic emission techniquesFatigue damageFatigue loading

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more thanthe empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

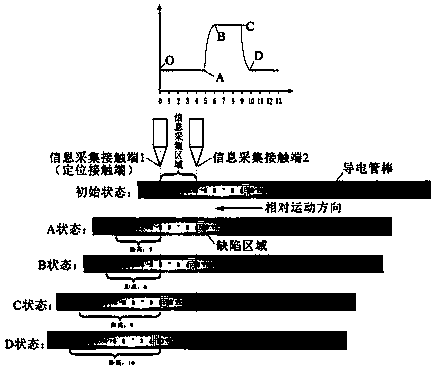

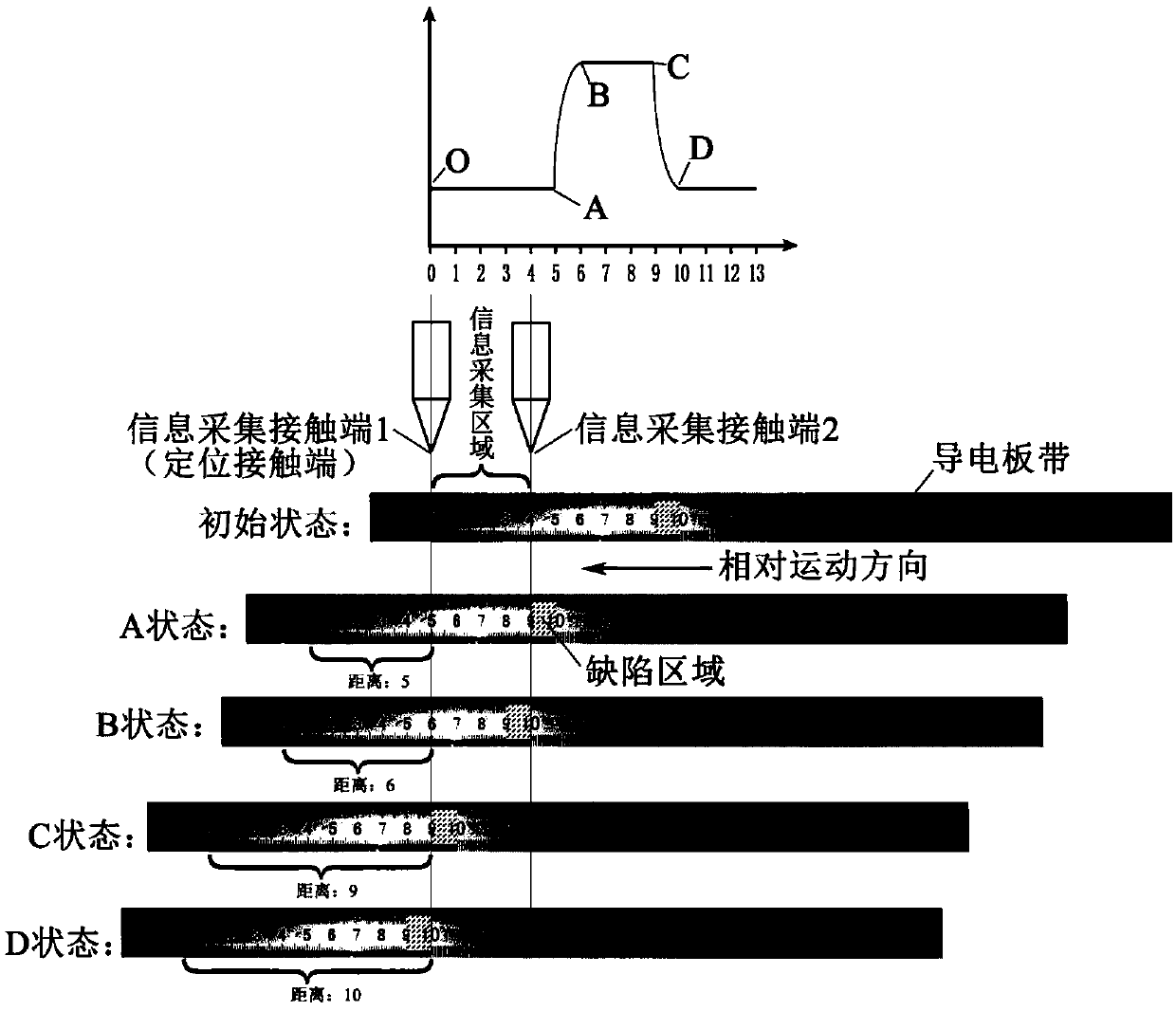

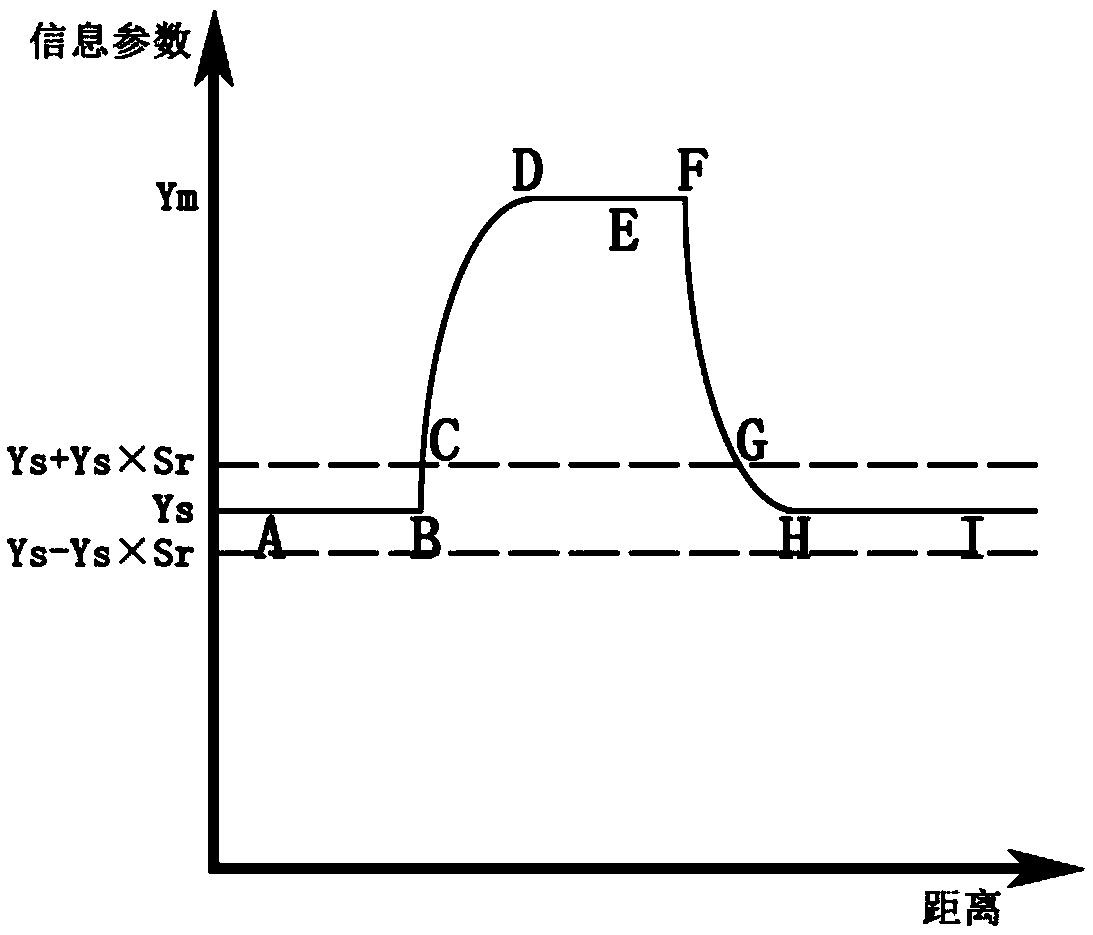

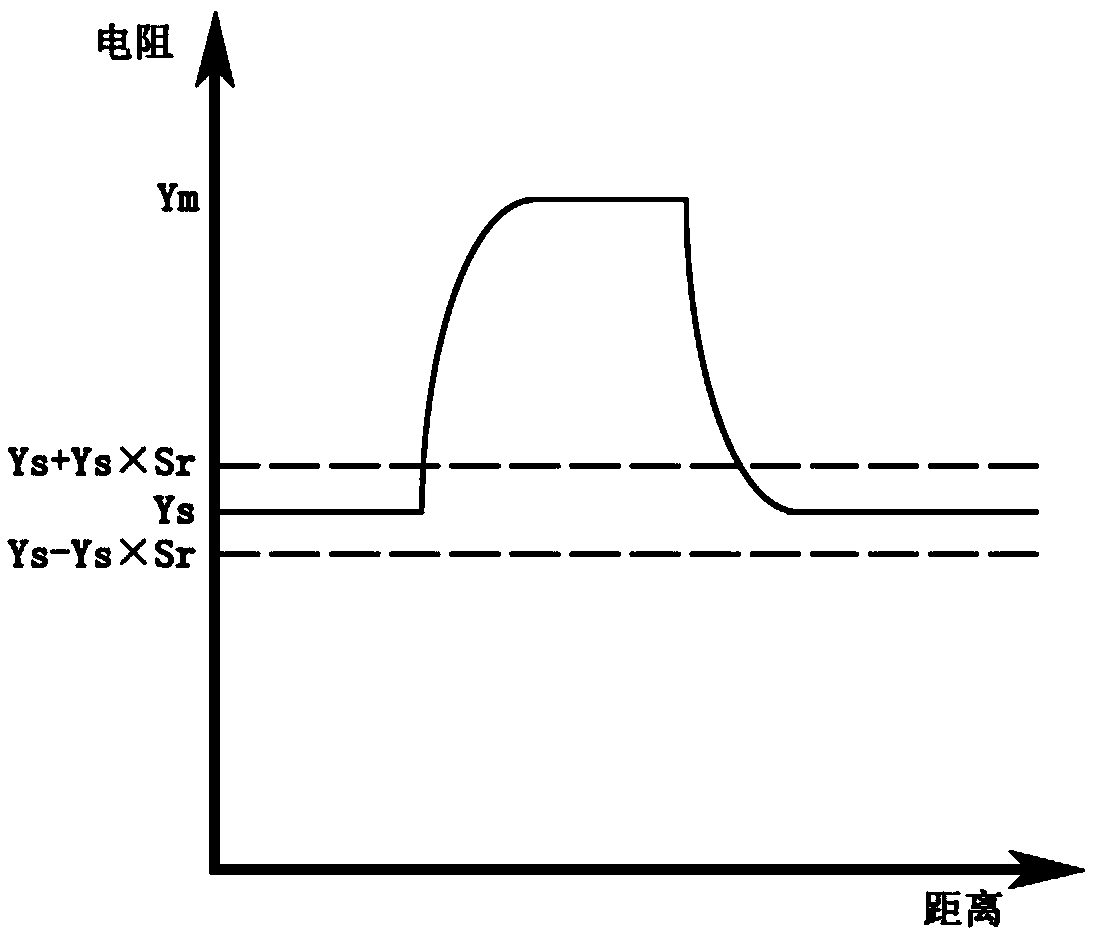

Method for detecting quality of conductive tube based on relative motion

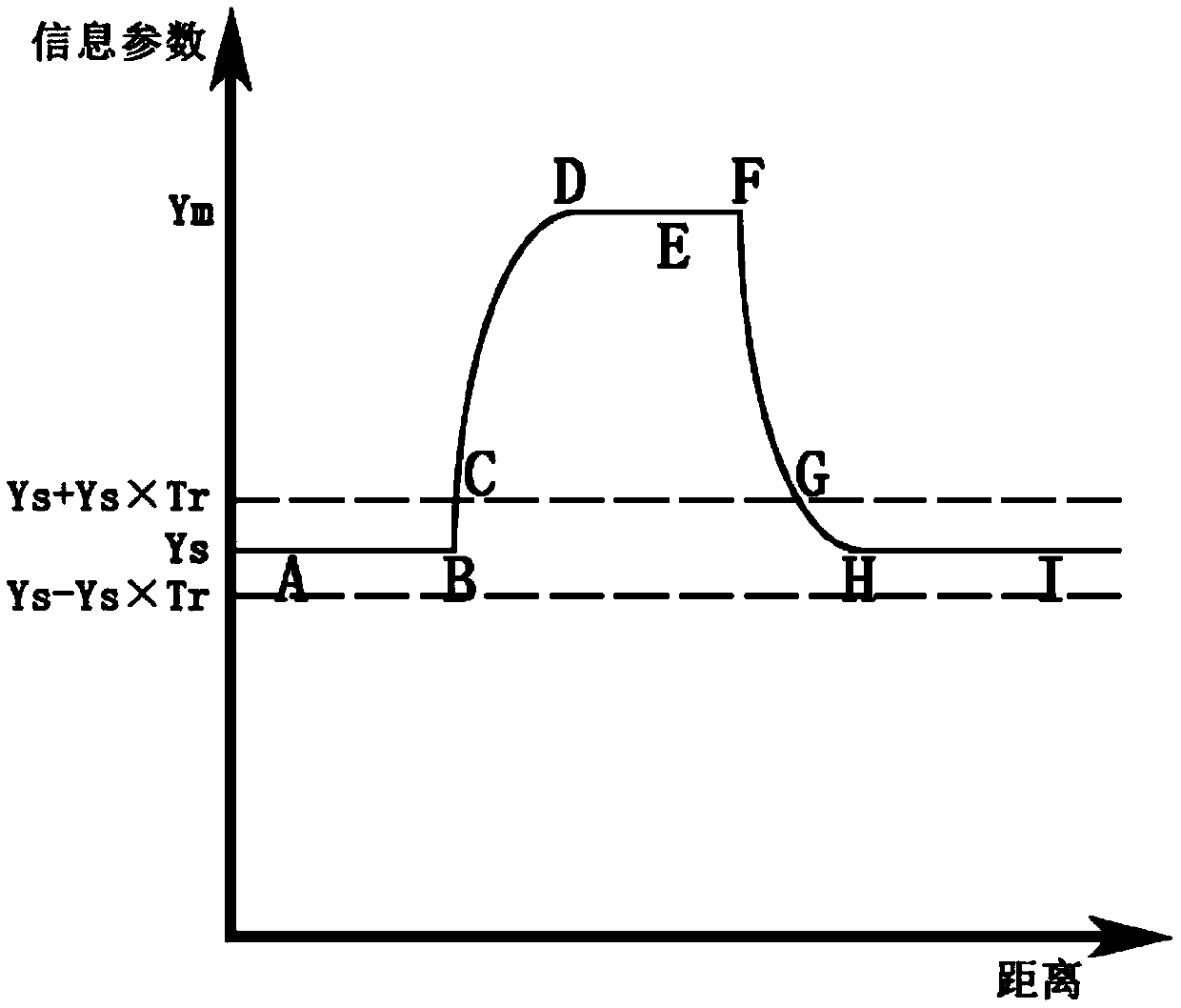

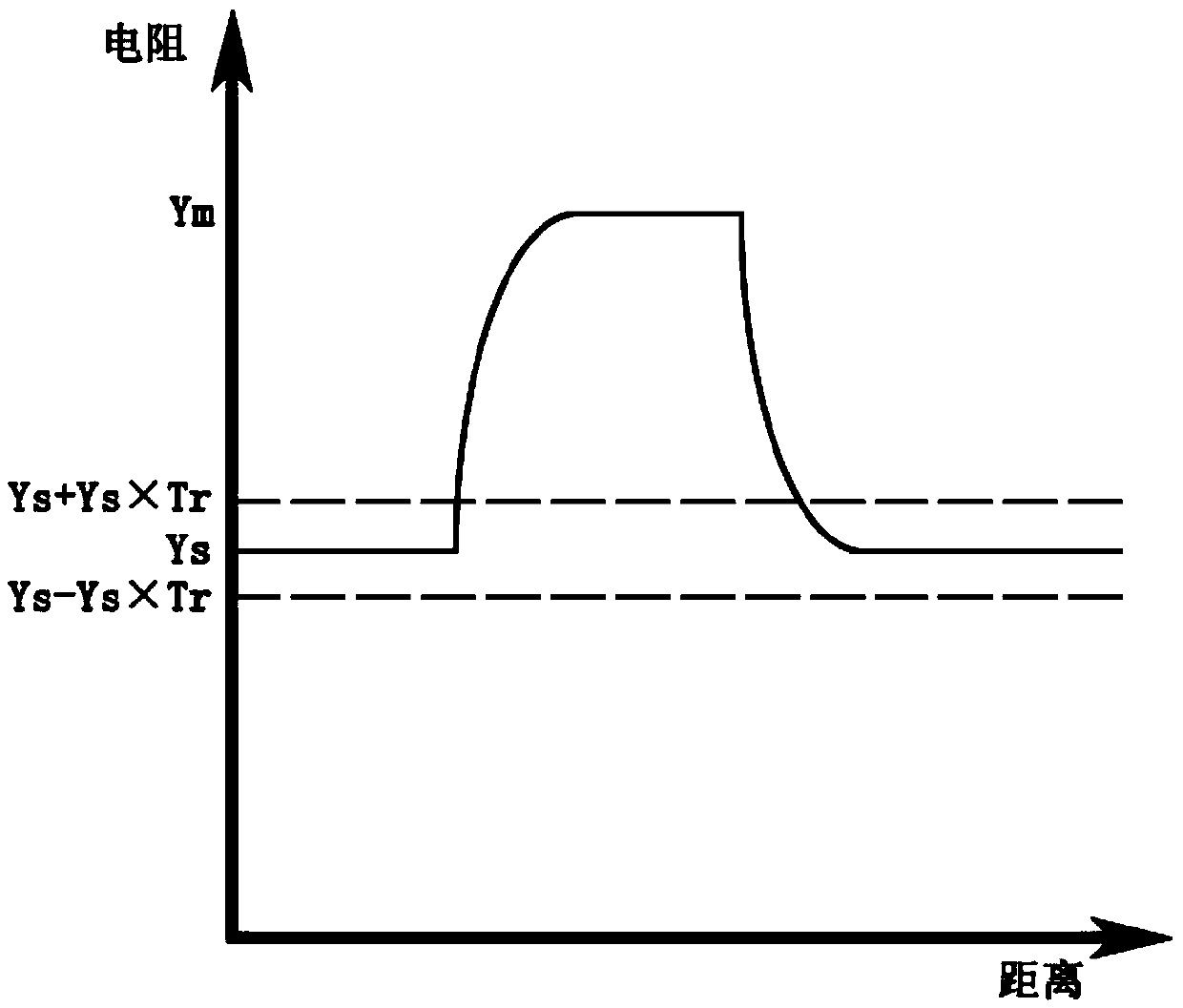

InactiveCN111289575ARealize continuous online detectionHigh practical valueMaterial resistanceElectrical resistance and conductanceComputational physics

The invention relates to a method for detecting the quality of a conductive tube rod based on relative motion, and belongs to the technical field of material quality detection. The method comprises the following steps that: during detection, a detection device and a conductive tube rod can move relatively, and the quality of the conductive tube rod is judged by continuously collecting informationand calculating information parameters, wherein the information comprises but is not limited to a voltage, a current and a position, and the information is continuous information and the information parameters are selected from one or more of the voltage, resistance, resistivity, conductivity and electrical conductivity; obtained actual information parameters are compared with standard informationparameters; when a result obtained by dividing the absolute value of the difference of the actual information parameter and the standard information parameter by the standard information parameter isgreater than or equal to a defect judgment threshold value, a defect is determined to exist in the region corresponding to the actual information parameter; and when the result obtained by dividing the absolute value of the difference of the actual information parameter and the standard information parameter by the standard information parameter is smaller than a defect judgment threshold, the quality of the region corresponding to the actual information parameter is determined to be qualified.

Owner:CENT SOUTH UNIV

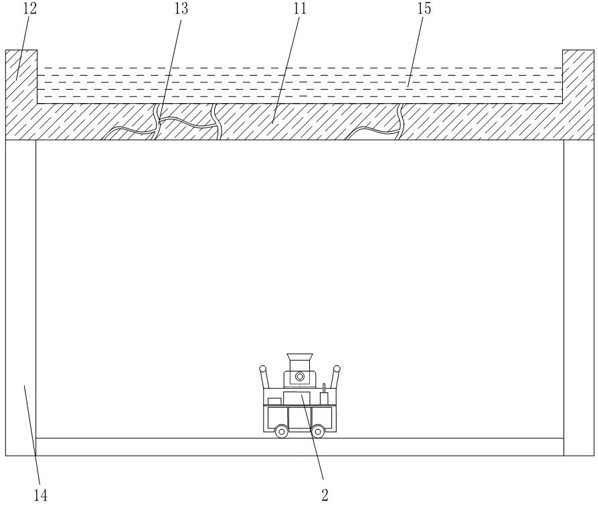

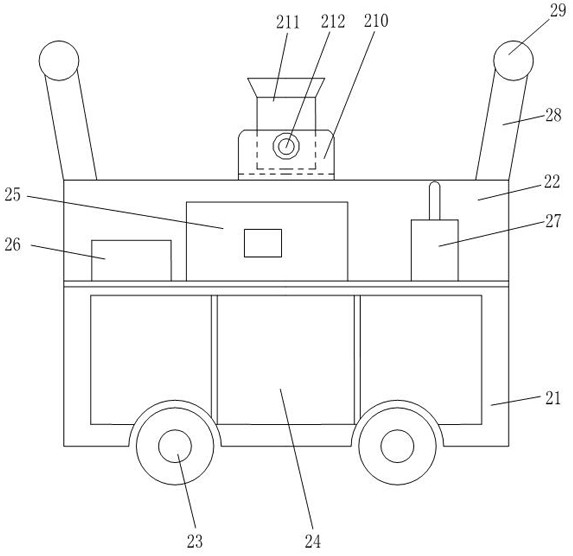

Building roof leakage detection device and method

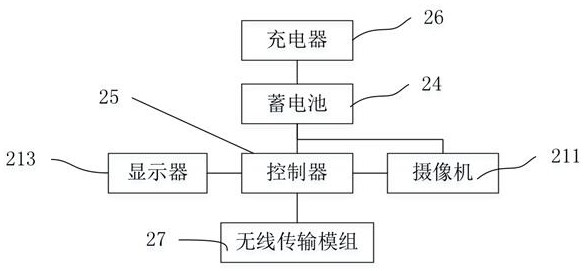

ActiveCN112113715ARealize continuous online detectionShorten the timeDetection of fluid at leakage pointWireless transmissionDisplay device

The invention relates to the technical field of roof leakage detection, and discloses a building roof leakage detection device and method. A main detection device comprises a housing, wheels, a storage battery, a controller, a charger, a wireless transmission module group, a holding rod support, a holding rod, a camera support frame, a camera, and a display. The housing comprises an upper housingand a lower housing. The upper housing is arranged on the upper portion of the lower housing, an upper installation chamber is formed in the upper housing, a lower installation chamber is formed in the lower housing, a plurality of wheels are symmetrically arranged at the bottom of the lower housing, the storage battery is arranged in the lower installation chamber, the controller, the charger andthe wireless transmission module are installed in the upper installation chamber, and the storage battery supplies power to the whole main detection device, and the charger is connected with the storage battery through a wire. Continuous online detection of building roof leakage can be achieved, the continuous development situation of roof leakage is obtained, time is saved, and the device is easy to operate and low in use cost.

Owner:ZHEJIANG COLLEGE OF CONSTR

An online detector

ActiveCN106645369BRealize continuous online detectionRealize continuous detectionMaterial analysis by electric/magnetic meansSpectroscopyMotor control

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for detecting thickness of steel tape on line

InactiveCN105806273ARealize continuous online detectionGet rid of the embarrassment of moving aroundUsing subsonic/sonic/ultrasonic vibration meansEngineeringTape drive

Owner:韩城泰达工贸有限公司

A method for in vitro simulated dissolution and continuous online detection of nicotine in bagged and mouth-containing tobacco products

ActiveCN104833641BSimple structureEasy to disassembleColor/spectral properties measurementsPeristaltic pumpElution

The invention relates to a device for in vitro simulated dissolution and continuous online detection of nicotine in bagged and buccal tobacco products, which comprises: a chromogenic agent holding device (R1); an eluting agent holding device (R2); The first peristaltic pump (P1) downstream of the colorant storage device (R1) and connected to it through pipelines; the second peristaltic pump (P2) located downstream of the eluent storage device (R2) and connected in sequence through pipelines , a dissolution tank (A), a decolorization column (B), a reaction tank (R) and a spectrophotometer (D); wherein the reaction tank (R) is also located downstream of the first peristaltic pump (P1) and passed through the tube The road is connected to it, and the spectrophotometer (D) is connected to the data processing device (C). The invention also relates to a method for simulating dissolution of nicotine in vitro and continuous on-line detection in bagged and buccal tobacco products. The detection device and the detection method of the present invention can realize the continuous on-line detection of nicotine dissolution in vitro, and the operation is convenient and the detection is rapid.

Owner:CHINA TOBACCO YUNNAN IND

A device for detecting the thickness of steel strip coils for production

ActiveCN105698691BRealize continuous online detectionCompact structureUsing optical meansEngineeringBlock match

The invention discloses a device for detecting the thickness of a production-used steel strip coil steel strip, which comprises a box-type casing, an upper supporting plate, a lower supporting plate, a linear guide rail, a follow-up detection device, a pressure detection device, a CCD camera, a rechargeable battery and four pairs of transmission roller groups, wherein the follow-up detection device is provided with a guide rail sliding block matched with the linear guide rail; the follow-up detection device sleeves the linear guide rail via the guide rail sliding block and can vertically slide on the linear guide rail; the follow-up device moves together with the steel strip in the case of detection and is reset to the home position after detection is completed, the production process is not influenced; the thickness detection adopts the CCD camera, and the optical lens of the CCD lens right faces calibration lines of two horizontal pressing blocks inside the follow-up detection device. The device of the invention has the advantages that the structure is compact; the movement is facilitated; the operation is simple; the measurement process can be carried out in an online mode; the detection process is continuous; data calling is facilitated; measurement on a rolled steel strip is greatly facilitated; and mass promotion and use are facilitated.

Owner:浙江海宁经编产业园区开发有限公司

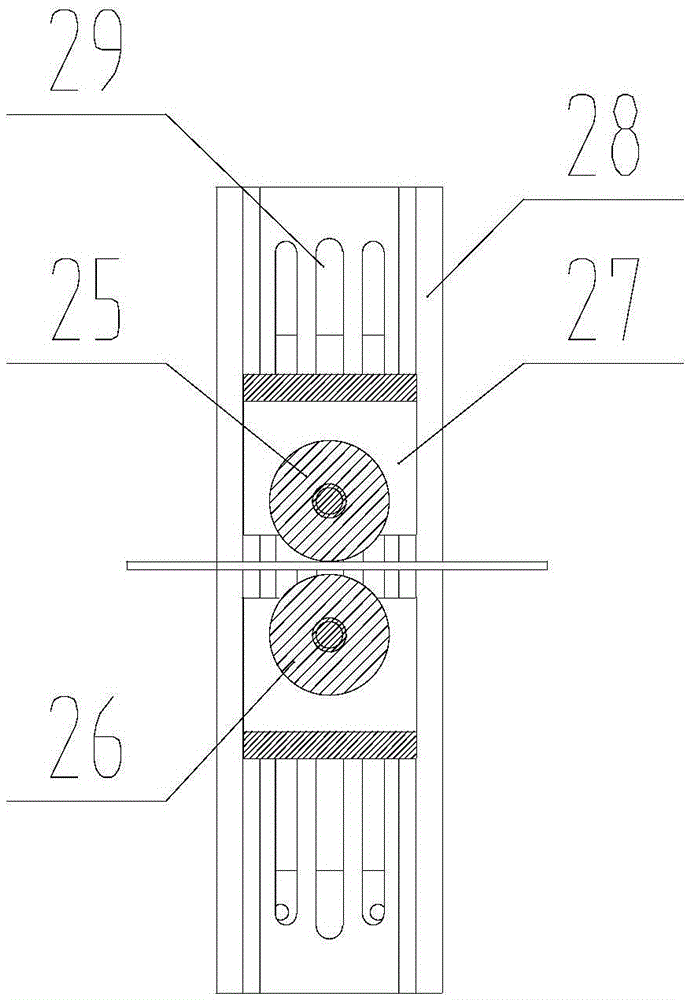

Steel tape thickness detection device having no influences on production process

ActiveCN105806294ARealize continuous online detectionCompact structureMeasurement devicesEngineeringBlock match

The invention discloses a steel tape thickness detection device having no influences on a production process. The device comprises a box-type housing, an upper support plate, a lower support plate, a linear guide rail, a following detection device, a pressure detection device, a charging battery and three pairs of transmission roller groups. A guide rail slide block matched with the linear guide rail is arranged on the following detection device. The following detection device sleeves the linear guide rail through the guide rail slide block and is capable of sliding up and down along the linear guide rail. The following detection device moves together with a steel tape in the detection process and is restored after the detection is finished, and the production process is not influenced. Two distance sensors are adopted for thickness detection, and the thickness of the steel tape is detected by probe retraction amounts of the two distance sensors. The steel tape thickness detection device has the advantages that the structure is simple and compact, the movement is convenient, the operation is simple, the measuring process can be carried out on line, the detection process is continuous, data obtaining is convenient, the measuring work of the rolled steel tape is substantially facilitated, and the steel tape thickness detection device is suitable for large-scale popularization and usage.

Owner:ZHEJIANG UNIV OF TECH

Device being able to continuously detect thickness of steel belt on line

ActiveCN105606044ARealize continuous online detectionCompact structureUsing subsonic/sonic/ultrasonic vibration meansEngineeringDistance sensors

The invention discloses a device being able to continuously detect thickness of a steel belt on line. The device includes a box type housing, a support plate, a rechargeable battery, a pressing device, a pair of ultrasonic distance sensors, four pairs of transmission roller trains, a steel belt buffer unit and pressure detection device, wherein the four pairs of transmission roller trains are respectively a first transmission roller train, a second transmission roller train, a third transmission roller train and a fourth transmission roller train; a left stopper, the first transmission roller train, the pressing device, the second transmission roller train and a right stopper are successively arranged in the horizontal motion direction of the steel belt in the box type housing; and the third transmission roller train, the steel belt buffer unit and the fourth transmission roller train are successively arranged in the horizontal motion direction of the steel belt outside the box type housing. The device being able to continuously detect thickness of a steel belt on line is convenient to move and is simple for operation and detection, and can measuring the thickness of the steel belt during the production process and can conveniently perform data retrieval, thus being very convenient for measuring rolls of steel belts and being suitable for popularization and usage on a large scale.

Owner:ZHEJIANG UNIV OF TECH

A real-time detection device for production steel strip thickness based on ccd camera

ActiveCN105651191BRealize continuous online detectionCompact structureTransmission systemsUsing optical meansData retrievalEngineering

Owner:浙江海宁经编产业园区开发有限公司

Method for on-line steel belt thickness detection by using steel belt damping device

PendingCN105783827ARealize continuous online detectionCompact structureMeasurement devicesEngineeringSteel belt

The invention discloses a method for on-line steel belt thickness detection by using a steel belt damping device. The method comprises: a steel belt in motion is clamped by using a compressing device and the part from an entrance steel belt segment to a clamped steel belt segment is kept to be in a static state; two pressure sensors that are arranged on an upper pressing block and a lower pressing block detect pressures applied on an upper surface and a lower surface of the clamped steel belt segment, and motion of a drive unit is stopped when the pressure values detected by the two pressure sensors reach a preset value; with a steel belt damping device, the entrance steel belt segment is guaranteed to be in a driving state all the time; and a thickness detection device carries out thickness detection on the clamped steel belt segment. According to the invention, on-line measurement of the steel belt thickness during the production process can be realized; data invoking can be carried out conveniently; and measurement work on the rolled steel belt becomes convenient.

Owner:ZHEJIANG UNIV OF TECH

A tubular membrane sampling device in an online mass spectrometer ionization source

ActiveCN103531431BIncreased diffusion rateImprove ionization efficiencySamples introduction/extractionMass spectrometersSolenoid valveCapillary Tubing

The invention designs a tubular membrane sampling device in an on-line mass spectrometer ionization source, which comprises: a tubular membrane, a heating lamp, a sampling metal tube, a particle filter net and an emergency shut-off electromagnetic valve. The tubular membrane is a non-porous dense polydimethylsiloxane tubular membrane. In the device, the tubular membrane is directly placed in the ionization zone; a heating lamp is placed outside the membrane as a membrane heating device; both ends of the membrane are connected with metal capillaries as the sampling inlet and outlet. A pump is installed on the side wall of the ionization zone cavity, and the pump port has an adjustable valve to adjust the vacuum degree of the ionization zone; an array of tubular membranes can be used in the ionization zone to facilitate large-flow sampling; this device improves the penetration of samples in the membrane rate, and improve sample ionization efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of on-line detector of propofol in blood and its application

ActiveCN106645368BRealize continuous online detectionIncrease sampling volumeMaterial analysis by electric/magnetic meansIntravenous propofolMedicine

The invention designs an online detector for propofol in blood. The instrument uses ion mobility spectrometry as the basic detection technology, combined with sample thermal analysis and headspace sampling technology. The medical waste blood in the clinical operation of the hospital is taken as the blood sample, without complicated blood sample pretreatment, and the blood sample is sprayed to the surface of the sampling piece in the thermal analysis chamber by using a high-pressure air source. During the blood injection process, the propofol in the blood is rapidly vaporized in the thermal analysis chamber, and then carried by the carrier gas into the detector for online detection and analysis.

Owner:苏州邦伊医疗科技有限公司

A steel strip thickness detection device that does not affect the production process

ActiveCN105806294BRealize continuous online detectionCompact structureMeasurement devicesEngineeringBlock match

The invention discloses a steel tape thickness detection device having no influences on a production process. The device comprises a box-type housing, an upper support plate, a lower support plate, a linear guide rail, a following detection device, a pressure detection device, a charging battery and three pairs of transmission roller groups. A guide rail slide block matched with the linear guide rail is arranged on the following detection device. The following detection device sleeves the linear guide rail through the guide rail slide block and is capable of sliding up and down along the linear guide rail. The following detection device moves together with a steel tape in the detection process and is restored after the detection is finished, and the production process is not influenced. Two distance sensors are adopted for thickness detection, and the thickness of the steel tape is detected by probe retraction amounts of the two distance sensors. The steel tape thickness detection device has the advantages that the structure is simple and compact, the movement is convenient, the operation is simple, the measuring process can be carried out on line, the detection process is continuous, data obtaining is convenient, the measuring work of the rolled steel tape is substantially facilitated, and the steel tape thickness detection device is suitable for large-scale popularization and usage.

Owner:ZHEJIANG UNIV OF TECH

Chlorine dioxide detection device of tap water quality

InactiveCN109738377ARealize continuous online detectionExempt from sampling inspection processColor/spectral properties measurementsResidual chlorineConstant current source

The invention relates to a chlorine dioxide detection device of tap water quality. Structurally, the chlorine dioxide detection device comprises six units: water injection drive unit, a chlorine dioxide detection unit, an LED constant current source circuit unit, a magnetic agitation unit, a reagent injection drive unit, and a microprocessor control unit, wherein the microprocessor control unit isconnected with the water injection drive unit, the chlorine dioxide detection unit, the LED constant current source circuit unit, the magnetic agitation unit, and the reagent injection drive unit, the microprocessor control unit is used for controlling the whole system to work and completing wireless uploading of detection data. The chlorine dioxide detection device based on an illumination principle can be installed at the end of a water pipe network, and the microprocessor control unit circularly detects light absorption amount of illuminated liquid so as to detect residual chlorine dioxidein to-be-tested water online, and can realize constant online detection.

Owner:姚绍卫 +1

Online steel wire rod cold heading test recording method and system

InactiveCN104155460AGuaranteed reliabilityGuaranteed accuracyWithdrawing sample devicesPreparing sample for investigationProduction lineEngineering

The invention relates to an online steel wire rod cold heading test recording method and system, aiming at solving the problems that when an existing steel wire rod meter is detected, manual detection is adopted, so that the production efficiency is low, the safety is poor, and labor and force are consumed. The system comprises a straightening system, a conveying system, a first clamping device, a cutting system, a cold header, a second clamping device and a meter detection device; a steel wire rod cut from a production line is straightened, conveyed, clamped, cut and treated by cold heading and meter detection, so that online steel wire rod cold heading test recording can be realized. The method can completely replace the manual detection, and is simple in technology, safe, reliable, high in efficiency, time-saving, labor-saving and environmentally friendly.

Owner:武汉钢铁有限公司

Method for rapidly detecting quality of conductive plate strip

InactiveCN111289872ARealize continuous online detectionRich varietyElectronic circuit testingElectrical resistance and conductanceEngineering

The invention relates to a method for rapidly detecting quality of a conductive plate strip, and belongs to the technical field of rapid quality detection. The method comprises the following steps: during detection, making a detection device and the conductive plate strip move relatively, and judging the quality of the detected conductive plate strip by continuously collecting information and calculating information parameters, wherein the information includes but is not limited to a voltage, a current and a position, the information is continuous information, and the information parameters are selected from at least one of a resistance, resistivity, electric conductivity, conductivity and the voltage; comparing the obtained actual information parameters with standard information parameters; and when |the actual information parameter-the standard information parameter| / the standard information parameter is greater than or equal to a defect judgment threshold value, judging that a defect exists in a region corresponding to the actual information parameters, and judging that the quality of the region corresponding to the actual information parameters is qualified when |the actual information parameter-the standard information parameter| / the standard information parameter is less than the defect judgment threshold.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com