Device for detecting thickness in using process of rolled steel belt

A coiled steel strip, thickness detection technology, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as error-prone, inconvenient detection, influence of accuracy of steel strip thickness detection, etc., to prevent Threat of electric shock, avoidance of inaccurate measurements, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

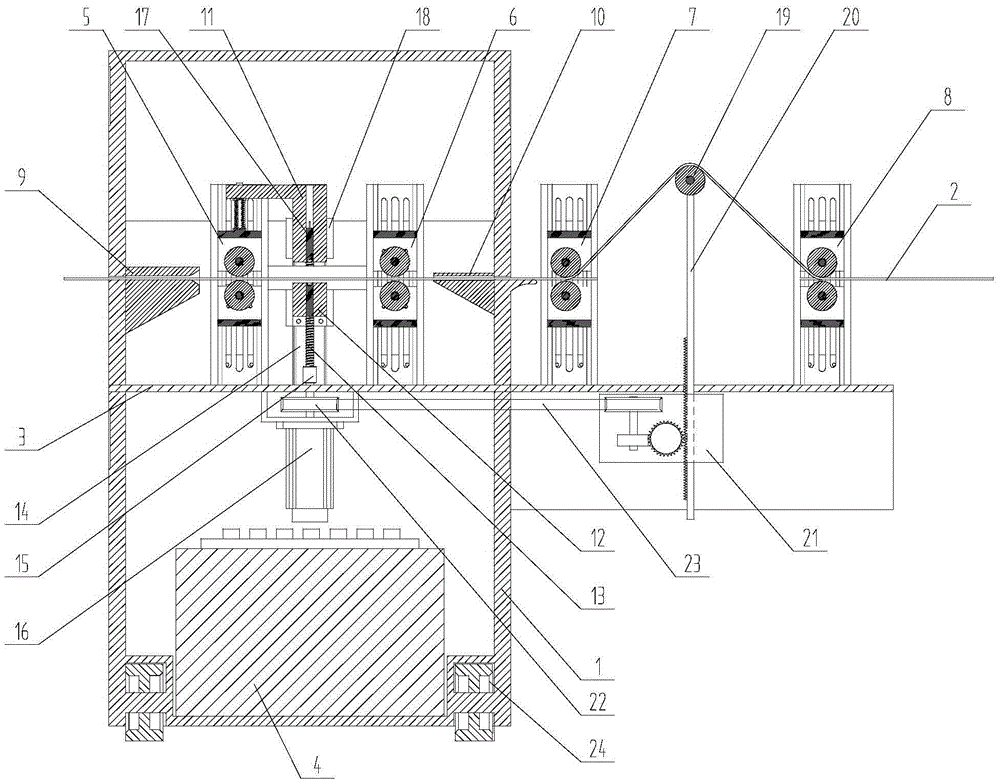

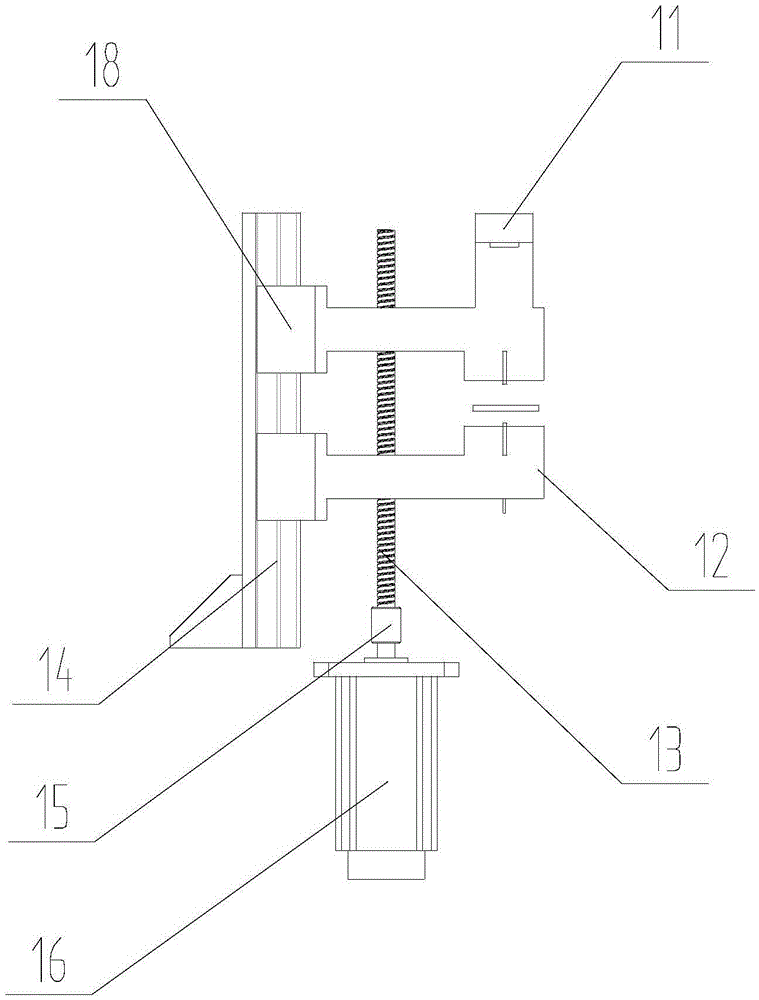

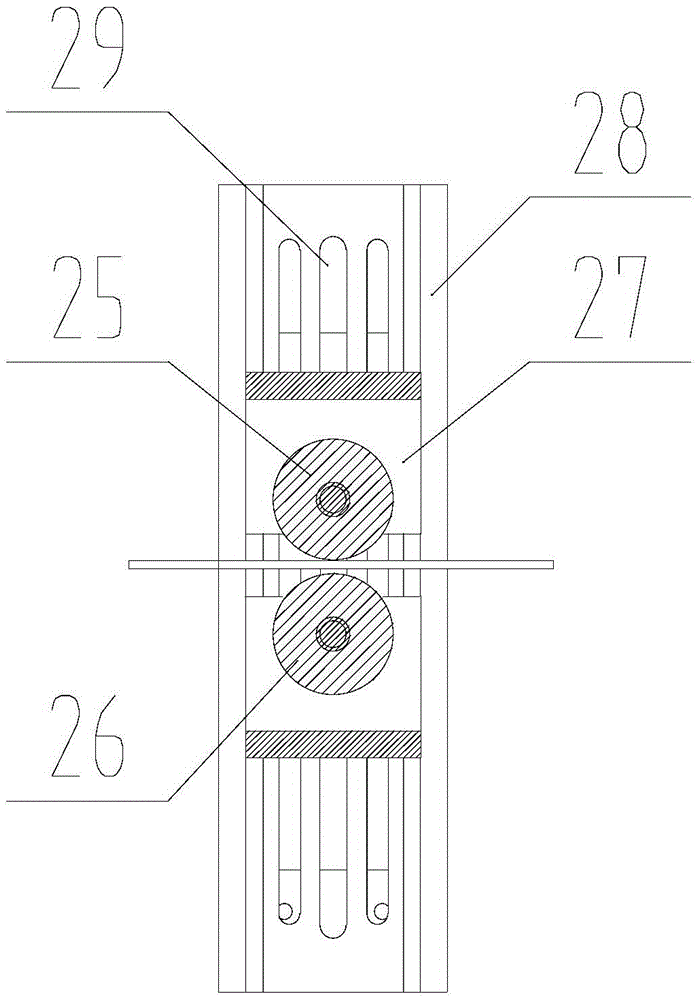

[0029] refer to figure 1As shown, a device for detecting the thickness of a coiled steel strip in the present invention includes a box-type housing 1, a support plate 3, a rechargeable battery 4, a flattening device, a pair of ultrasonic distance sensors 30, and four pairs of driving rollers. group, a steel belt buffer device and a pressure detection device, the support plate 3 is arranged horizontally, a part of the support plate 3 is fixed inside the box-type casing 1, and the other part protrudes from one side of the box-type casing 1, and the charging The battery 4 is fixed on the bottom plate of the box-type casing 1, and the four pairs of transmission rollers are located at the first transmission roller group 5, the second transmission roller group 6, the third transmission roller group 7 and the fourth transmission roller group 8, the first transmission roller group The roller group 5 and the second transmission roller group 6 are fixed on the support plate 3 inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com