Method for on-line steel belt thickness detection by using steel belt damping device

A buffer device and steel belt technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as inconvenient detection, error-prone, and influence on the accuracy of steel belt thickness detection, so as to avoid inaccurate measurement, prevent the threat of electric shock, The effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

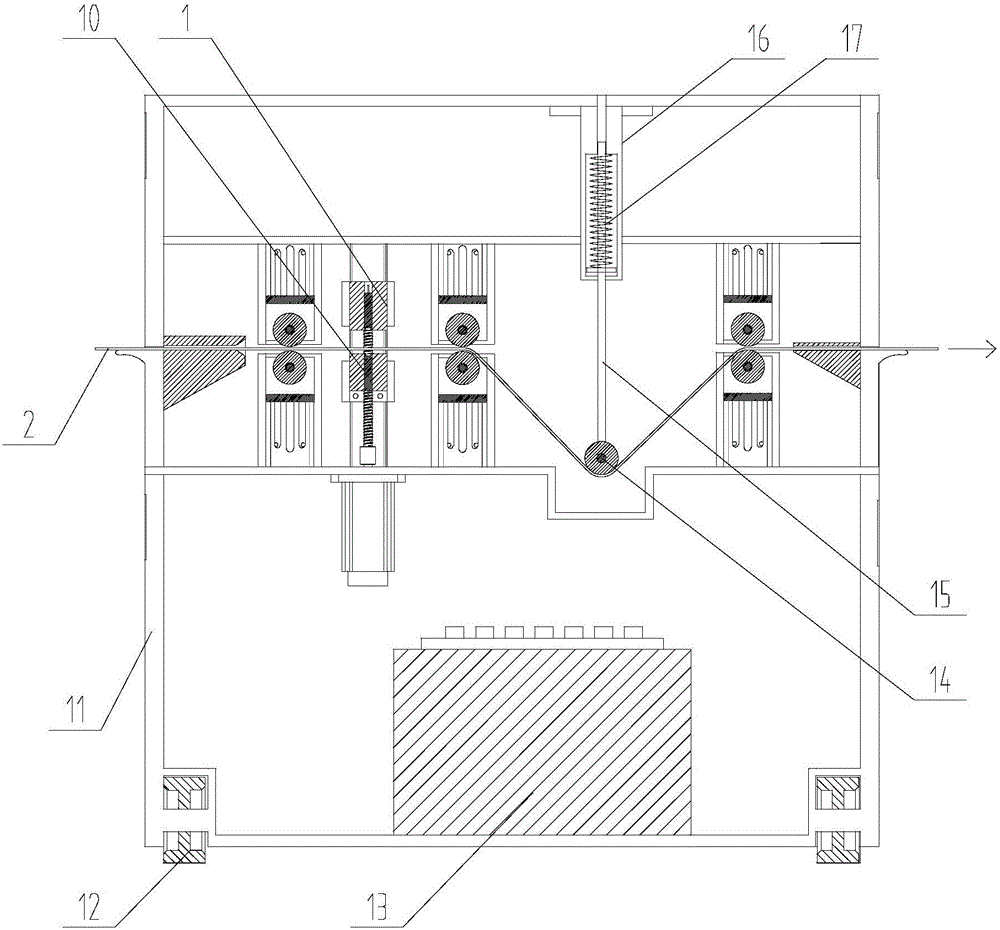

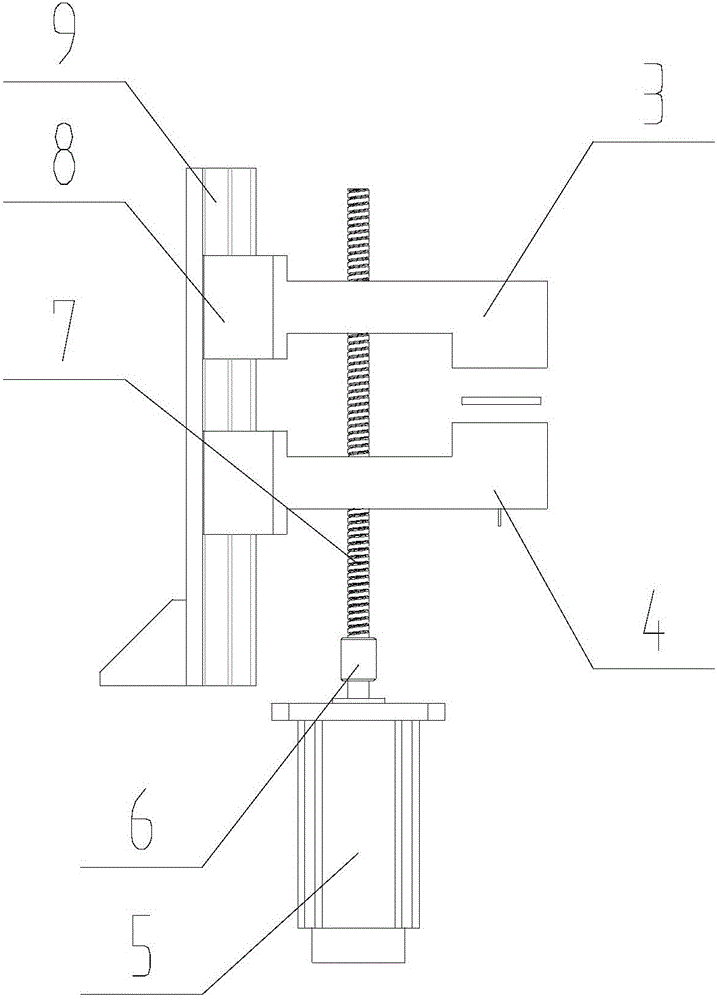

[0032] refer to figure 1 and figure 2As shown, a method for online detection of steel strip thickness using a steel strip buffer device of the present invention is characterized in that it includes the following steps: clamping the moving steel strip 2 by a clamping device 1, and keeping the steel strip 2 from the entrance section The steel strip brought to the clamping section remains in a static state; the pressing device 1 includes an upper pressing block 3, a lower pressing block 4, and a driving device for driving the upper pressing block 3 and the lower pressing block 4 to clamp and separate each other, and the upper pressing block 3 is set Above the steel belt 2, the lower pressing block 4 is arranged below the steel belt 2, and the driving device synchronously drives the clamping and separation of the upper pressing block 3 and the lower pressing block 4; Two pressure sensors 10 detect the pressure on the upper and lower surfaces of the steel belt in the clamping sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com