Bead embroidery embroidering machine and bead feeding method

An embroidery machine and bead technology, which is applied in the bead embroidery machine and bead feeding field, can solve the problems of difficult to meet the required standards, uneven surface contours and pinholes of beads, and difficulty in precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

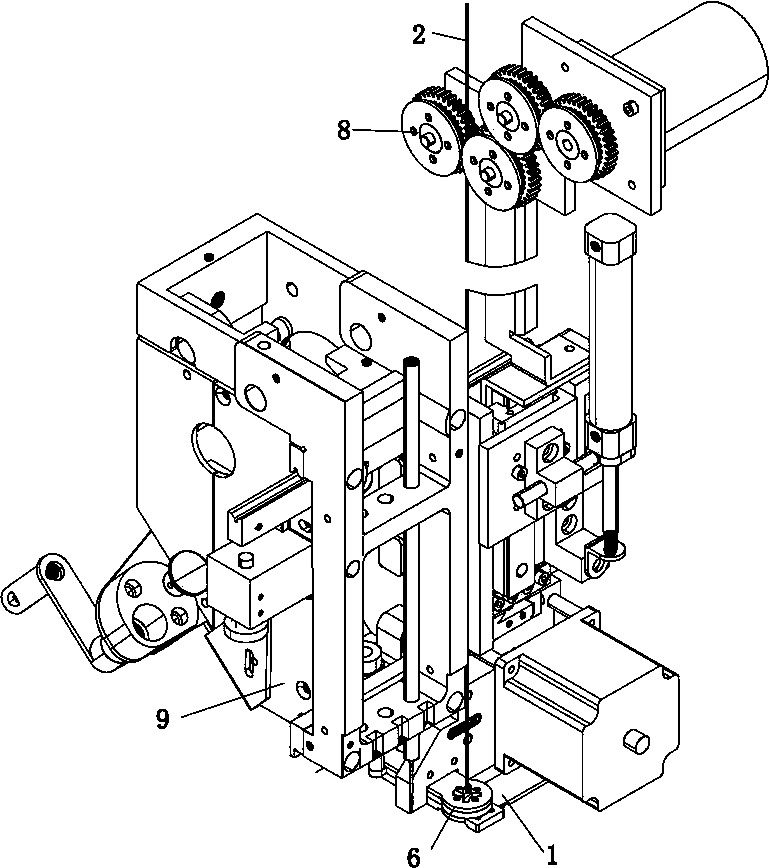

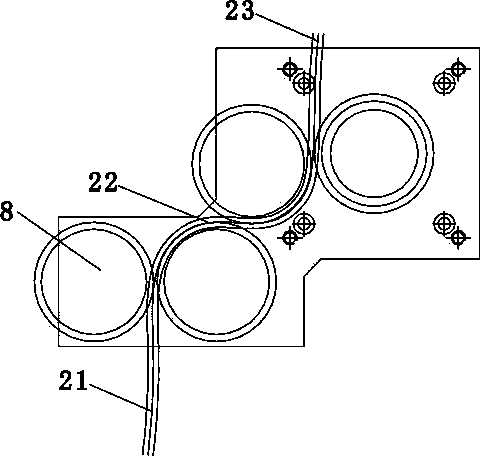

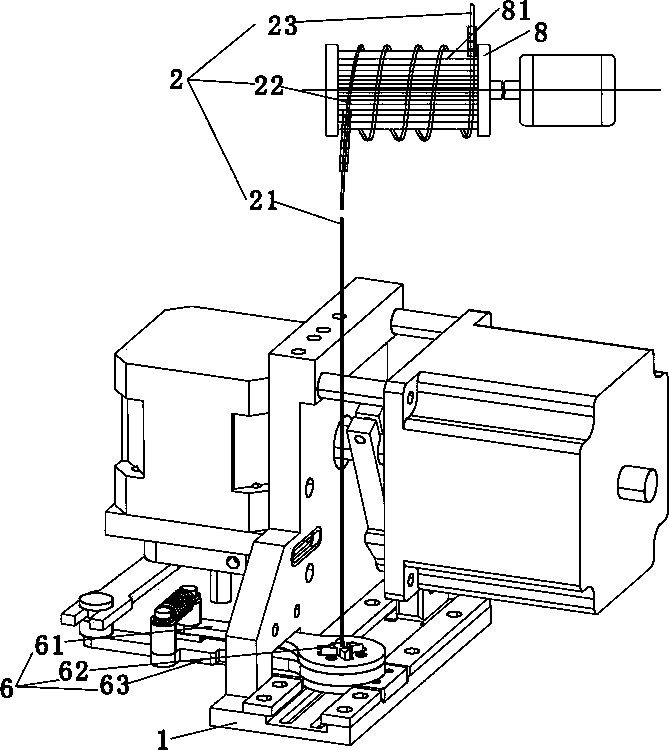

[0029] See Figure 1-11 This embodiment includes the machine body, one or more machine heads 9 are provided on the machine body, and the machine head 9 is connected with a feeding mechanism 1 that conveys embroidery beads one by one to the position directly below the embroidery needle 92 of the embroidery machine. The feeding mechanism 1 can It is arranged on the machine head 9 by sliding guide rails or double connecting rods so as to be separated from the machine head 9 when not working. The feeding mechanism 1 is provided with a clamping port for conveying embroidery beads. A bead guide rod 2 that continuously supplies embroidery beads to the feeding mechanism is suspended above the feeding mechanism 1. The bead guide rod 2 is threaded with embroidery beads to form a bead string. The bead string cooperates with the feeding mechanism 1 to continuously provide embroidery beads. The embroidery beads will drop their own weight to the corresponding place of the feeding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com