Embroidery bead feeding device and embroidery machine using the device

A feeding device and embroidery machine technology, applied in the direction of automatic control embroidery machines, embroidery machines, embroidery machine mechanisms, etc., can solve the problems of difficult precise positioning, uneven bead surface contours and pinholes, and difficult to meet requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

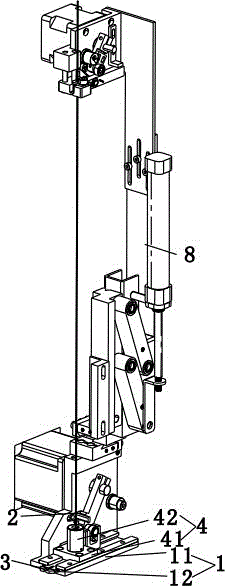

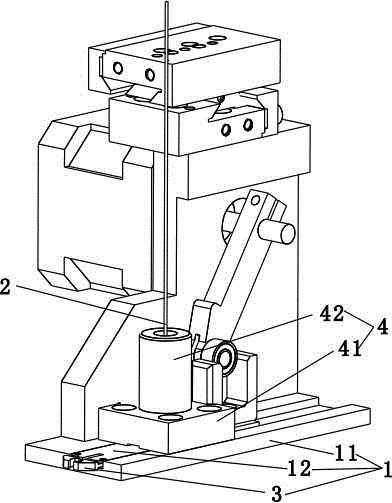

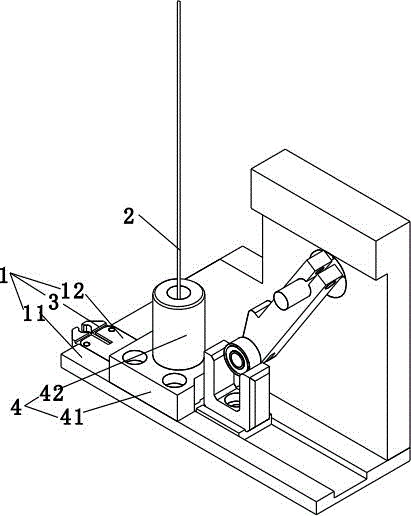

[0031] see Figure 1-5 , this implementation case includes a feeding mechanism 1 that conveys embroidery beads one by one to the position directly below the embroidery needle of the embroidery machine. A bead guide rod 2 that continuously supplies embroidered beads to the feed mechanism is suspended above the feed mechanism 1. On the bead guide rod 2 Beads are worn to form a bead string, and the bead string cooperates with the feed mechanism 1 to continuously provide embroidered beads, and the embroidered beads will fall to the corresponding position of the feed mechanism 1 by their own weight.

[0032] The feeding mechanism 1 includes a support plate 11 and a clamping structure 3 that reciprocates relative to the support plate 11 to clamp and transport the embroidery beads to the position directly below the embroidery needle. The support plate 11 can be provided with a guide clamping structure 3 to reciprocate Sliding guide groove.

[0033] The feeding mechanism 1 also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com