Embroidery beads feeding method

A technology for embroidering beads and feeding materials, which is applied to embroidery machines, embroidery machine mechanisms, and automatically controlled embroidery machines. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

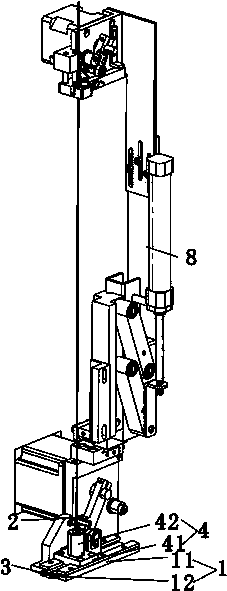

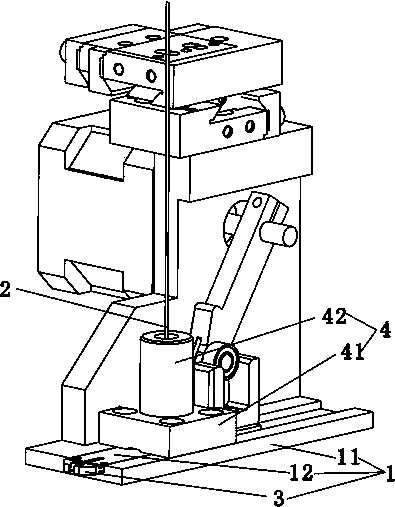

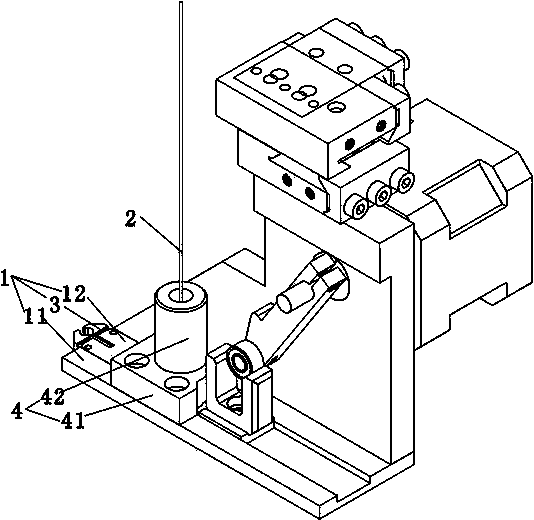

[0019] see Figure 1-5 , a feeding method of embroidered beads, the embroidered beads are worn on the bead guide rod 2 to form a bead string, and the bead string is suspended at the corresponding position of the feed mechanism 1 to cooperate with the feed mechanism 1 to continuously supply the feed mechanism 1. The bead guide rod 2 is linked with the feeding of the feeding mechanism 1 to reciprocate up and down, positioning and sliding down the embroidery beads at the corresponding position of feeding of the feeding mechanism 1 .

[0020] In order to ensure the quality of the embroidered beads and enable the embroidered beads to be accurately positioned, the external diameter screening and classification of the embroidered beads are also included.

[0021] As a further optimization, a bead guide tube adapted to the outer contour of the bead string is arranged outside the bead string.

[0022] The clamping structure of the feeding mechanism 1 bidirectionally clamps the embroid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com