Embroidery bead feeding device and feeding method

A technology of feeding device and embroidery bead, applied in auxiliary device, mechanism of embroidery machine, embroidery machine, etc., can solve the problems of difficult to meet the required standard, uneven surface contour and pinhole of beads, difficult to accurately locate and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

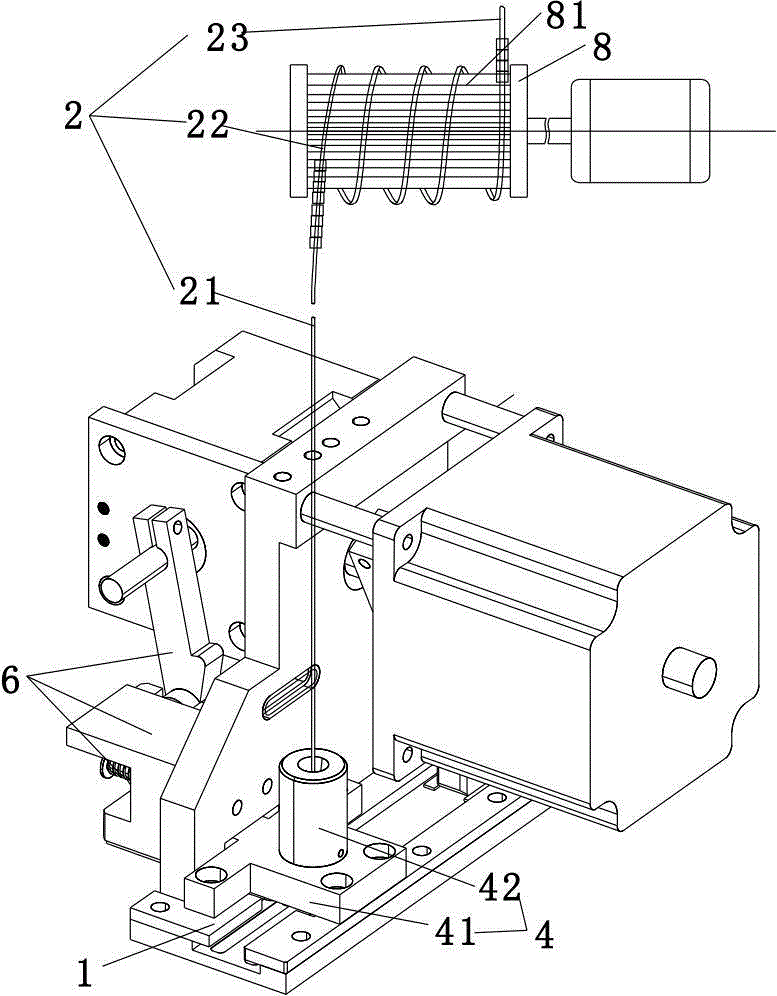

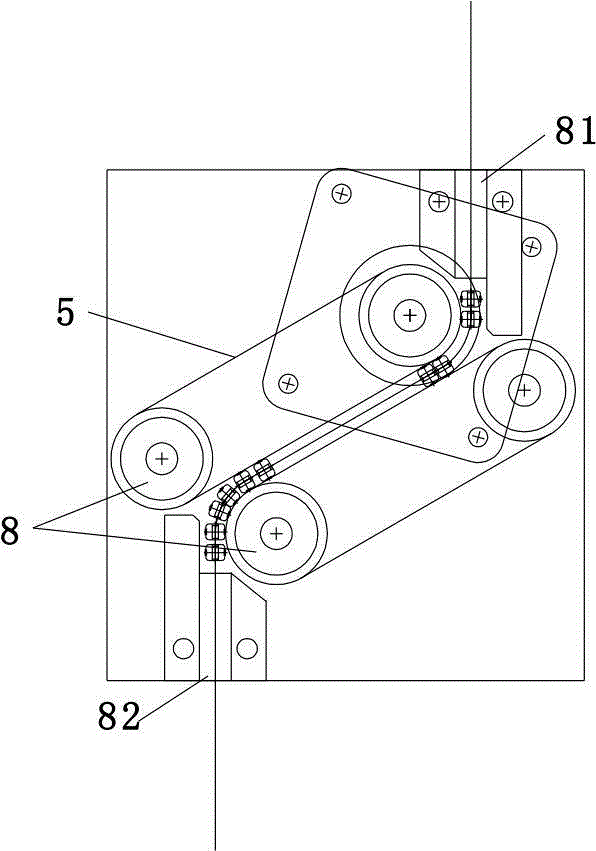

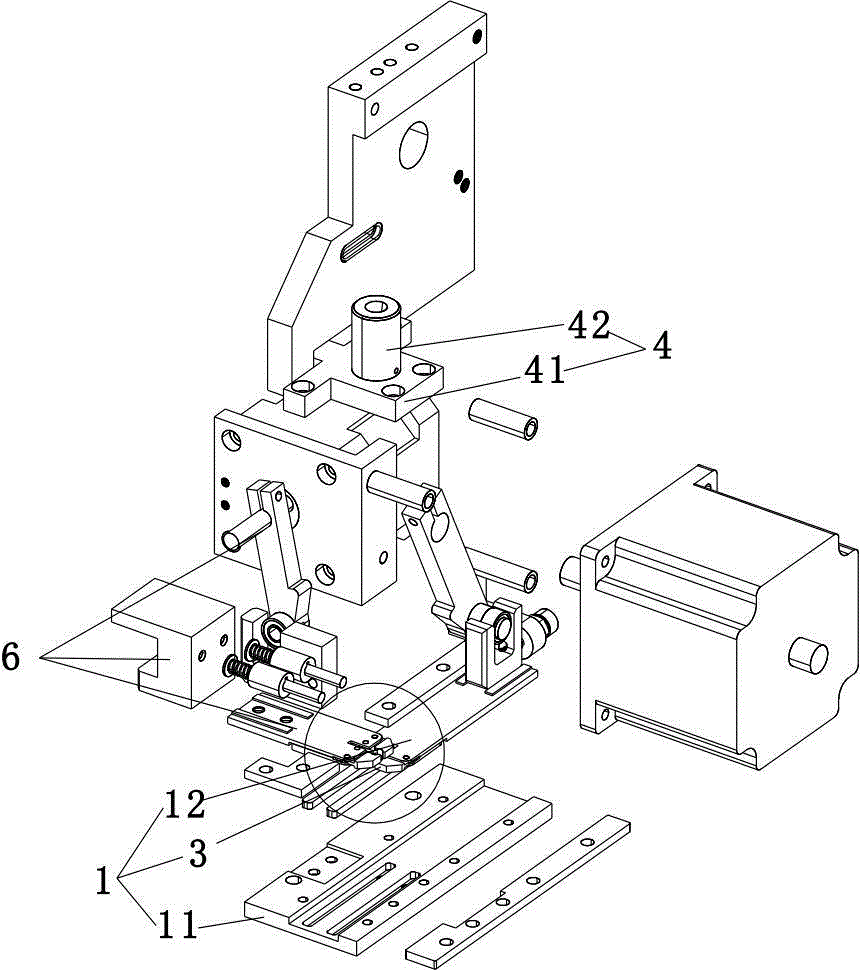

[0027] see Figure 1-9 , this implementation case includes a feeding mechanism 1 that transports the embroidered beads one by one to the position directly below the embroidery needle of the embroidery machine, and the feeding mechanism 1 is provided with a clamping port for clamping and positioning the embroidered beads. A bead guide rod 2 is suspended above the feeding mechanism 1 to continuously supply embroidery beads to the feeding mechanism. Beads are threaded on the guide rod 2 to form a bead string, and the bead string cooperates with the feed mechanism 1 to continuously provide embroidery beads. The embroidered beads will fall to the corresponding place of the feeding mechanism 1 by their own weight.

[0028] Since the embroidered beads will slide relative to the bead guide rod 2, and the quality of the embroidered beads is usually small, a necessary gap needs to be set between the bead pinhole and the bead guide rod 2 to ensure that the embroidered beads slide down c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com