Bead feeding device and embroidery machine

A technology of feeding device and beads, applied in embroidery machine, embroidery machine mechanism, automatically controlled embroidery machine, etc., can solve the problems of poor bead conveying accuracy, inconvenient installation and debugging, loose structure, etc., and achieves simple structure and volume. Small, large-scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

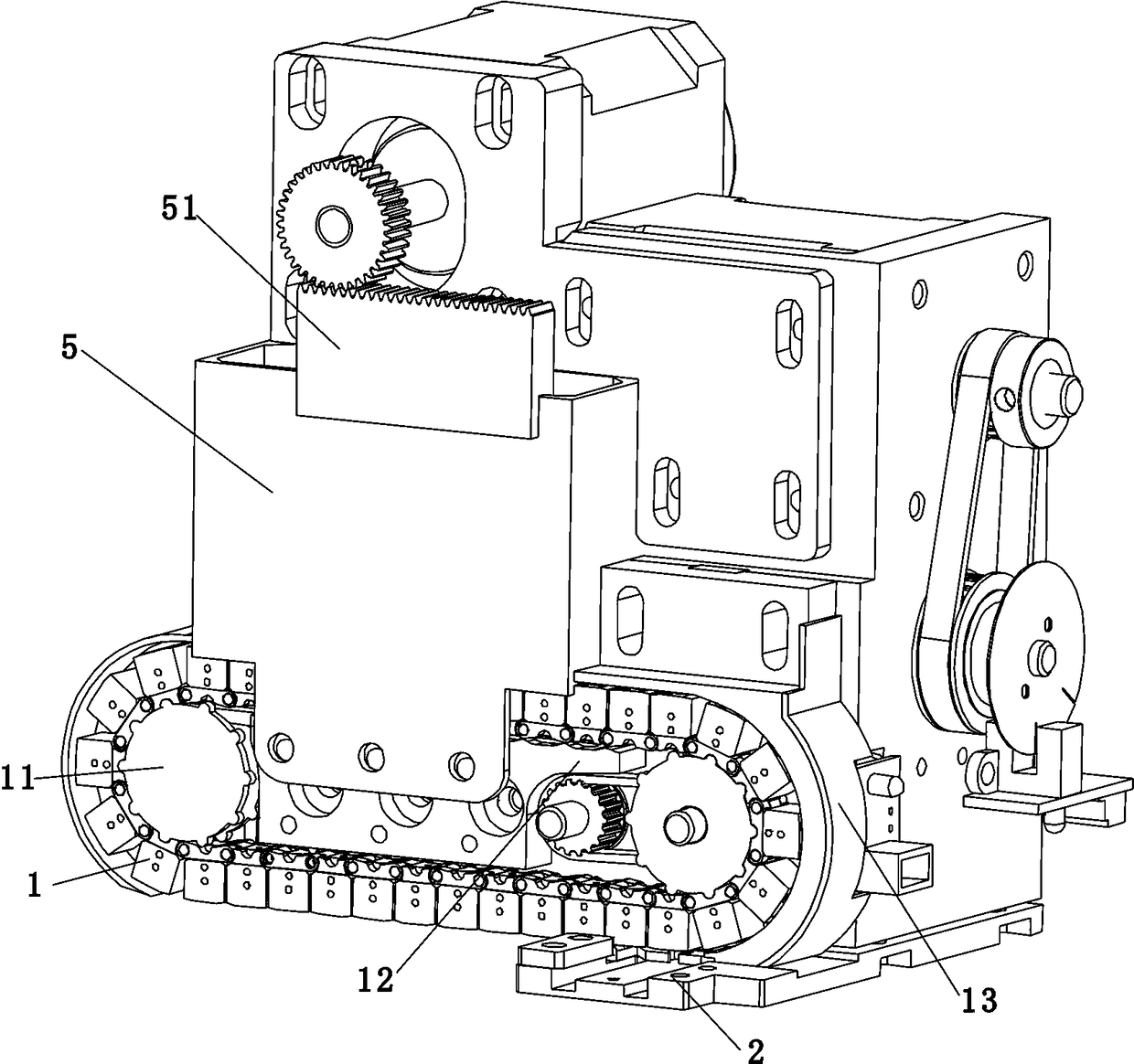

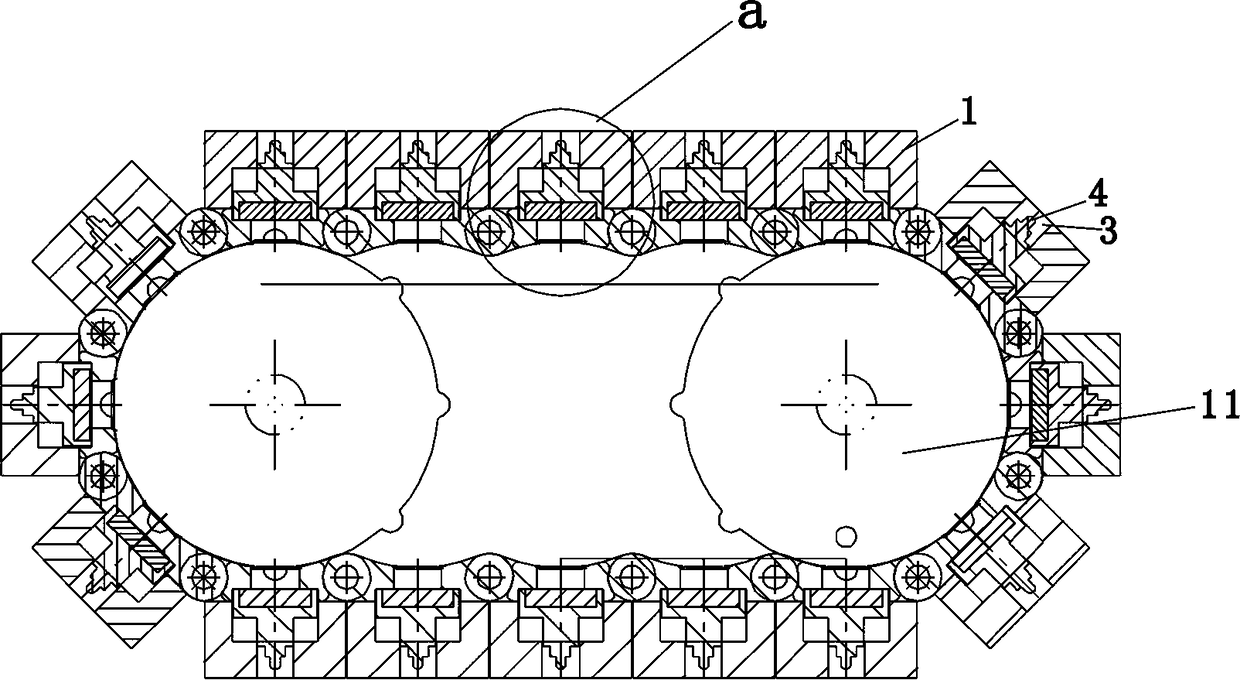

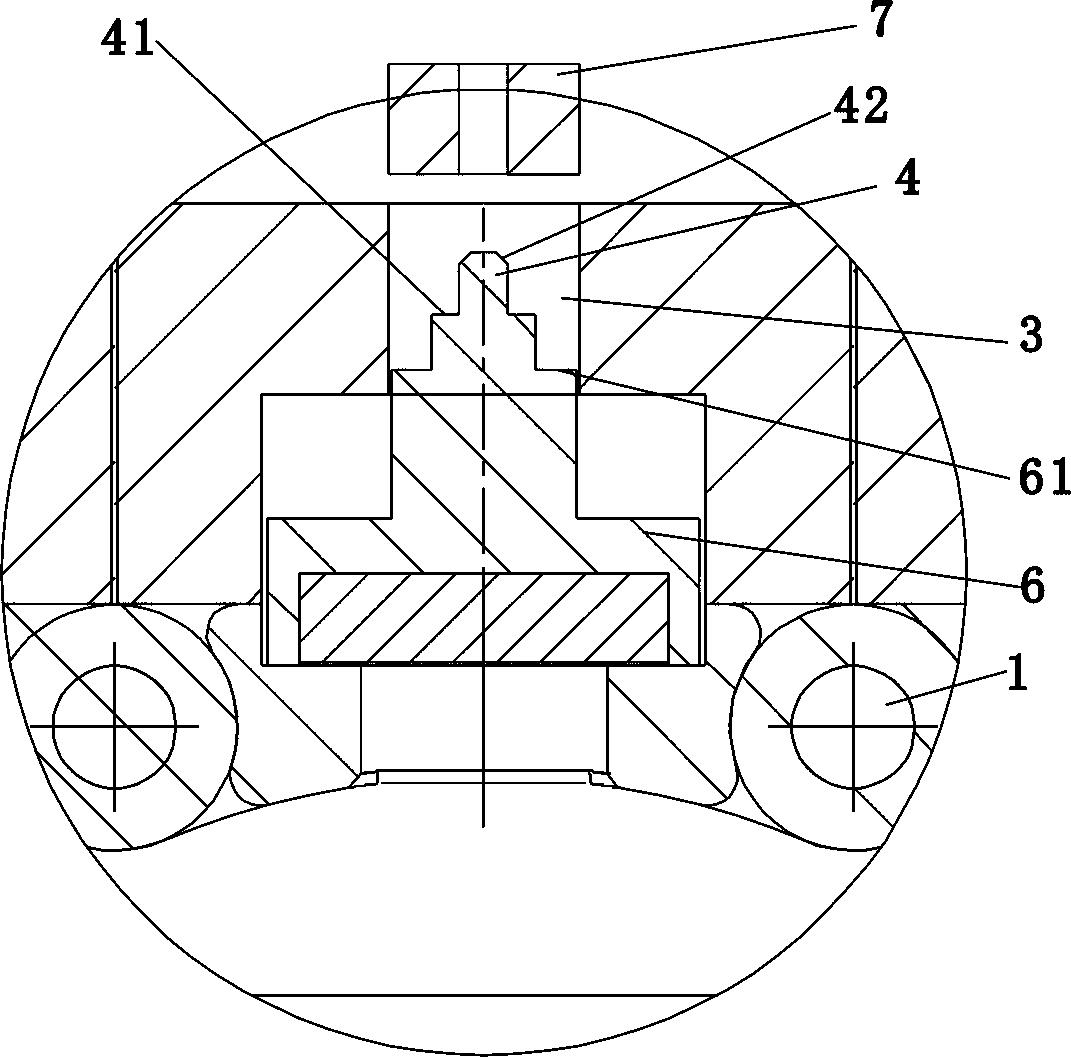

[0035] see Figure 1-10 , this implementation case includes a bead feeding device, including a conveying carrier 1 that locates and conveys beads 7 from the bead feeding mechanism 5 to the corresponding place of the feeding mechanism 2, the conveying carrier 1 is a chain or a belt, and the conveying carrier 1 is provided with a driving conveying The driving wheel 11 of the carrier 1 is provided with at least one storage hole 3 on the transportation carrier 1. In this embodiment, the storage holes 3 are evenly distributed on the transportation carrier 1. As shown in the figure, each chain of the chain is provided with a storage hole. 3. Of course, multiple storage holes 3 can be arranged sequentially along the conveying direction on each chain, and one or more rows of storage holes 3 can be arranged according to the conveying requirements of the emergency structure 2 . If a belt is used, then a plurality of storage holes 3 are uniformly arranged in one or more rows along the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com