Glass bead feeding device of glass bead embroidery

A technology of bead embroidery and bead clipping, which is applied in the direction of auxiliary devices, embroidery machines, embroidery machine mechanisms, etc. It can solve the problems of bead embroidery failure, broken thread and needle, and inflexible mechanism movements, etc., and achieves reasonable structure and convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

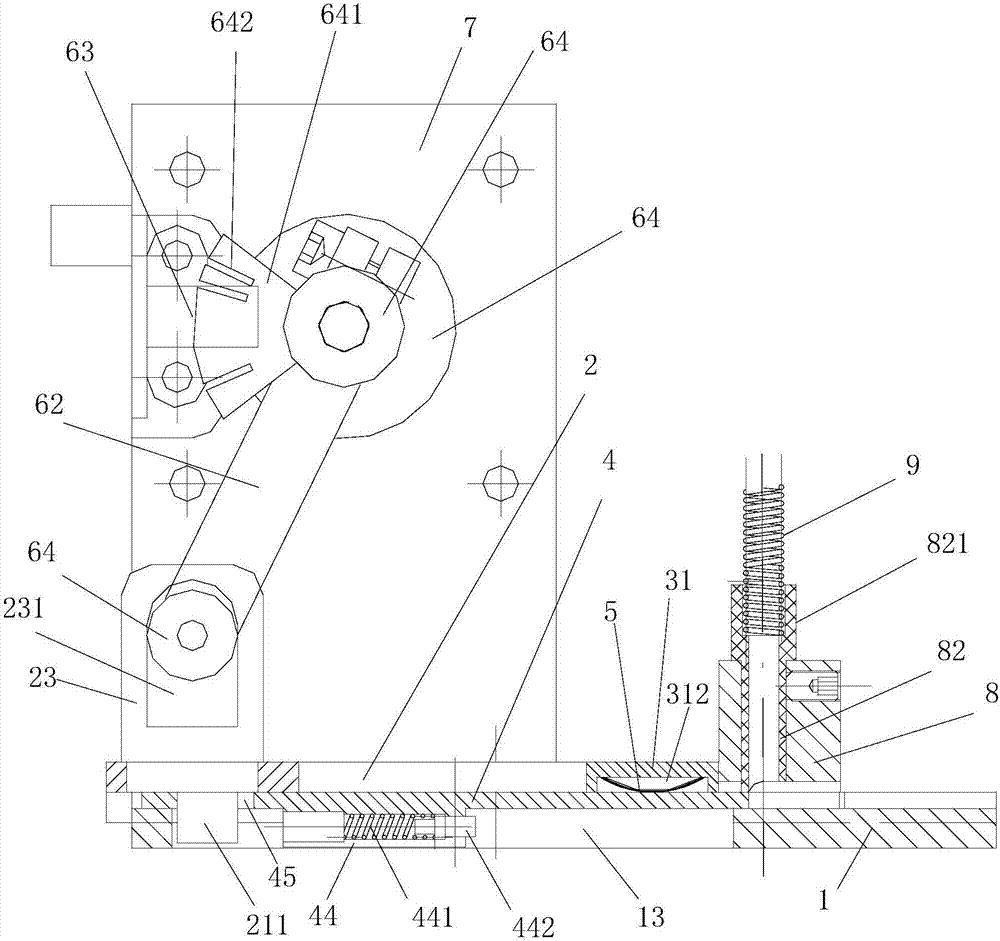

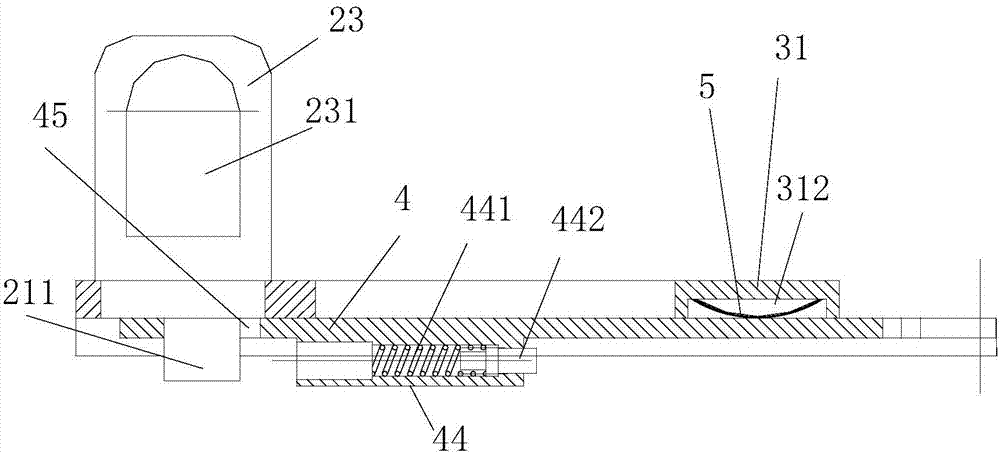

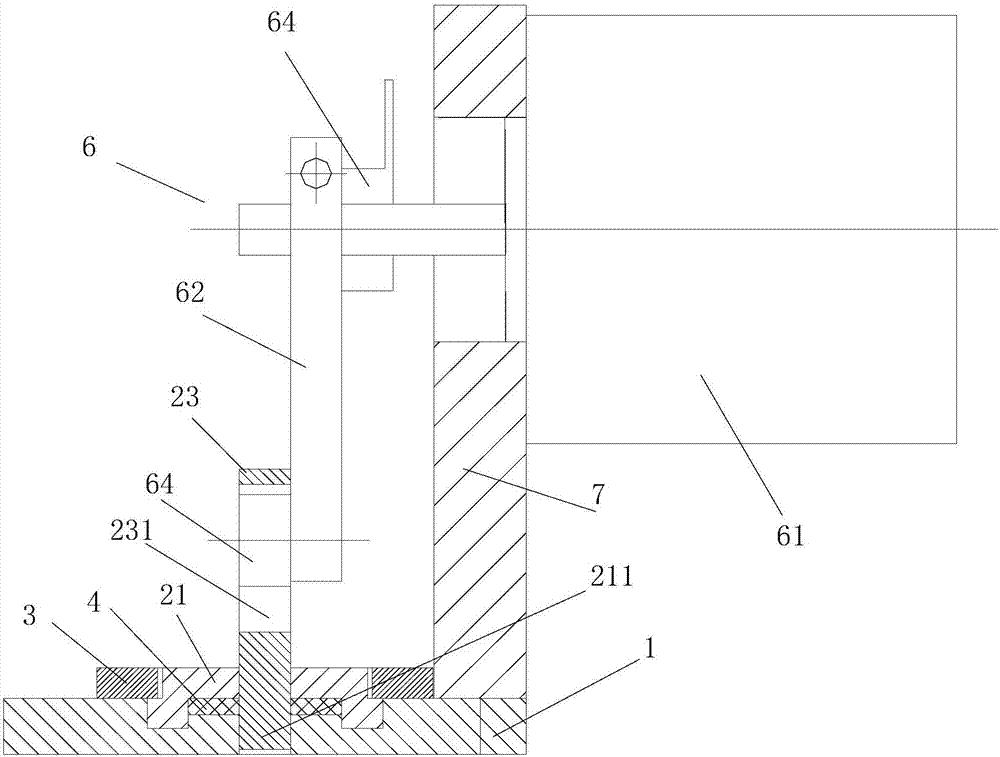

[0030] Embodiment 1: refer to Figure 1-7. A bead embroidery bead feeding device, comprising a fixed base plate 1, a bead clamping sliding plate 2, an elastic bead clamping plate 4, and a lateral sliding drive mechanism 6, the upper side of the fixed base plate 1 is provided with a horizontal chute 11, and the lateral chute 11 Lateral guide grooves 12 are provided on the two sides, and the bead clamping sliding plate 2 includes a push seat 21 and guide plates 22 arranged on both sides of the push seat 21, and the elastic bead clamp plate 4 is clamped and placed on both sides of the guide plate On the lateral chute 11, the guide plates 22 on both sides are guided and connected with the lateral guide grooves 12 on both sides of the lateral chute 11, and the lateral sliding drive mechanism 6 is connected to the push seat 21; the elastic bead clamping plate 4 includes a top plate 42 and the splint 41 that is connected to both sides of the top plate 42 and extends forward. The fro...

Embodiment 2

[0033] Embodiment 2: refer to figure 1 with 8 . A bead outlet seat 8 is provided at the front end of the upper elastic bead clamping plate 4 of the fixed bottom plate 1 . The bead outlet seat 8 is fixedly connected with the fixed bottom plate 1, and the bead outlet seat 8 is provided with a single longitudinal bead outlet hole 81, and a bead outlet conduit 82 is arranged in the longitudinal bead outlet hole, and a connecting portion 821 is provided at the upper end of the bead outlet conduit 82. , and the lower ball spring tube 9 is connected through the connecting portion 821 .

Embodiment 3

[0034] Embodiment 3: refer to figure 1 with 9 . On the basis of Embodiment 1, the bead outlet seat 8 is movably connected to the upper end of the fixed bottom plate 1, and several longitudinal bead outlet holes 81 arranged in a single row or in double rows are arranged on the bead outlet seat 8, and each longitudinal bead outlet hole Bead outlet conduits 82 are respectively provided, and the upper ends of each bead outlet conduits 82 are respectively provided with connecting parts 821 , and the upper ends of each bead outlet conduits 82 are respectively connected with the lower bead spring tubes 9 through the connection parts 821 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com