Tube-bead embroidery automatic feeding device

A technology of automatic feeding and feeding device, which is applied in the field of embroidery machinery, can solve the problems of heavy sewing workload, high processing cost and low work efficiency of operators, achieve significant economic benefits, improve sewing quality, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

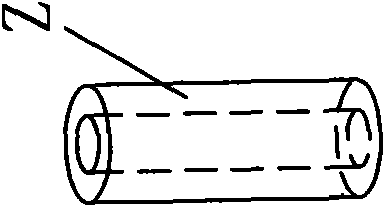

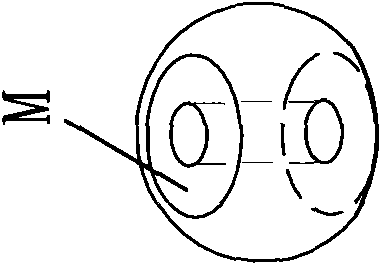

[0024] figure 1 , figure 2 The shown bead tube Z or rice bead M, because the length is only about 2-7mm, so the efficiency of manual sewing is low, and the sewing quality is unstable, so as to affect the overall quality and decorative effect of the garment.

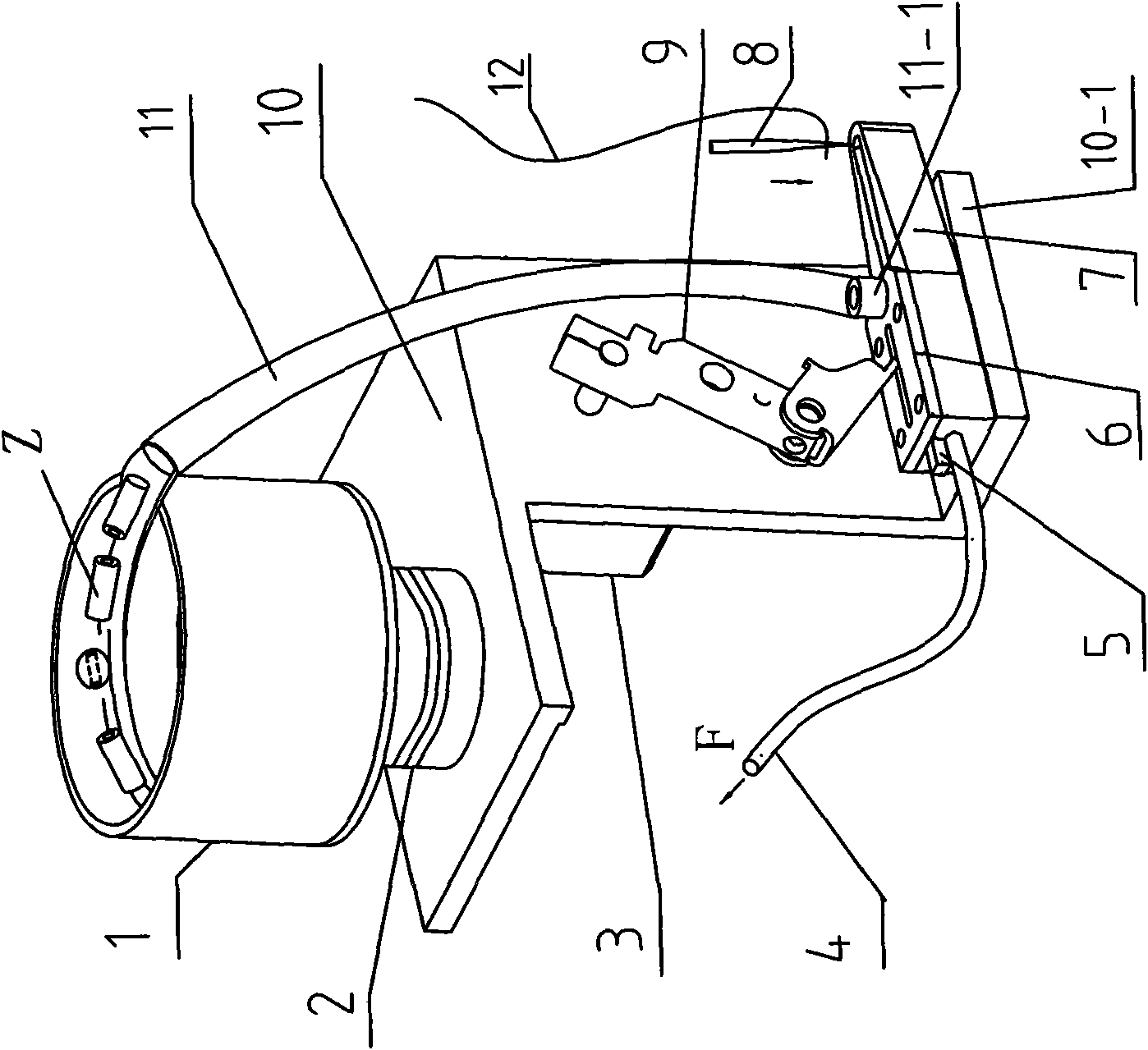

[0025] The automatic feeding device for bead tube rice bead embroidery provided by the present invention includes a feeding device fixed on the mounting plate 10 and a pushing device connected with the feeding device and capable of reciprocating linear motion; the feeding device includes a vibrating type feeder (the oscillating feeder is a common conventional equipment, widely used in pharmaceutical packaging, nail making equipment and other occasions that need to convey small products in an orderly manner. It can be directly purchased), the feeder includes a vibrator 2 and The vibrating plate 1 installed on the upper end of the vibrator; the circumferential walls of the vibrating plate are formed with a channel 13 spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com