Elastic material cutting transverse state converter on production line of disposable sanitary articles

A hygienic product and elastic material technology, which is applied in the field of cutting and turning devices, can solve the problems that the mold cannot be realized, and achieve the effect of reasonable design and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

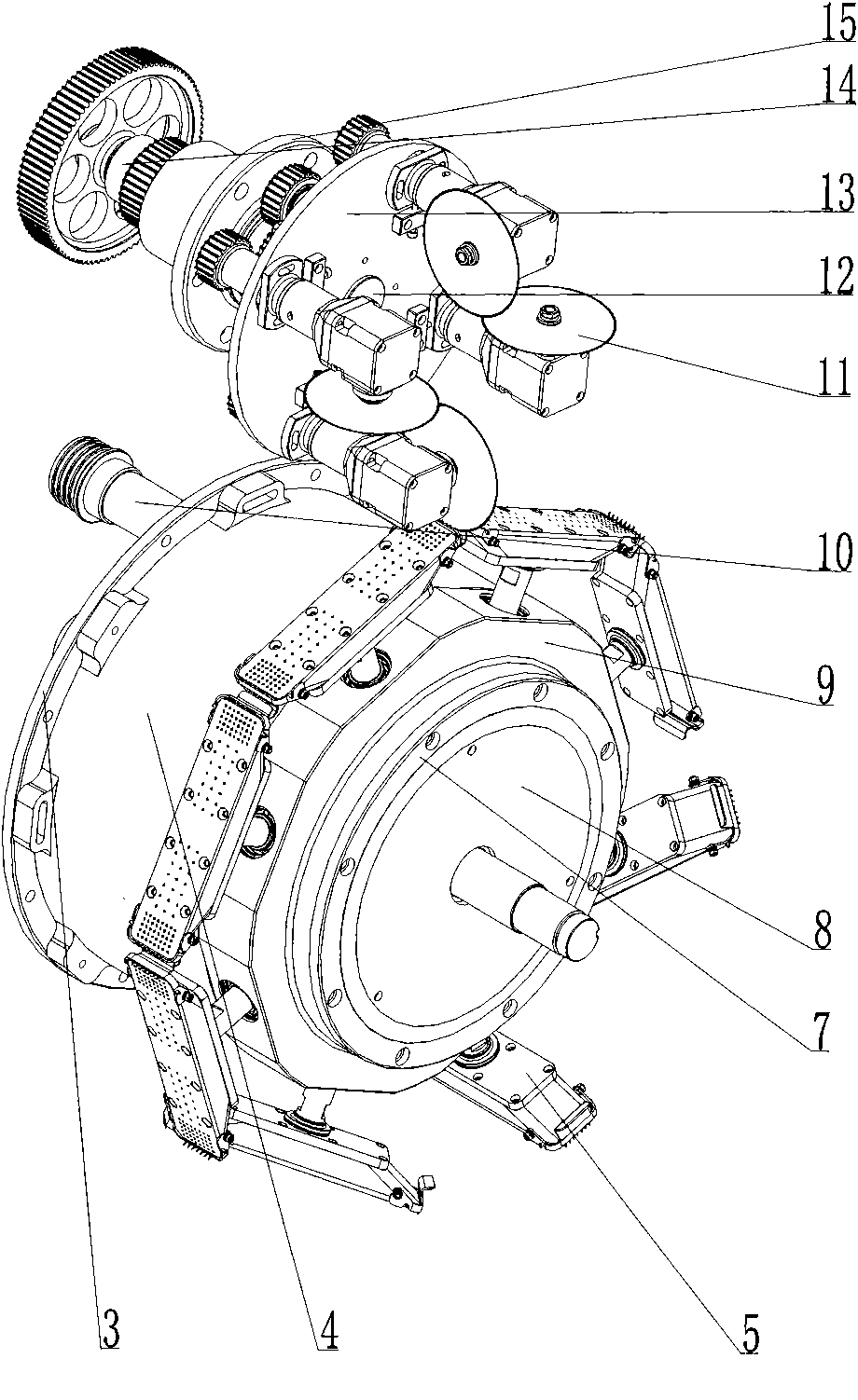

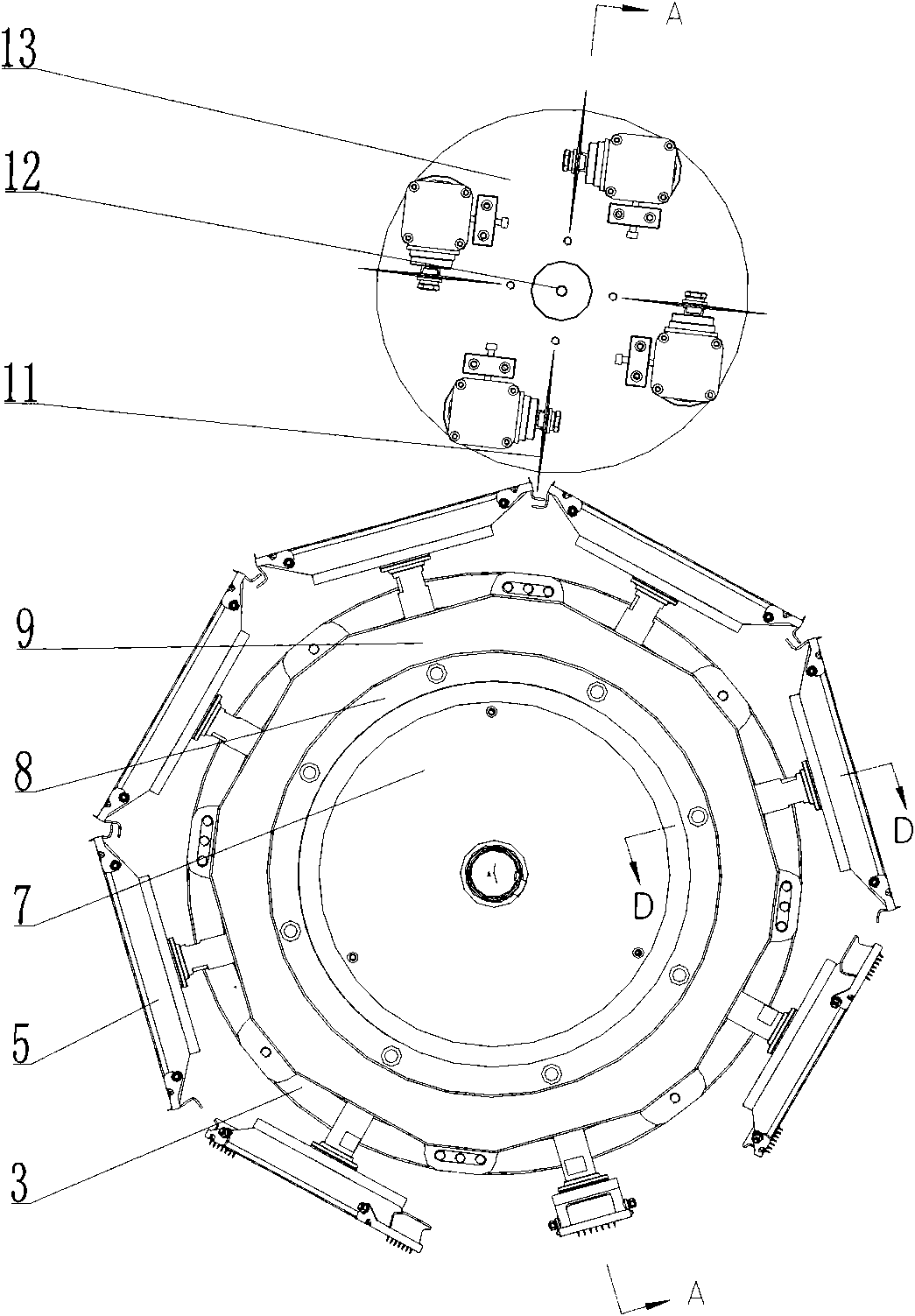

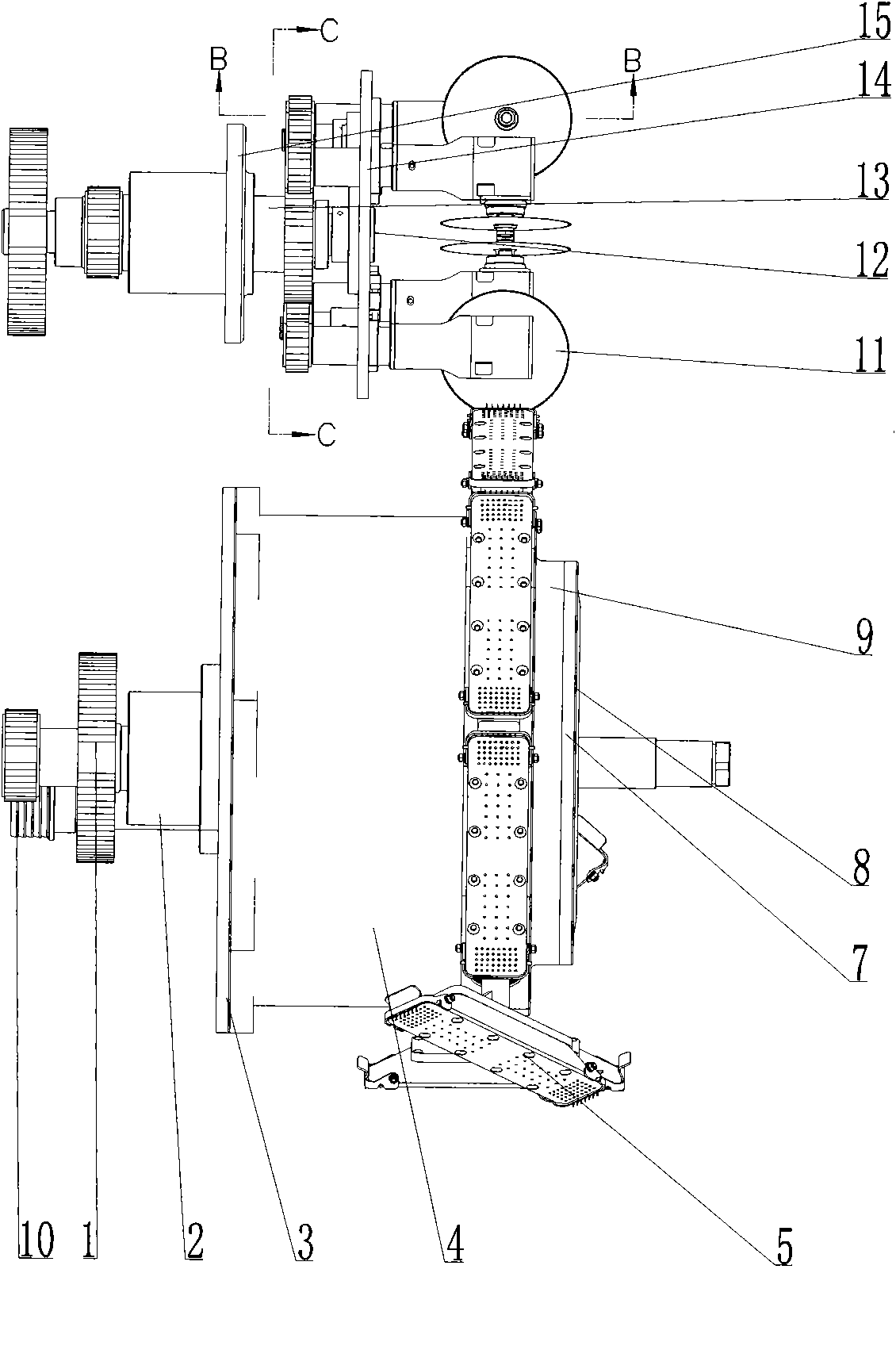

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 12 , The elastic material cutting and turning device on the production line of disposable sanitary products includes a turning mechanism and a cutting mechanism.

[0037] One end of the horizontal turning main shaft 1 of the horizontal turning mechanism is connected to the horizontal bearing seat 2 through a bearing, and a positioning disc 3 is installed on the horizontal bearing seat 2, and the positioning disc 3 is connected to the suction ring 4, and the axial direction of the horizontal bearing seat 2 The other end is covered with a cam seat 6, and the air control assembly 10 is installed on the suction ring 4, and the suction ring 4 is evenly distributed with suction grooves, see Figure 11 ; The other end of the horizontal main shaft 1 extends to the outside of the suction ring 4, a rotary disc support 7 is installed on the extended end of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com