Horn basin frame for improving voice coil concentricity and manufacture method for horn

A technology of a speaker cone frame and a manufacturing method, which is applied to the fixing/tightening of the diaphragm, sensors, electrical components, etc., can solve the problems of inability to guarantee the dimensional accuracy, increase the cost of drum paper, hinder the vibration of the voice coil, etc. The effect of stability, improved yield and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

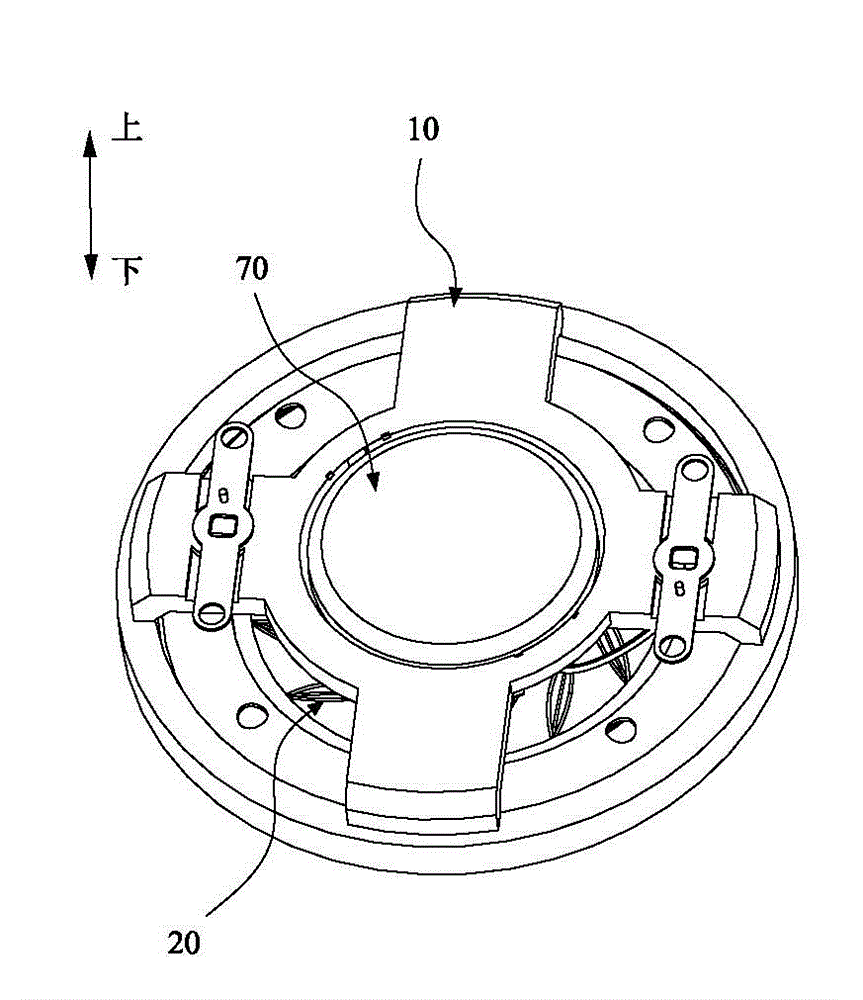

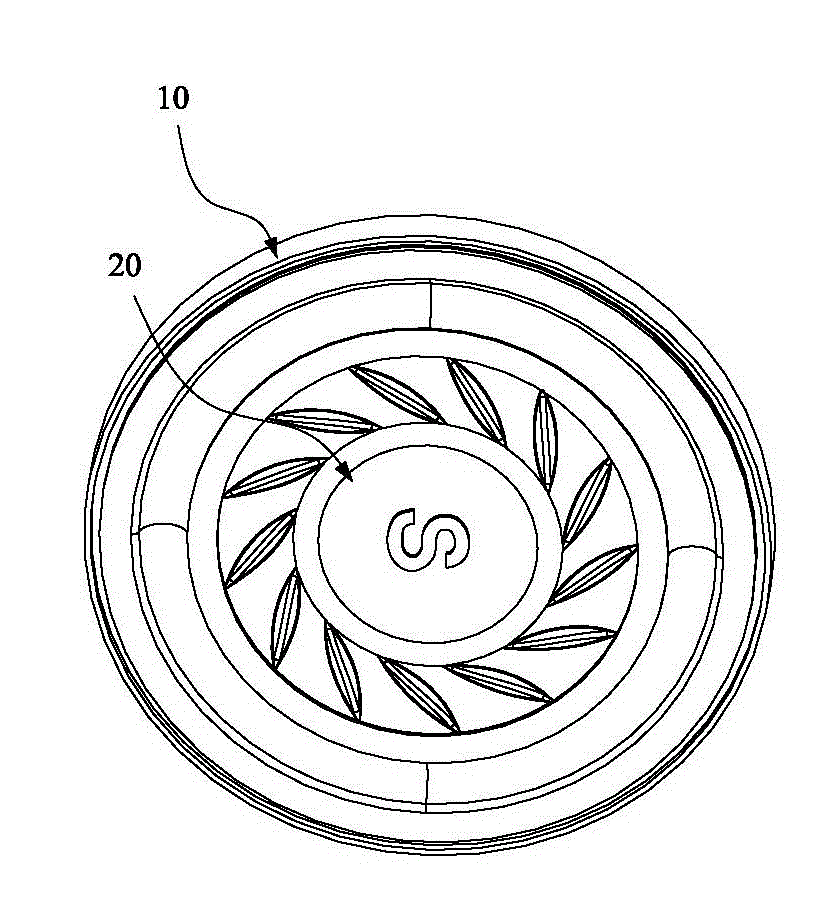

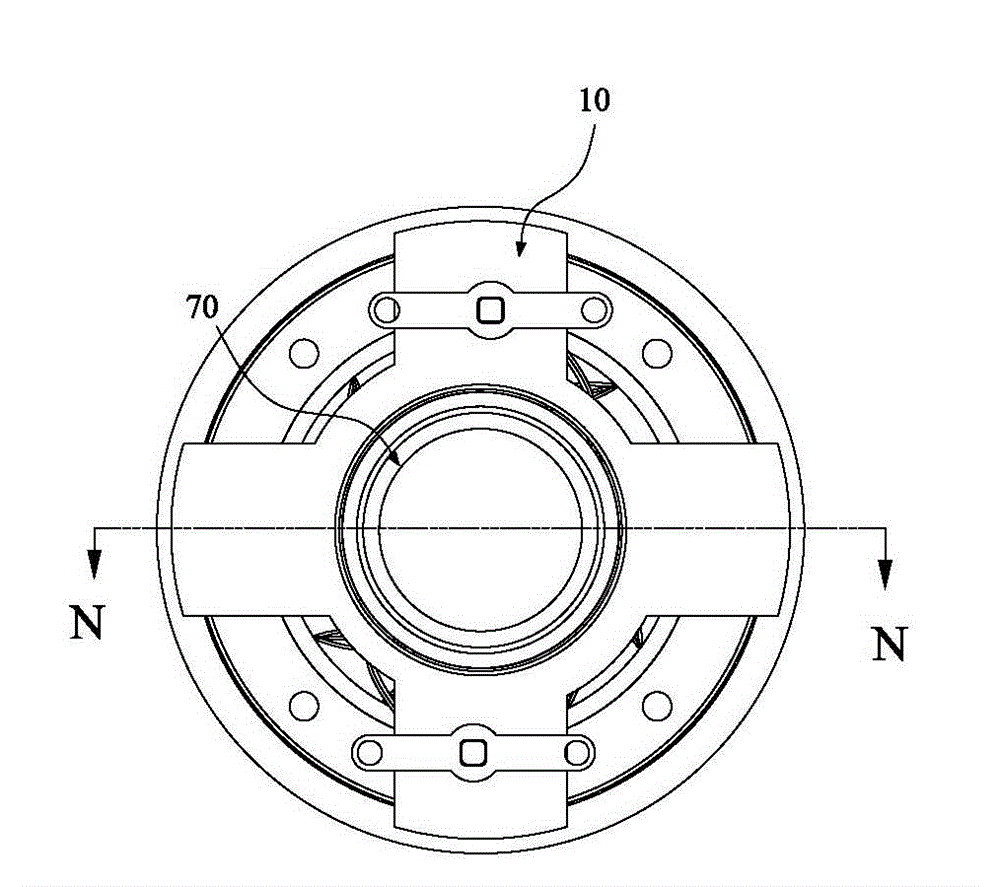

[0054] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a circular basin frame 10, drum paper 20, double folding ring 30, voice coil 40 and a magnetic component, which in turn includes an outer cover 70 and a magnetic circuit arranged inside the outer cover 70. The magnetic circuit is composed of a magnet 60 and a washer 50 stacked up and down. The centers of the frame 10, the drum paper 20, the voice coil 40, the washer 50, the magnet 60 and the outer cover 70 are on the same straight line.

[0055] The up and down directions mentioned in the text of this embodiment are figure 1 The direction indicated shall prevail.

[0056] Wherein, the basin frame 10 includes an inner ring portion 11, an outer ring portion 12, and a plurality of frames 13 connected between the inner ring portion 11 and the outer ring portion 12. The inner ring portion 11 and the top of the frame 13 are flush with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com