Embroidery machine glass bead feeding device

A glass bead and embroidery machine technology, applied in the field of embroidery equipment, can solve the problems of few embroidery colors, poor aesthetics, and single pattern color, etc., and achieve the effects of various embroidery colors, good aesthetics, and rich colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

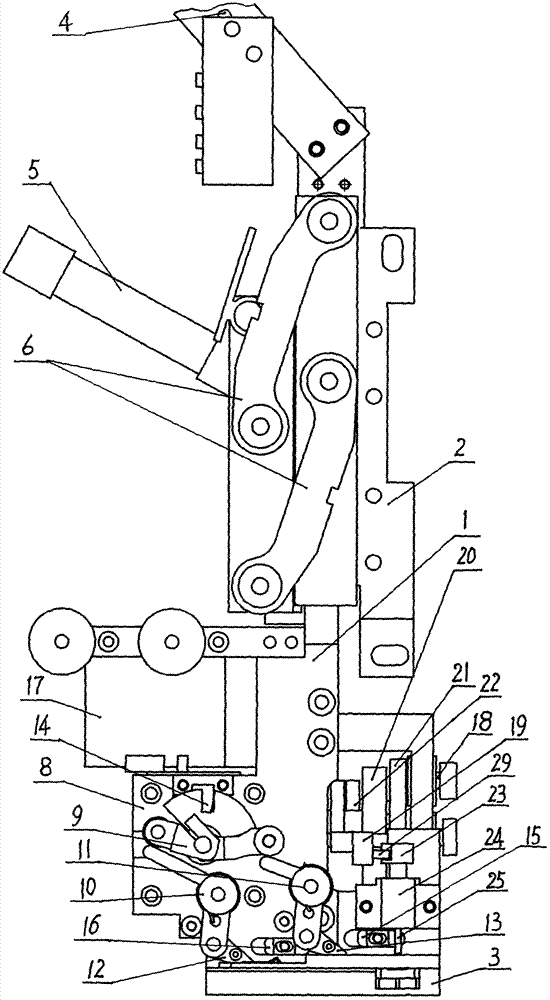

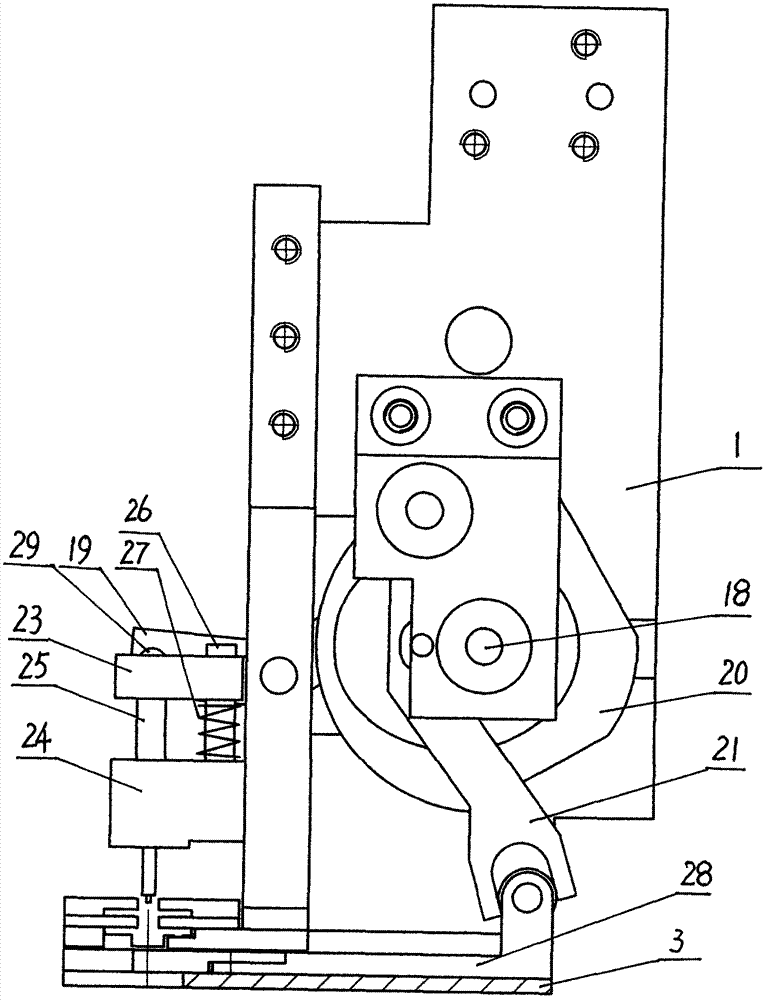

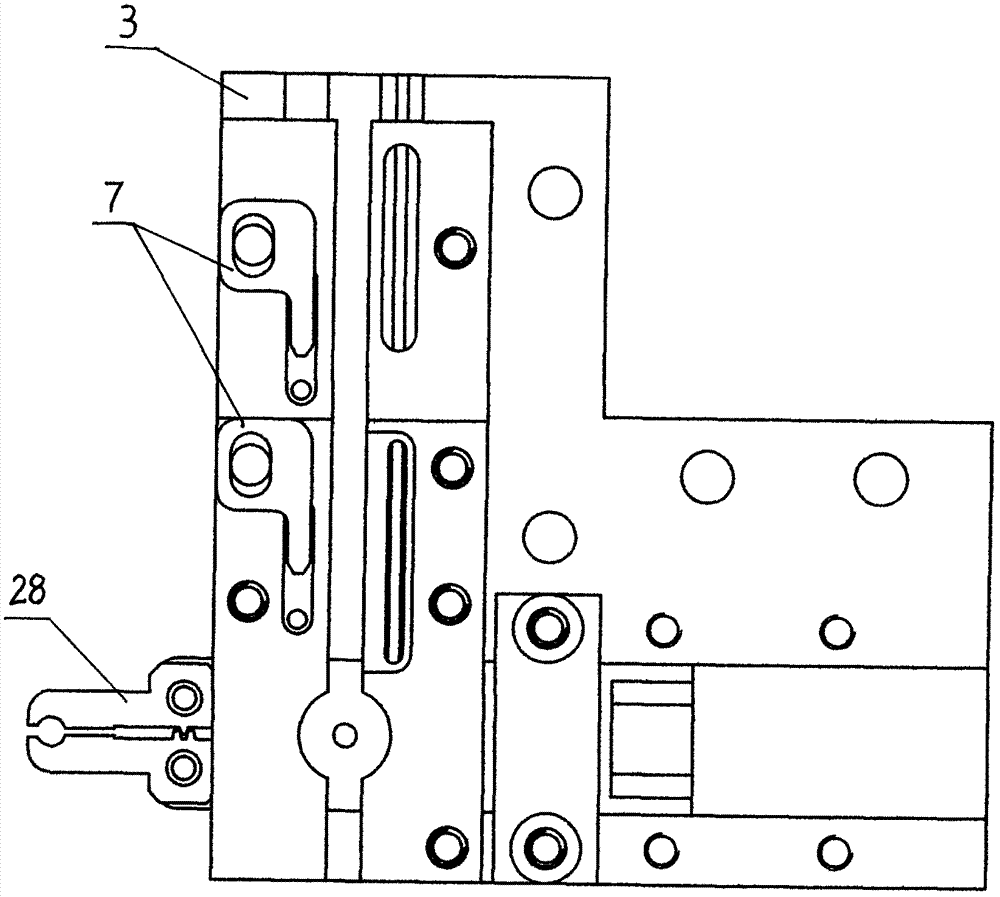

[0011] Such as figure 1 The glass bead feeding device of the embroidery machine shown includes a frame 1, a mounting plate 2, a chassis 3, a tape rack 4, a tape feeding mechanism, a bead feeding mechanism, a lifting mechanism and a control mechanism, and the mounting plate 2 is fixedly installed on the embroidery machine. On the mounting frame of the head, the chassis 3, the belt feeding mechanism and the bead feeding mechanism are installed on the frame 1, and the frame 1 is connected with the mounting plate 2 through a lifting mechanism. The lifting mechanism is composed of a cylinder 5 and a connecting rod 6. The cylinder of the cylinder 5 The body is fixedly installed on the frame 1, the piston rod end of the cylinder 5 is fixedly connected with the mounting plate 2, and the two ends of the connecting rod 6 are respectively hinged with the frame 1 and the mounting plate 2. When the piston rod of the cylinder 5 is pushed out, the chassis 3 Lift up and leave the cloth, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com