Multicolor bead and bead pipe embroidering device

A catheter device and bead technology, applied in embroidery machines, embroidery machine mechanisms, and automatically controlled embroidery machines, etc., can solve the problems of process influence, increased labor intensity, inconvenient operation, etc., so as to improve work efficiency and reduce labor intensity. , to ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

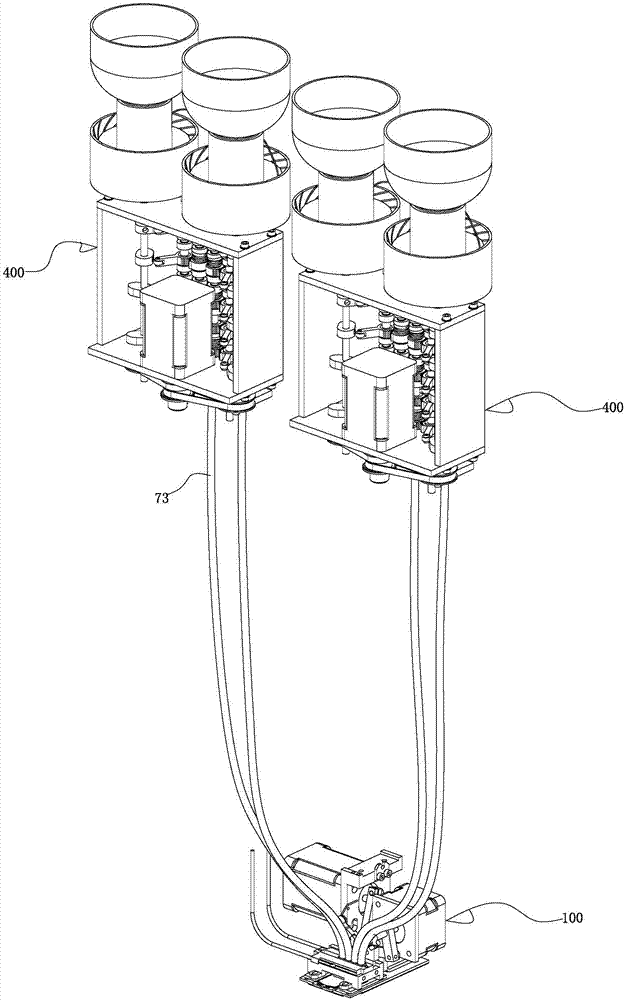

[0031] See Figure 1-10 Shown is a multi-color bead and bead tube embroidery device, at least one set of multi-color bead embroidery catheter device 400 and a multi-color bead embroidery color changing device 100 correspondingly installed with the multi-color bead embroidery catheter device 400 .

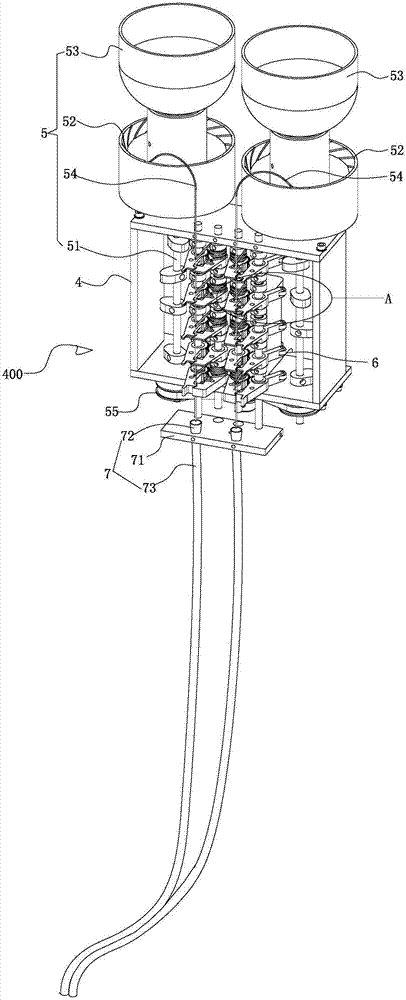

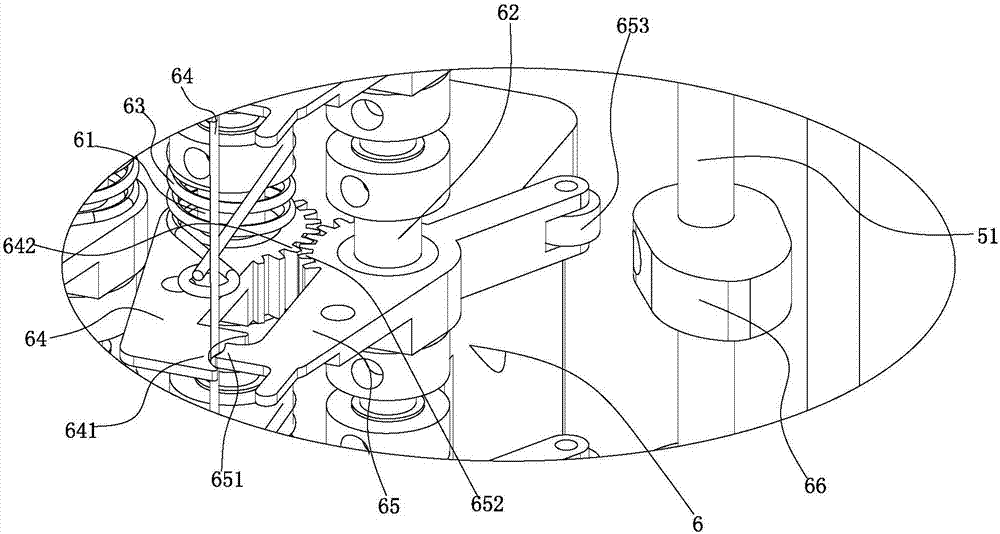

[0032] combine Figure 2-4 As shown, the multi-color beaded beading catheter device 400 includes: a frame 4, a beading mechanism 5 installed on the upper end of the frame 4, a buffer beading mechanism 6 installed in the frame 4 and cooperating with the beading mechanism 5 and The conduit assembly 7 installed on the lower end of the frame 4 and adapted to the beading mechanism 5 is docked with the multi-color bead embroidery color-changing device 100 and transmits beads to the multi-color bead embroidery color-changing device 100 .

[0033]Described be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com