Double-color bead embroidery device on embroidery machine

An embroidery machine and color bead technology, which is applied to the mechanism of embroidery machines, embroidery machines, automatic control embroidery machines, etc., can solve the problems of increasing production costs and occupying space on the factory site, not being able to realize the same device, and being unsuitable for popularization and application. , to achieve good embroidery effect, suitable for popularization and application, and save space for site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

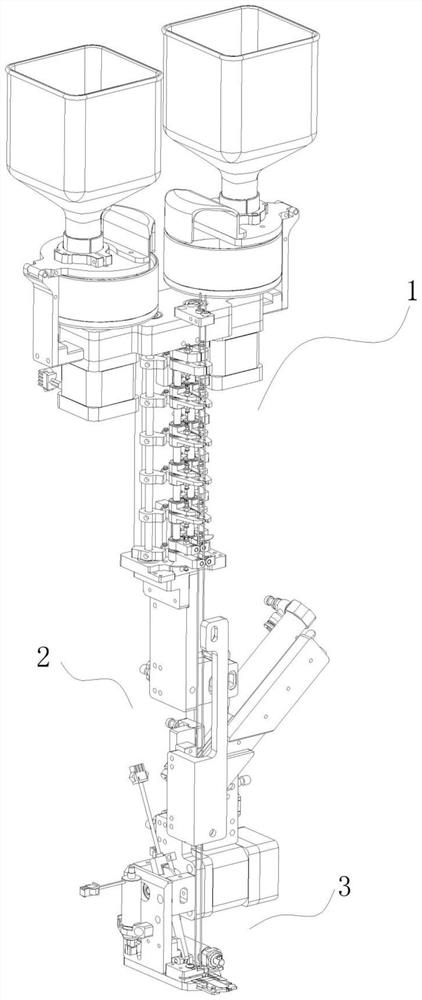

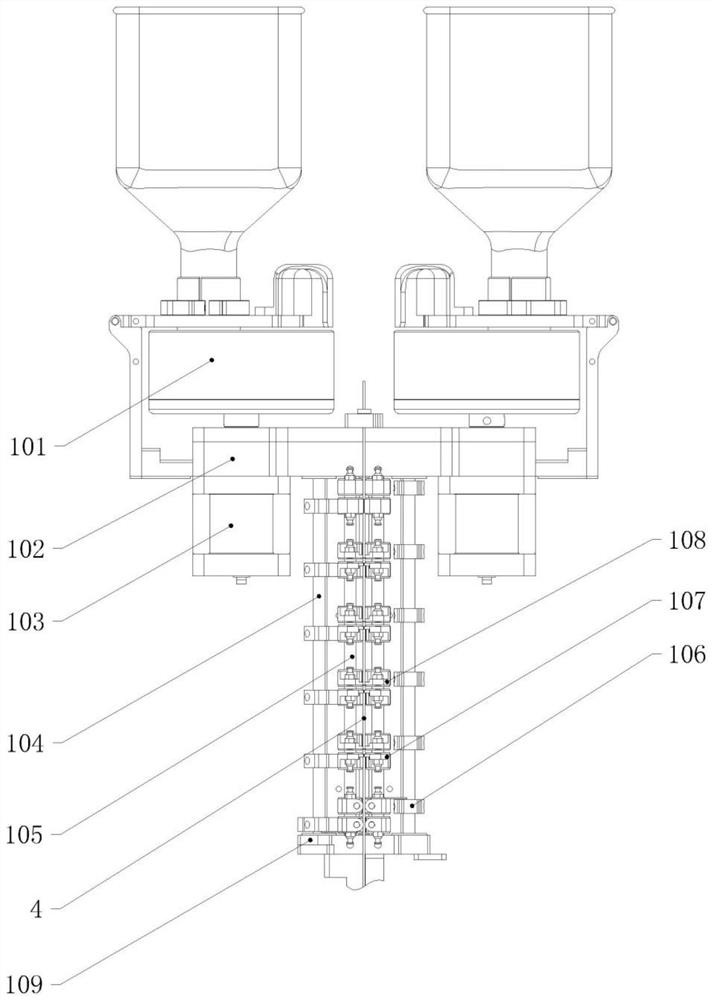

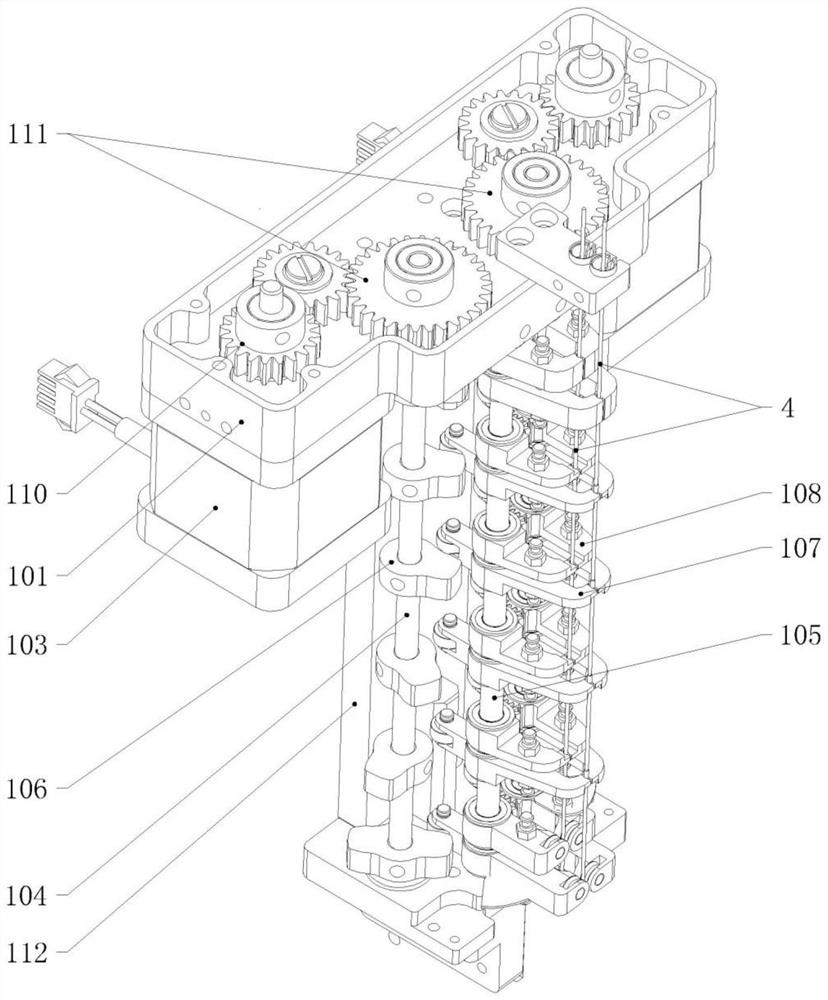

[0026] Example: as attached figure 1 To attach Figure 4 As shown, a two-color bead embroidery device on an embroidery machine includes a feeding assembly 1, a lifting assembly 2, and a bead assembly 3 arranged in sequence from top to bottom. The bead assembly 3 includes a fixedly arranged first base plate 301, the first base plate 301 is provided with a first side plate 302 and a second side plate 305, a bead clip 311 and a pusher 312 are slidably installed on the first bottom plate 301, the bead clip 311 is provided with a bead clamping hole, and the first side plate 302 is installed with a push pusher 312 For the reciprocating swing arm 307, the first bottom plate 301 is fixedly equipped with a guide bead block 308, the guide bead block 308 is provided with a front bead hole 3081 and a rear bead hole 3082, and the bead guide block 308 is equipped with a structure for closing the front bead hole 3081 or The bead lock bar 310 is opened.

[0027] A reciprocating motor 306 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com