Bead feeding mechanism for bead embroidery machine and bead embroidery machine

A technology of bead embroidery machine and embroidery thread, applied in the field of bead embroidery machine, can solve the problem of flying beads, not too big (clamping force is too large, the beads will be crushed, and the embroidery thread will enter the clamping groove and touch the clamping groove. Beads and other problems, to achieve the effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

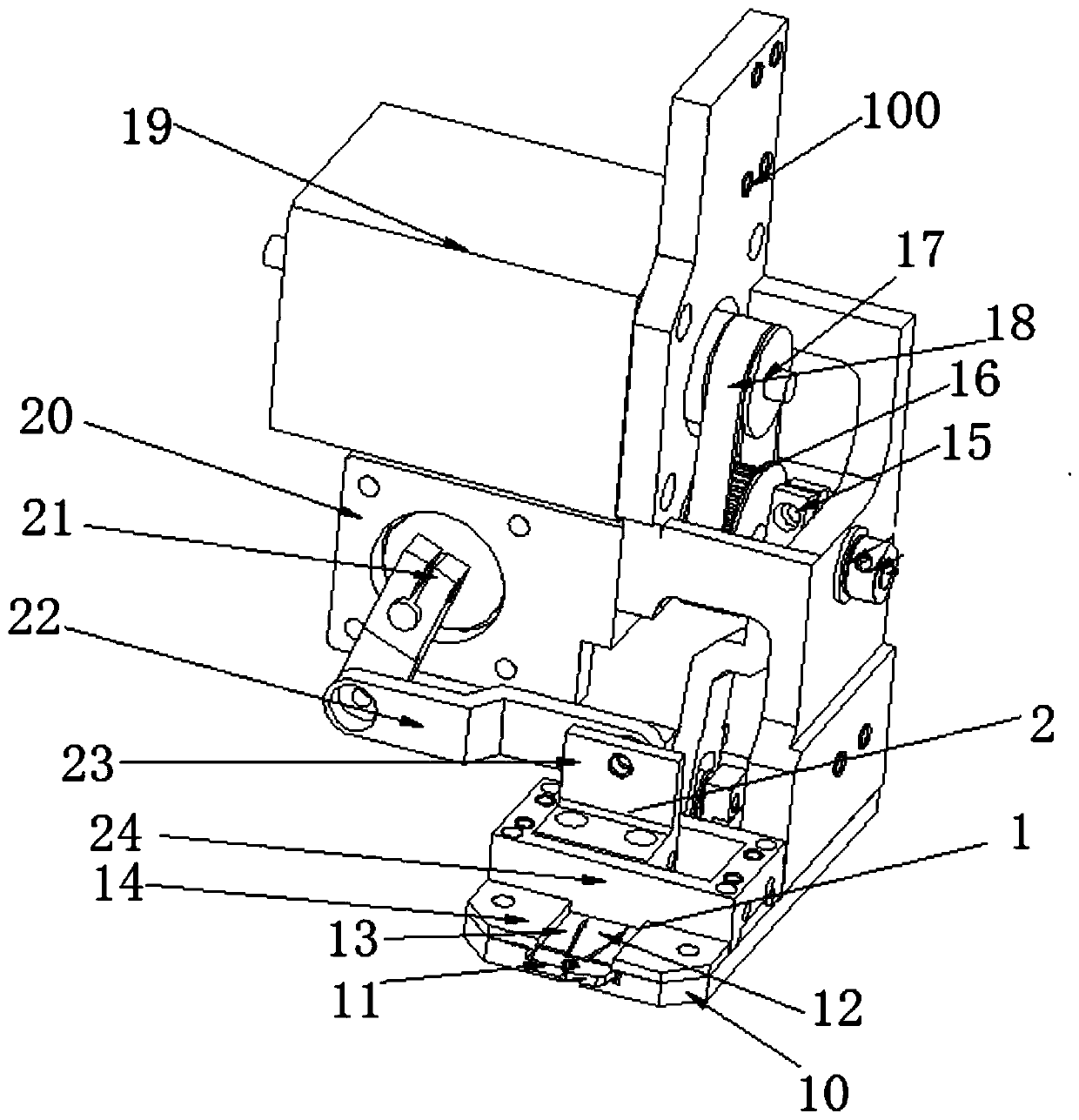

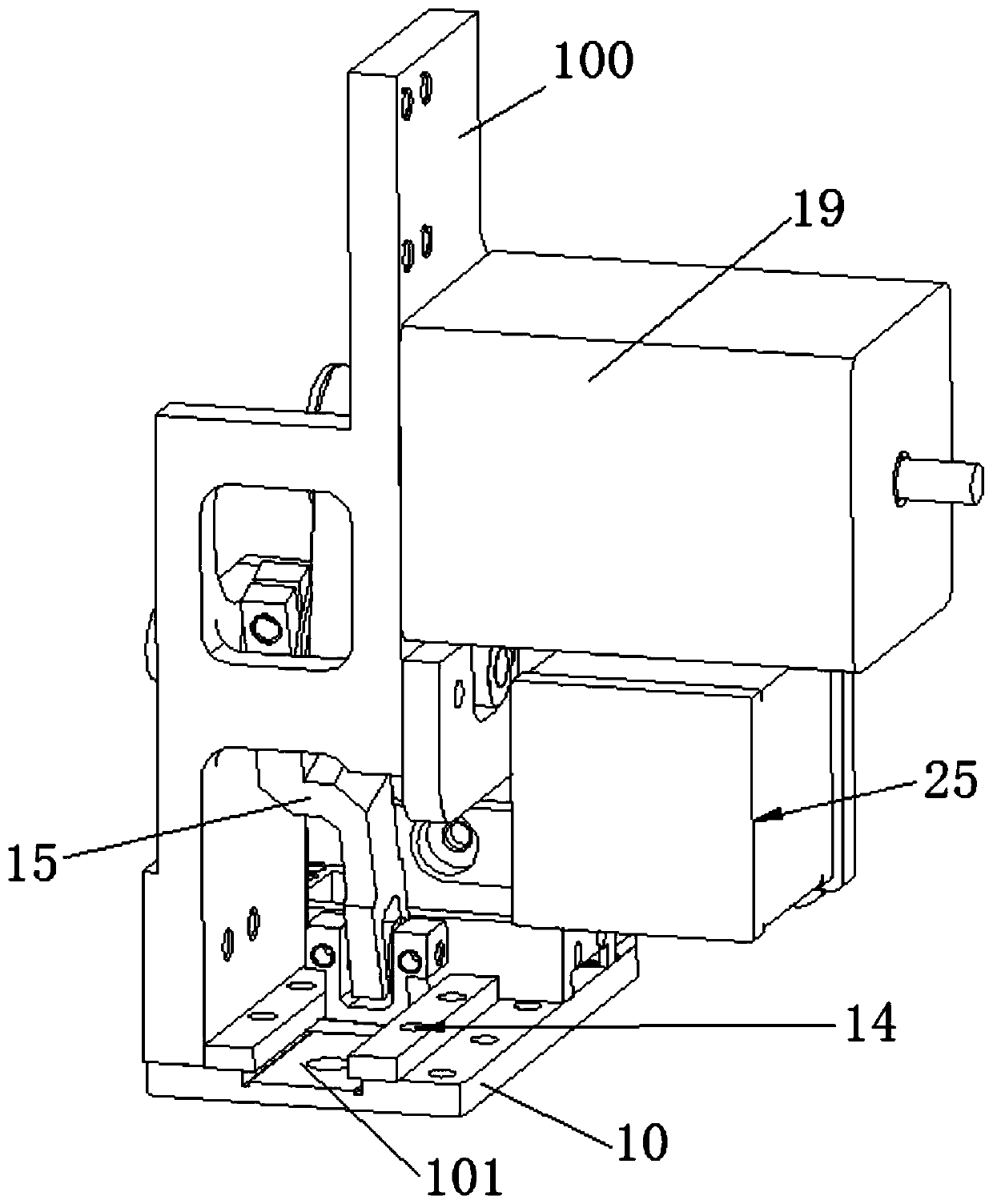

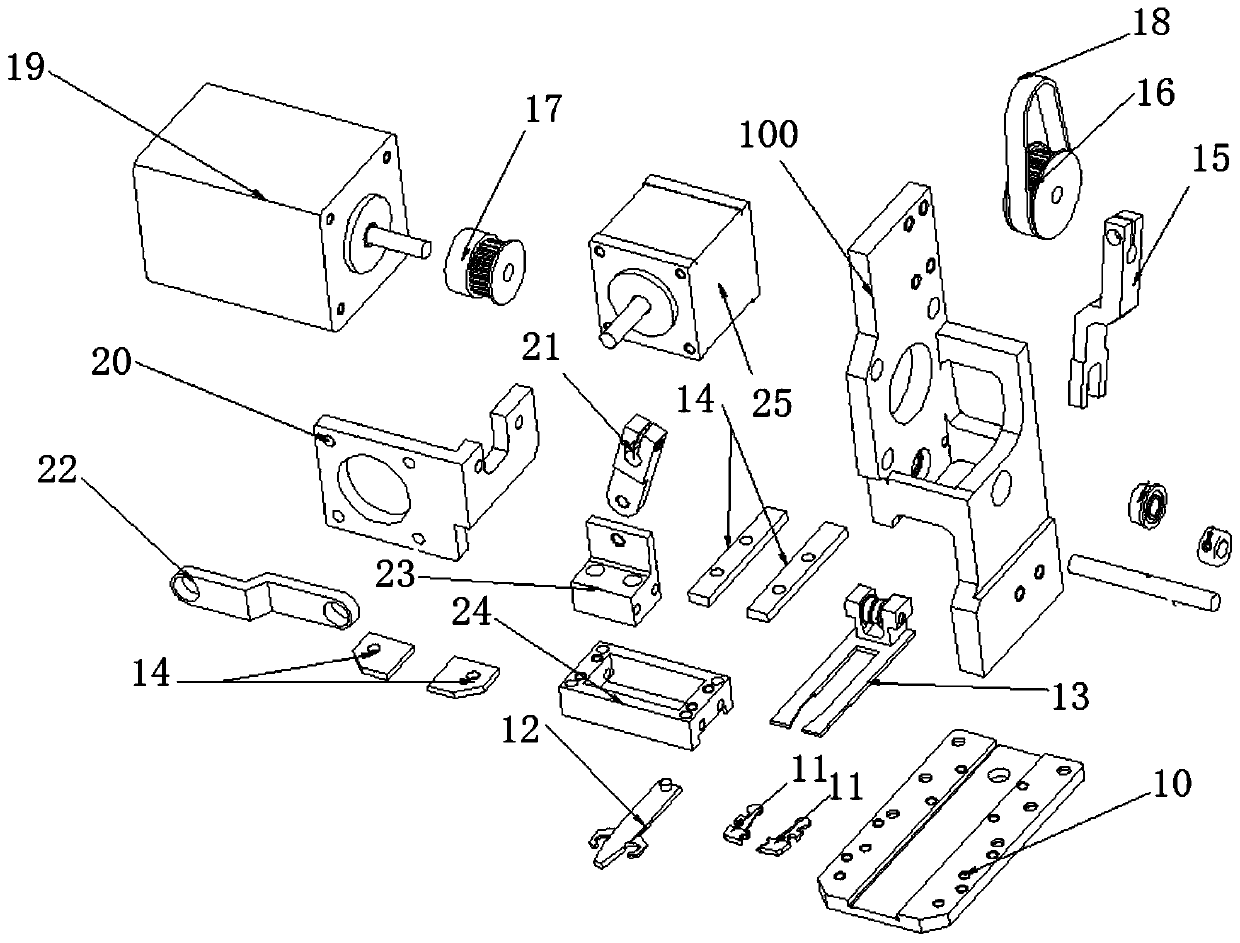

[0036] reference Figure 1 to Figure 6 As shown, the bead feeding mechanism 1 of the bead embroidery machine includes a bottom plate 10 having a ball pushing chute 101, and a ball pusher that slides back and forth along the ball pushing chute. The ball pusher includes two relatively clamped or openable Clip 11, two clips 11 form a ball-pushing clip, the front of the clip is provided with a chuck, the inner side of the chuck is provided with a clamping groove 111 for holding the bead, and the front of the chuck of one of the clips A blocking head 114 extending toward the front side of the chuck of another clip is provided on the side.

[0037] During the embroidery process, when the two clamping pieces 11 are clamped and pushed forward through the clamping groove to clamp the beads, the embroidery thread penetrating the cloth surface moves upwards and approaches the chuck. Due to the blocking of the blocking head 114, the embroidery thread will not pass through. The thread gap ent...

Embodiment 2

[0050] The bead embroidery machine includes the bead feeding mechanism 1 described in the first embodiment.

[0051] In addition, it also includes a bead embroidering color-changing device 2, which includes a color-changing frame 24 provided with a color-changing rail, a color-changing slider 23 that can slide horizontally along the color-changing rail, and a color-changing The color-changing link 22 hinged with the slider, the color-changing pendulum rod 21 hinged with the color-changing link, and the color-changing motor 25 that drives the color-changing pendulum rod to swing, the color-changing motor is installed in the color-changing motor bracket 20, The slider 23 is provided with at least two lower bead holes penetrating up and down, and at least two lower bead holes are arranged side by side. The lower bead hole is used to receive the beads dropped from the upper lower bead steel wire, and fall into the bead pushing clamp clamp of the bead pusher through the lower bead hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com