Rope embroidery machine head

A machine head and rope embroidery technology, applied in the field of rope embroidery machine heads, can solve the problems of large manual workload, uneven cutting of thread ends, easy to cut and break the load, etc., and achieve high trimming quality, neat trimming, and economical embroidery. rope effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

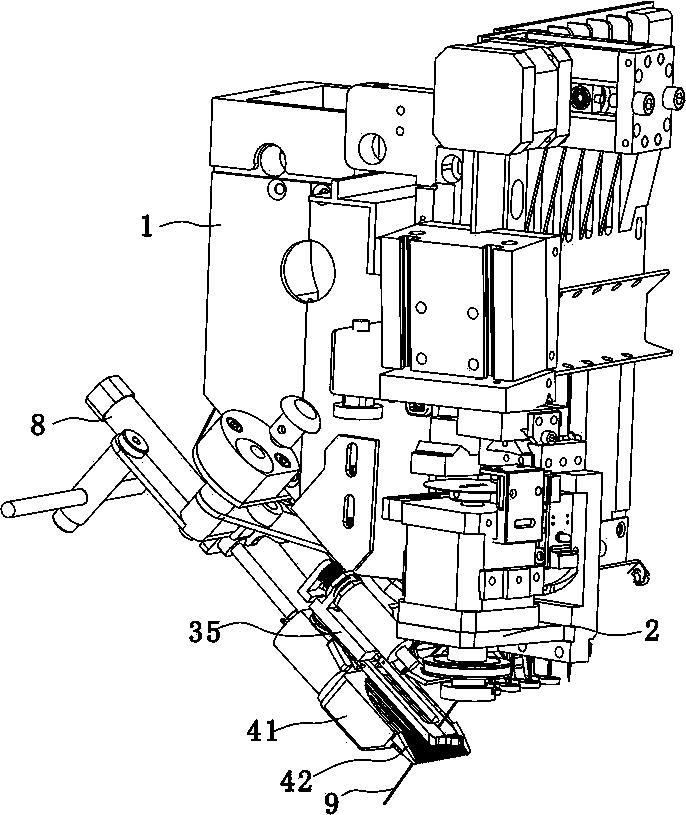

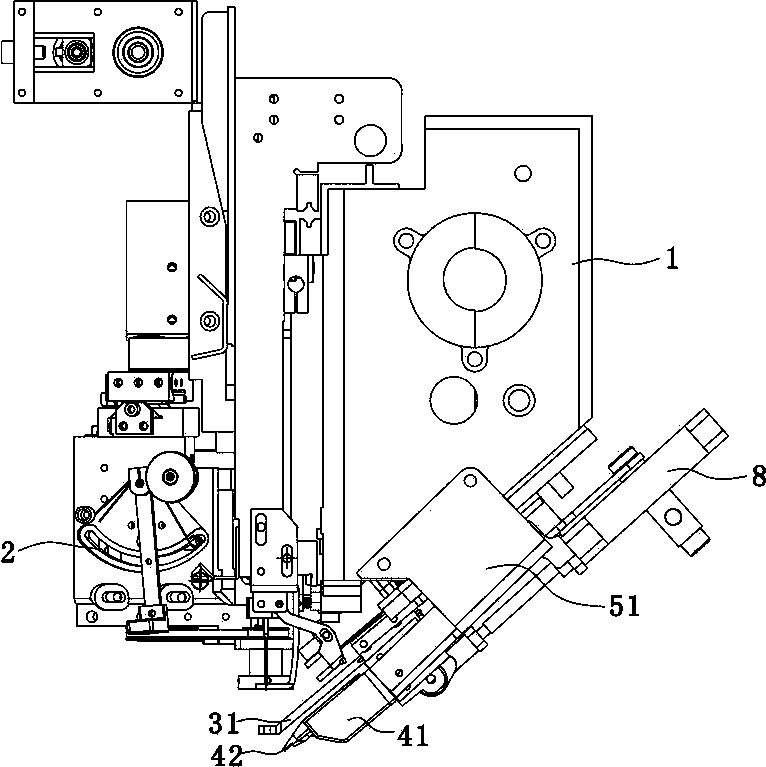

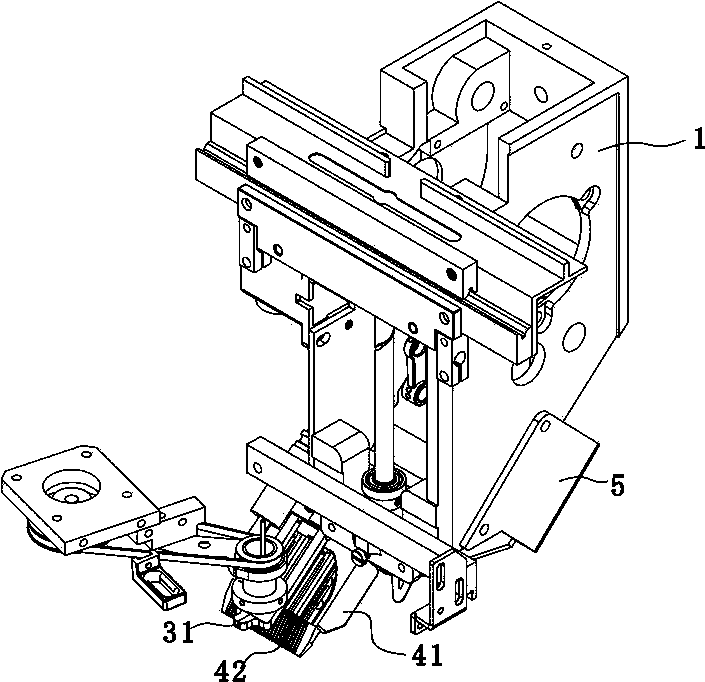

[0022] see Figure 1-8 , this implementation case includes machine head housing 1, rope feeding device 2, control system, the bottom of feeding rope device 2 is located on the output path of embroidery rope 9, and is successively provided with clamping device 3 and cutting device 4 for cutting embroidery rope 9, control The system drives the clamping device 3 and the cutting device 4 to work together, and the command to cut the embroidery rope can be programmed into the program to realize a complete automatic operation when the embroidery machine is corded. The clamping device 3 and the cutting device 4 are fixedly arranged on the lower side of the machine head housing 1 to facilitate the cutting of the corresponding place of the embroidery rope 9 through a bracket. A slide rail 6 and a slide block 7 connected to the scissor head are arranged, and the second driving structure 8 can drive the slide block 7 to drive the scissor head 41 to advance the thread trimming.

[0023] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com