Main drive shaft sharing integrated embroidery machines

A main drive shaft, embroidery machine technology, applied in the field of embroidery machines, can solve the problems of large size, complex embroidery machine structure, reduced installation size, etc., to achieve the effects of simple structure, convenient embroidery, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

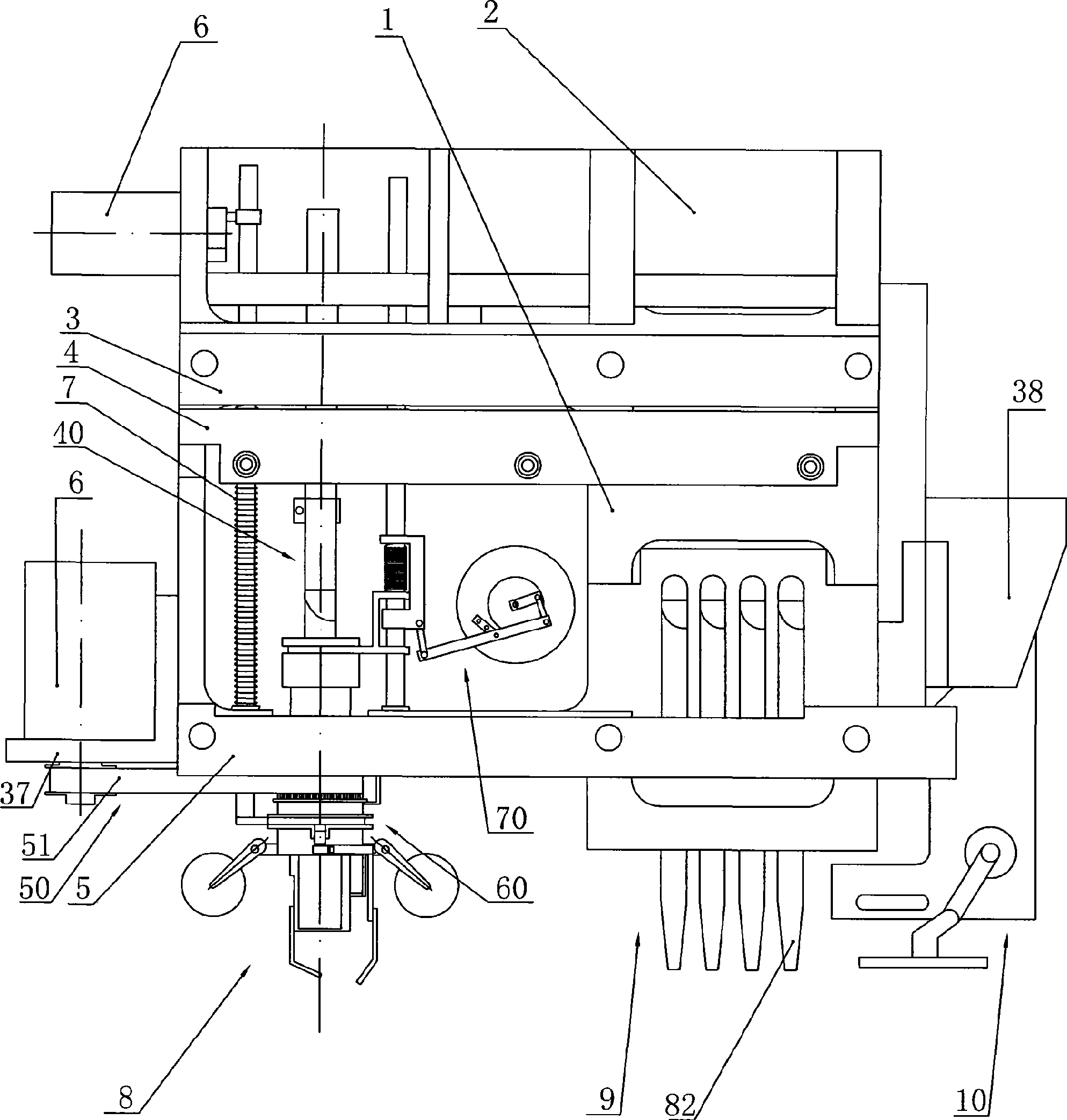

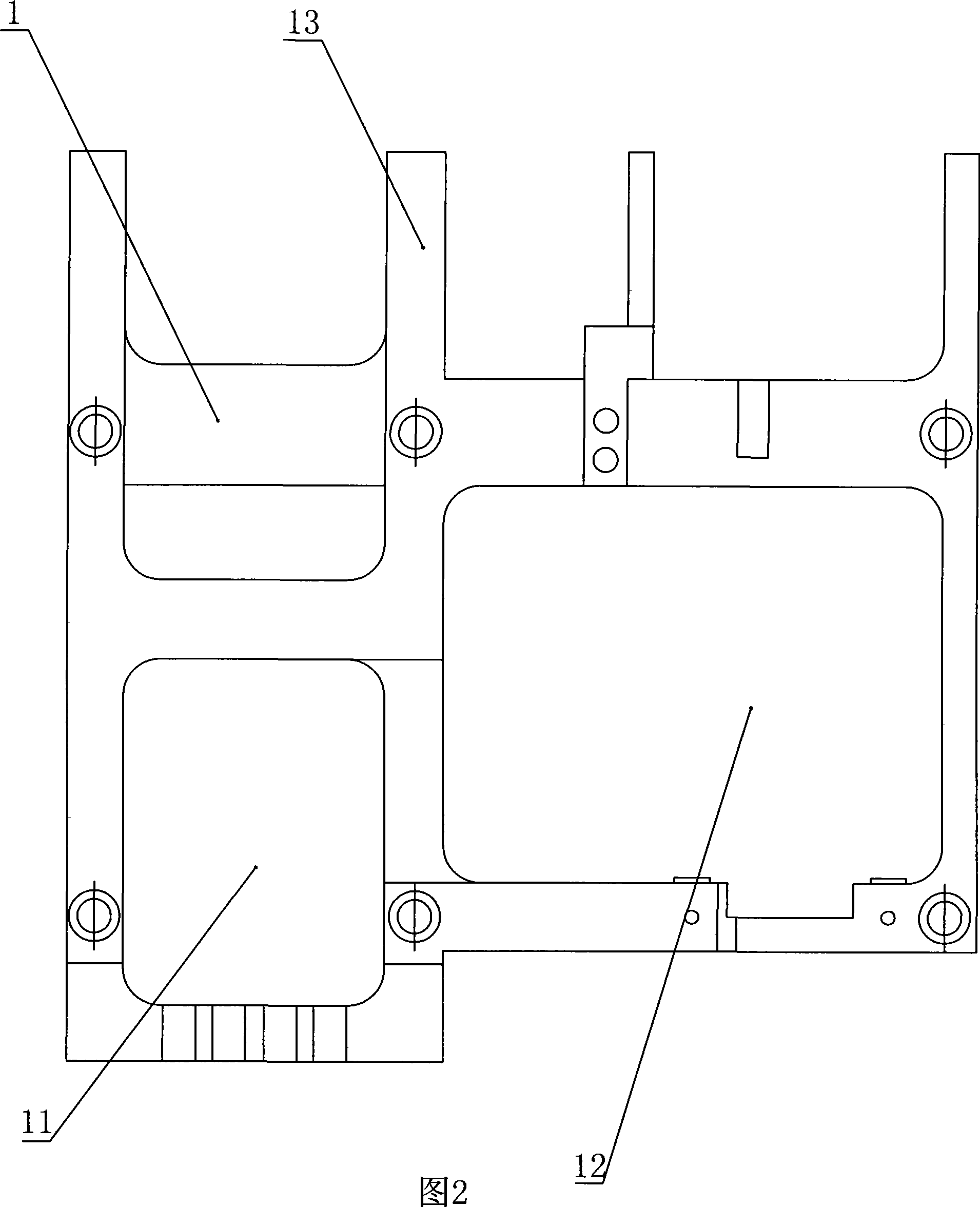

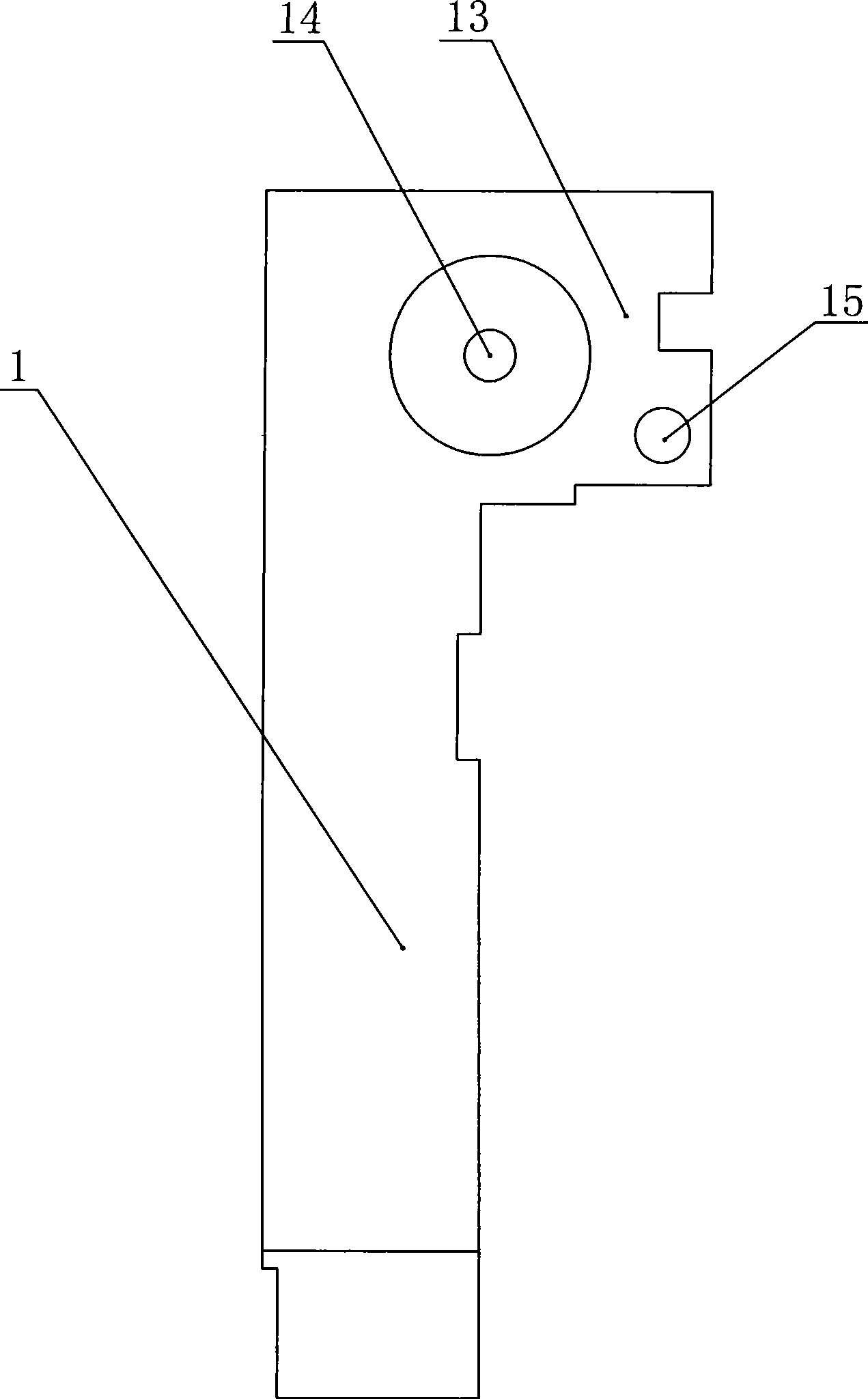

[0033] Embodiment: a kind of main transmission shaft shares the integrated embroidery machine (see attached figure 1 ), including tape embroidery module 8, flat embroidery module 9 and sequin embroidery module 10, which are arranged on the machine base through the transmission seat 23 at the back, and are connected to the main transmission shaft, tape embroidery module, flat embroidery module and sequin embroidery module The three-in-one embroidery module is fixed on the overall frame 1, and the front of the overall frame is covered with a panel 2 (see attached Figure 8 ), the position corresponding to tape embroidery and flat embroidery on the panel is provided with a thread take-up insertion strip 32 equal to the number of needles, and a drive motor hole 33 is also provided at the tape embroidery position, and the overall frame is divided into tape embroidery The mold frame 11 and the flat embroidery mold frame 12, the taping embroidery module includes a tape rotation mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com