Three-gold embroidery side-by-side piece feeding mechanism

A technology for feeding pieces and sequins, which is applied in the field of three-gold embroidery side-by-side piece-feeding mechanism, which can solve the problems of affecting work efficiency, embroidery quality problems, easy blockage of sequins, etc., to improve work efficiency, reduce the number of motors, The effect that is not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

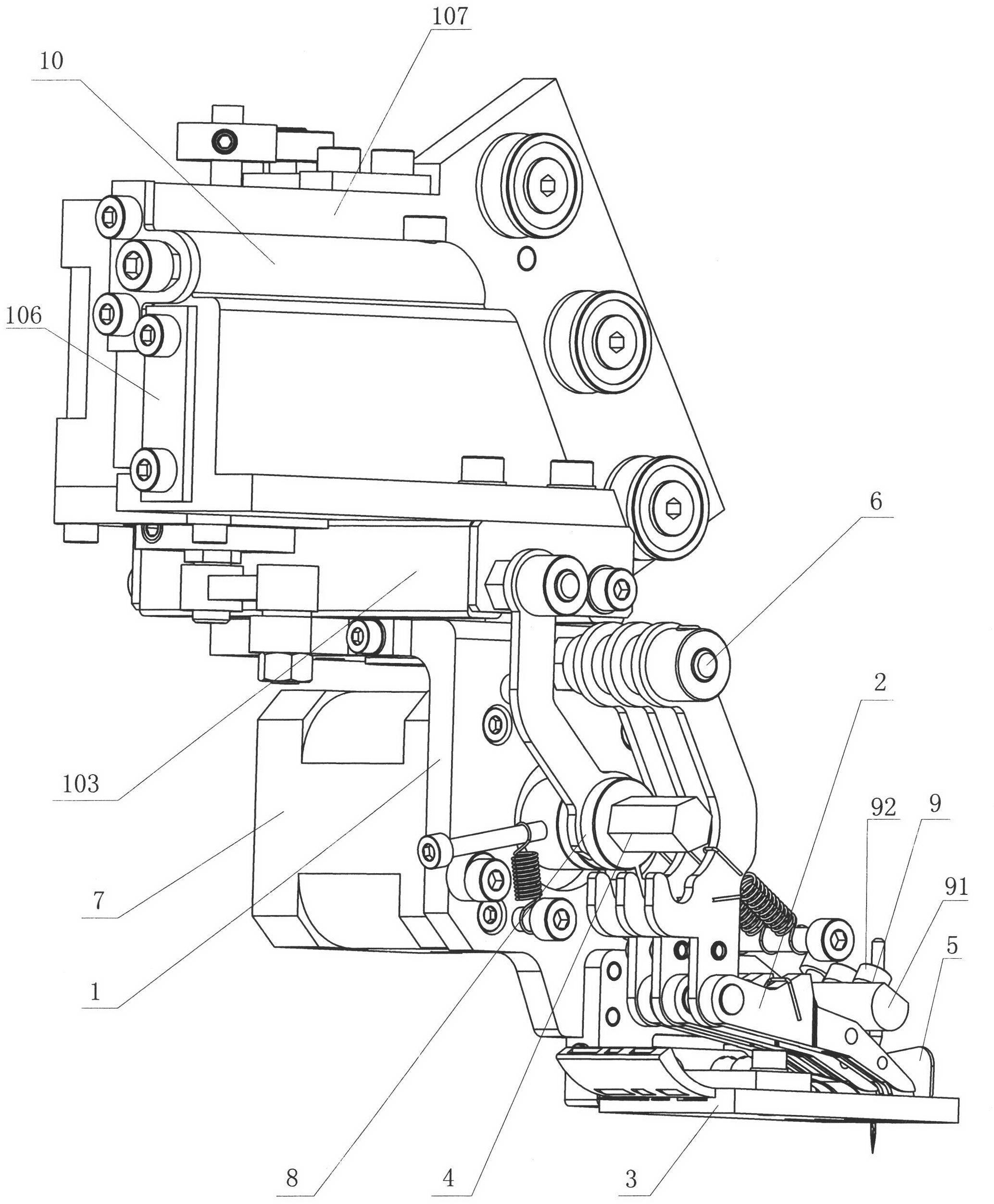

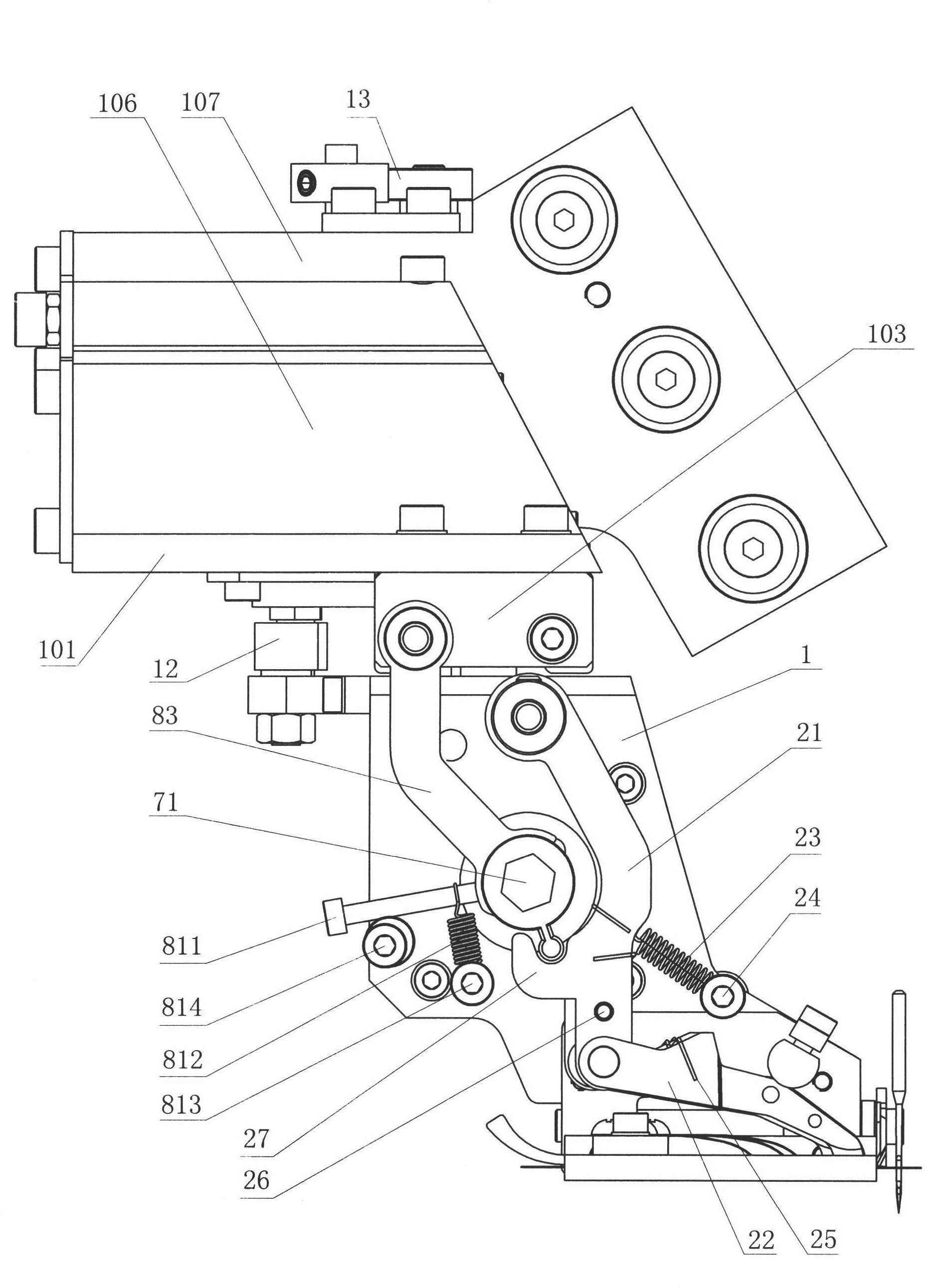

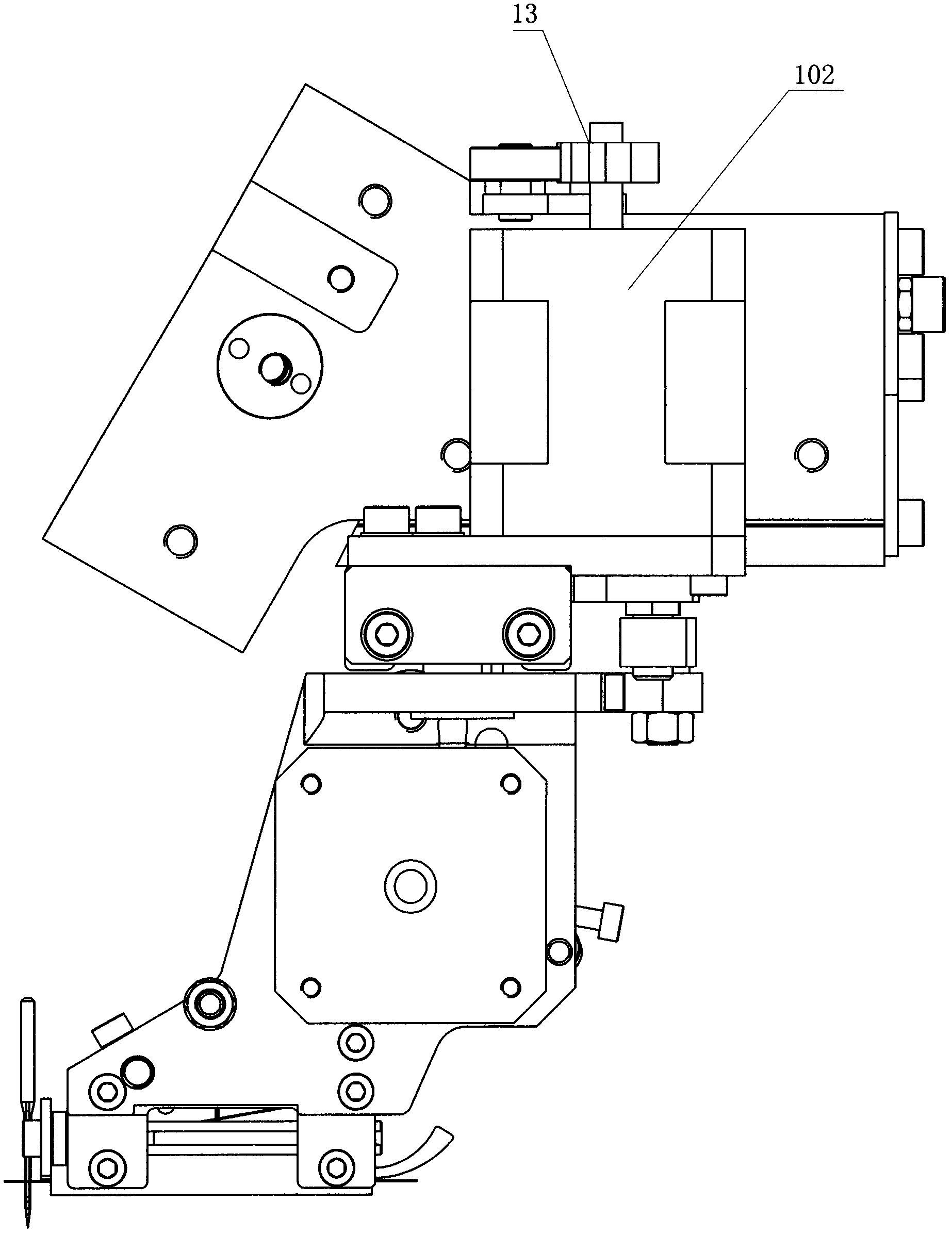

[0035] Depend on Figure 1-20As shown, the embodiment of the three-gold embroidery side-by-side sheet feeding mechanism of the present invention is: including a sheet feeding transposition mechanism 10 that can move in the X and Y axis directions, a sheet feeding machine base 1, and a film feeding machine base 1 There are three film-feeding pusher devices 2, film-feeding slots 3 with three side-by-side film-feeding positions, film-changing device 4 and slicing device 5, and the film-feeding base 1 is fixed on the film-feeding transposition mechanism 10 And move along the X and Y axis directions with the drive, the said film feeding push foot device 2 includes a push arm 21 and a push foot 22 hinged to its lower end, the three film feeding push foot devices 2 and the three film feeding slots 3 The film feeding positions are distributed side by side in one-to-one correspondence. The upper ends of the push arms 21 of the three film feeding pusher devices 2 are hinged in series on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com