Integrated glove machine and production technology thereof

A glove machine and glove technology, applied in the field of knitting machinery, can solve problems such as low work efficiency, non-uniform glove size, cutting and sewing defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

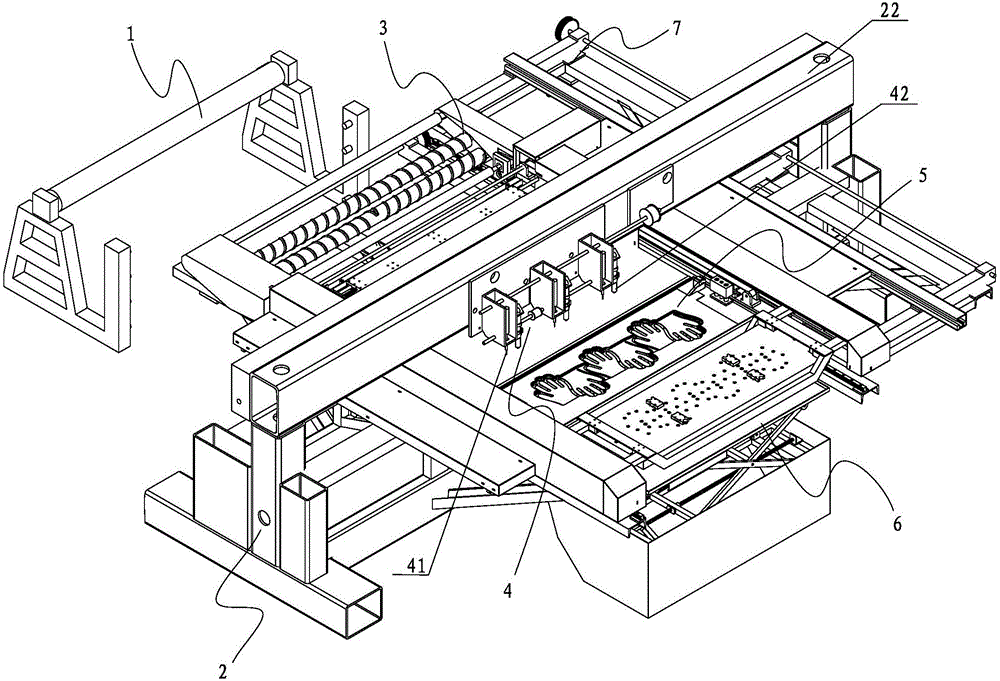

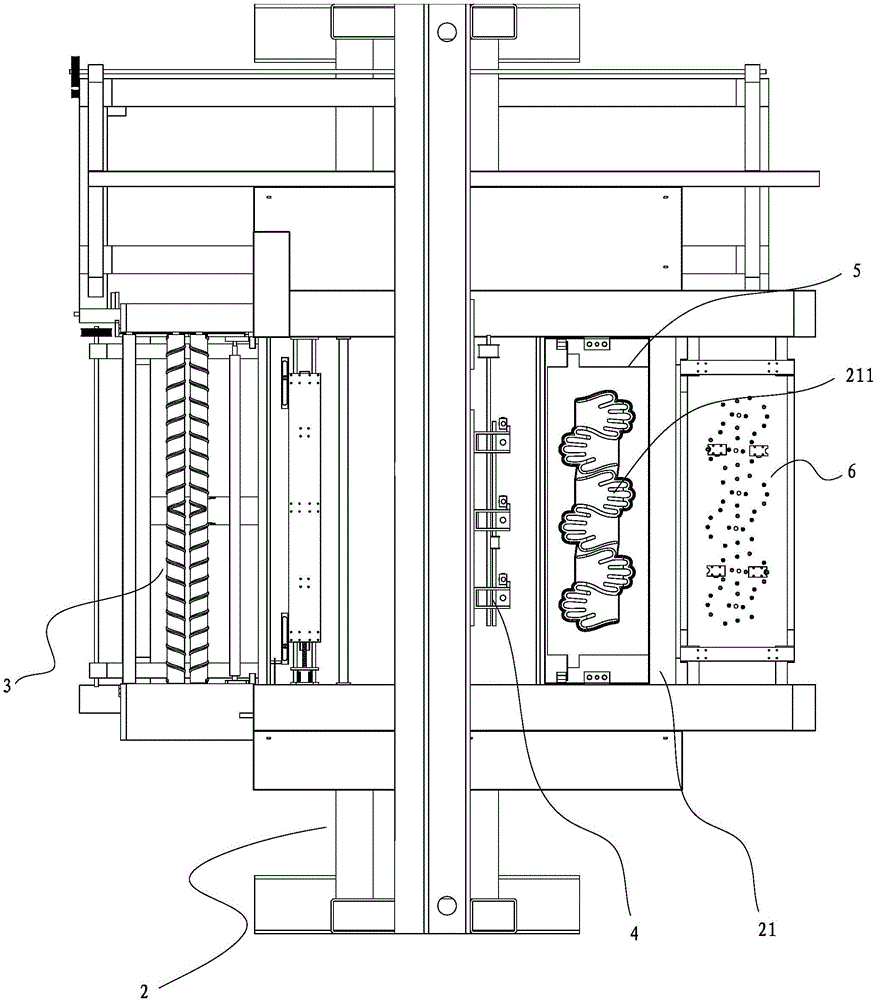

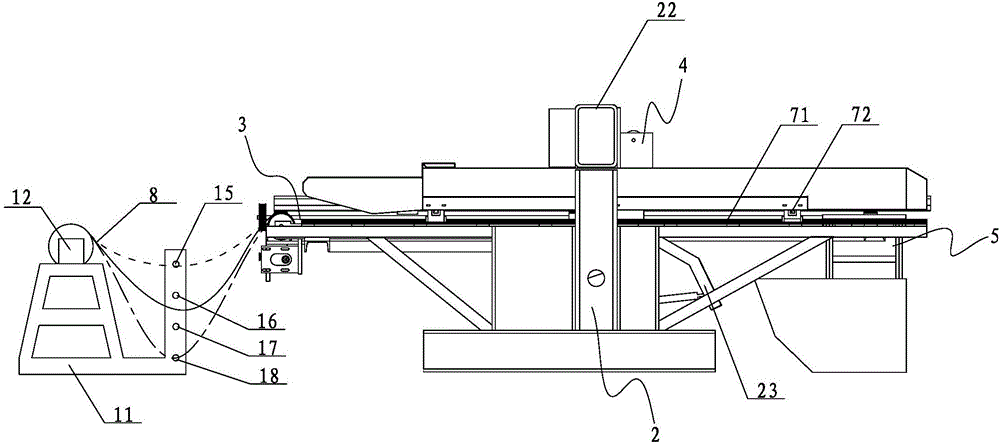

[0047] Such as Figure 1-3 As shown, the integrated glove machine includes a cloth conveying mechanism 1, a machine base 2, and a cloth alignment mechanism 3 arranged on the machine base 2, a cloth embroidery mechanism 4, a cloth grabbing mechanism 5, a glove placing mechanism 6, and a driving mechanism 7. As for the control mechanism used to control the actions of the above-mentioned mechanisms, the control mechanism can be controlled by a computer or an embedded system. The cloth embroidery mechanism 4 includes a plurality of embroidery heads 41 and laser cutting heads 42 (the present embodiment is 3 embroidery heads 41 and 3 laser cutting heads 42), each embroidery head and laser cutting head are fixed Installed on the frame beam 22. The base 2 is provided with a bottom plate 21, and the drive mechanism 7 is connected to the bottom plate 21 for driving the bottom plate 21 to move freely horizontally. The drive mechanism 7 includes an X-axis 71 and a Y-axis 72, and the X-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com