Device for arranging embroidering bead tube for common embroidery machine

An embroidery machine and bead tube technology, applied in the direction of embroidery machine mechanism, embroidery machine, automatic control embroidery machine, etc., can solve the problems of reducing the competitiveness of embroidery fabrics and machine embroidery machinery, sewing bead tubes, and high labor intensity , to achieve the effect of improving grade and viewing, improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

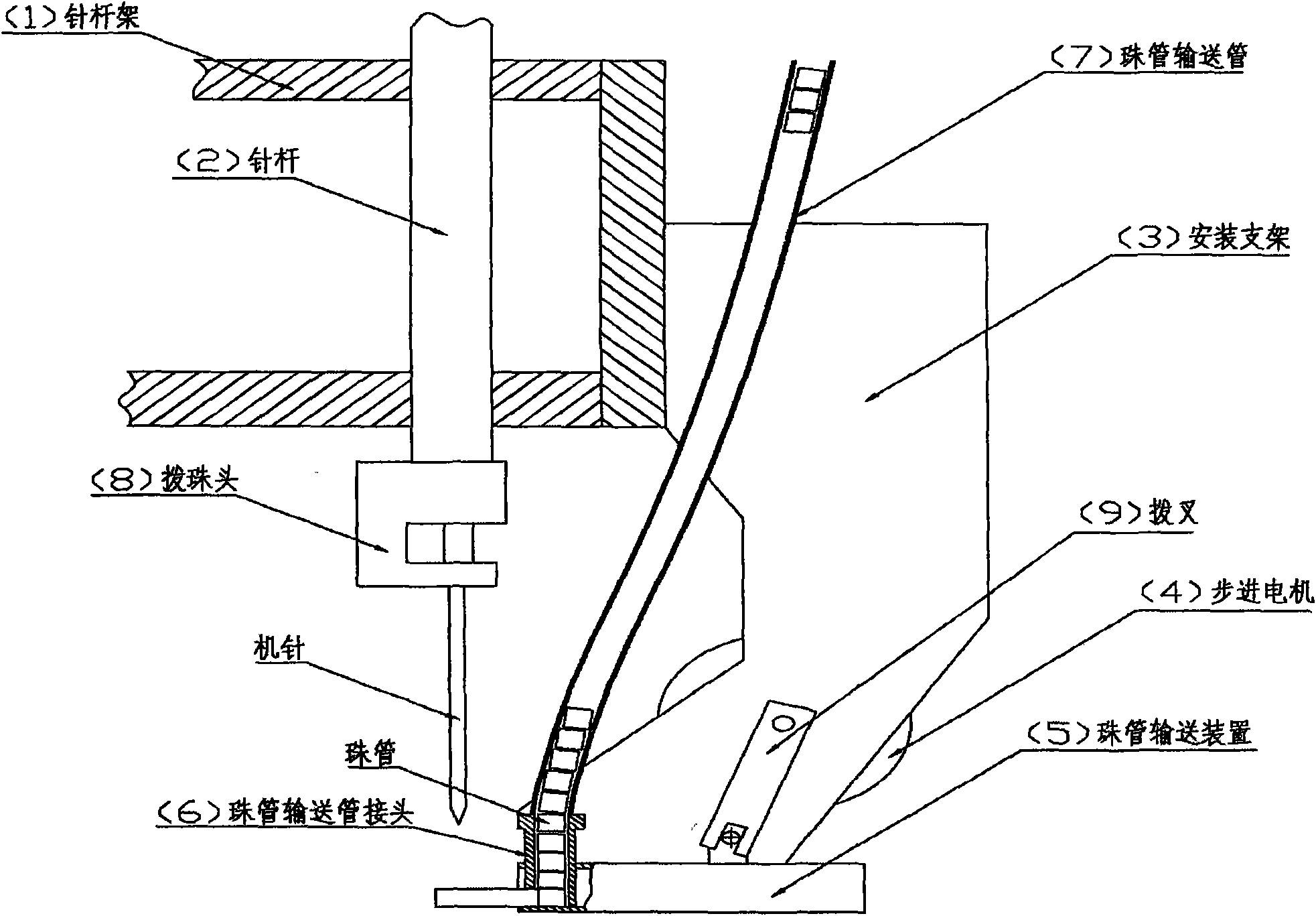

[0015] Embodiment 1: as figure 1 As shown, the ordinary embroidery machine is equipped with a device for embroidery bead tubes, including: needle bar frame 1, needle bar 2, mounting bracket 3, stepping motor 4, bead tube delivery device 5, bead tube delivery pipe joint 6, bead tube Pipe delivery pipe 7, bead dial head and machine needle 8, and shift fork 9, needle bar 2 is installed in the needle bar frame 1, and the side is fixed with the mounting bracket 3, and the stepping motor 4 is fixed in the middle of the mounting bracket 3, The bead tube delivery device 5 is fixed on the lower part of the mounting bracket 3, the bead tube delivery device 5 is movably connected with the stepper motor 4 through a shift fork 9, the bead tube delivery pipe joint 6 is mounted on the front plane of the bead tube delivery device 5, and the bead tube delivery device 5 is mounted on the front plane of the bead tube delivery device 5. The pipe conveying pipe 7 is connected with the bead pipe co...

Embodiment 2

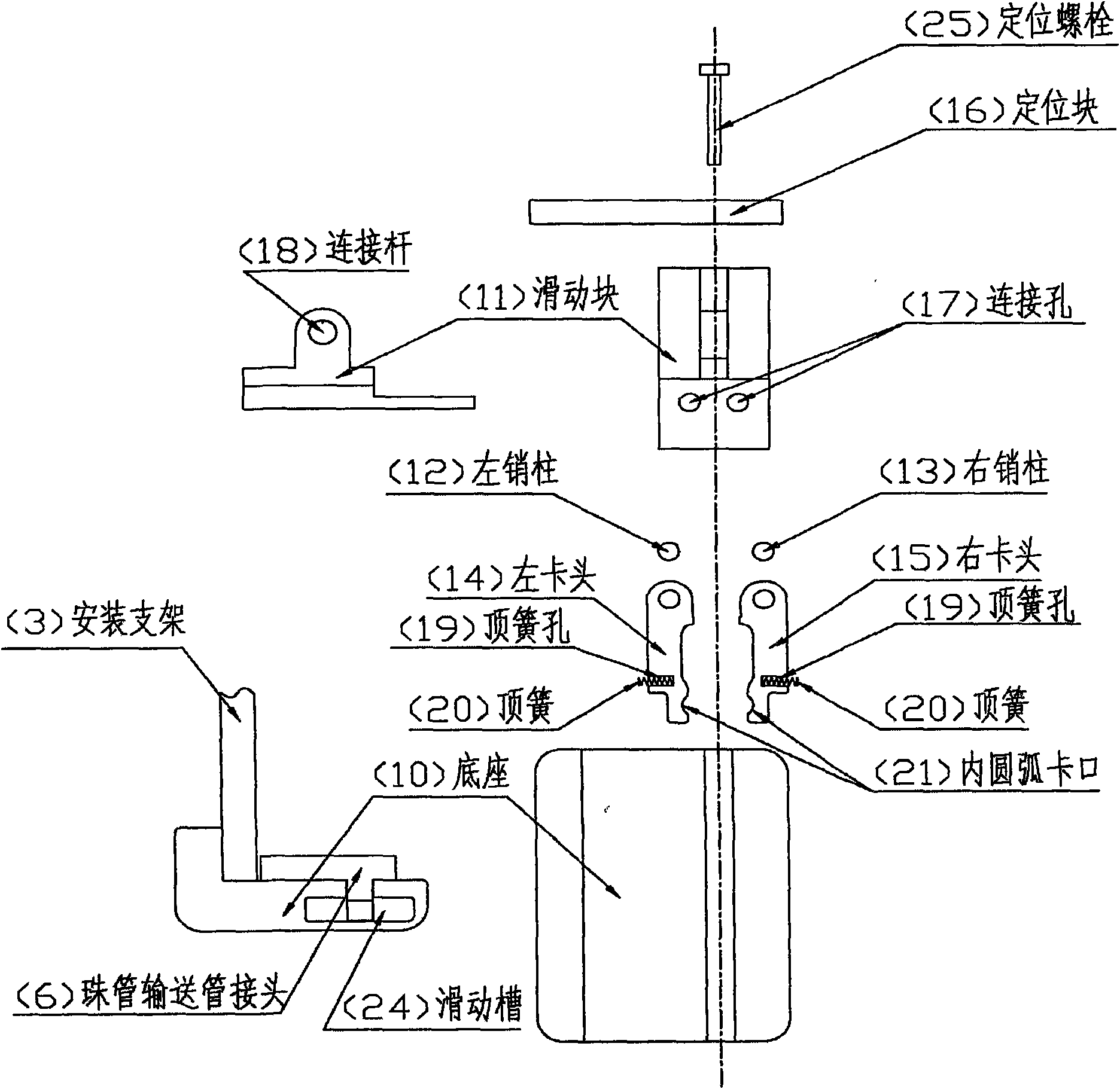

[0016] Embodiment 2: as figure 1 and figure 2 As shown, the ordinary embroidery machine is equipped with a bead tube conveying device for embroidery bead tubes, including: a base 10, a sliding block 11, a left pin 12, a right pin 13, a left clamping head 14, a right clamping head 15, positioning Block 16, sliding groove 24 and positioning bolt 25, sliding block 11, left pin 12, right pin 13, left chuck 14 and right chuck 15 are all assembled in sliding groove 24, left chuck 14 and right chuck 15 is movably connected with the connecting hole 17 located at the front of the sliding block 11 through the left pin 12 and the right pin 13, the positioning block 16 is fixed on the rear end of the base 10, the positioning bolt 25 is fixed in the positioning block 16, and the sliding block 11 The upper part is fixed with a connecting rod 18 that is movably connected with the fork 9. The contact point between the front end and the backstop bead position 22 of the bead pipe delivery pip...

Embodiment 3

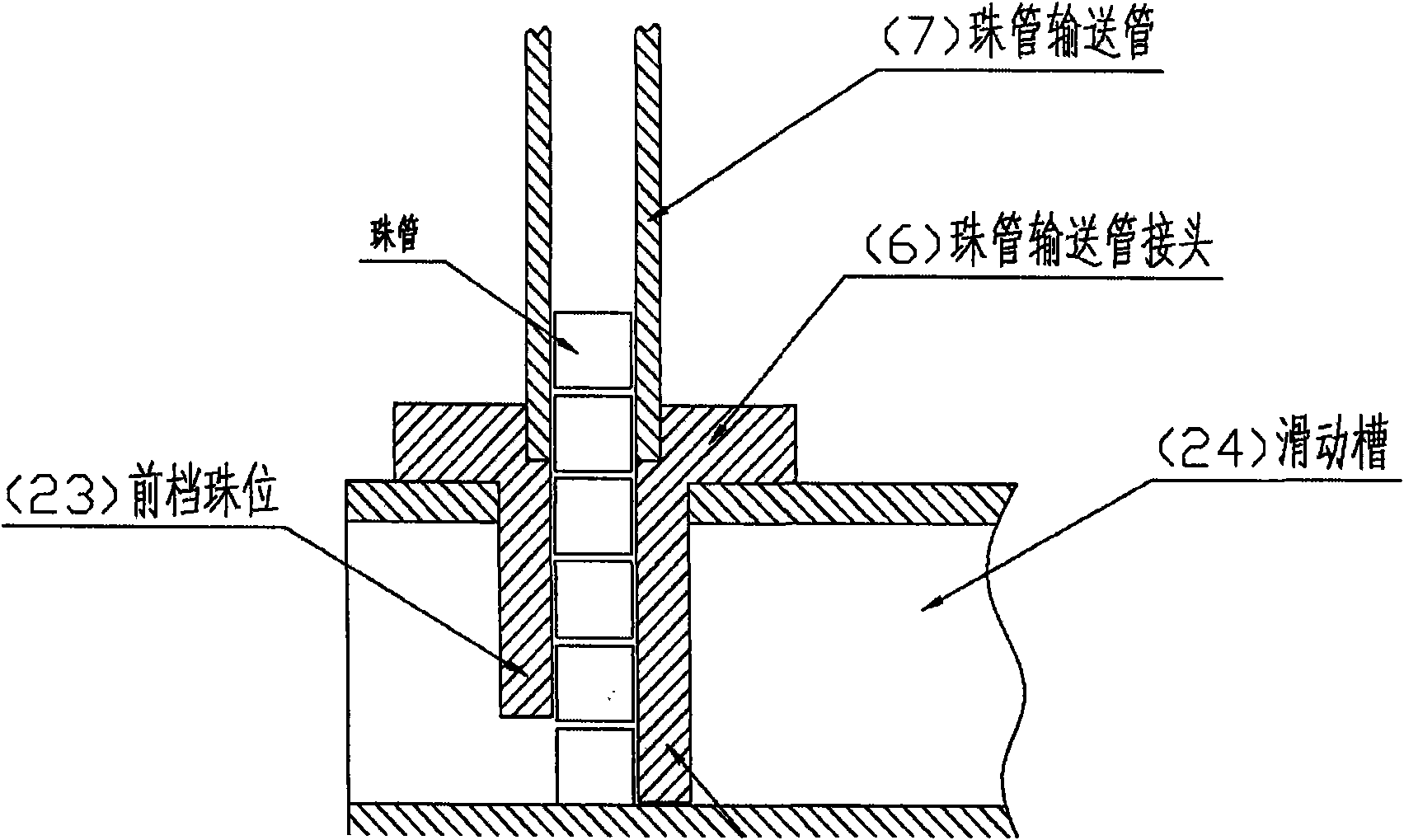

[0017] Embodiment 3: as figure 1 , figure 2 and image 3 As shown, the common embroidery machine is equipped with the bead pipe delivery pipe joint and the bead pipe delivery pipe of the bead pipe embroidery device, including: a backstop bead position arranged on the rear side of the lower part of the bead pipe delivery pipe joint 6 to prevent the bead pipe from retreating 22. The front stop bead position 23 on the front side of the lower part to prevent the bead tube from falling forward. The bottom plane of the groove contacts, and the end face of the front retaining bead position and the bottom plane of the slide groove have a gap slightly higher than the height of a single bead tube, and the bead tube delivery pipe 7 is a spring type delivery tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com