An online magnetic threading machine

A technology of magnetic penetration and manipulator, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low productivity, unstable quality, and difficult magnetic strips, and achieve the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

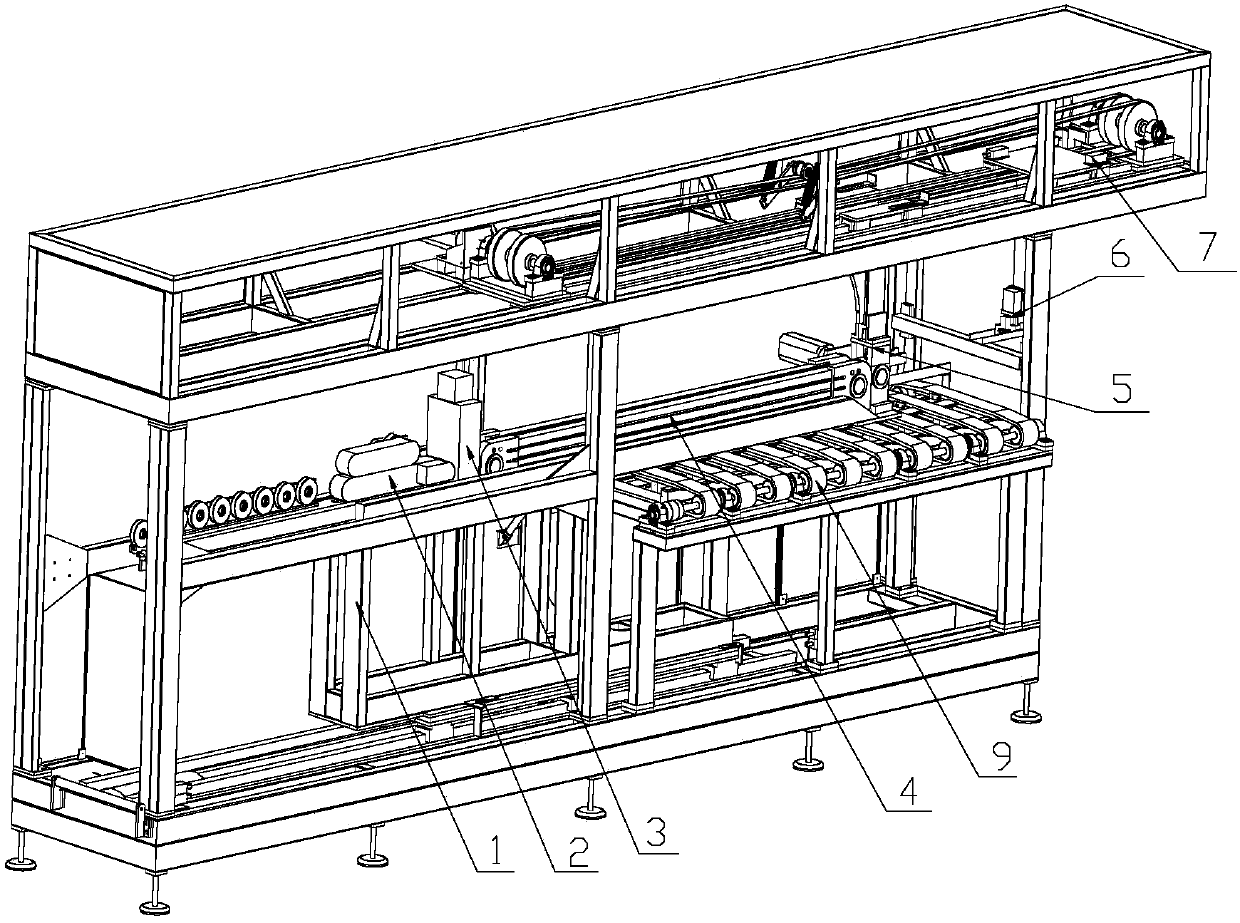

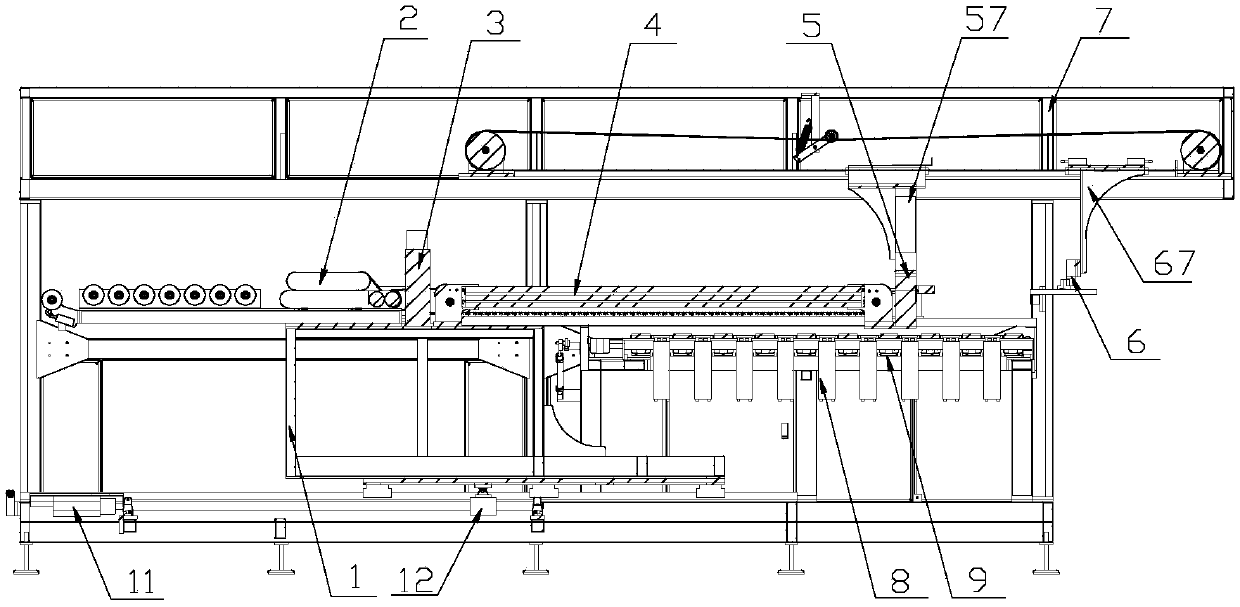

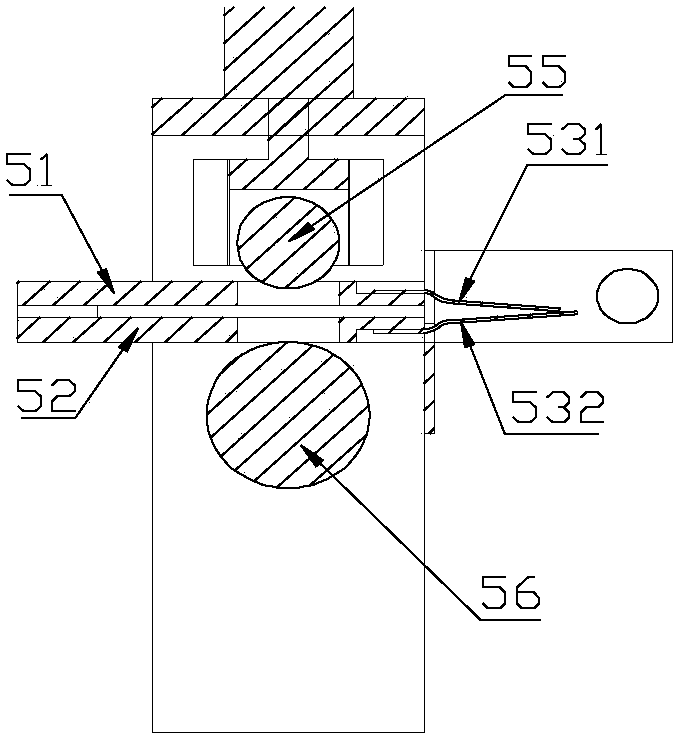

[0026] like figure 1 and figure 2 As shown, an online magnetic threading machine includes a support 1 and a magnetic strip tractor 2, a magnetic strip trimming machine 3, a conveying mechanism 4, and a magnetic threading guide 5 sequentially located on the support 1. The online magnetic threading machine also includes a manipulator 6. The fixed frame 7, at least one support cylinder 8 and at least one conveyor belt 9, the preferred support cylinder 8 in this embodiment is 9, the conveyor belt 9 is 9, and the manipulator 6 is used to clamp the sealing strip, The shape of the inner side of the manipulator 6 is the same as that of the sealing strip, which increases the stressed area of the sealing strip during clamping, ensures that the sealing strip is not deformed, and is convenient for the penetration of the magnetic strip. The fixed frame 7 is positioned above the magnetic guide machine 5 and the manipulator 6, and the fixed frame 7 includes a guide rail, a synchronous be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com