Reset device for metal pipe surface damage recession

A surface damage and reset device technology, which is applied to positioning devices, feeding devices, storage devices, etc., can solve problems that affect project quality, unsuitable curved metal pipes, hidden safety hazards for construction personnel, etc., and achieve the effect of ensuring repair accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

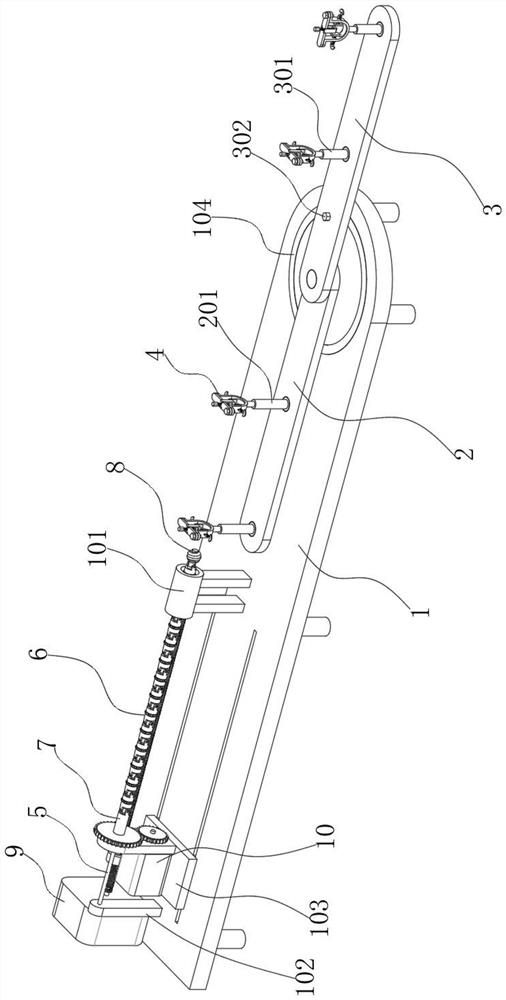

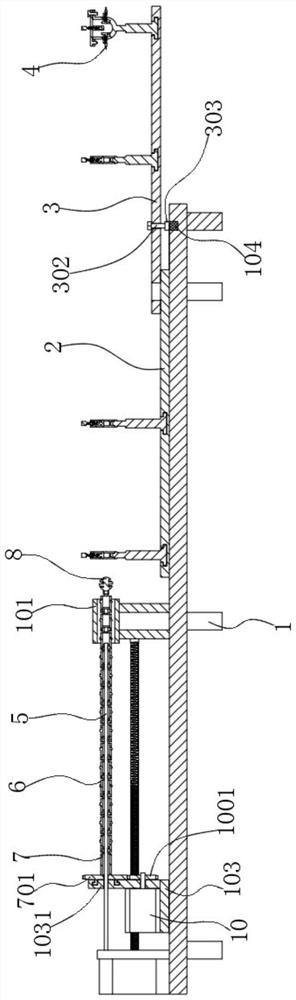

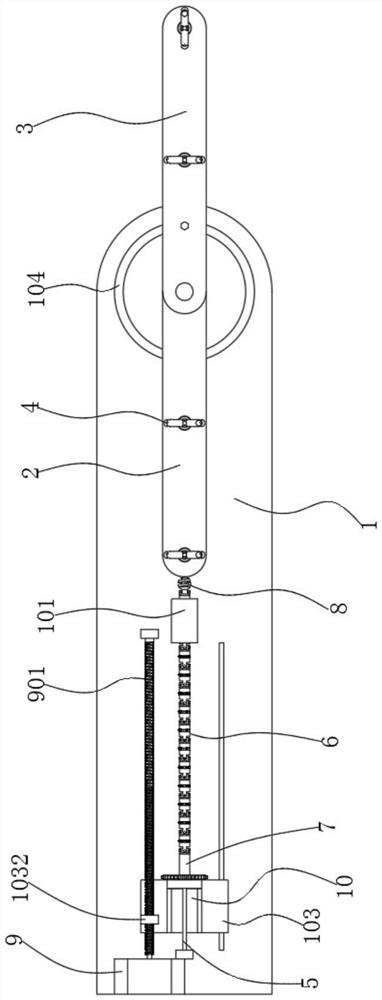

[0044] For the reset of the linear metal pipe wall depression, the metal pipe is first clamped by the cooperation of the main pallet 2 and the auxiliary pallet 3, and the telescopic height of the main telescopic rod 201 and the side telescopic rod 301 is adjusted to ensure that the main pallet 2 and the The pipe fitting fixing seat 4 on the supporting plate 3 is on the same horizontal straight line; the top plate 401 at the top of the pipe fitting fixing seat 4 is removed, the metal pipe is put into the inner bottom of the pipe fitting fixing seat 4, and the metal pipe is supported by the support bar 402, Then by tightening the limit bolt 4031, the two side clamping bars 403 are clamped on both sides of the metal pipe to assist the positioning of the metal pipe, and then the top plate 401 is put on, fixed by the fastening bolt, and the compression bolt 4011 is tightened. Compress the pressing frame 404 by pressing the bolt 4011, so that the pressing frame 404 can press the top ...

Embodiment 2

[0046] For the reset of the curved metal pipe wall depression, first place one end of the metal pipe through the pipe fixing seat 4 on the main supporting plate 2, so that the end of the metal pipe is aligned with the guide sleeve 101 to ensure that it slides out from the guide sleeve 101 The reset extrusion head 8 can just enter the metal pipe; adjust the height of the two main telescopic rods 201 so that the two pipe fitting holders 4 on the main pallet 2 are flush, remove the top plate 401 at the top of the pipe fitting holder 4, and place the Put the metal pipe into the inner bottom of the pipe fitting holder 4, put it into one end of the metal pipe, and then turn the supporting plate 3 so that the other end of the metal pipe is put into the pipe fitting fixing seat 4 on the attaching plate 3, and tighten the anti-skid bolt 302, carrying out the fixation of the supporting plate 3; carrying out the support of the metal pipe through the support bar 402, and then tightening th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com