Ball mounting device for combination module of transmission belt

A technology of conveyor belts and installers, applied in the directions of transportation and packaging, conveyors, hand-held tools, etc., can solve the problem that the ball installation efficiency of the combined module cannot be improved, and achieve the effect of improving the installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

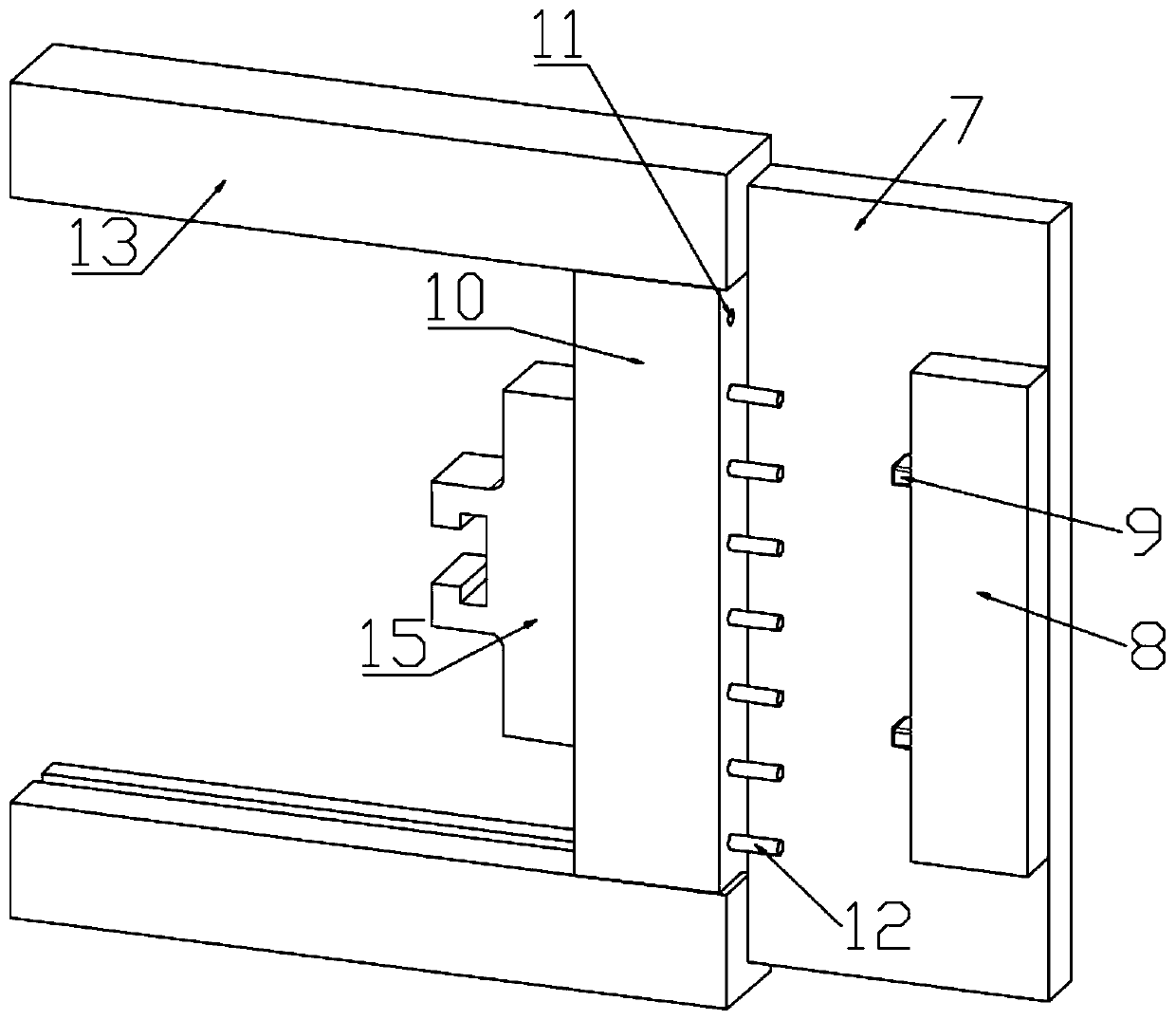

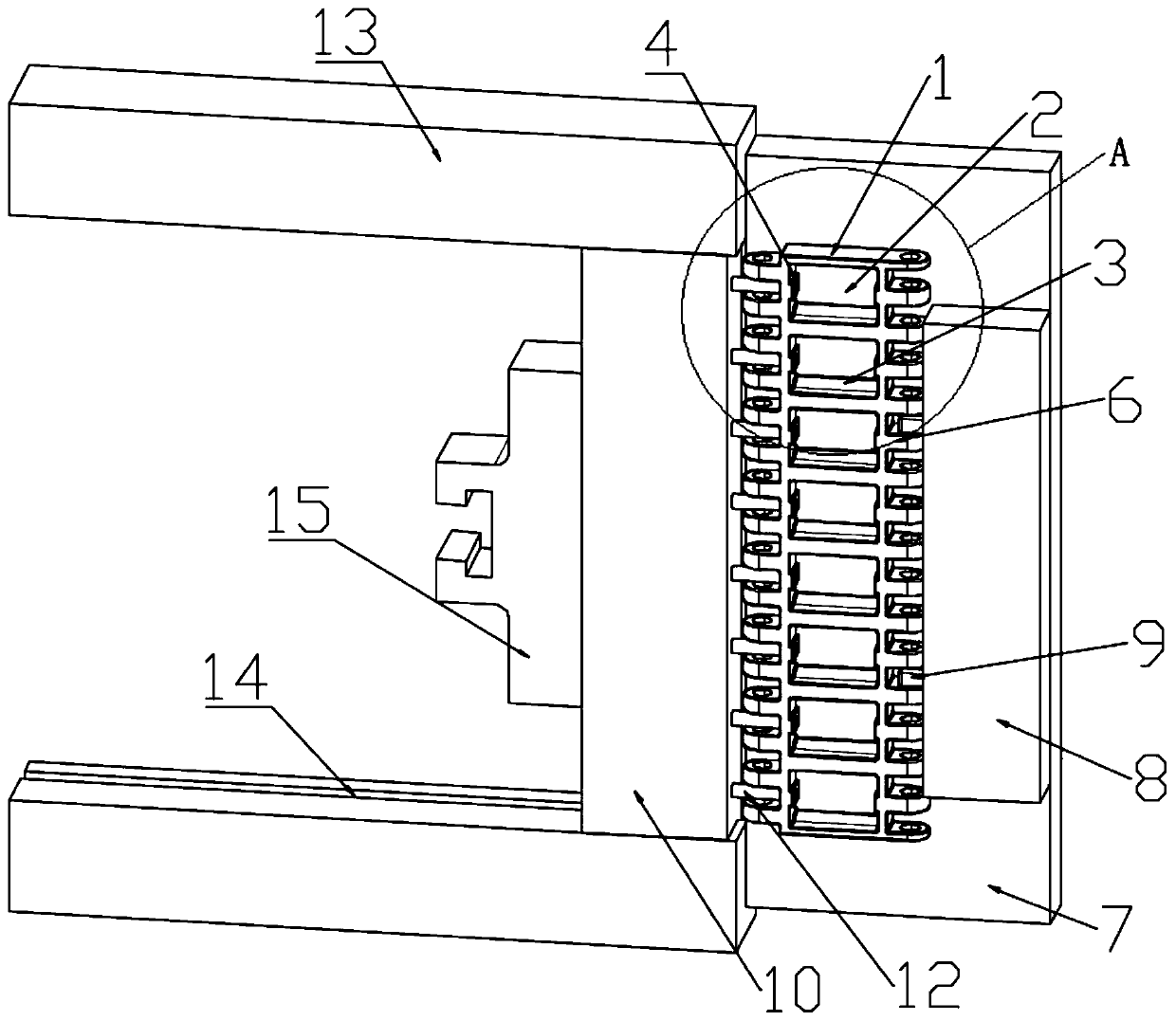

[0028] A ball installer for a combination module of a transmission belt is used to fix several balls in the combination module 1 at one time, which can effectively improve the installation efficiency of the balls.

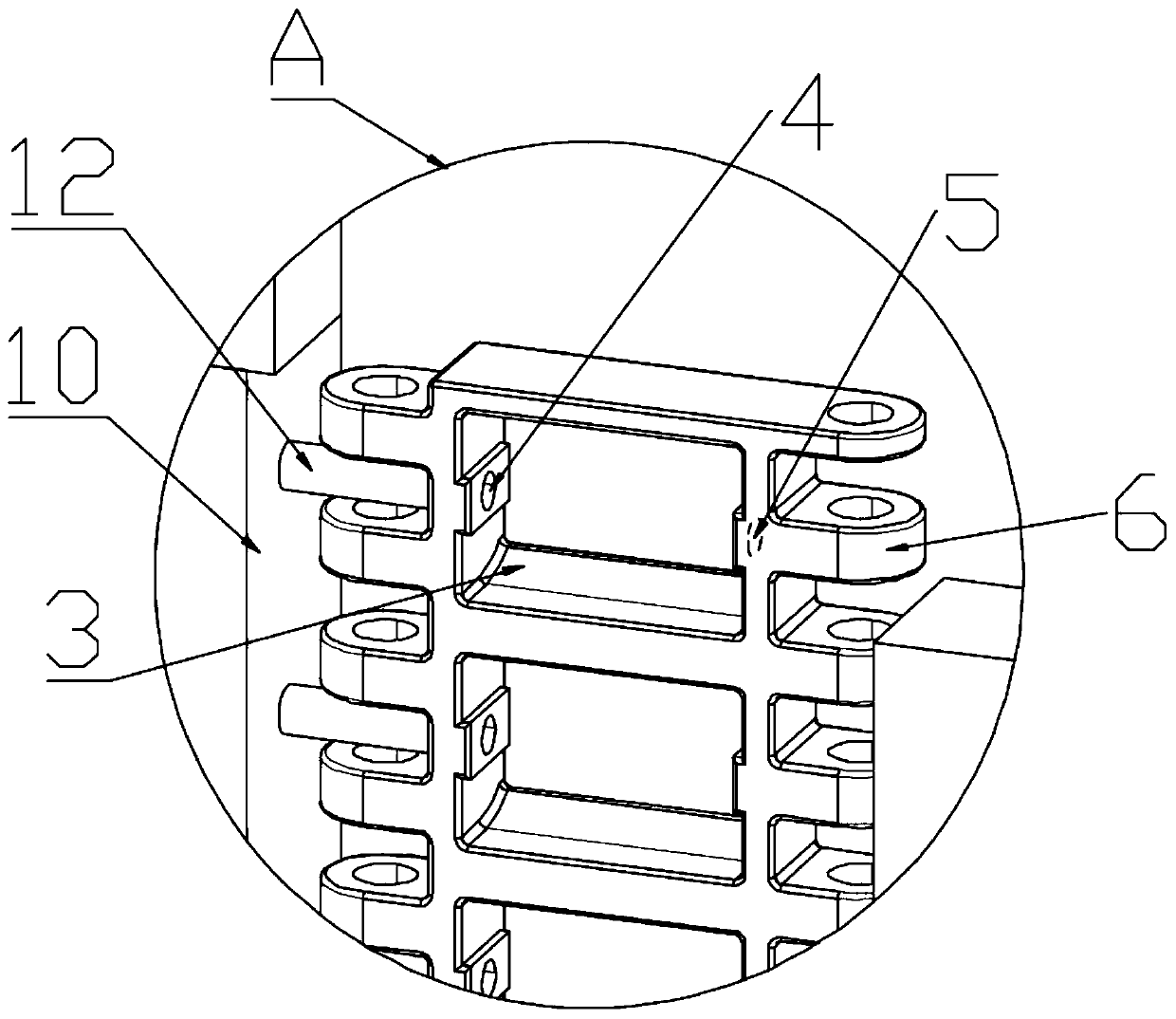

[0029] Such as Figure 1~3 As shown, the combined module 1 is provided with several ball frames 2, and each ball frame 2 can be assembled with a ball correspondingly. And the edge of the inner bottom of the ball frame 2 is provided with a limit block 3, the outer contour of the limit block 3 coincides with the outer contour of the ball, so that the width of the bottom of the ball frame 2 is smaller than the width of the top of the ball fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com