Patents

Literature

30results about How to "Realize automatic threading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

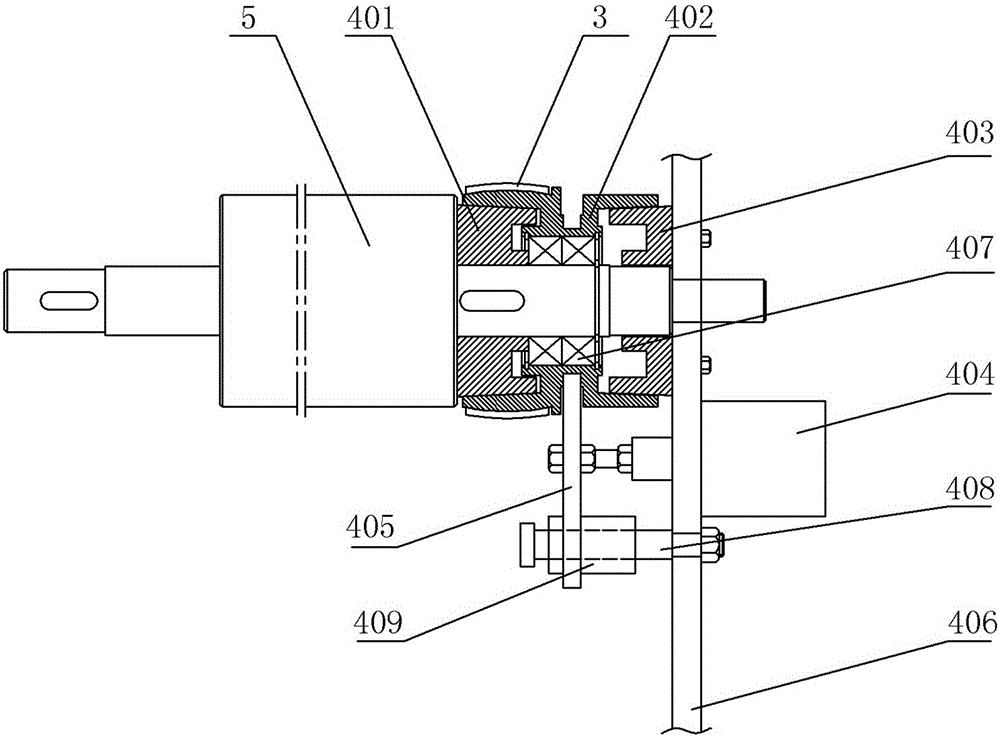

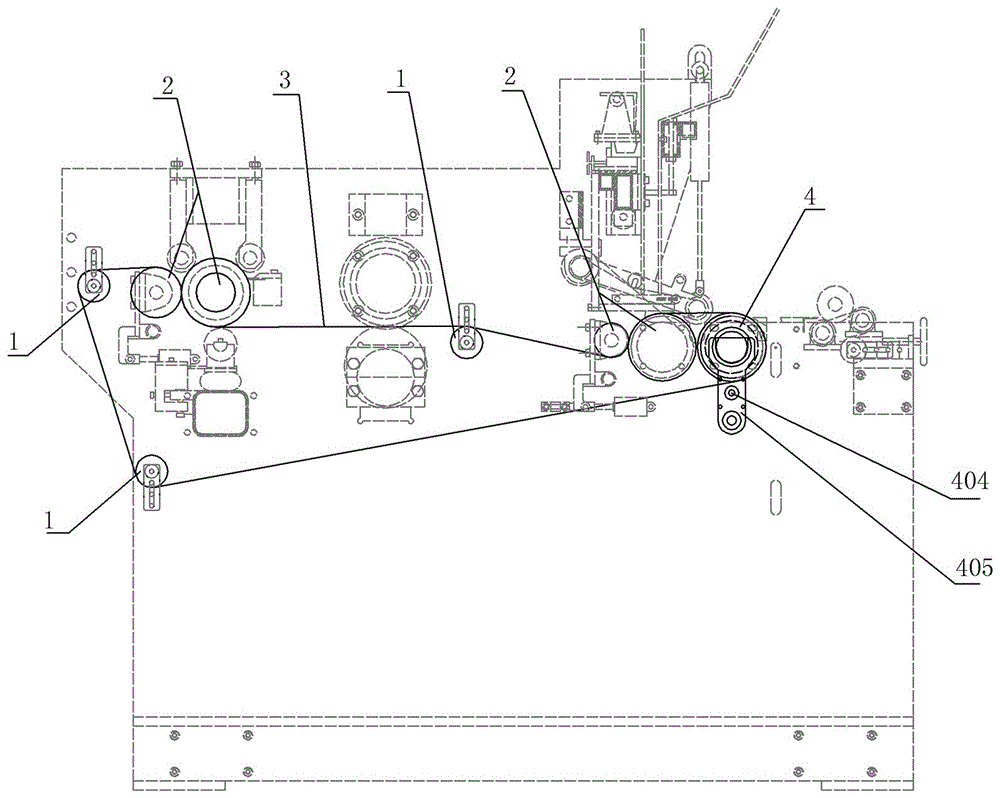

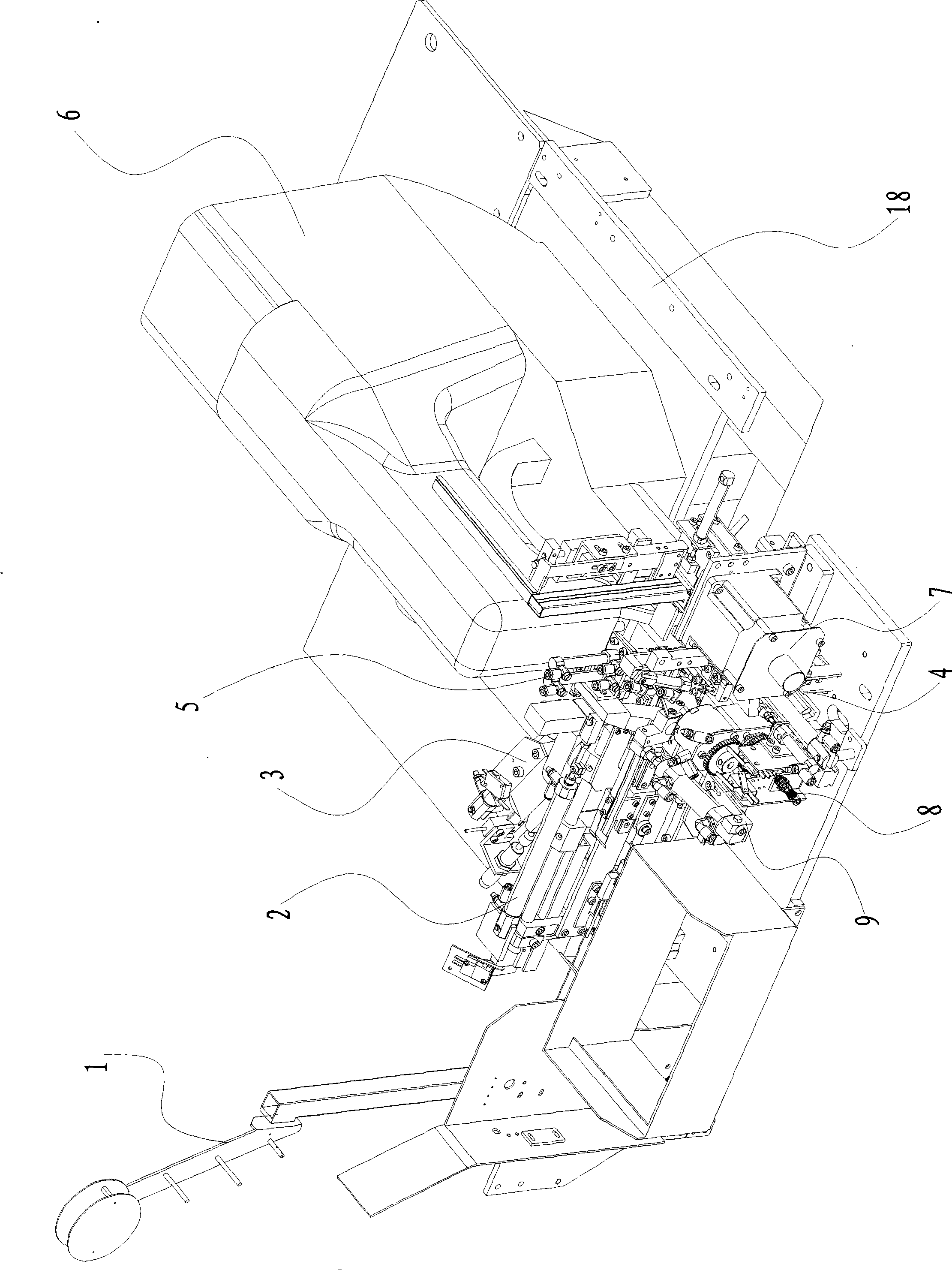

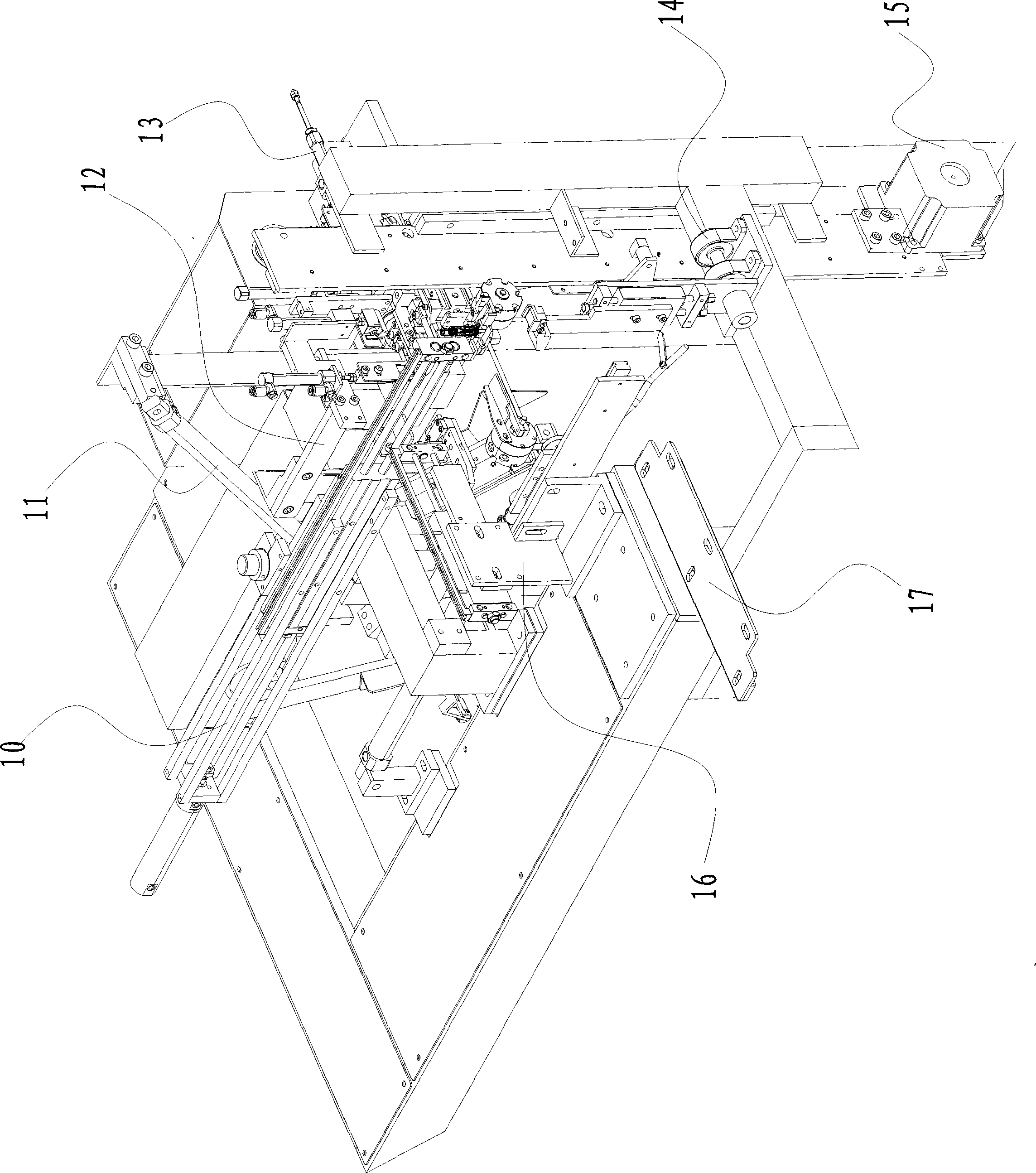

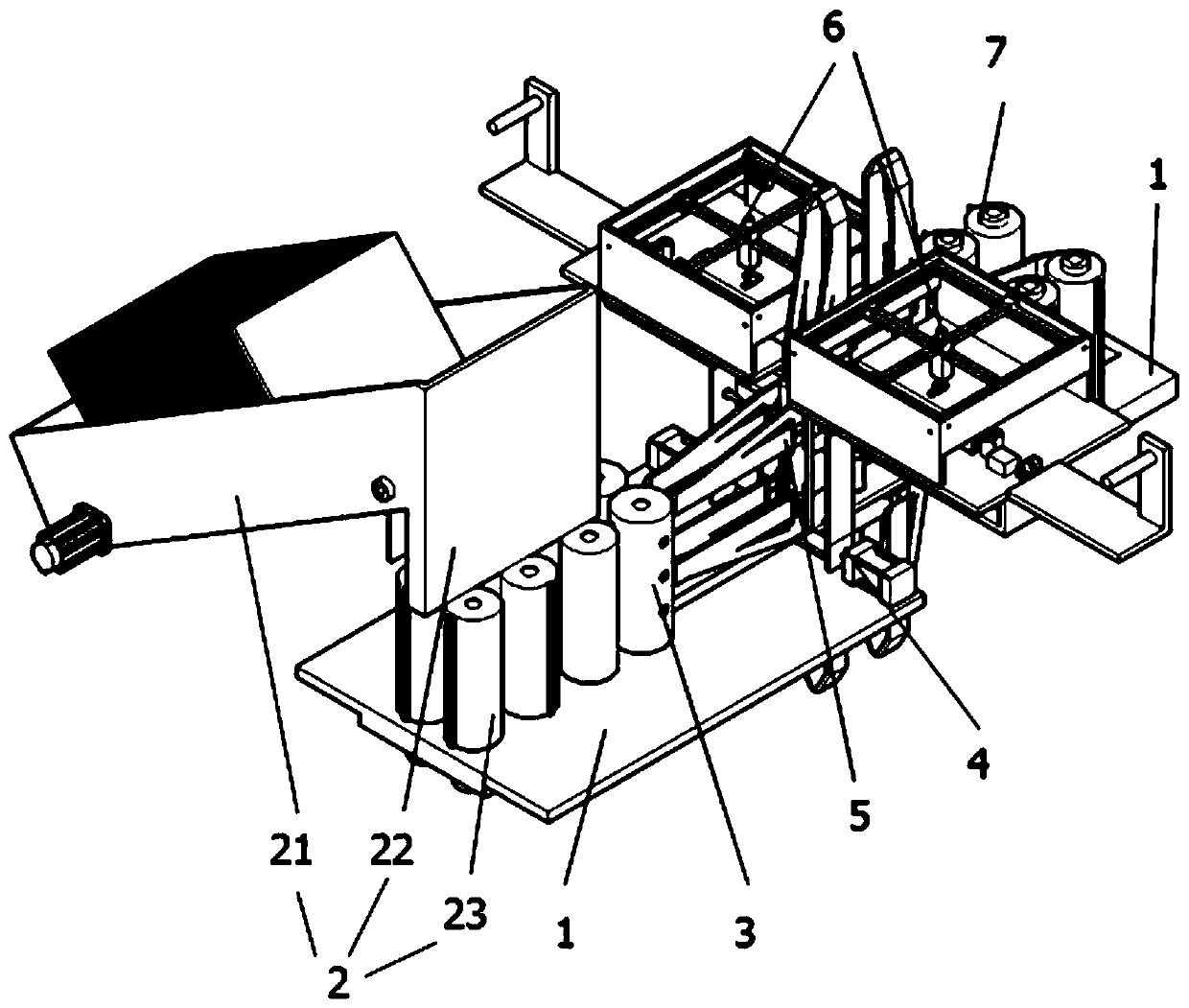

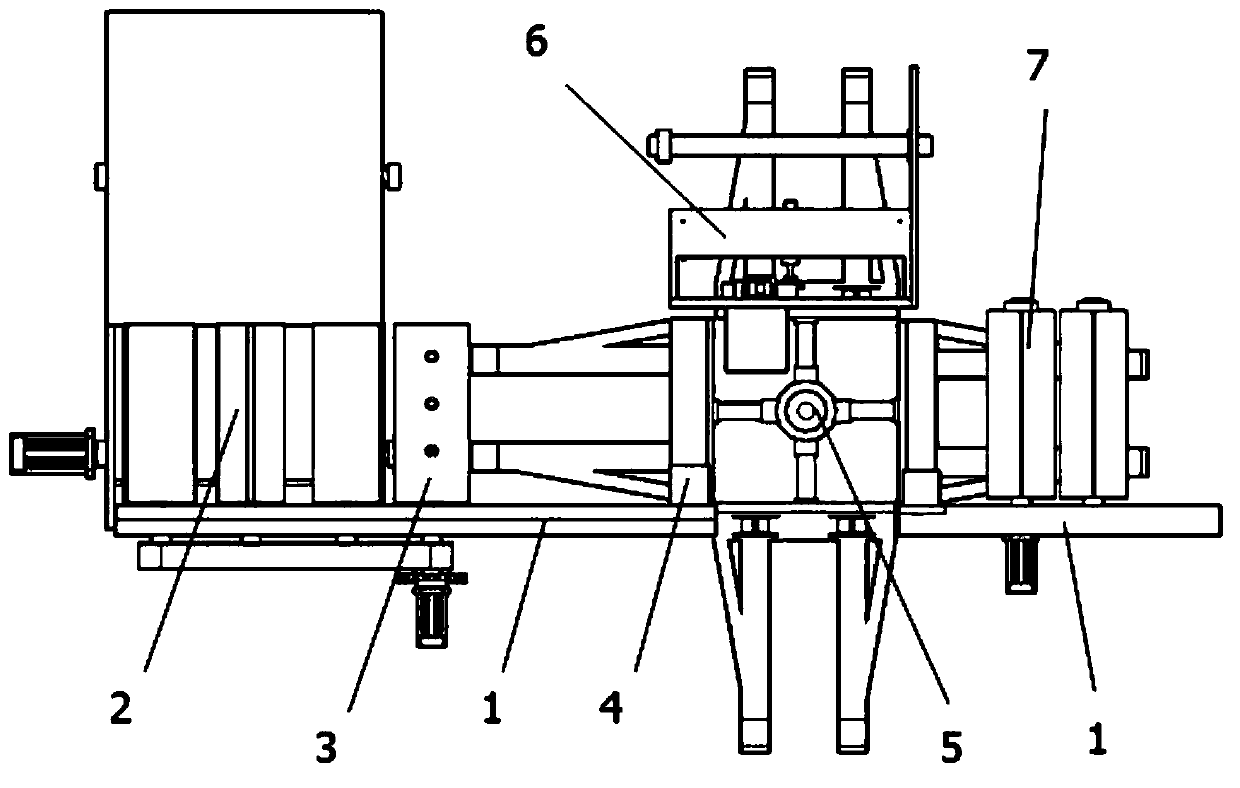

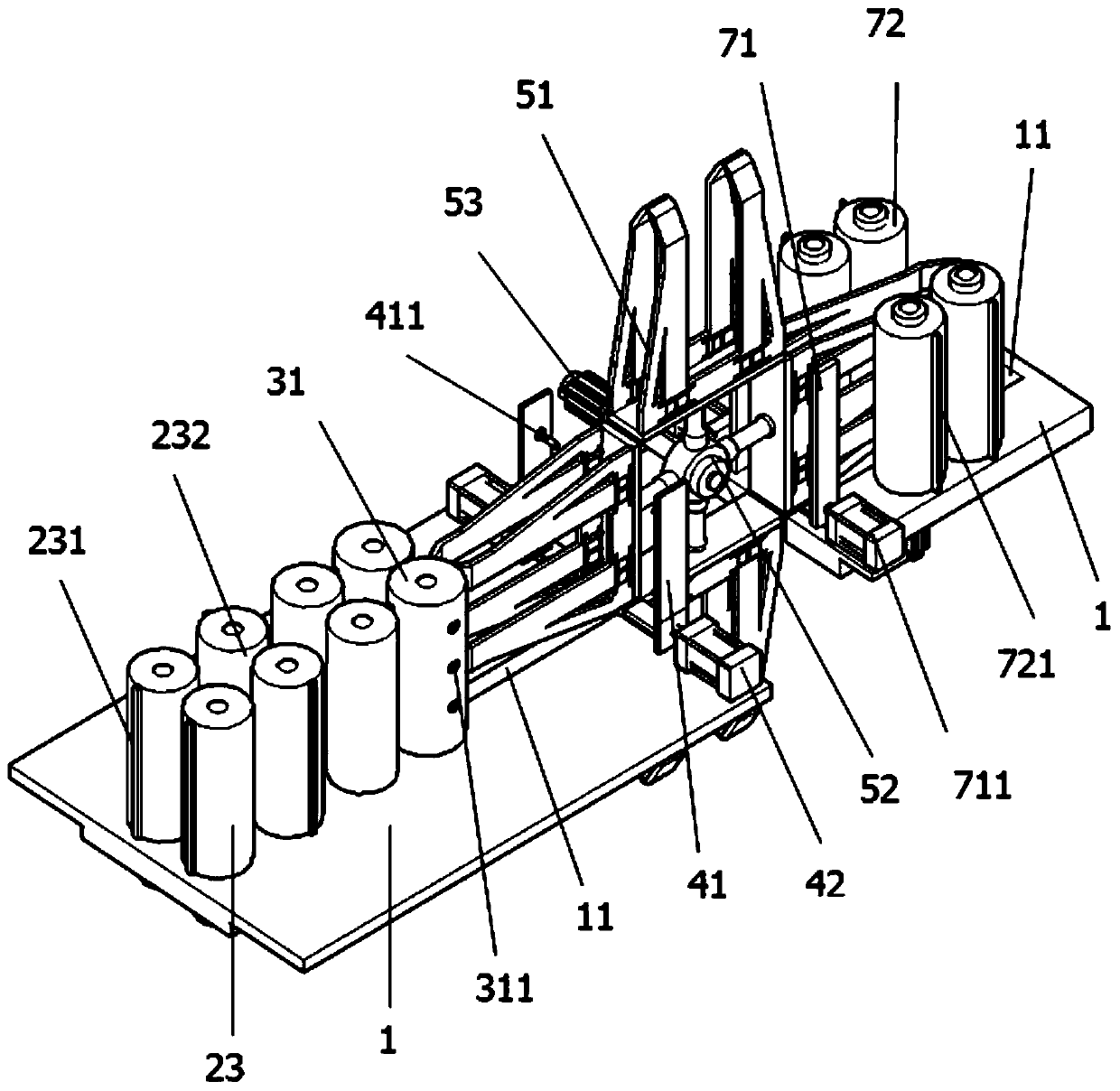

Full-automatic shoulder belt sewing machine

InactiveCN102605562AReasonable structural designEasy to useWorkpiece carriersWork-feeding meansEngineeringSewing machine

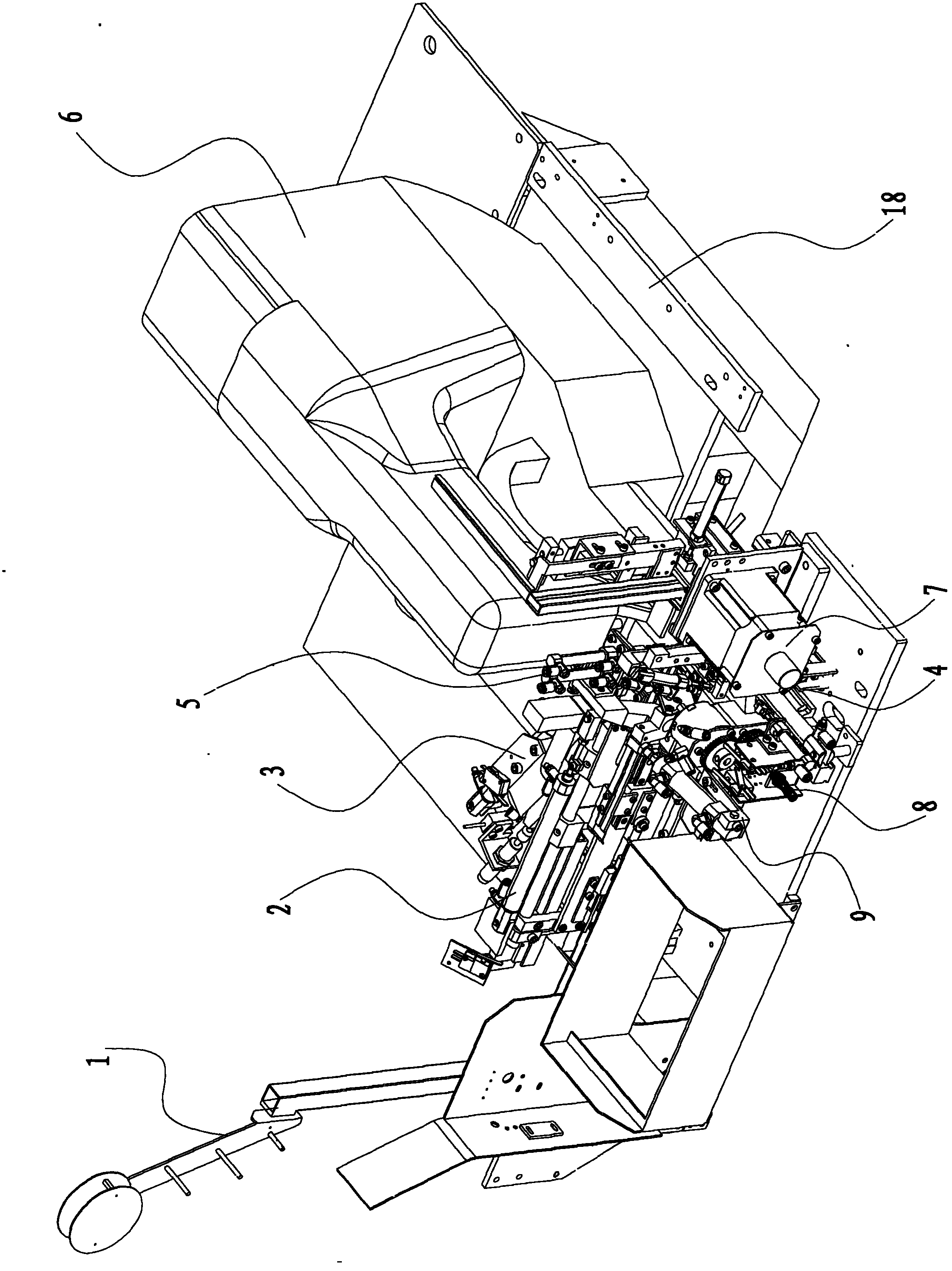

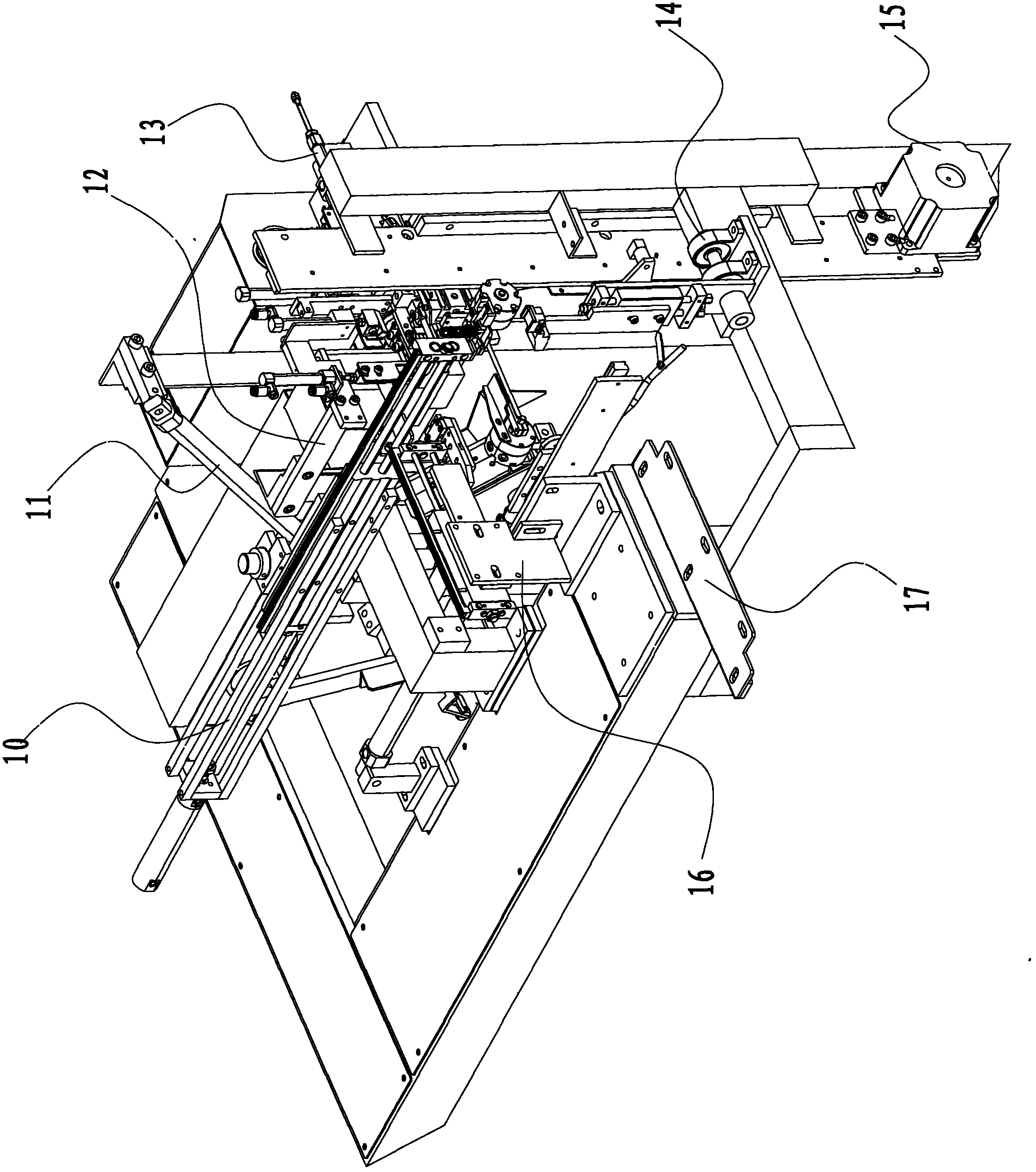

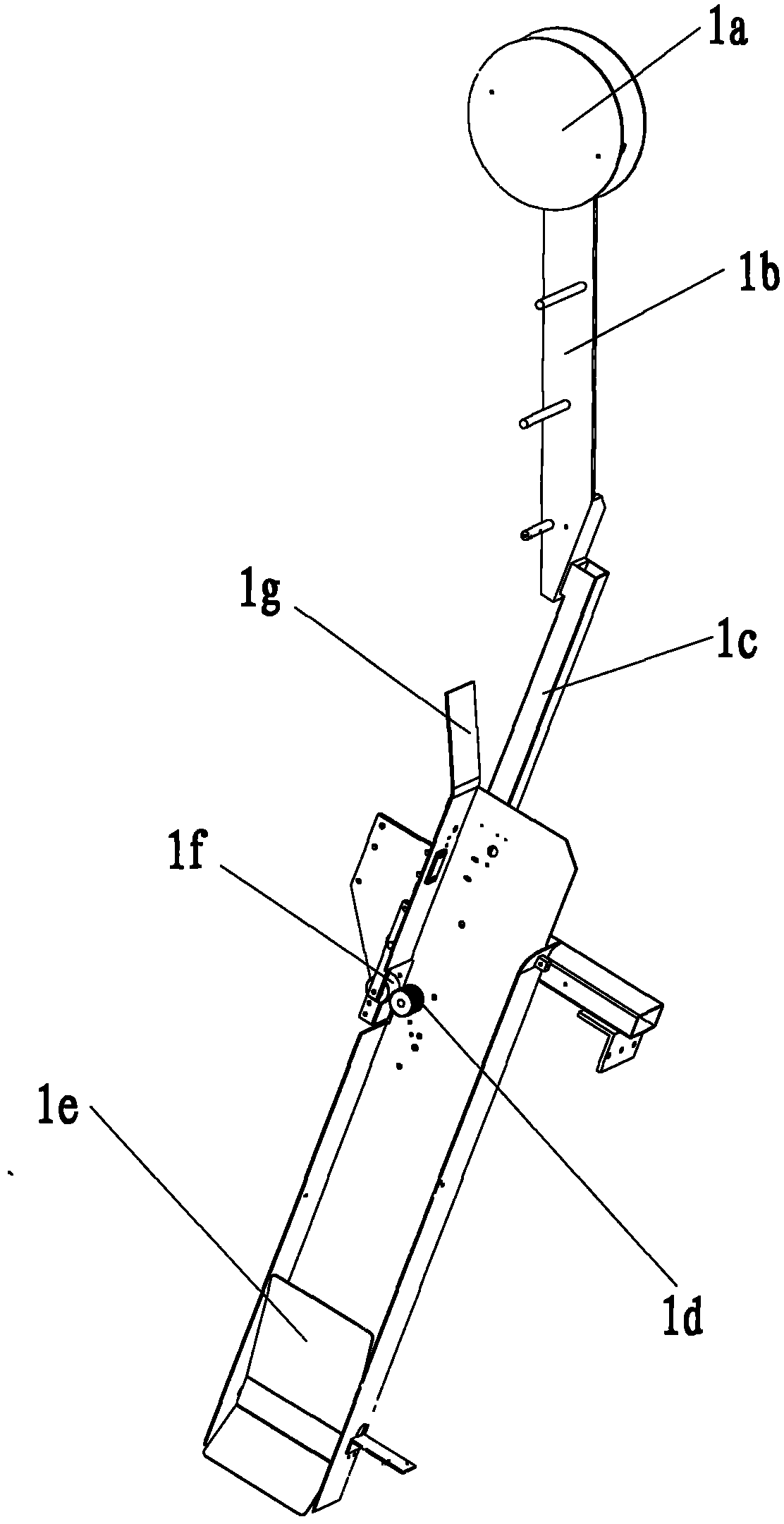

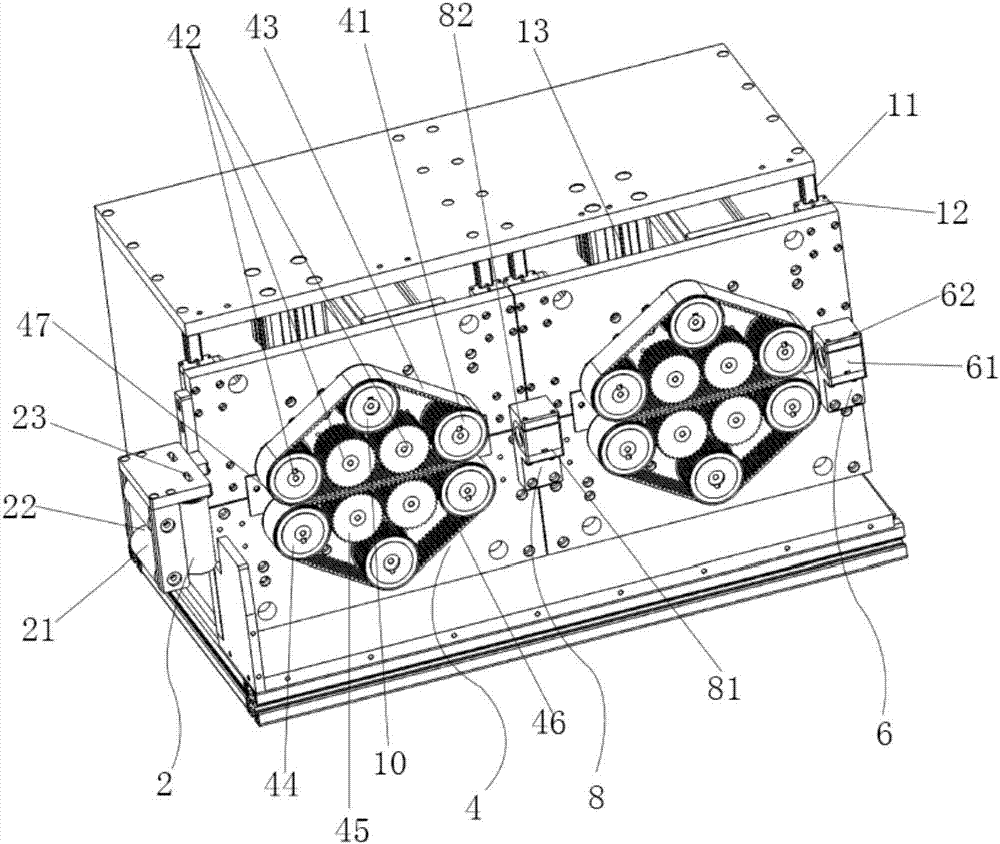

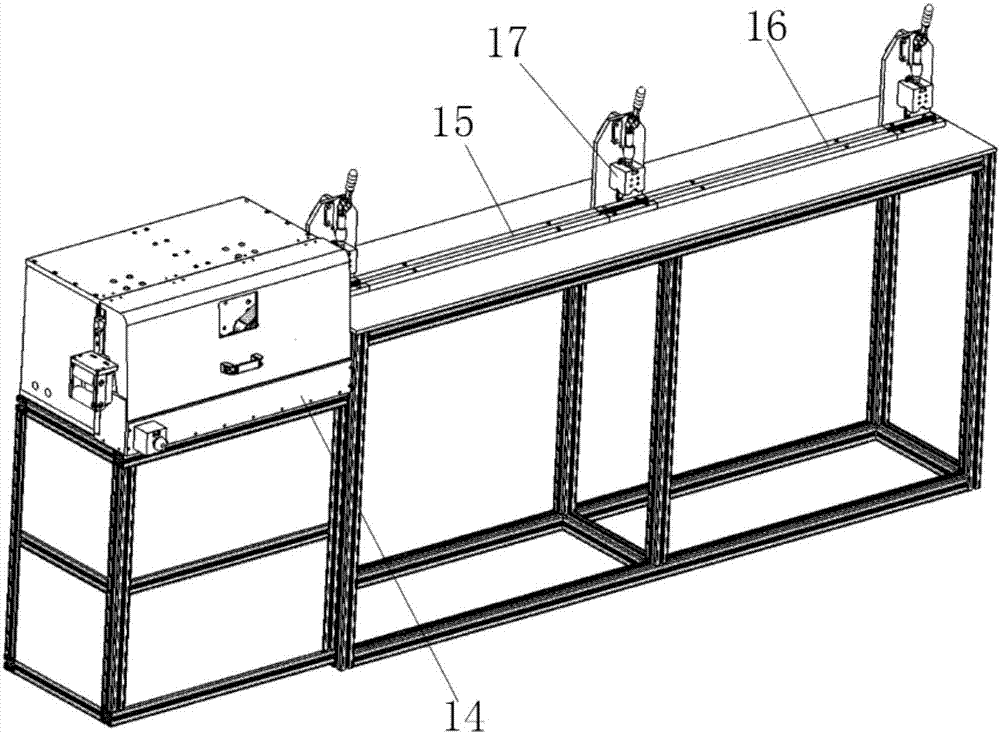

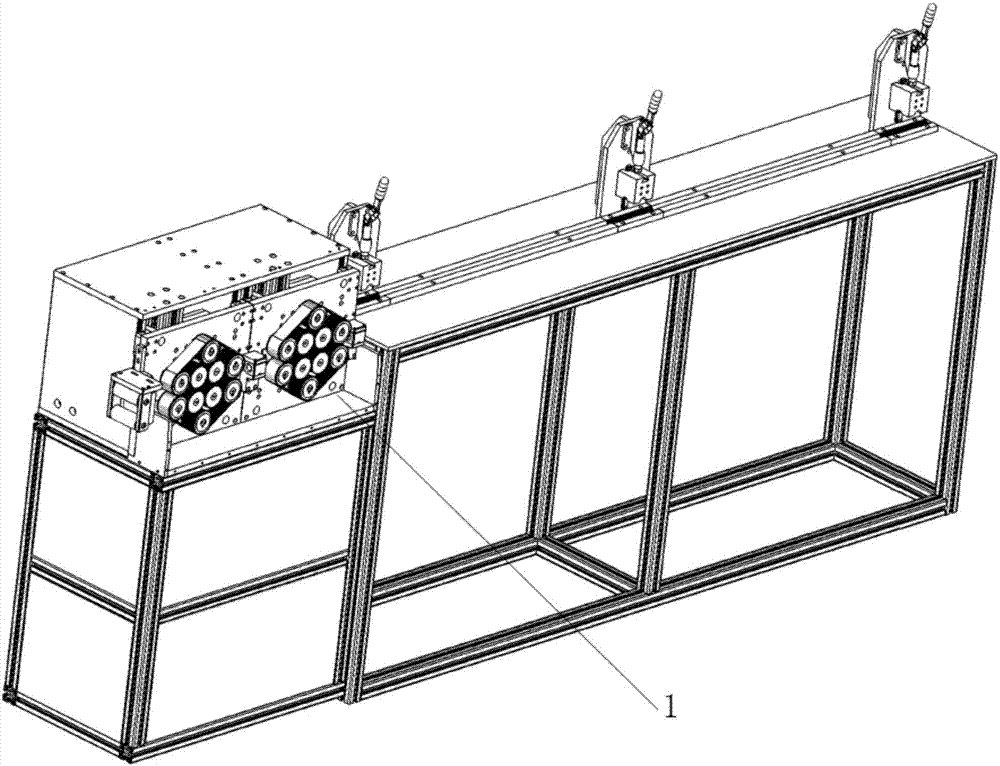

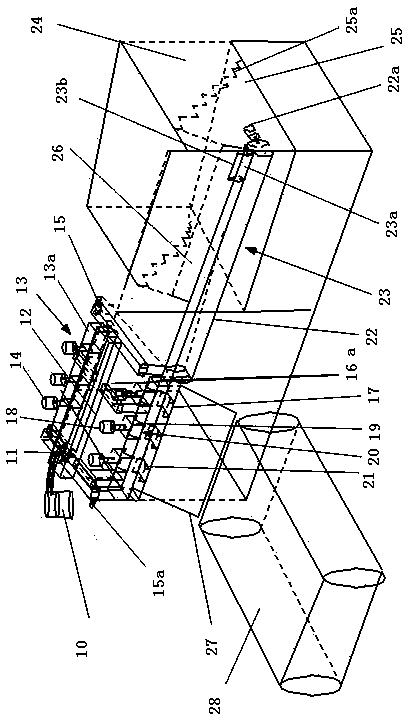

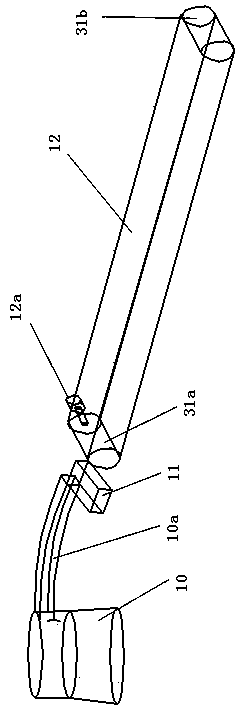

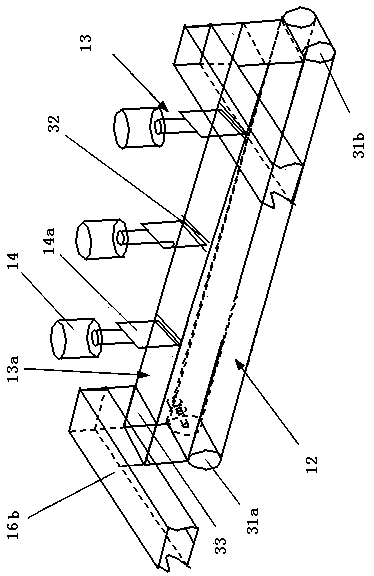

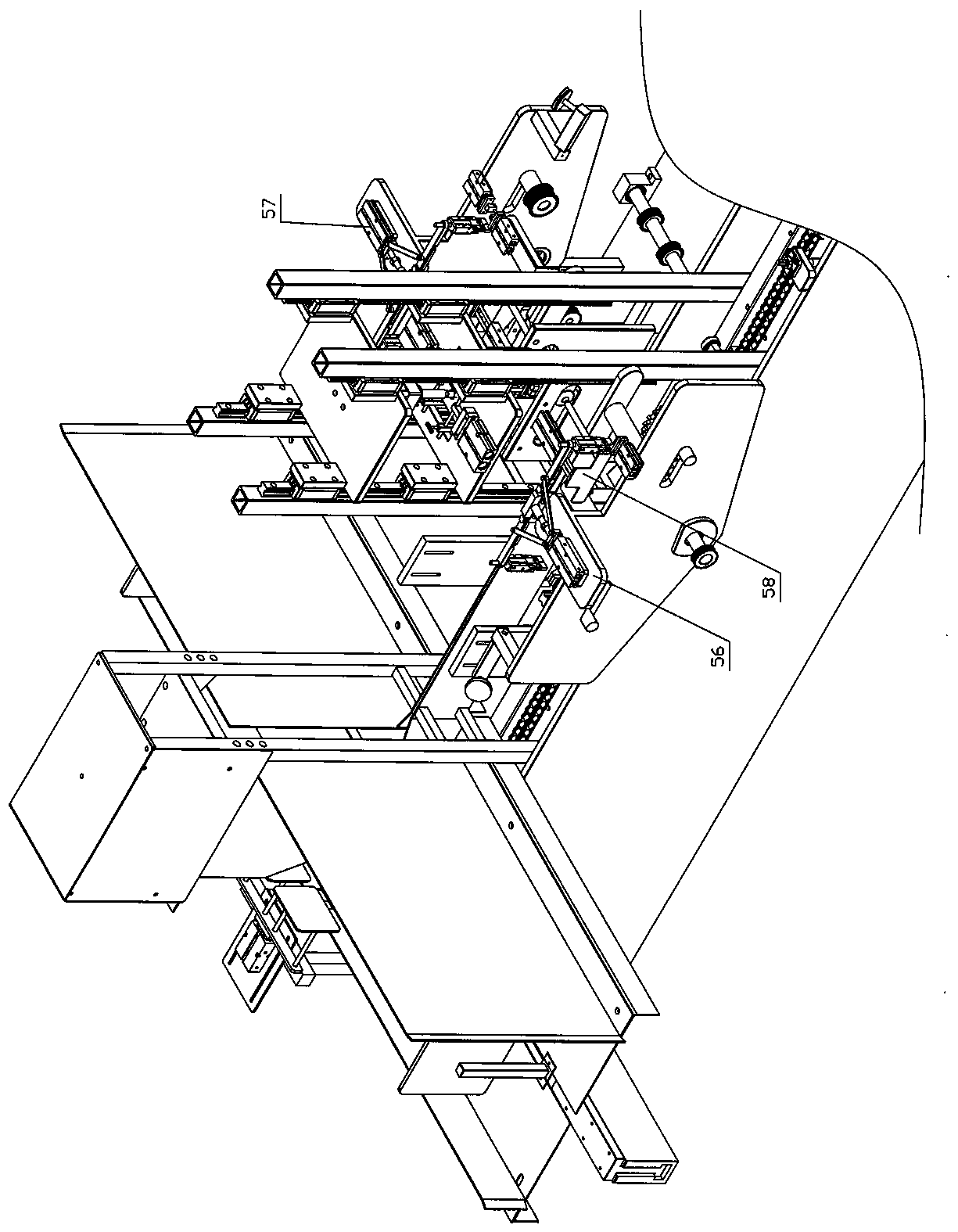

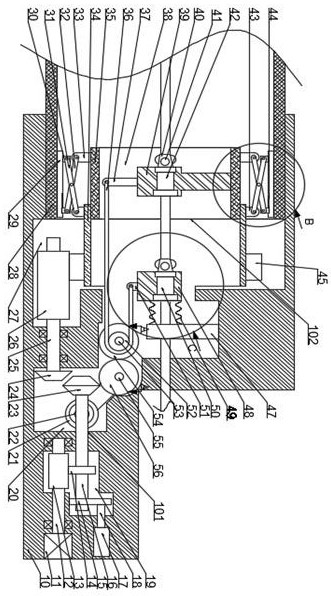

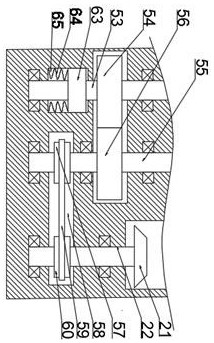

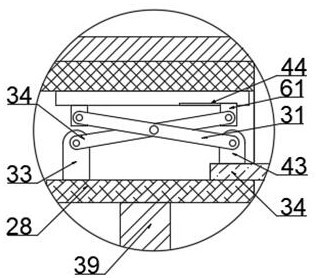

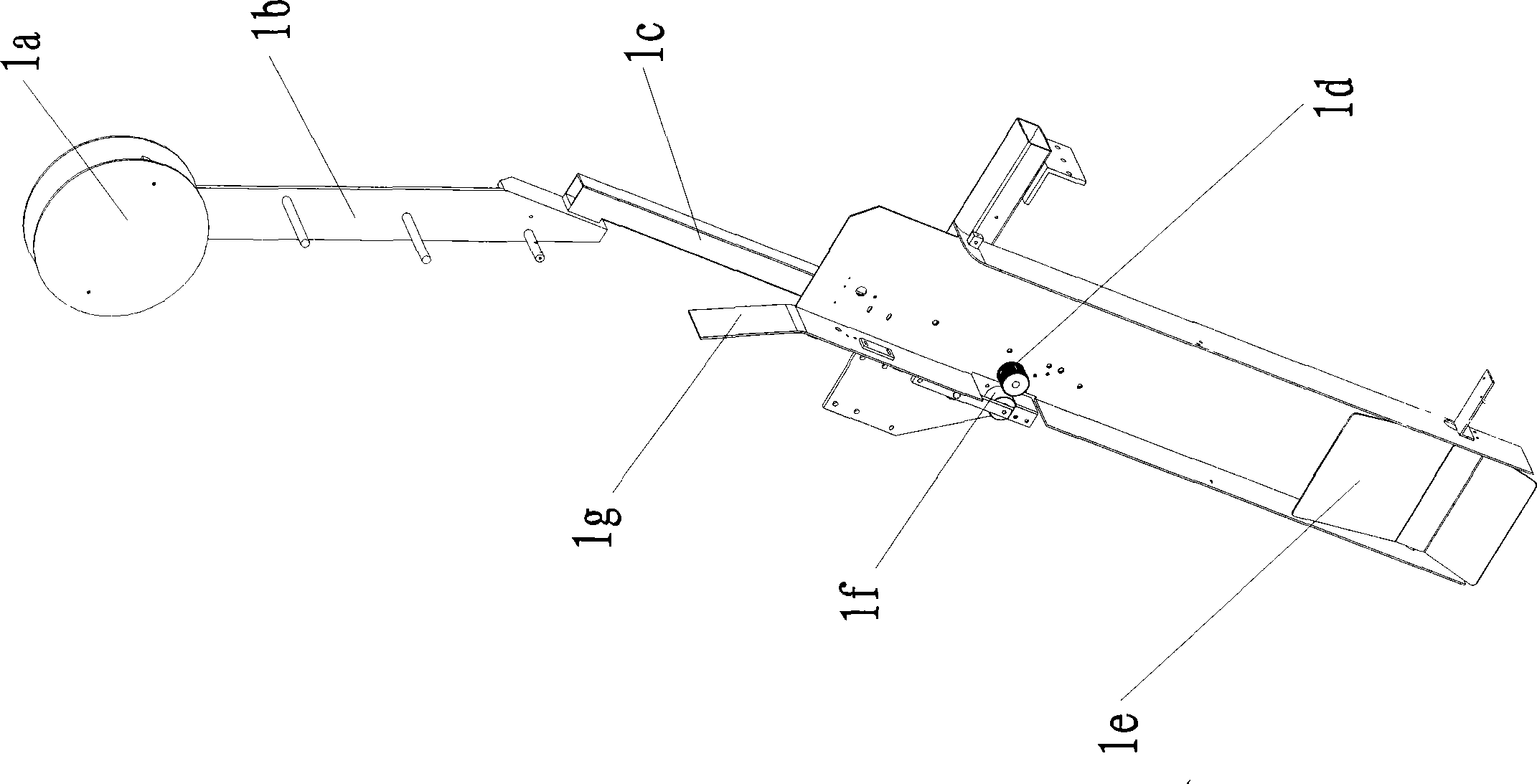

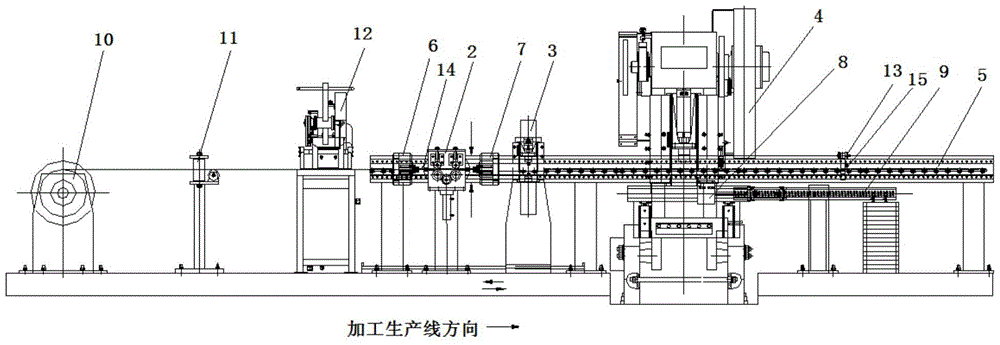

The invention relates to a full-automatic shoulder belt sewing machine which consists of a front processing machine and a rear processing machine which are spliced and fastened together by a front processing machine connecting plate and a rear processing machine connecting plate; the front processing machine mainly comprises a belt conveying device, a belt pushing device, a belt cutting device, an eight-button conveying device, a nine-button conveying device or a zero-button conveying device, a belt threading device, a rotary button turning device, a belt drawing device and a sewing device; the belt pushing device is connected with the belt conveying device; the belt threading device is connected with the belt drawing device, the eight-button conveying device, the nine-button conveying device or the zero-button conveying device; and the rear processing machine mainly comprises a belt connecting device, a rear processing belt drawing device, a belt protecting device, a secondary rotarybutton turning device, a belt head clamping device, a tensioning device and a belt connecting button pushing device. By the design of the shoulder belt sewing machine, the automatic button threading of eight buttons and nine buttons on the shoulder belt can be realized; and the front processing machine and the rear processing machine are assembled independently, thereby facilitating the conveyingsafety.

Owner:尤文聘

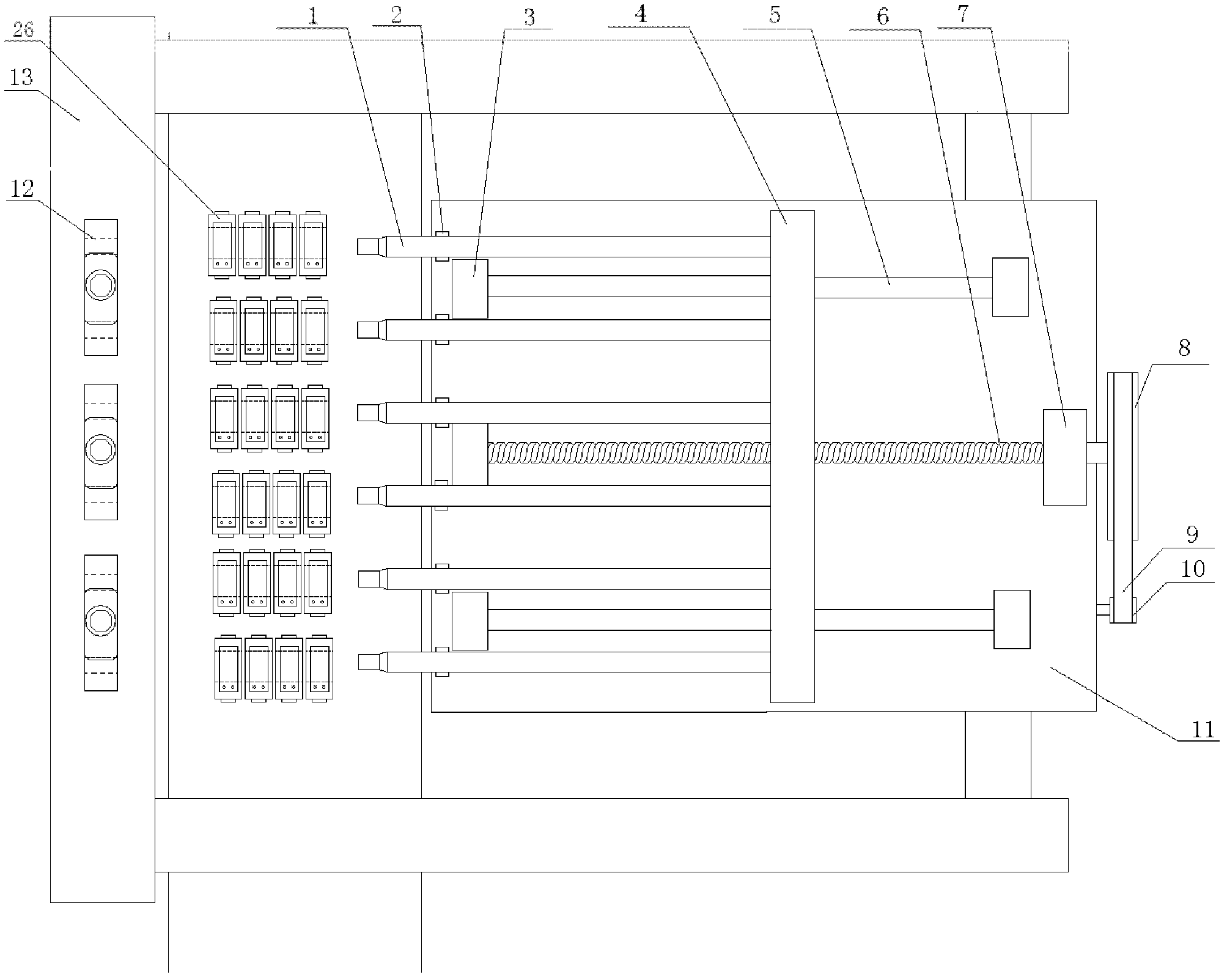

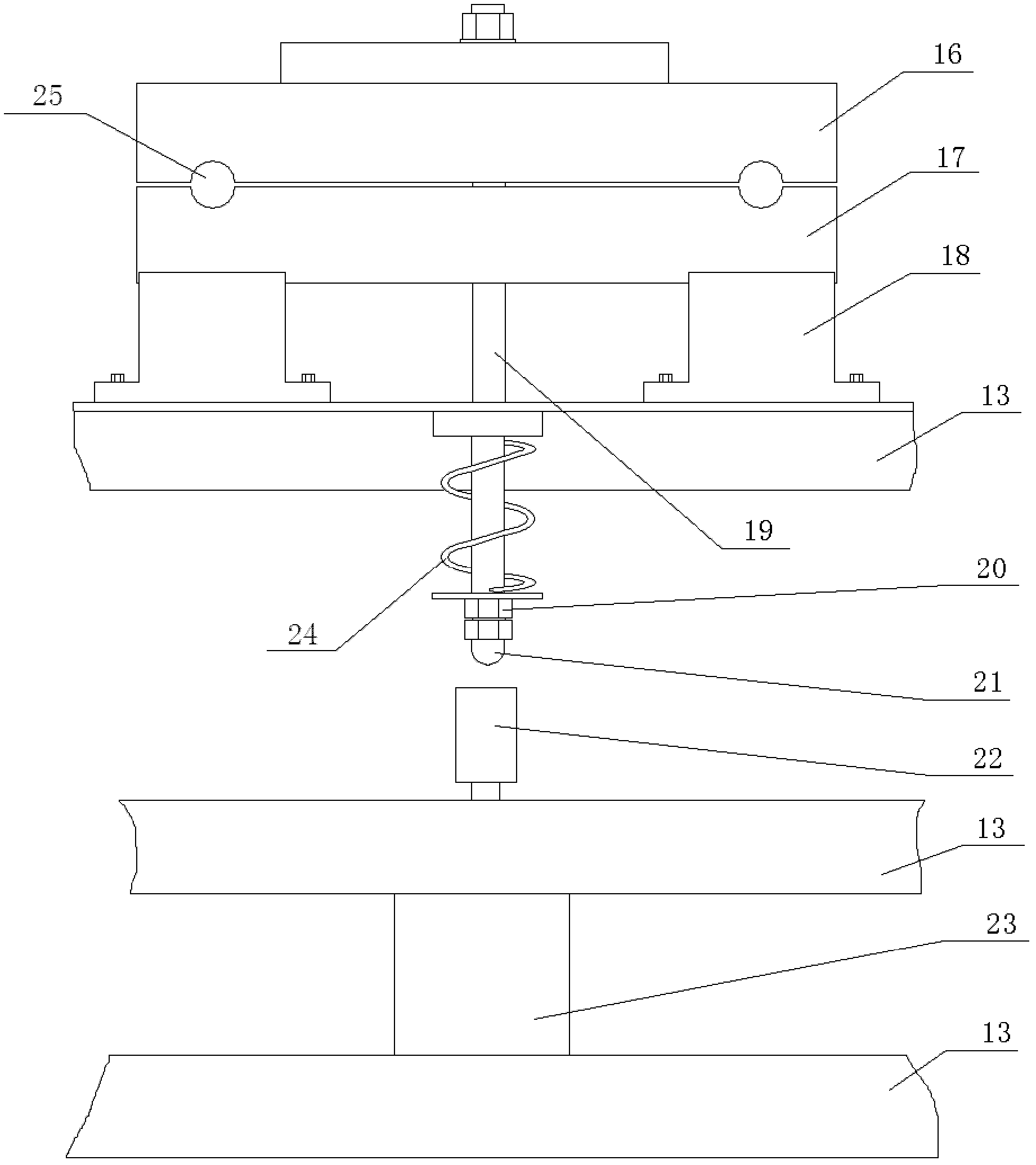

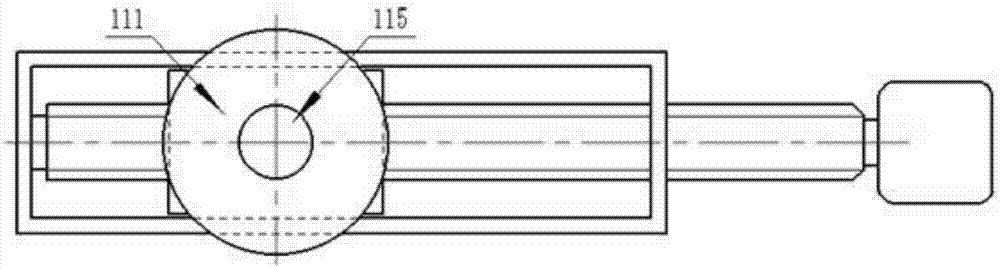

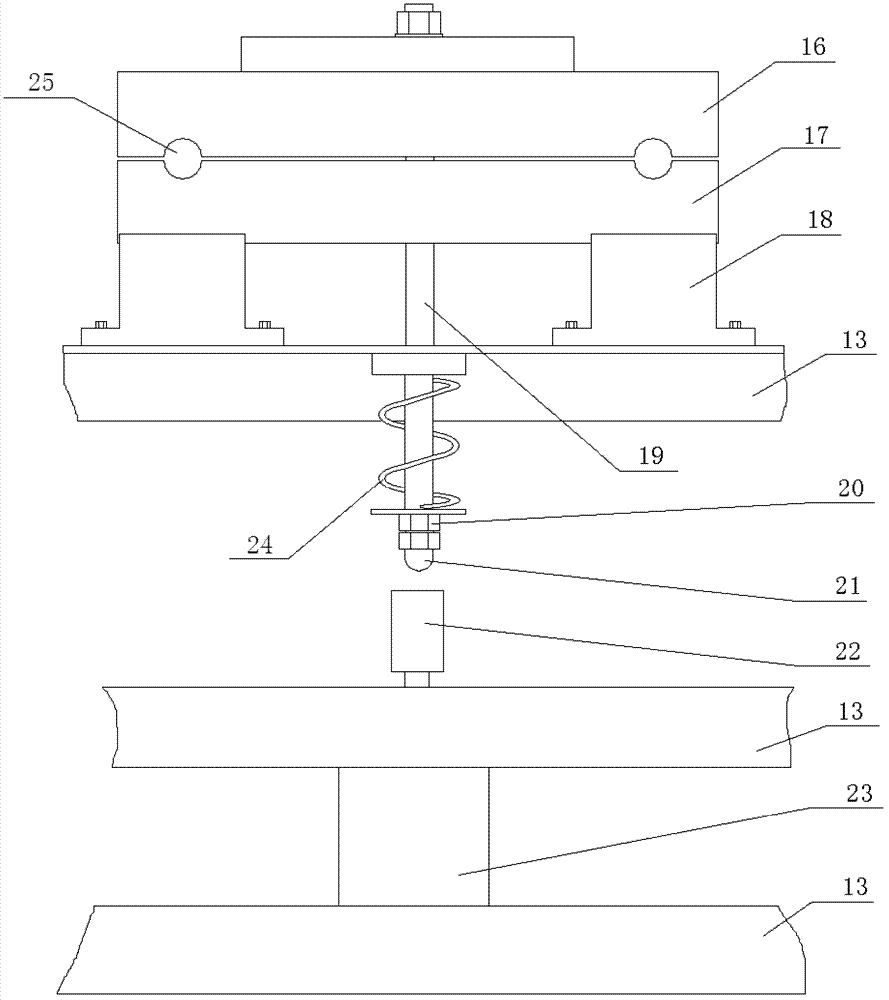

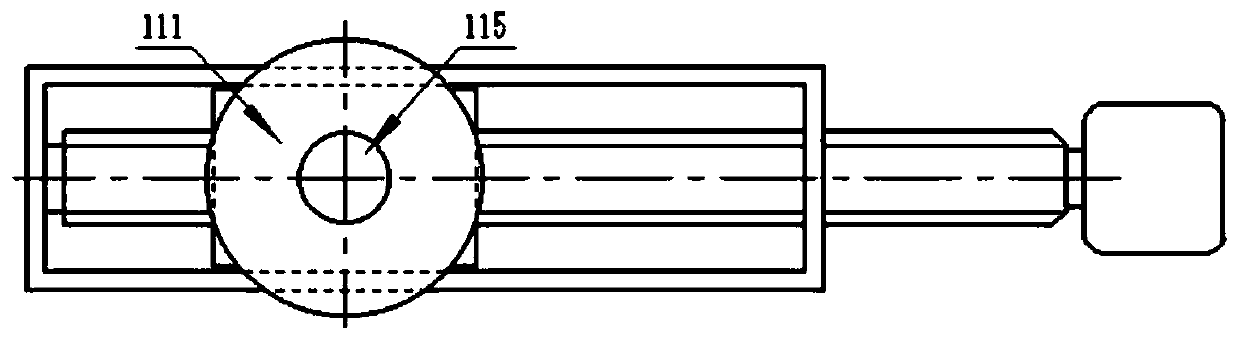

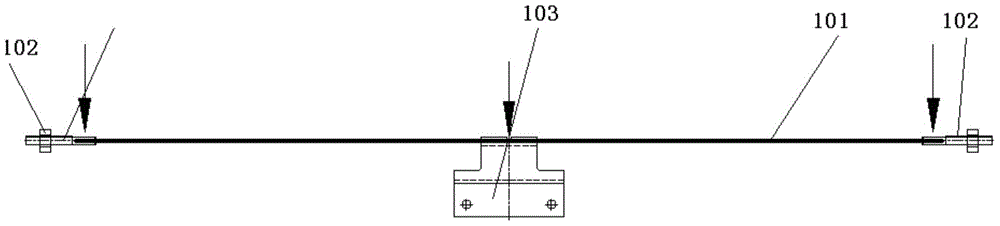

One-time threading device for automatic detection line of mutual inductor

InactiveCN102628929ARealize automatic threadingReduce wearElectrical measurementsInductorFixed frame

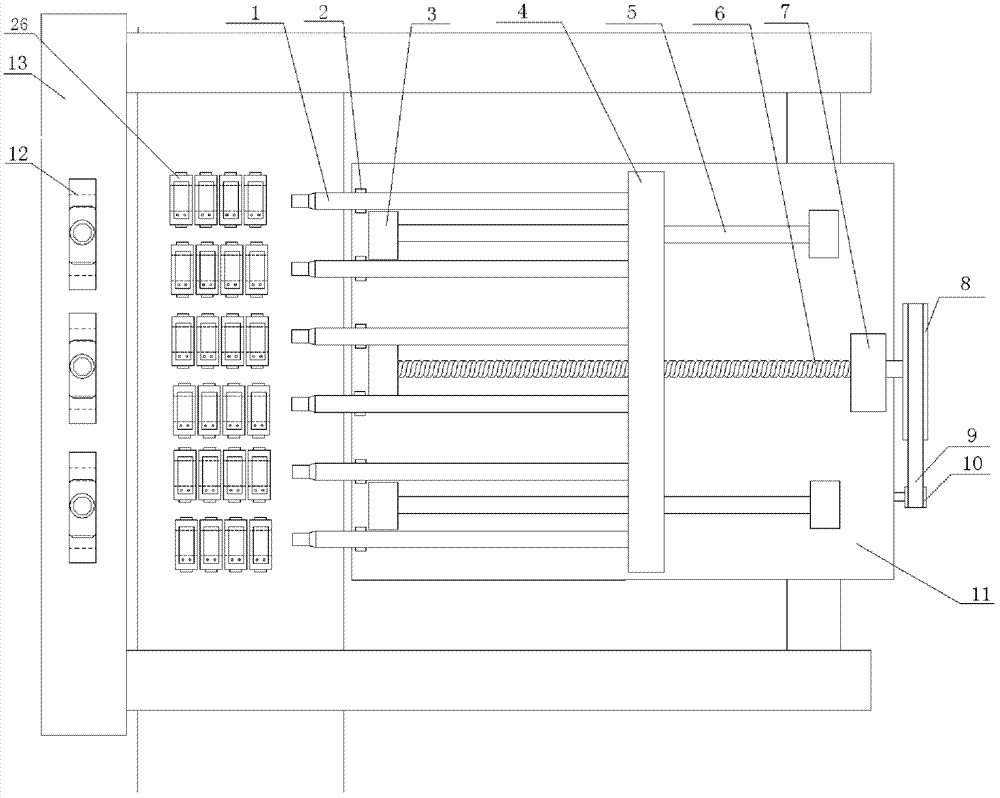

The invention discloses a one-time threading device for an automatic detection line of a mutual inductor, which belongs to the technical field of detection of the mutual inductor, particularly relates to a one-time threading device for a piercing current transformer, and is used for solving the problem of automatic one-time threading of the mutual inductor of a uniform appearance and uniform specification. The one-time threading device mainly comprises a fixing frame, a fixing platform, a piercing conductor, a piercing conductor frame, a conductor bracket, a guide rail, a guide rail slide block, a guide rail base, a lead screw transmission mechanism and a conductor socket assembly. The one-time threading device is suitable for verifying piercing current transformers on a large scale in a measuring and verifying center.

Owner:STATE GRID CORP OF CHINA +1

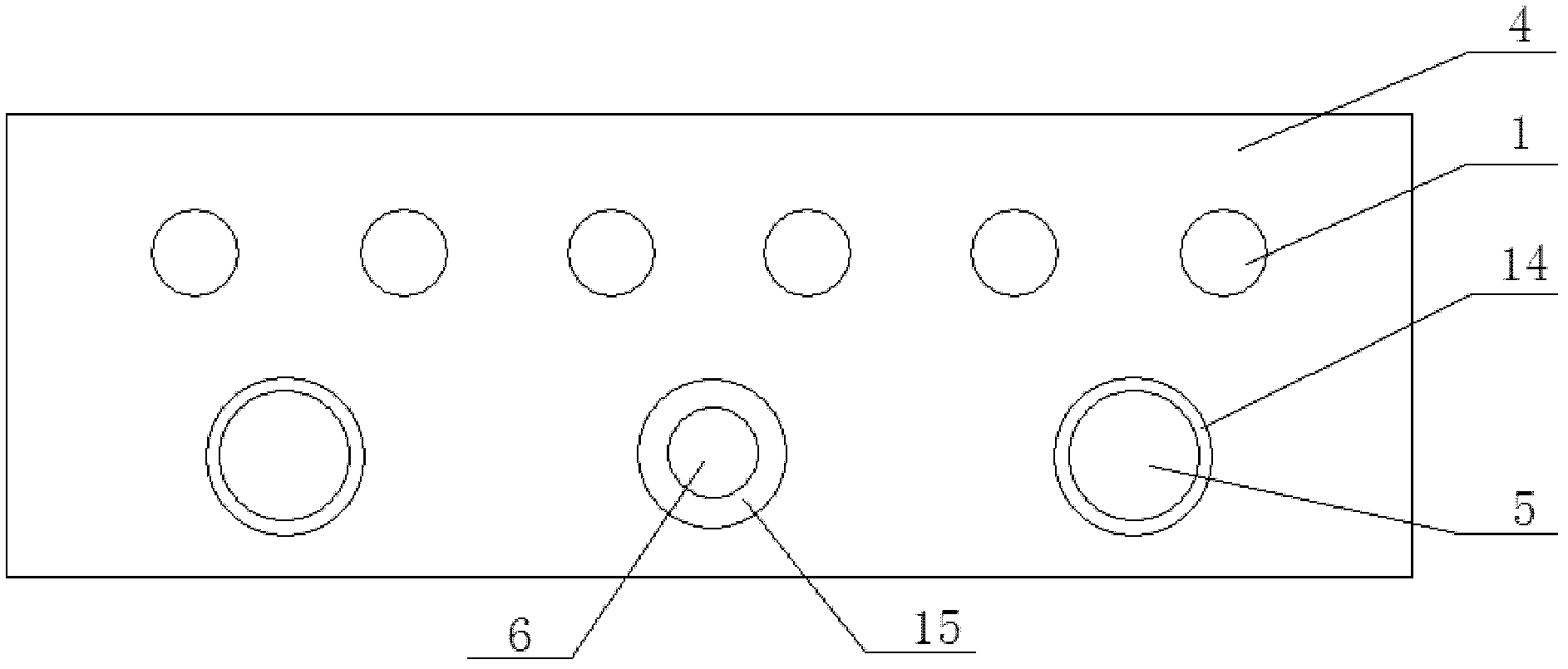

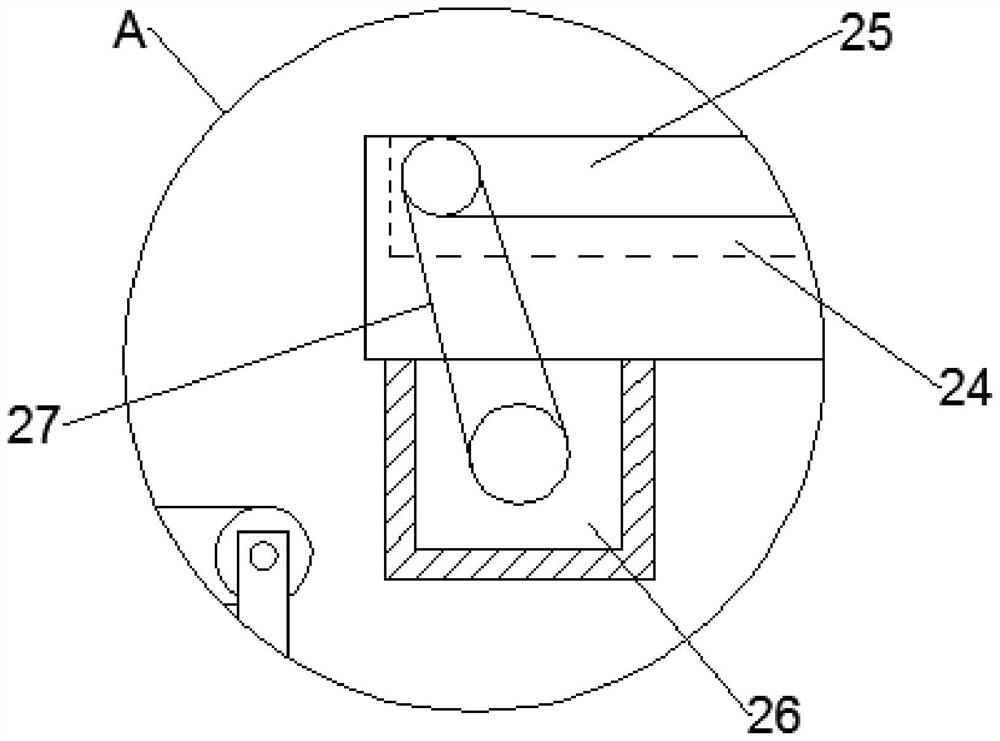

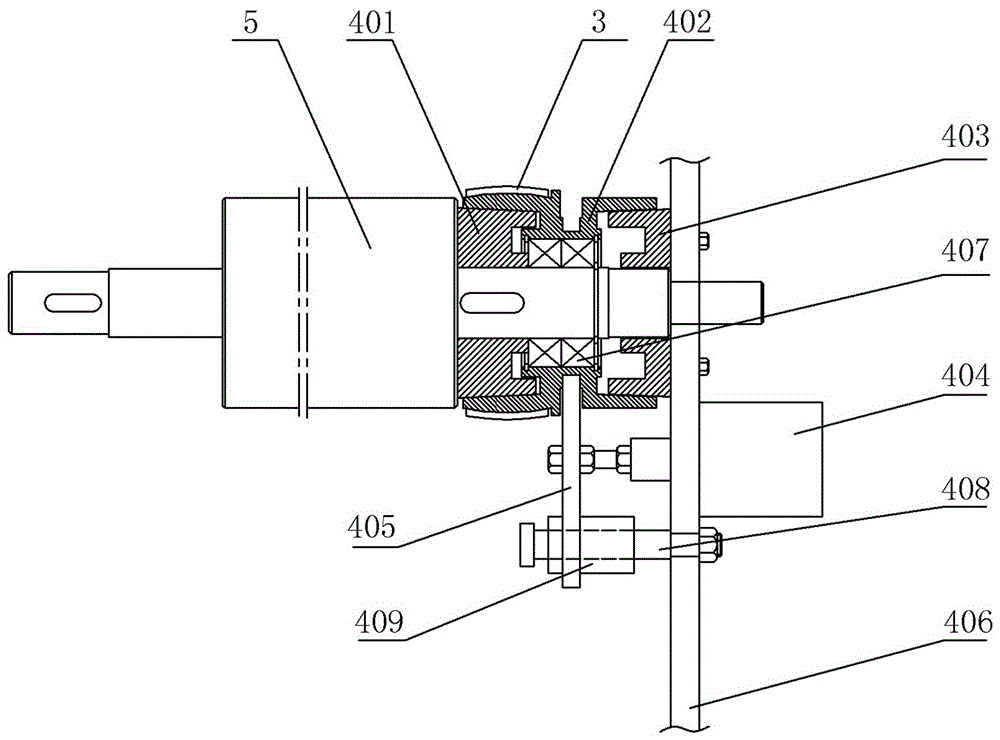

Automatic paper leading device used on operating side of paper winding machine

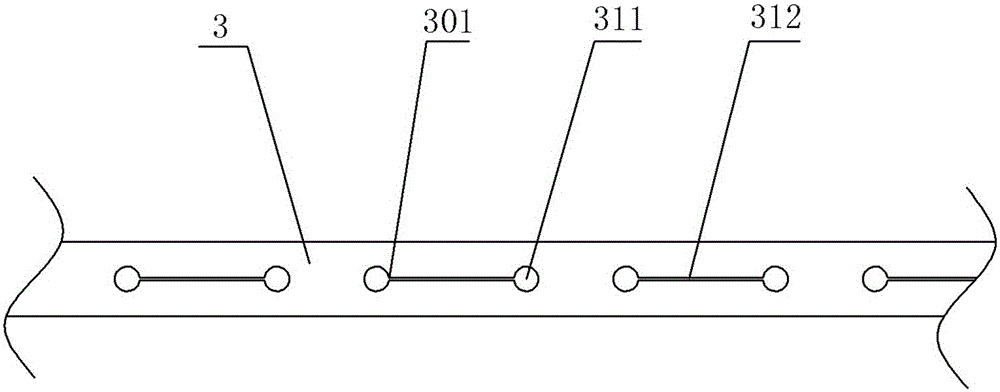

InactiveCN105129474ARealize automatic threadingHigh degree of automationWebs handlingWinding machinePaper tape

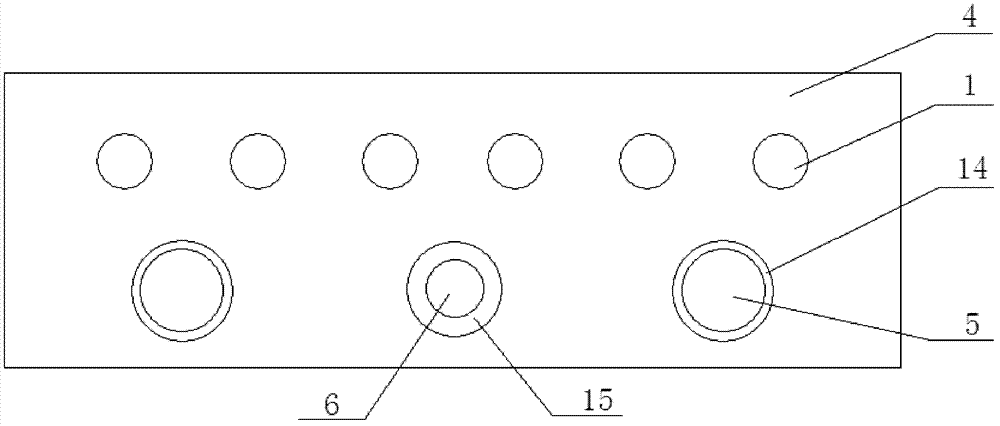

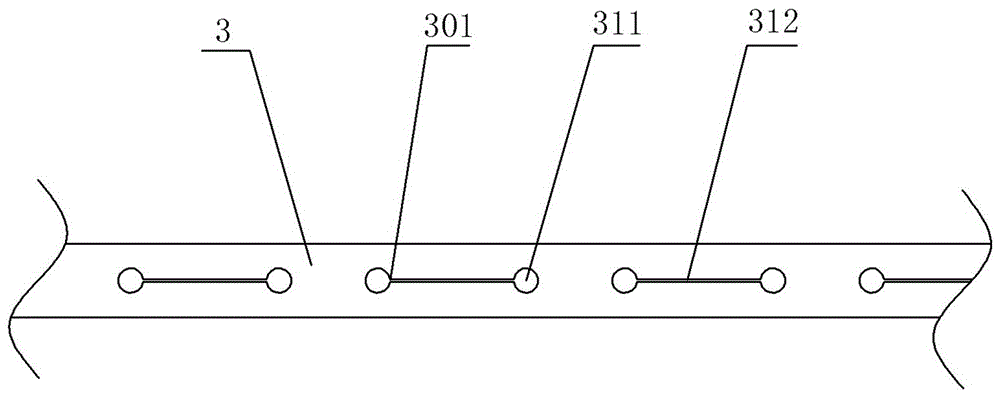

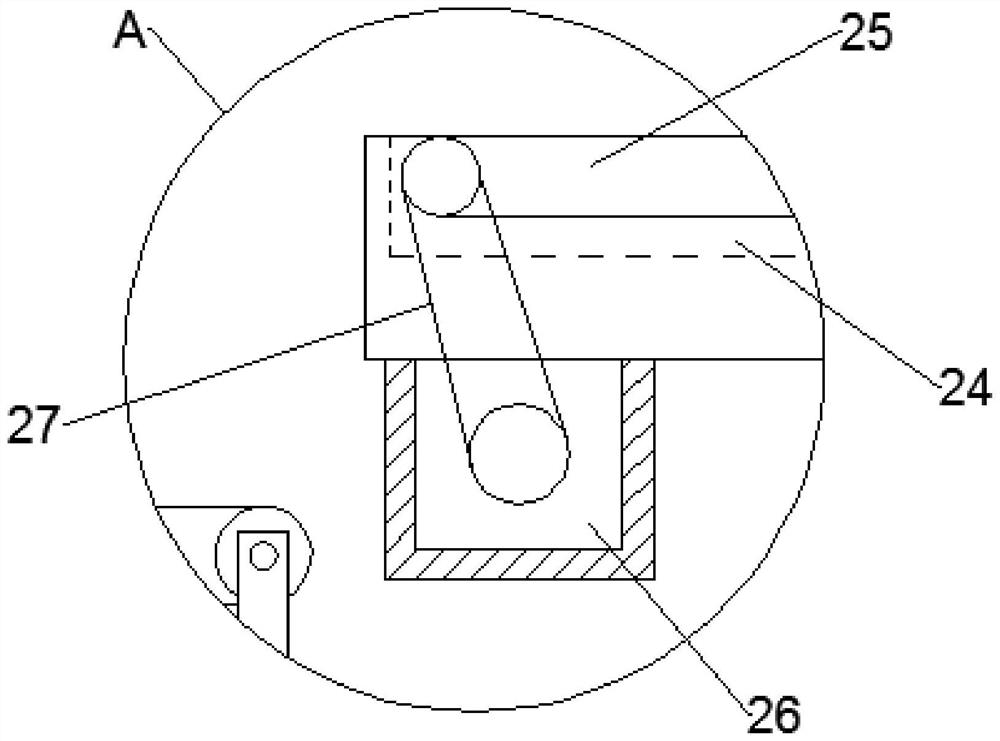

The invention relates to the field of papermaking machines, in particular to an automatic paper leading device used on the operating side of a paper winding machine. The automatic paper leading device comprises a guiding tensioning wheel, an idle pulley and a paper leading belt. Paper leading through grooves are evenly distributed in the middle of the paper leading belt in the length direction of the belt. The automatic paper leading device further comprises a paper leading belt engagement and disengagement mechanism which is coaxial with a paper winding roller of the paper winding machine. The paper leading belt surrounds the guiding tensioning wheel. The idler wheel and the paper leading belt engagement and disengagement mechanism rotate cyclically. According to the automatic paper leading device used on the operating side of the paper winding machine, paper tape can be led to the position nearby the paper winding roller from one end of the paper leading belt by controlling a cylinder to stretch out and draw back at a long distance, full-automatic paper leading is achieved, and the automation degree is greatly improved; meanwhile, safety accidents which are easily caused by manual paper leading are avoided, and safe production is quite greatly promoted; and one worker can completely finish paper leading operation, manual investment in a factory is reduced, manpower is saved, and production cost is reduced for enterprises.

Owner:程黔

Corrugated pipe threading device

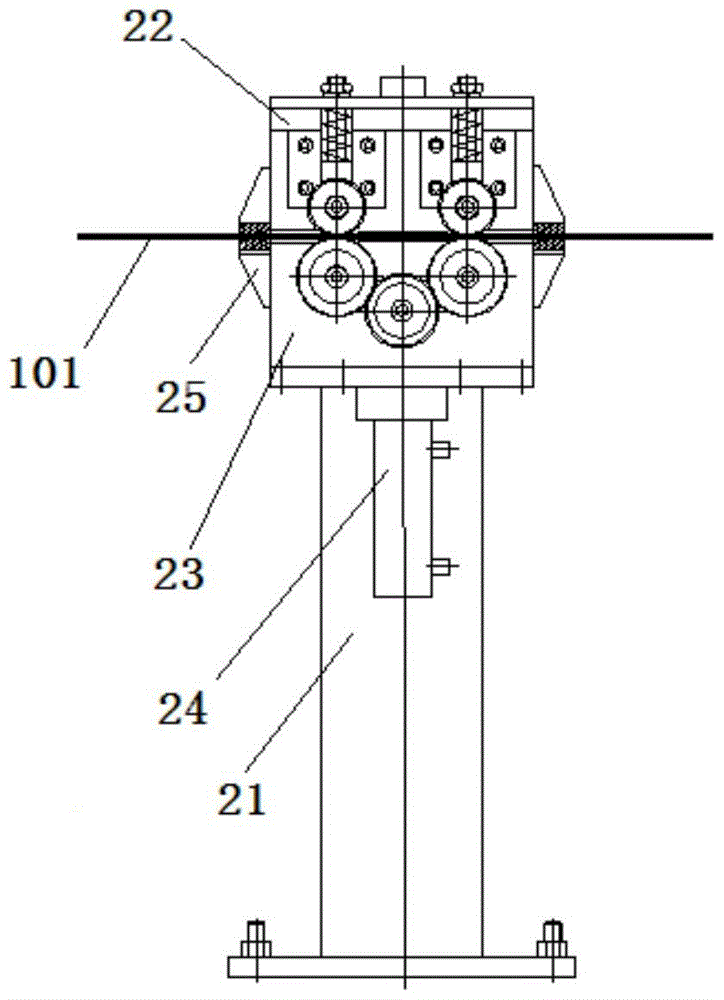

PendingCN107248438AImprove threading efficiencyReduce manual labor intensityCable/conductor manufactureApparatus for laying cablesEngineeringStructural engineering

The invention provides a corrugated pipe threading device. The corrugated pipe threading device comprises a cable input and guide mechanism, a cable traction mechanism and a cable output and guide mechanism, which are sequentially arranged along the cable moving direction; the cable input and guide mechanism comprises two pairs of guide rollers; a first clearance for a cable to pass is between each pair of guide rollers; the cable traction mechanism comprises a first traction component and a second traction component, which are matched to pull the cable to move; a second clearance for the cable to pass is between the first traction component and the second traction component; the cable output and guide mechanism comprises a wire outgoing base; a wire outgoing hole is formed on the wire outgoing base; and, under the drive of a driver, the cable is axially threaded in a corrugated pipe after being pulled to pass through the first clearance, the second clearance and the wire outgoing hole sequentially and linearly. By means of the corrugated pipe threading device disclosed by the invention, artificial threading is replaced; the threading efficiency is increased; the manual labour intensity is reduced; a cable, the length of which is beyond 10 M, can be smoothly threaded; and the corrugated pipe threading device is steady to operate, reliable and safe, and suitable for threading cables having multiple pipe diameters and sizes.

Owner:江苏亨通新能源智控科技有限公司

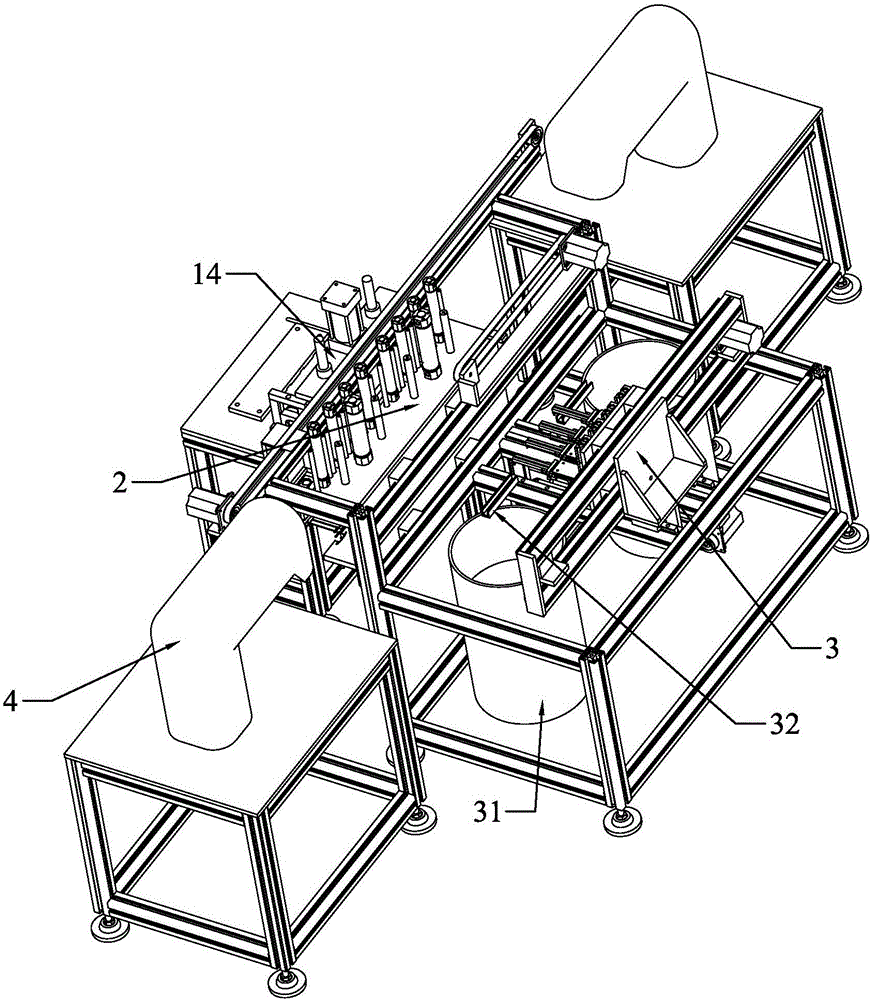

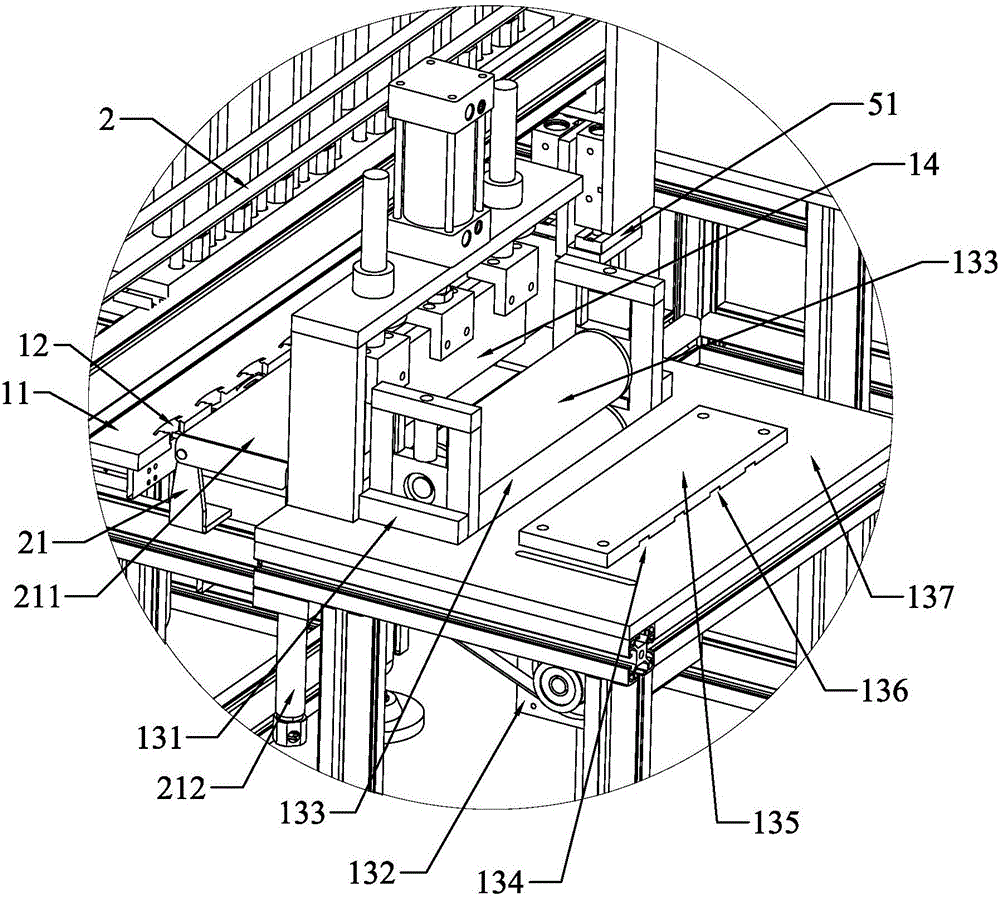

Installation method of reinforcing steel bar insulated sleeve

The invention discloses an installation method of a reinforcing steel bar insulated sleeve, and belongs to the field of HSR (High-Speed Rail). The reinforcing steel bar insulated sleeve comprises a vibrating hopper. The installation method of the reinforcing steel bar insulated sleeve is implemented in a reinforcing steel bar insulated sleeve installation device, wherein the reinforcing steel barinsulated sleeve installation device comprises a carrying and separating device of an insulated sleeve, a carrying and transmitting device of reinforcing steel bars, a sleeve heating and shrinking device and a controller, wherein after the insulated sleeve is separated on the carrying and separating device, the insulated sleeve is transmitted into a groove for fixing after separating, the reinforcing steel bars are installed in the insulated sleeve by utilizing the carrying and transmitting device of the reinforcing steel bars; heating and shrinking can be realized by the sleeve heating and shrinking device. According to the installation method disclosed by the invention, manual installation is replaced, the installation efficiency of a sleeve can be increased, the labor intensity of a worker is reduced, vortex generated when a train passes through a ballastless track can be removed, and the running stability of a passenger transport line can be increased.

Owner:河南省鼎鼎实业有限公司

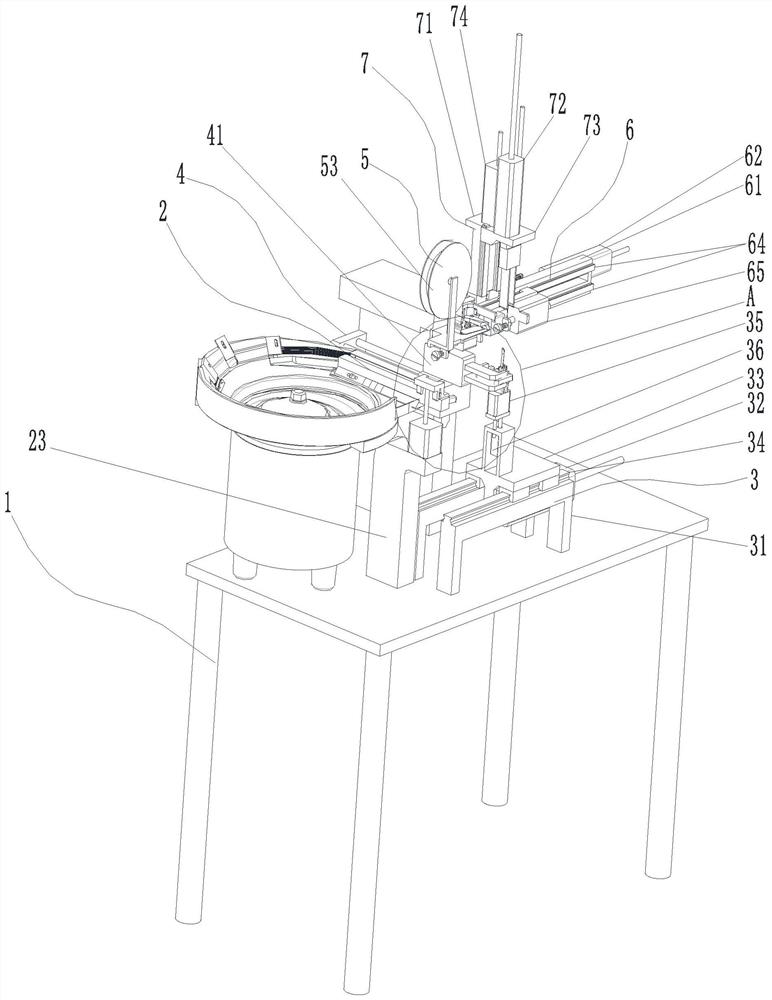

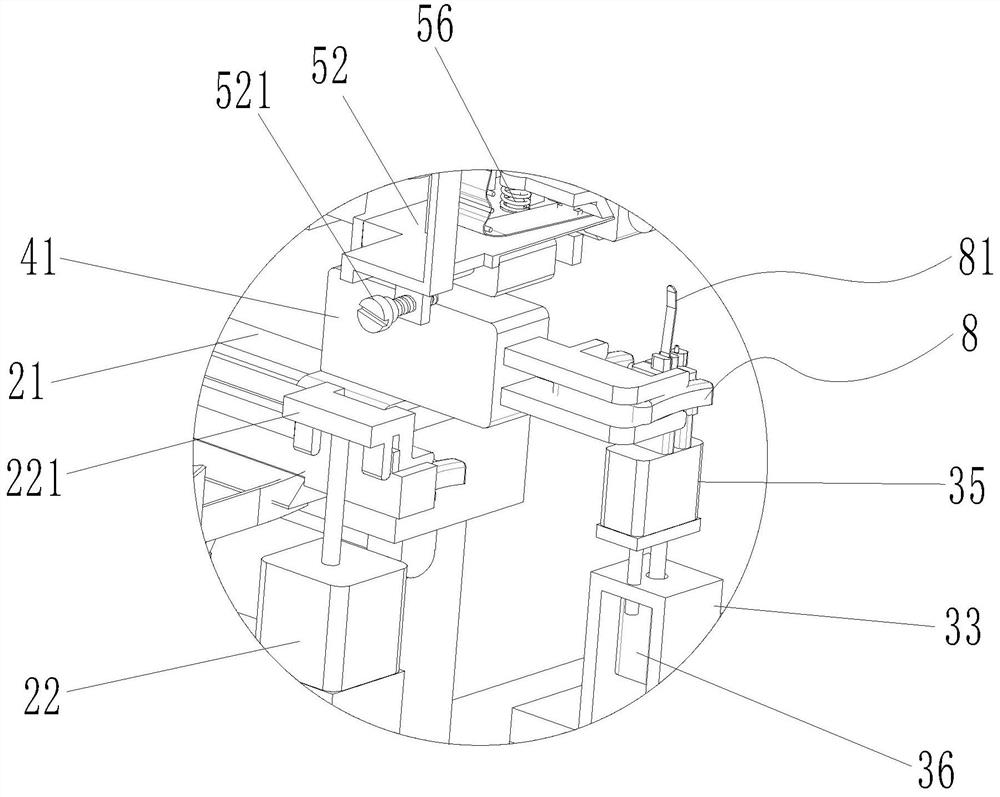

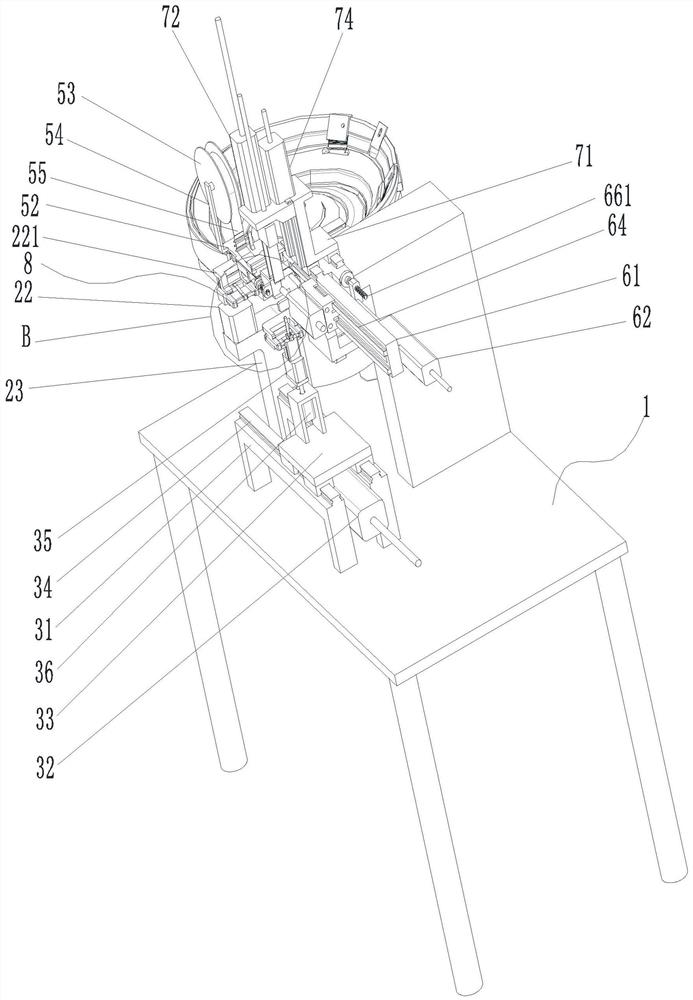

Automatic buckle-belt-passing machine

The invention relates to an automatic buckle-belt-passing machine, comprising a belt passing apparatus and a transfer apparatus; the belt passing apparatus comprises a buckle fixing mechanism, a belt conveying mechanism and a belt cutting mechanism, the buckle fixing mechanism is provided with buckle fixing positions, the belt conveying mechanism is provided with a belt conveying driver and belt passages, the belt conveying driver drives belts to move along the belt passages, the buckle fixing positions correspond to the belt passages so that holes of buckles fixed to the buckle fixing positions are aligned with the belt passages, the belts are driven by the belt conveying driver out of the belt passages and then passed through the holes of the buckles fixed to the corresponding buckle fixing positions, the belt cutting mechanism cuts off the belts after the belts are passed through the holes of the buckles, the transfer apparatus comprises a belt turning mechanism and a gripping mechanism, the belt turning mechanism is arranged at the front ends of the buckle fixing positions, and the belt turning mechanism turns the belts passed through the holes so that the gripping mechanism performs gripping after the belts are cut off; the manual buckle belt passing manner is changed, automatic buckle belt passing is achieved, and production efficiency is improved.

Owner:罗数基础(天津)机器人技术有限公司

High-speed reciprocating two-way servo wire tightening mechanism

ActiveCN106944690APromotion application value is goodOvercome the difference in tightnessElectrical-based machining electrodesElectric machineryWire cutting

The invention discloses a high-speed reciprocating two-way servo wire tightening mechanism. The mechanism comprises a wire loading mechanism, wire cylinder mechanism and a wire arrangement mechanism arranged on a machine body of a wire cutting machine tool in sequence; the wire loading mechanism comprises a motor, and a tension wheel connected with the motor; the wire arrangement mechanism comprises two sets of connecting rod combination mechanisms arranged on the same one plane in a mirror image manner; and the connecting rod combination mechanisms comprise manual wire tightening mechanisms arranged on the same one plane for enabling electrode wires to penetrate through, automatic wire tightening mechanisms, slide mechanisms and fixed guide wheels for changing a wire arrangement direction. The mechanism realizes intelligent high-frequency real-time detection and intelligent two-way servo wire tightening, thoroughly solves the problems of single-edge wire looseness and tension of molybdenum wires of a wire cutting machine tool, overcomes the defect of different elastic degrees of electrode wires caused by manual wire loading, reduces influence on the tension of the electrode wires by manual intervention, guarantees consistent tension of the electrode wires, and reduces the operation difficulty of wire cutting staff.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

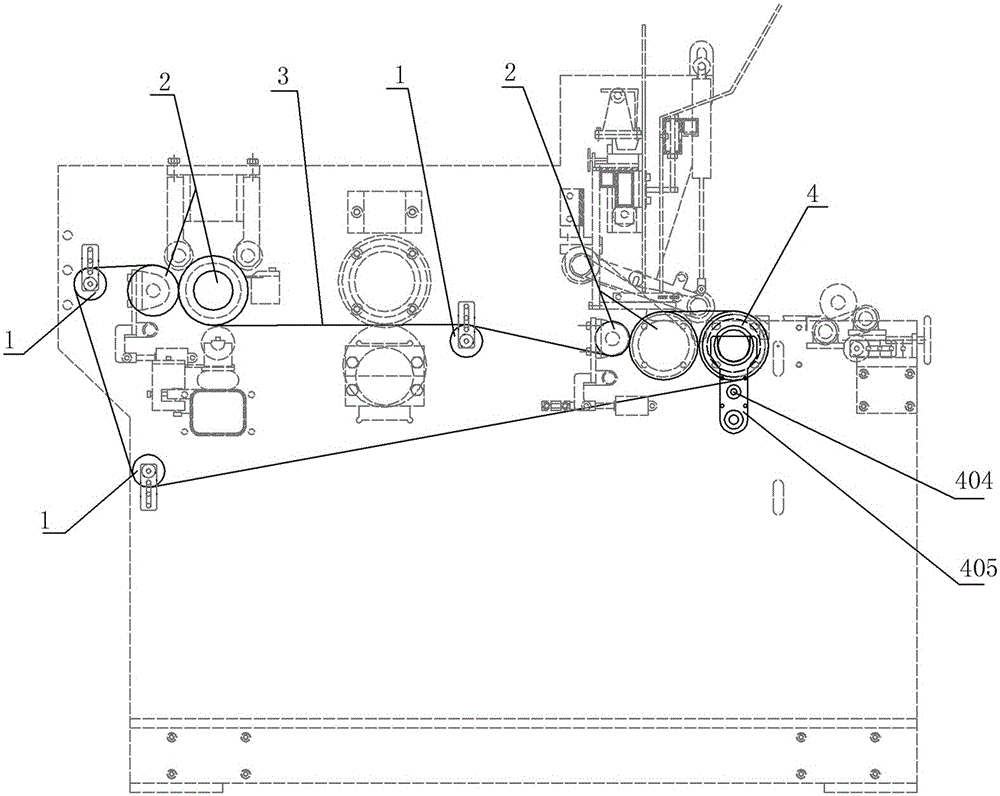

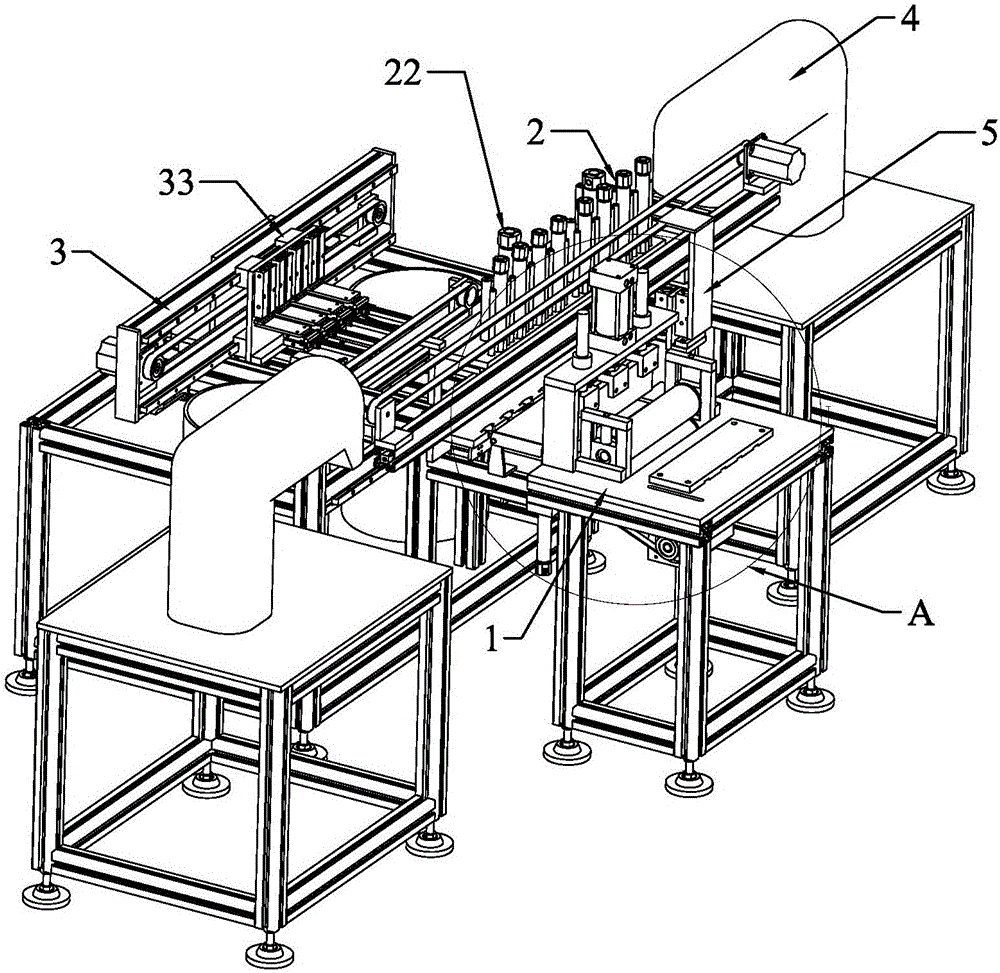

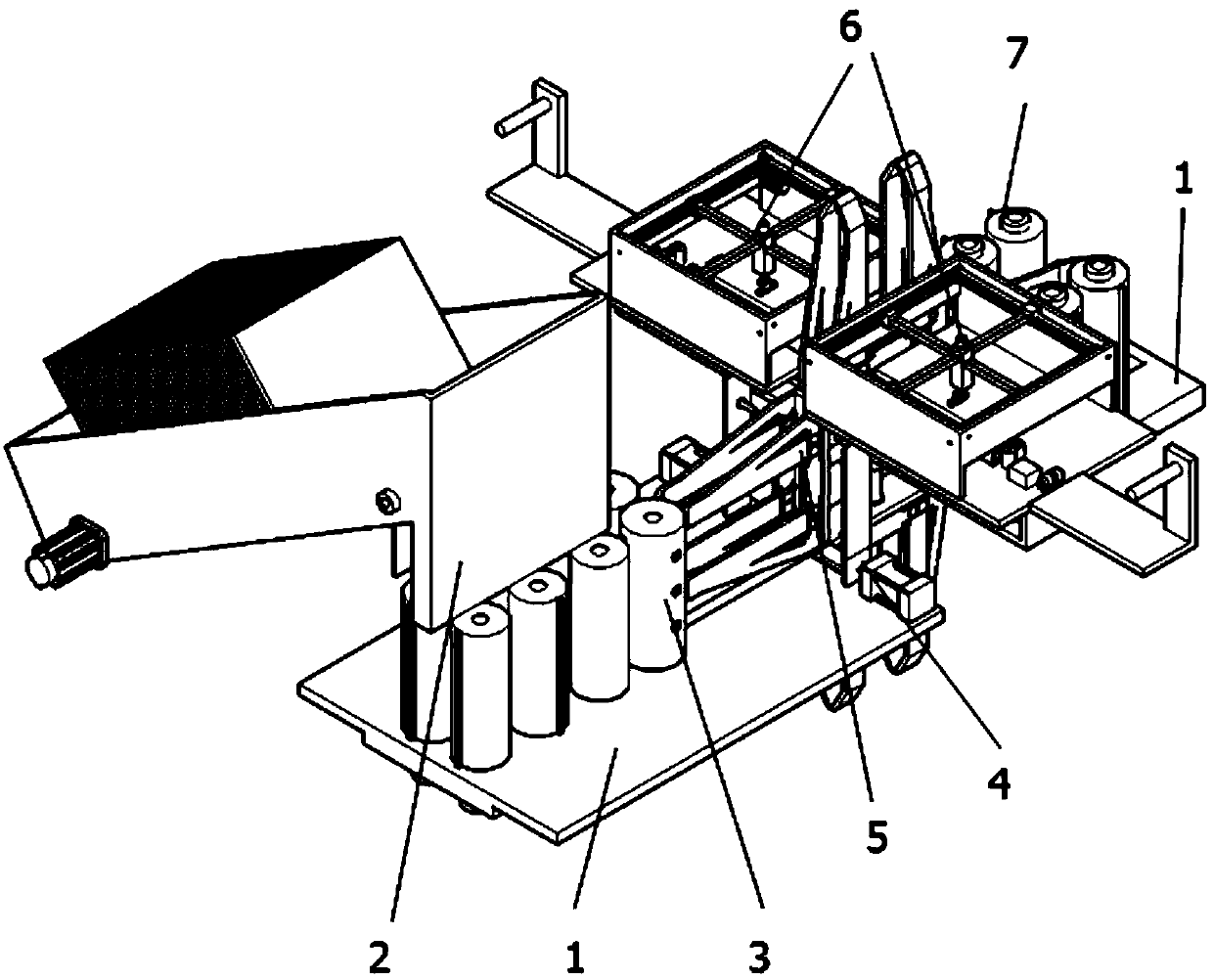

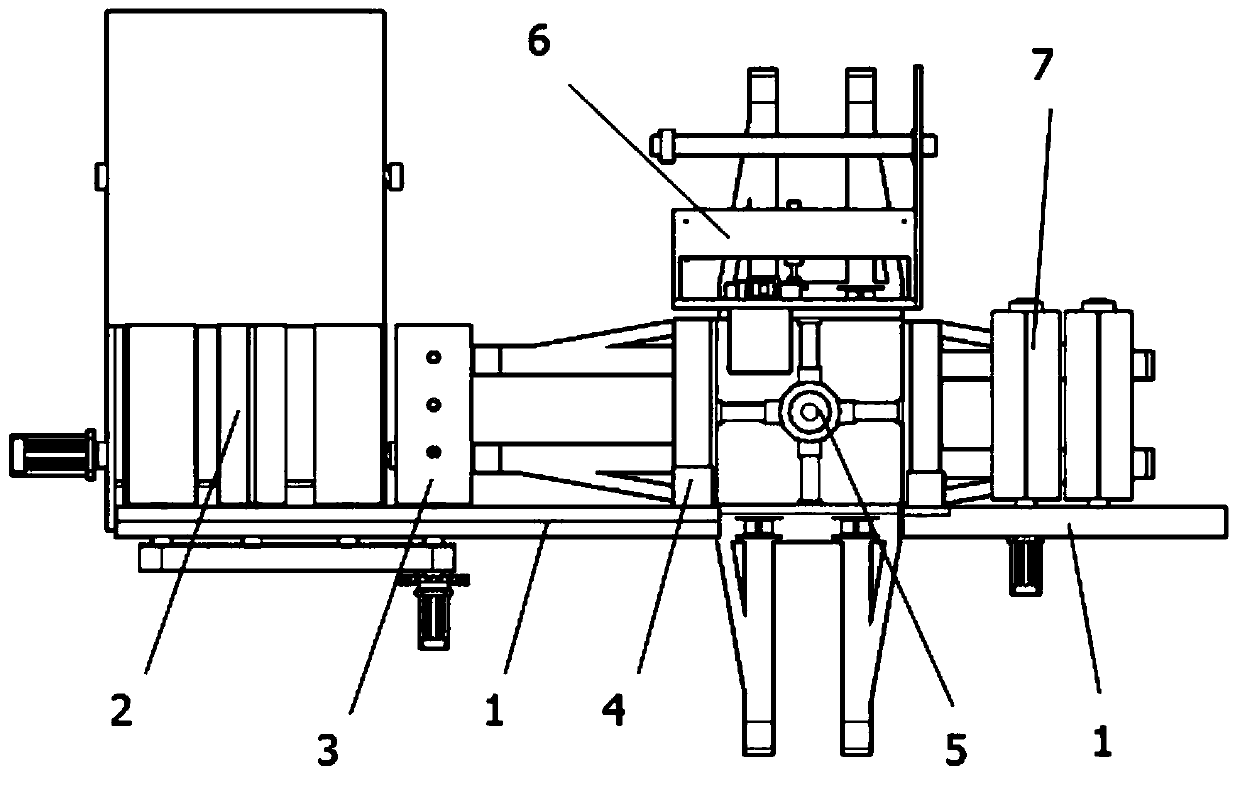

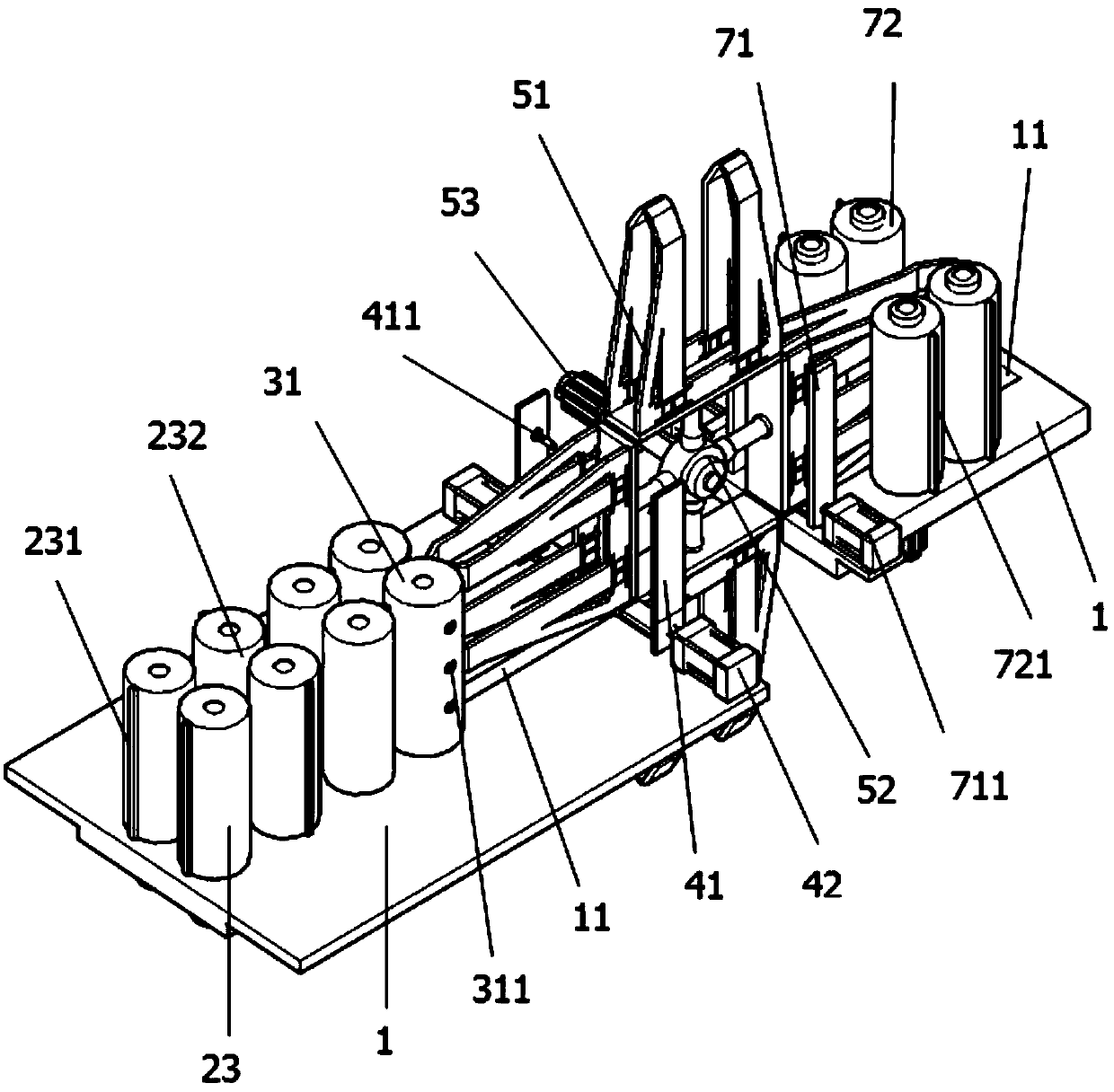

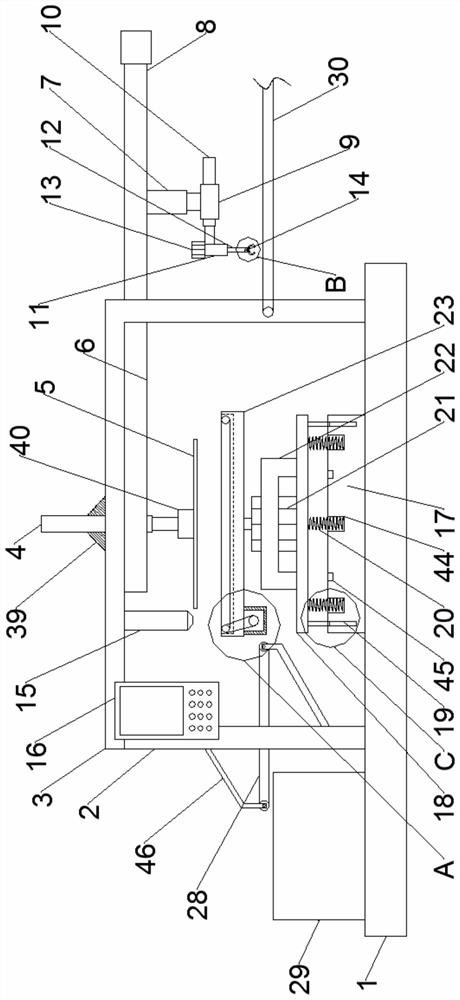

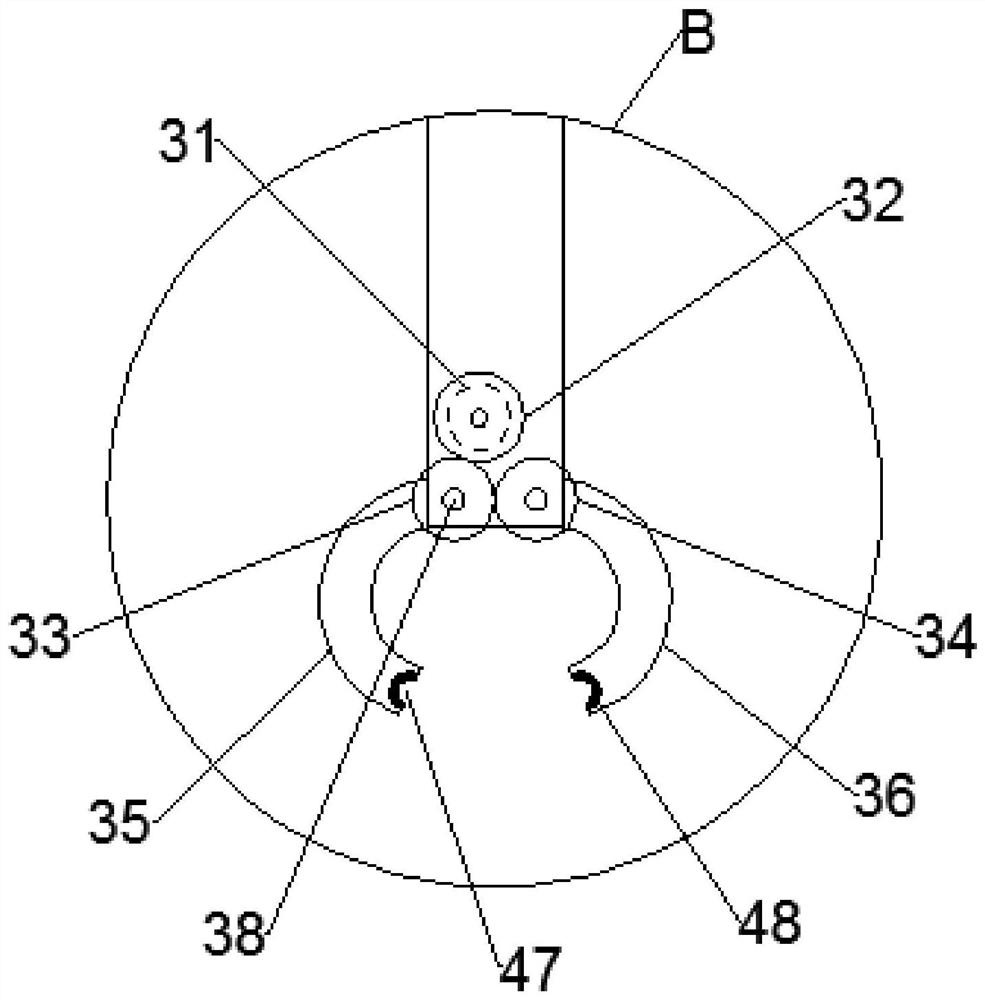

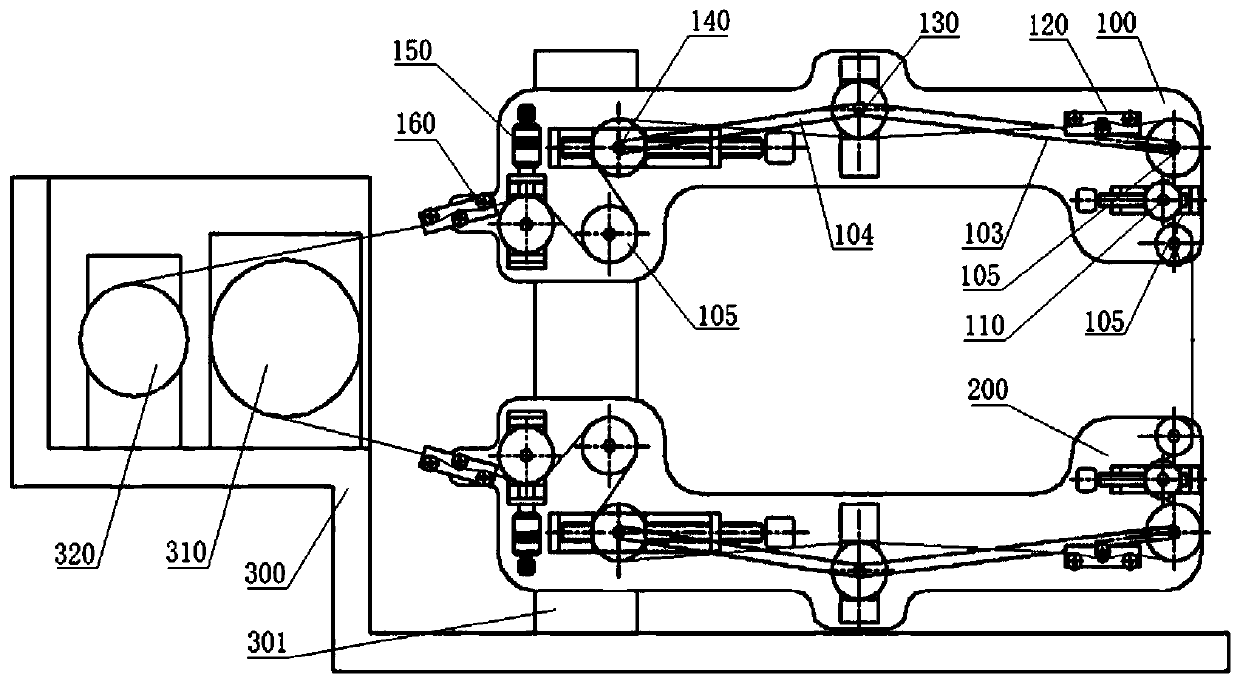

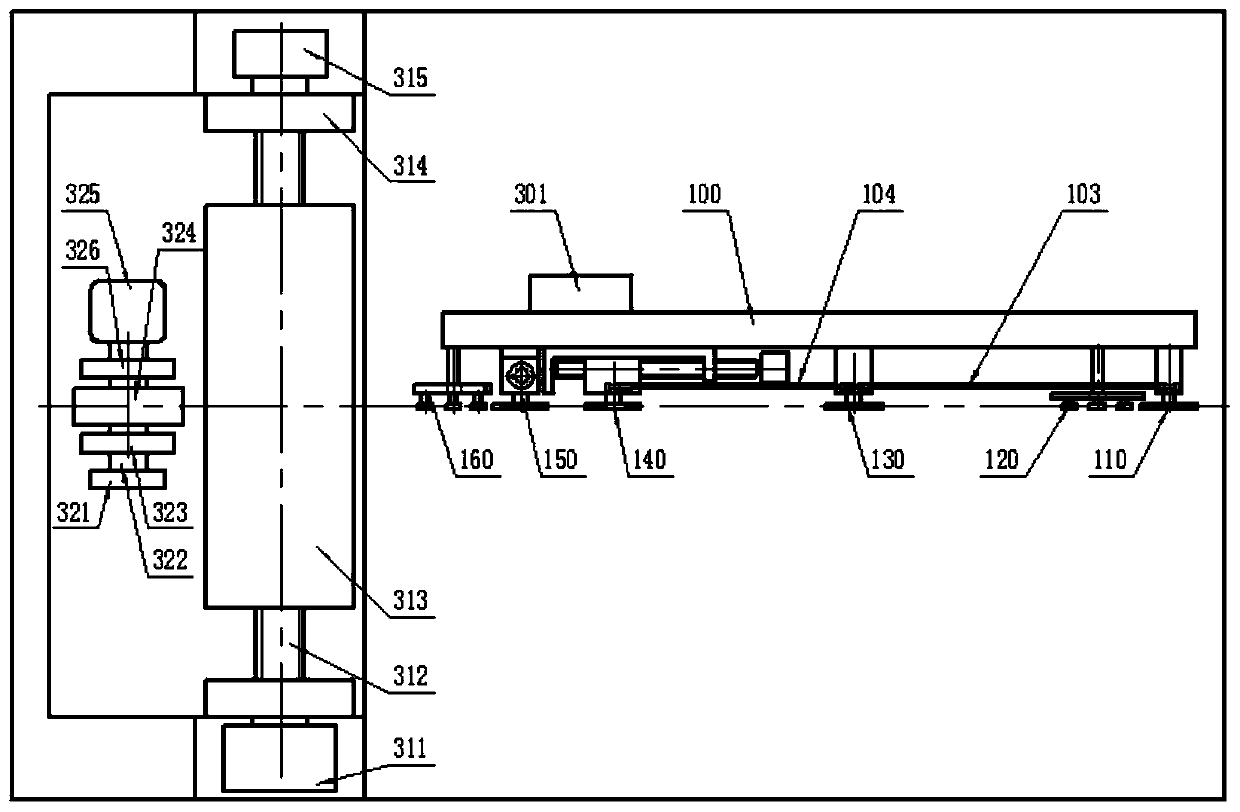

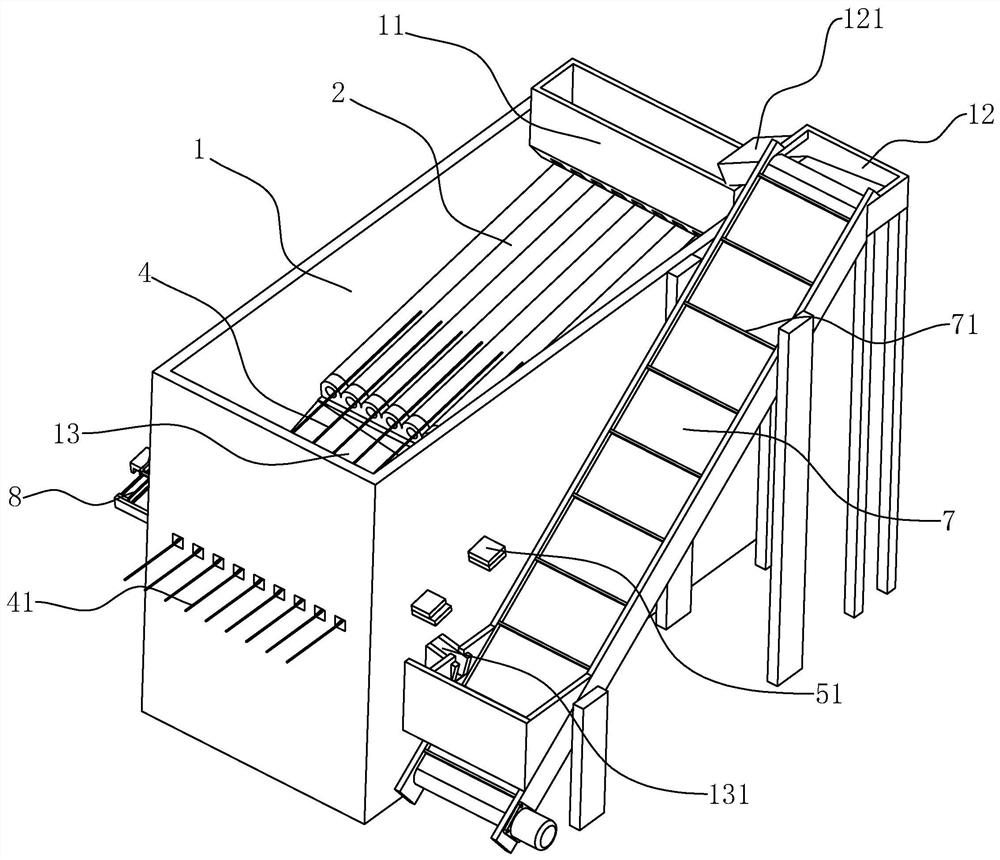

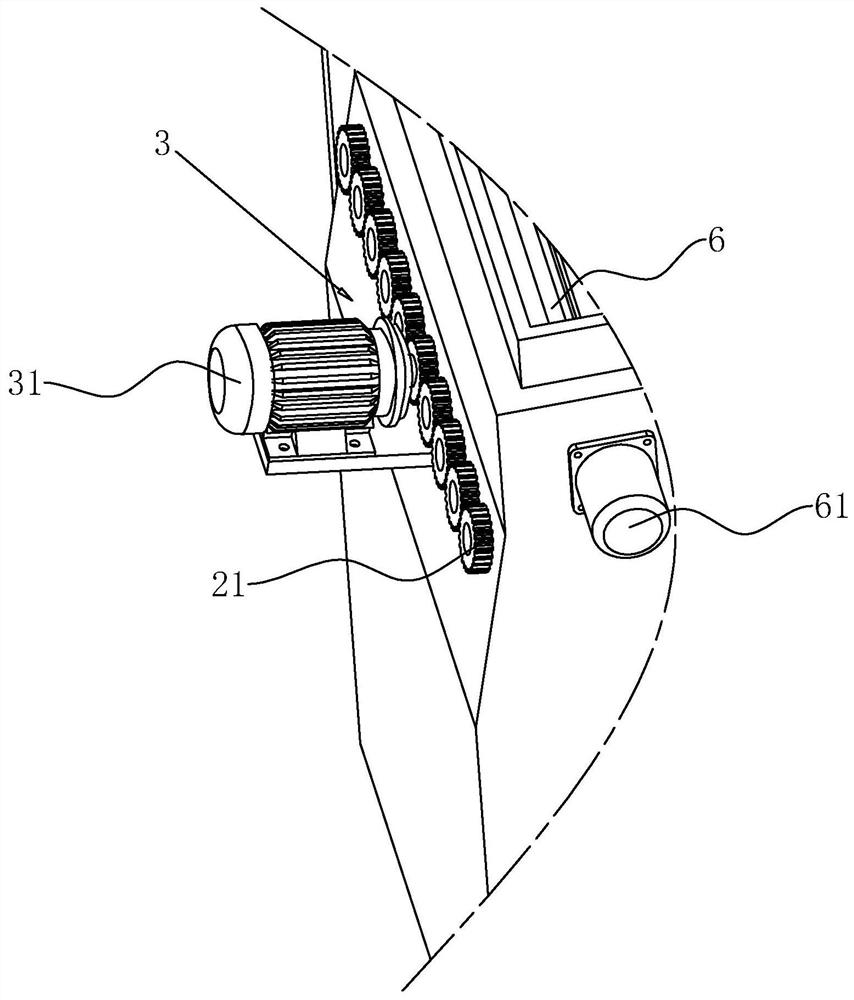

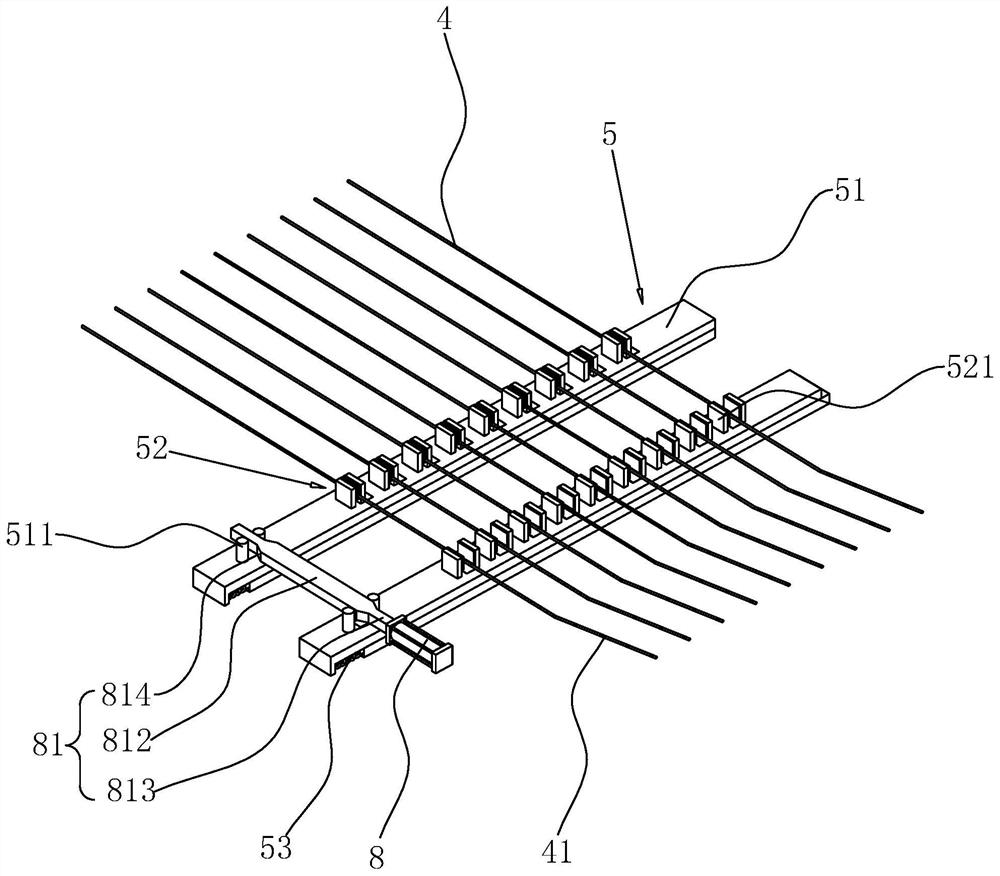

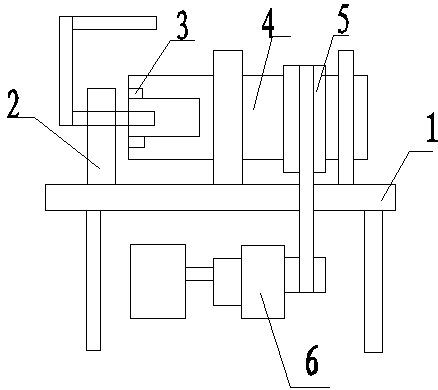

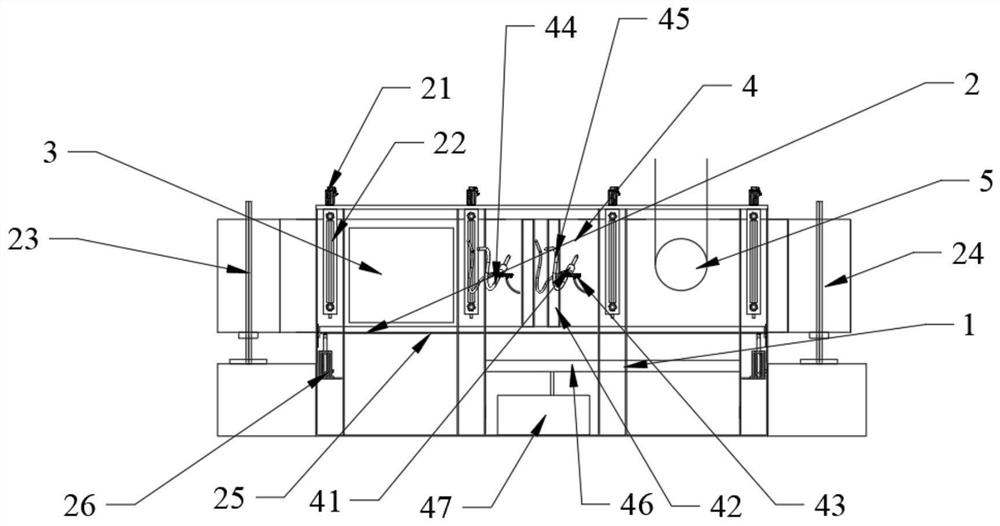

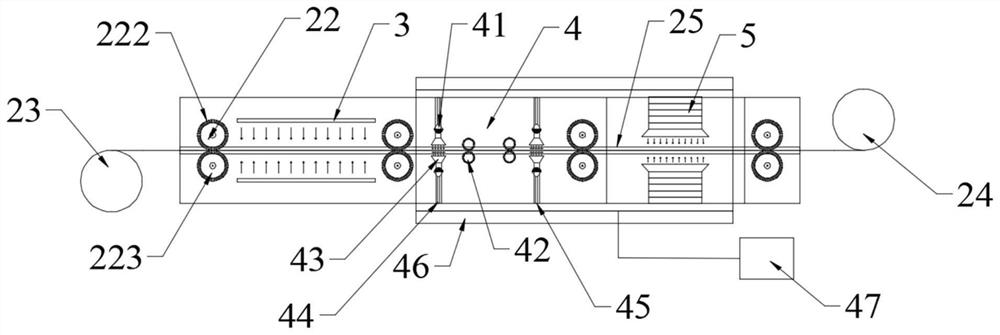

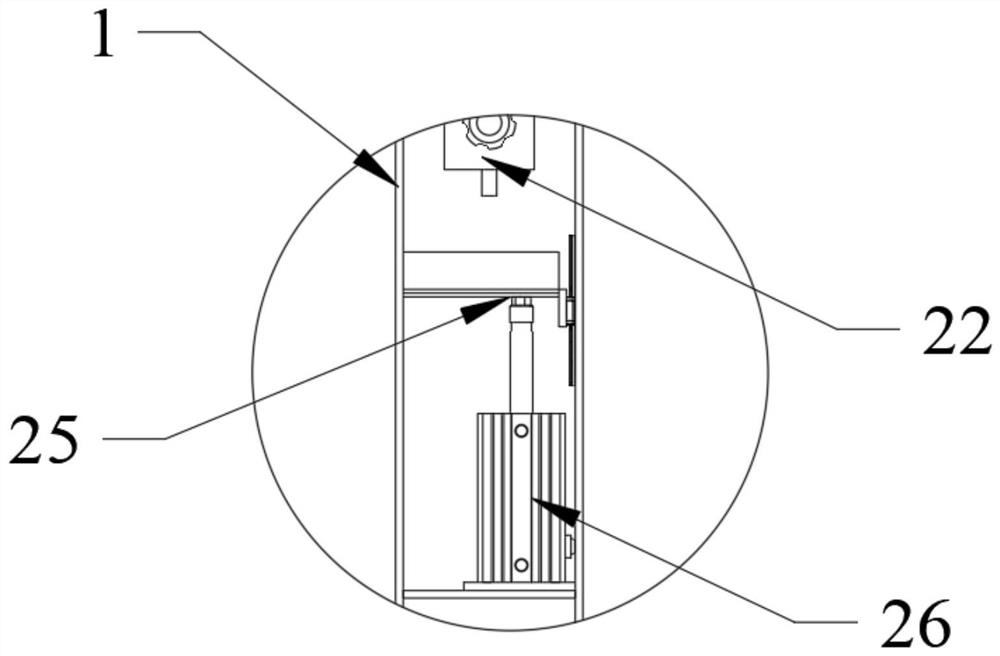

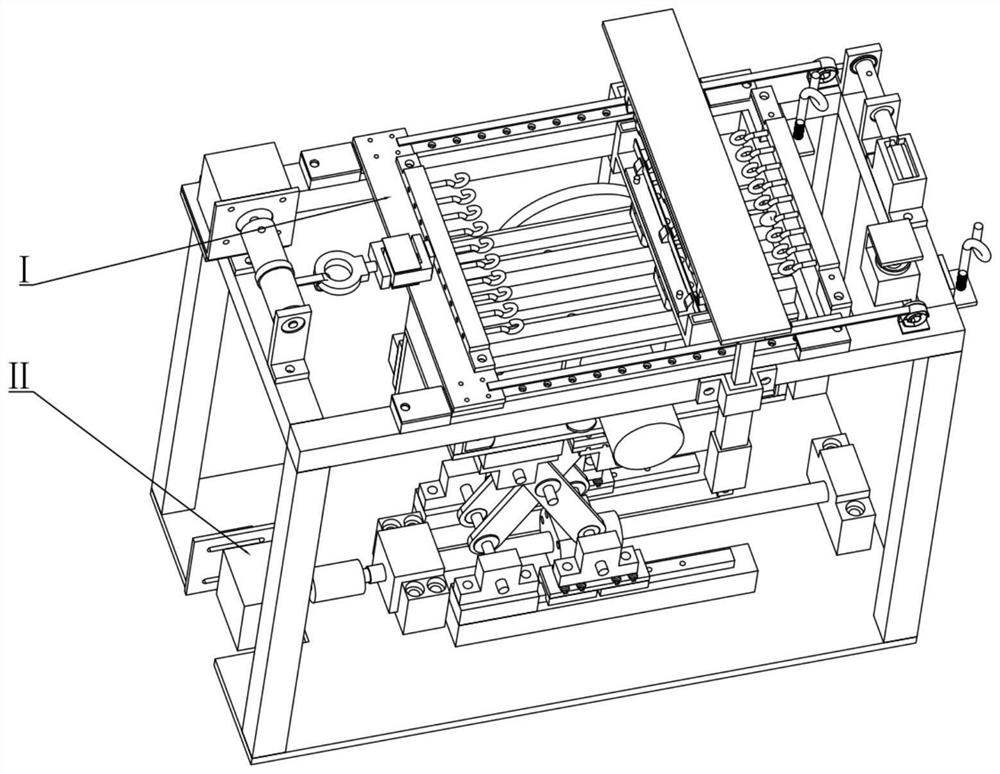

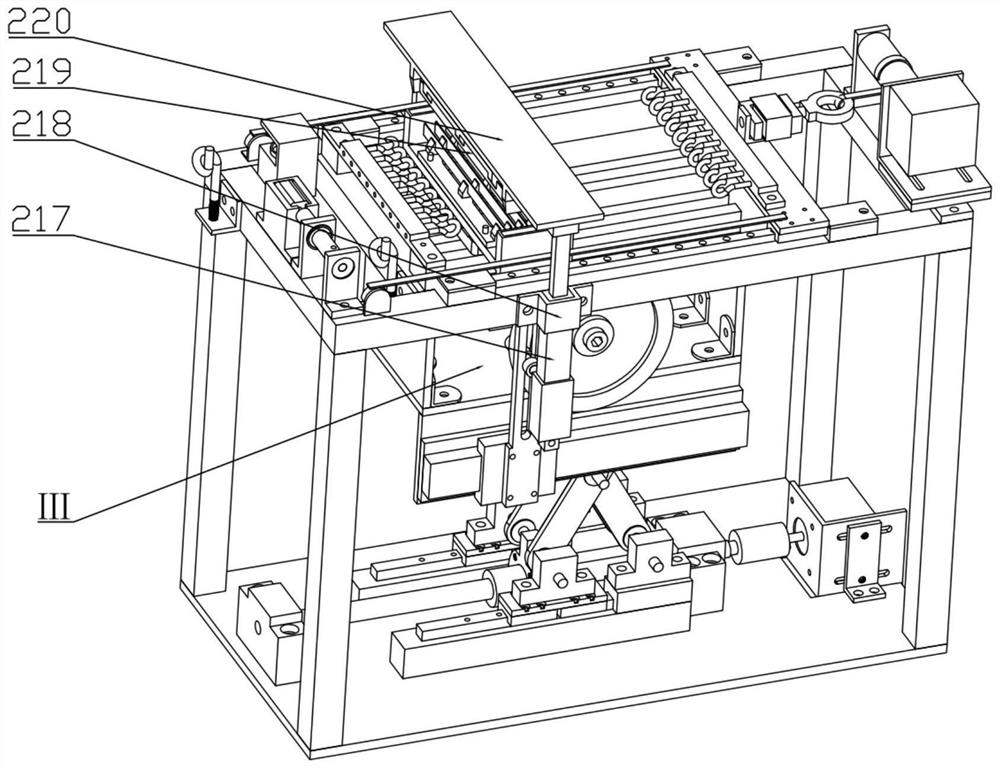

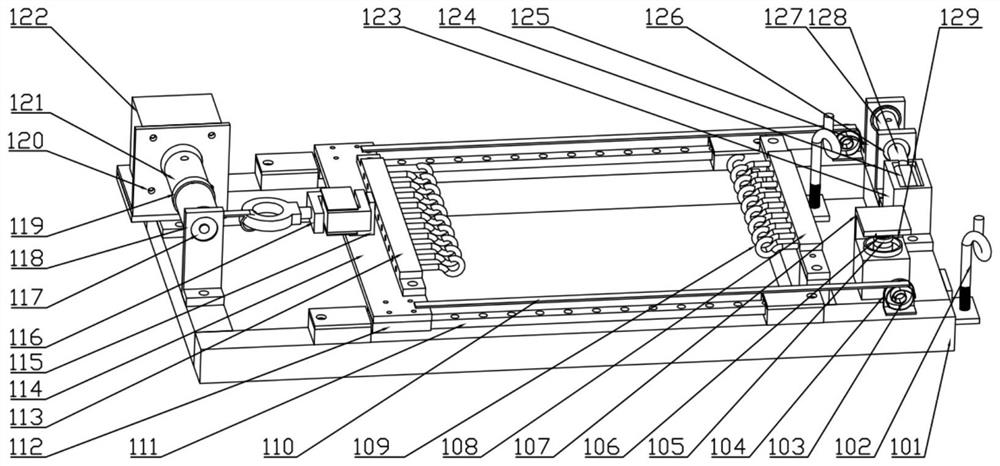

Threading machine and threading method for portable paper bag

InactiveCN109648919AImprove work efficiencyIncrease productivityBag making operationsPaper-makingPunchingPulp and paper industry

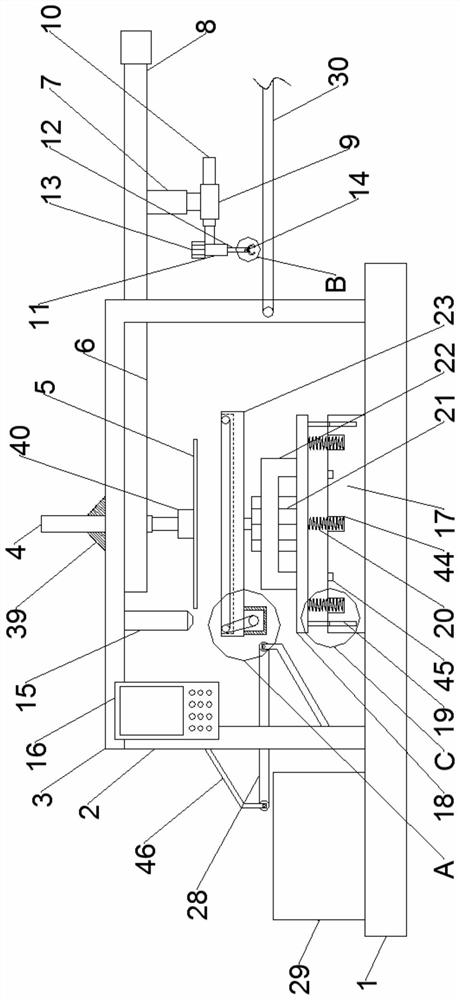

The invention relates to full-automatic portable paper bag processing equipment, in particular to a threading machine for a portable paper bag. The threading machine comprises a processing platform, afeeding mechanism, a bag opening mechanism, a punching mechanism, a bag expanding turnover mechanism, threading mechanisms and a discharging mechanism, the processing platform is composed of two flatplates which are horizontally arranged at intervals, in the conveying direction of the paper bag, the feeding mechanism is arranged above the front end of the processing platform, the bag opening mechanism is arranged at the position, below the feeding mechanism, of the processing platform, the punching mechanism is arranged at the position, behind the bag opening mechanism, of the processing platform, the bag expanding turnover mechanism is arranged at the interval between the two flat plates of the processing platform, and is arranged behind the bag opening mechanism, the number of the threading mechanisms is two, the two threading mechanisms are correspondingly arranged on the two sides of the upper end of the bag expanding turnover mechanism, and the discharging mechanism is arrangedat the position, behind the bag supporting turnover mechanism, of the processing platform. The threading machine for the portable paper bag combines a threading method so that the threading work of the portable paper bag can be rapidly completed.

Owner:射阳县农牧渔业总公司

Hand bag rope penetrating mechanism

PendingCN107650432ARealize automatic threadingReduce manual operationsBag making operationsPaper-makingEngineering

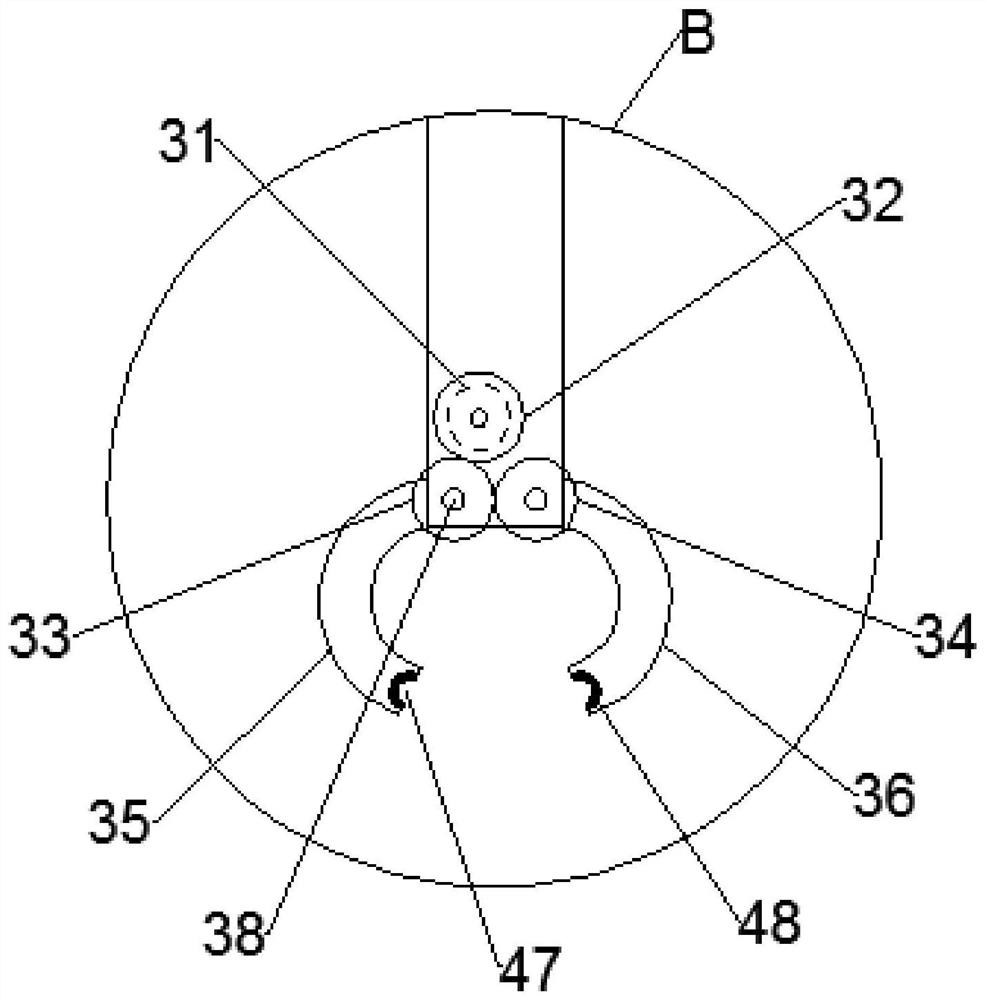

The invention discloses a hand bag rope penetrating mechanism. The hand bag rope penetrating mechanism comprises a rack, and is characterized in that a bag body opening device, inserting devices and pulling-out devices are further included; the inserting devices are used for grabbing a cut hand rope and inserting clamp heads into rope penetrating holes; the pulling-out devices are used for enabling the inserted clamp heads to enter a bag body; the inserting devices comprise the left inserting device and the right inserting device; the pulling-out devices comprise the left pulling-out device and the right pulling-out device; a bag body channel is arranged on the rack; the left inserting device and the right inserting device are arranged on the two sides of the bag body channel correspondingly; and under the rope penetrating work condition, the inserting devices grab the clamp heads of the hand rope, and the clamp heads are aligned to the rope penetrating holes in the bag body and are inserted into the rope penetrating holes. According to the hand bag rope penetrating mechanism, automatic rope penetrating of a hand bag is achieved, manual operation is omitted, work efficiency is improved, and production cost is reduced.

Owner:李新娒 +1

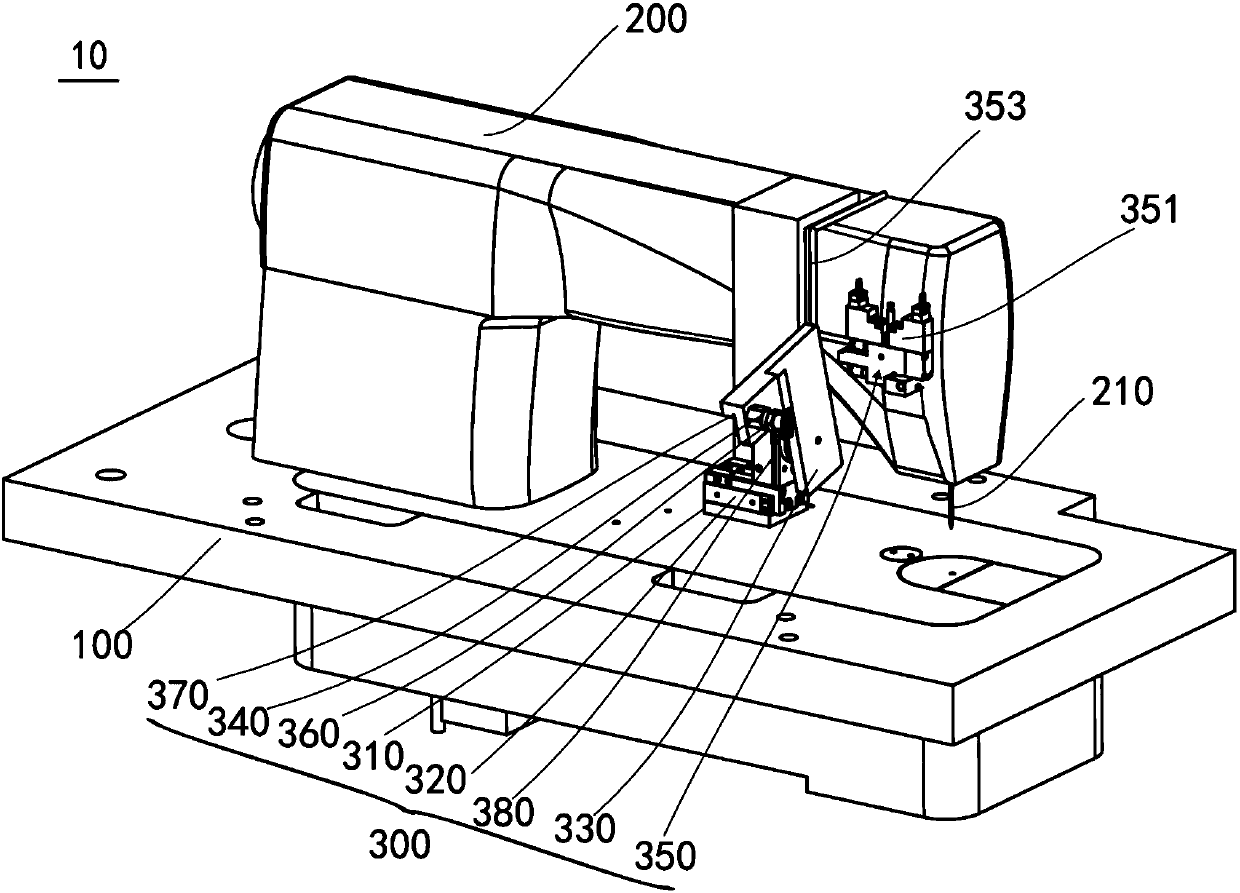

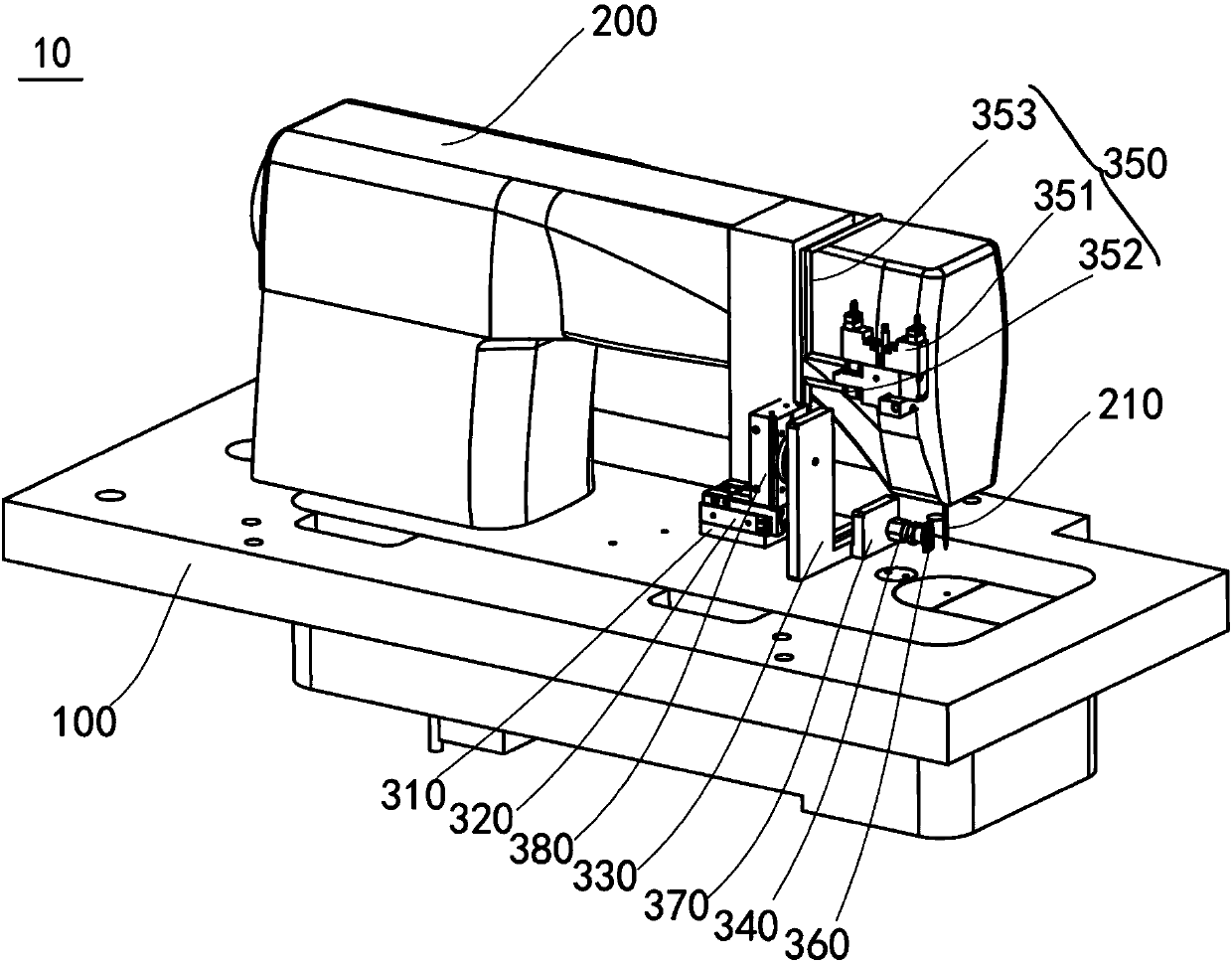

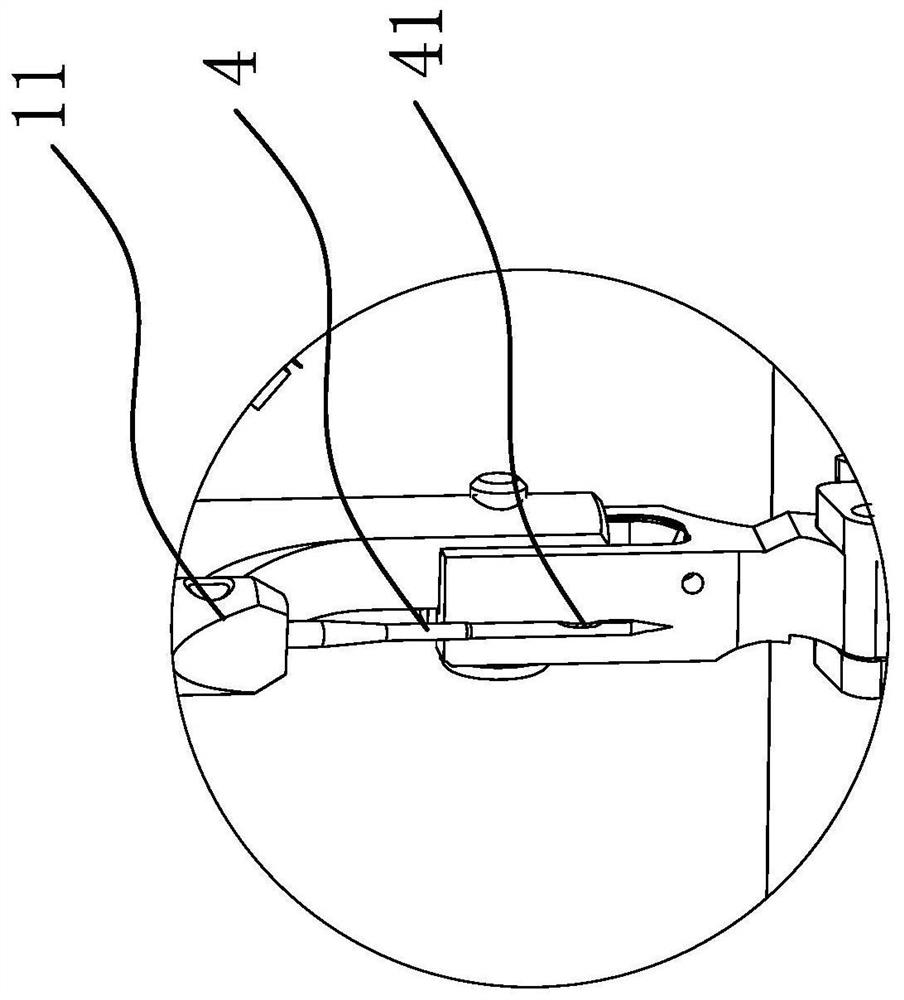

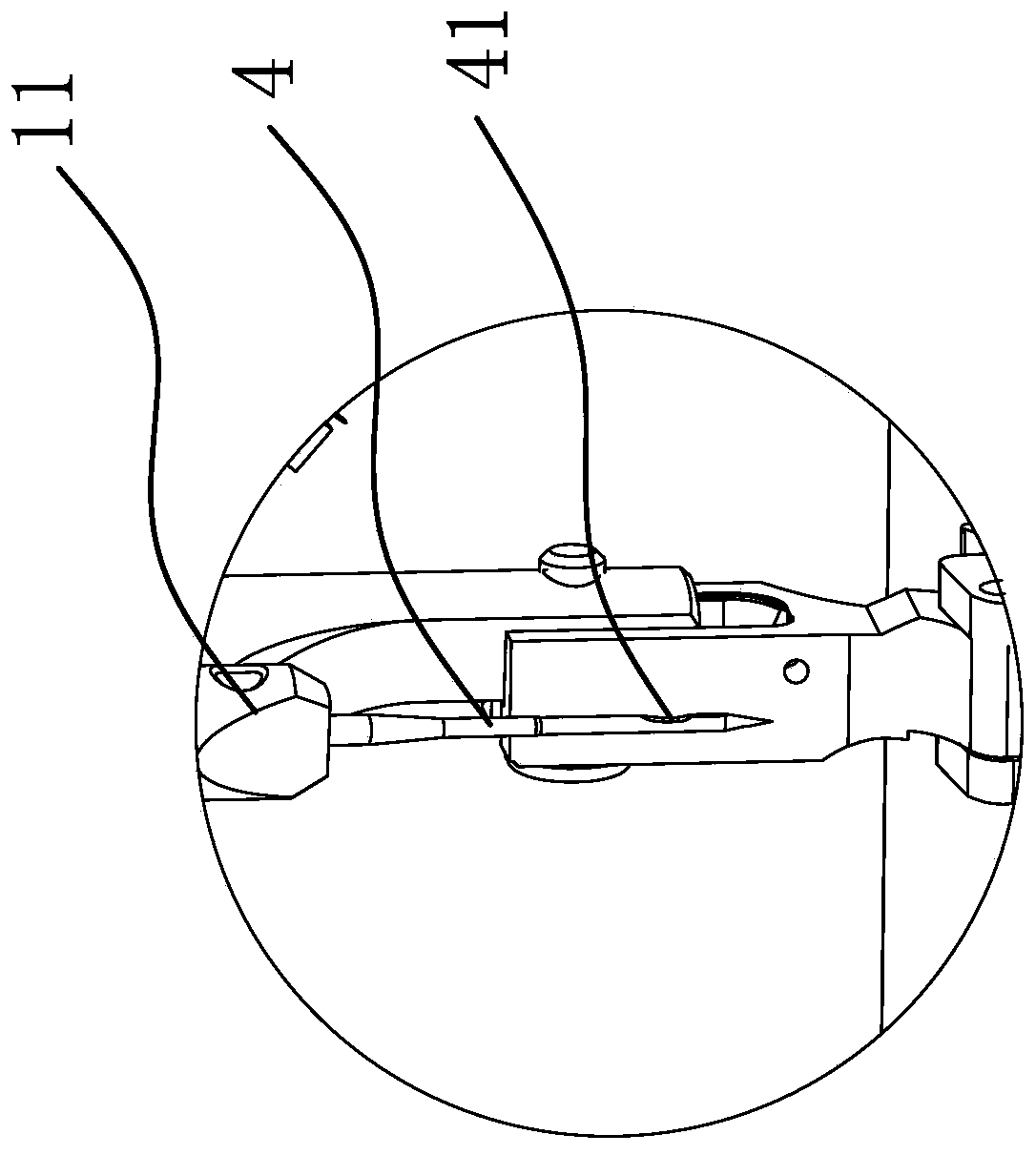

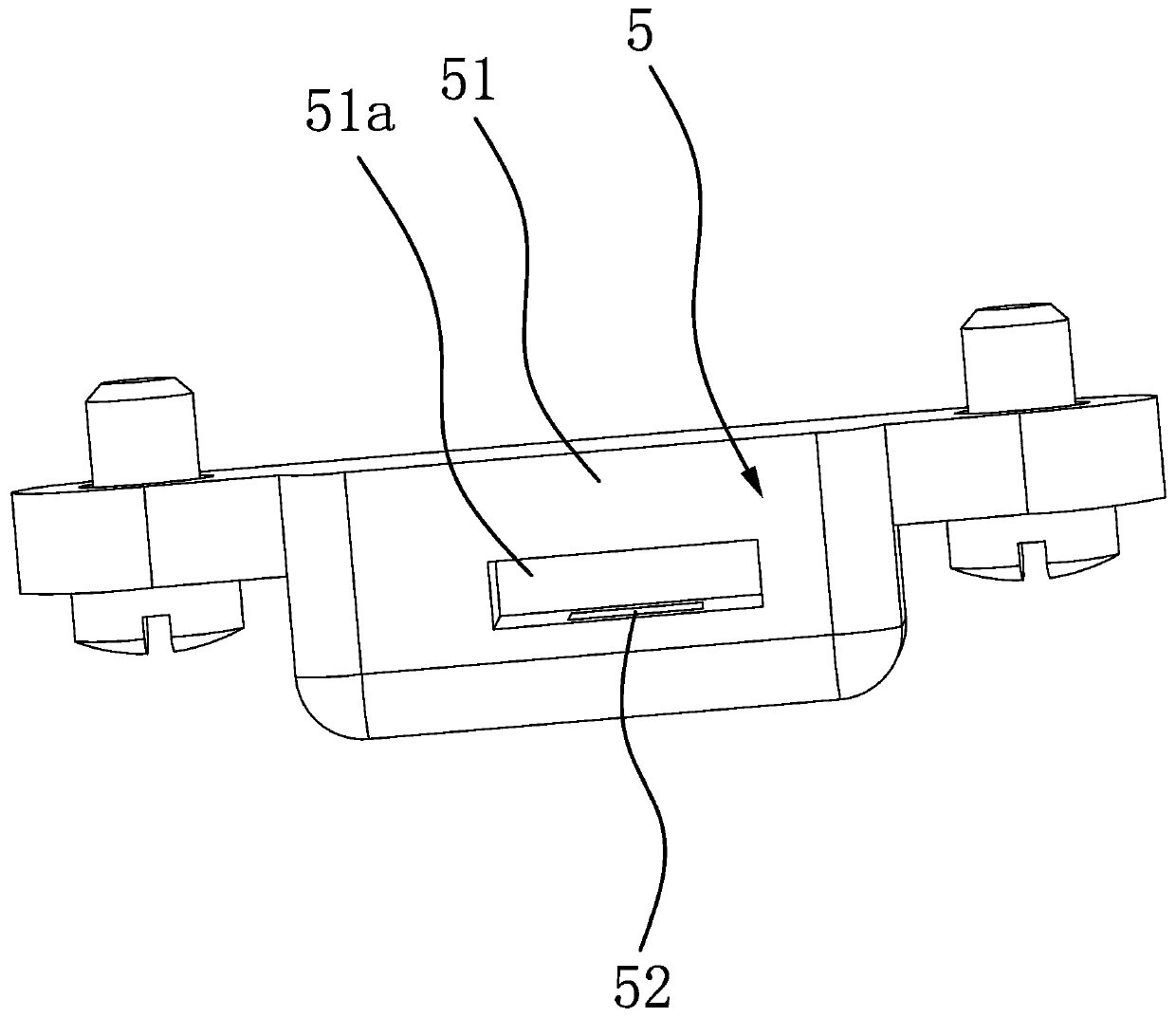

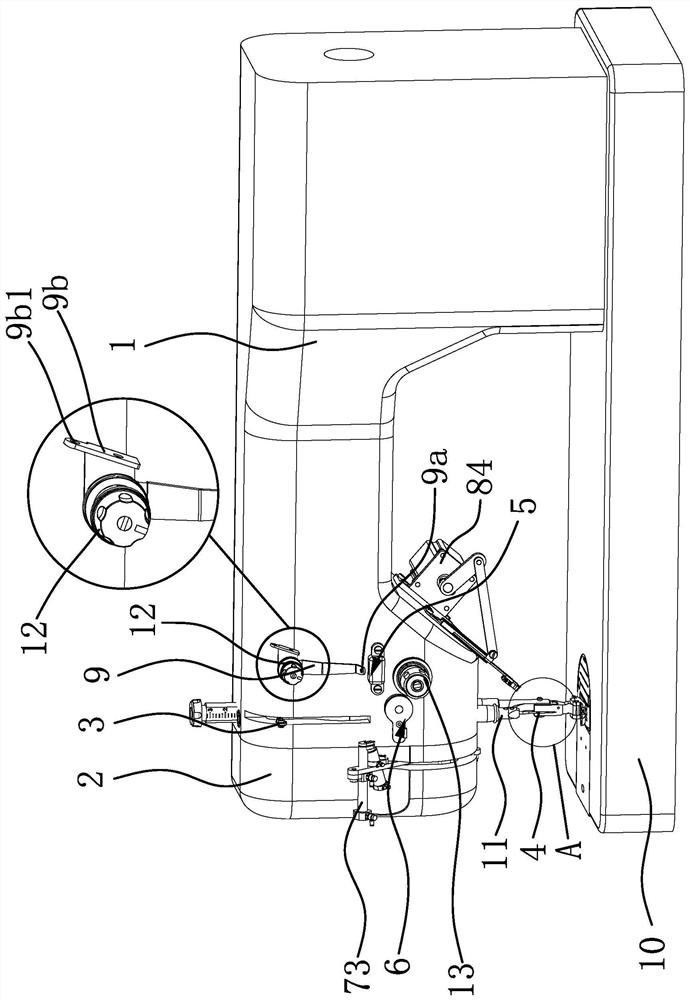

Auxiliary threading mechanism and sewing machine

ActiveCN107700099AAvoid manual threading actionRealize automatic threadingNeedle-threading devicesEngineeringSewing needle

The invention discloses an auxiliary threading mechanism and a sewing machine. The auxiliary threading mechanism comprises a base, a movable driving part, a connecting plate, an air suction pipe and an air suction part. The base is used for being connected to a sewing machine head, the movable driving part is arranged on the base and is connected to the connecting plate, the connecting plate is connected with the air suction pipe, the movable driving part can drive the connecting plate to move to drive the air suction pipe to move to a sewing needle of the sewing machine head or drive the connecting plate to drive the air suction pipe to return to the original position, the air suction pipe is communicated with the air suction part, and the air suction part is used for being connected to the sewing machine head so as to be used for sucking air through the air suction pipe. The auxiliary threading mechanism saves time and labor.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Automatic bra steel ring penetrating and connecting equipment

InactiveCN113229545ARealize automatic threadingRealize automatic feeding processBrassieresCorsetsRobot handVisual recognition

The invention discloses automatic bra steel ring penetrating and connecting equipment which comprises a supporting base, a supporting top plate is arranged at the top end of the supporting base, an electric telescopic rod is arranged in the middle of the supporting top plate, a pressing plate is arranged at the bottom end of the electric telescopic rod, and a guide rail is arranged at one end of the bottom of the supporting top plate. A first electric push rod, a second electric push rod and a second fixing clamping sleeve are arranged at the bottom end of the guide rail, a rotating shaft is arranged in the second fixing clamping sleeve, a mechanical arm is arranged at the bottom end of the rotating shaft, and a visual recognition sensor is arranged on one side of the bottom end of the supporting top plate. The top of the supporting base is provided with a supporting seat, and the top of the supporting seat is provided with a supporting plate, A servo motor is arranged at the top end of the supporting plate, and a supporting rotary disc is arranged at the top end of the servo motor. Theautomatic bra steel ring penetrating and connecting equipment has the beneficial effects that automatic threading of bra steel rings can be realized, multi-angle conversion can be realized according to the shapes of the steel rings during threading, the threading accuracy is improved, automatic feeding of the steel rings and automatic discharging of finished products can be realized, the production efficiency is effectively improved, and the working intensity of workers is reduced.

Owner:重庆知翔科技有限公司

PVC pipe threading equipment

InactiveCN112260147ARealize automatic threadingShorten the timeApparatus for laying cablesElectric machineDrive shaft

The invention relates to the field of PVC pipes, in particular to PVC pipe threading equipment, which comprises a box body, a motor is arranged in the box body, a large transmission cavity is formed in the box body, the box body is in power connection with a motor shaft extending leftwards to the right end wall of the large transmission cavity, a large gear is fixedly arranged on the motor shaft,and a small transmission cavity is formed in the box body. The left end wall of the large transmission cavity is rotatably provided with a transmission shaft extending leftwards into the small transmission cavity, the transmission shaft is fixedly provided with a transmission device in the small transmission cavity, and the box body is internally provided with an air cylinder. The PVC pipe threading equipment can achieve the automatic threading process of a PVC pipe, an electric wire penetrates into the PVC pipe through a threading device, and compared with traditional manual operation, a large amount of time is saved, and the production cost is reduced while the working efficiency is improved.

Owner:QINGDAO KEKA STATIONERY CO LTD

One-time threading device for automatic detection line of mutual inductor

InactiveCN102628929BRealize automatic threadingReduce wearElectrical measurementsElectrical conductorFixed frame

The invention discloses a one-time threading device for an automatic detection line of a mutual inductor, which belongs to the technical field of detection of the mutual inductor, particularly relates to a one-time threading device for a piercing current transformer, and is used for solving the problem of automatic one-time threading of the mutual inductor of a uniform appearance and uniform specification. The one-time threading device mainly comprises a fixing frame, a fixing platform, a piercing conductor, a piercing conductor frame, a conductor bracket, a guide rail, a guide rail slide block, a guide rail base, a lead screw transmission mechanism and a conductor socket assembly. The one-time threading device is suitable for verifying piercing current transformers on a large scale in a measuring and verifying center.

Owner:STATE GRID CORP OF CHINA +1

A high-speed reciprocating two-way servo tightening mechanism

ActiveCN106944690BDetect real-time dynamic tensionDetection components always detect real-time dynamic tensionElectrical-based machining electrodesWire cuttingMirror image

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Pearl necklace automatic threading machine

InactiveCN113876092ARealize automatic threadingHigh degree of automationJewelleryEngineeringCentrifugal force

The invention relates to a pearl necklace automatic threading machine, and relates to the field of pearl threading equipment. The pearl necklace automatic threading machine comprises a rack, the upper end part of the rack is rotatably connected with a plurality of mutually parallel round rollers, the round rollers are obliquely arranged along the length direction of the rack, the rack is provided with a driving device for driving the adjacent round rollers to reversely rotate, and a long needle is arranged between every two adjacent round rollers; and the long needle is parallel to the round rollers, one end of the long needle is connected with a soft rope, and the rack is provided with a fixing device used for fixing the long needle. The driving device drives the round rollers to rotate, pearls move downwards between every two adjacent round rollers and then are driven by the round rollers to roll, the axes of the pearl through holes are parallel to the long needle under the action of gravity and centrifugal force, the pearls are automatically strung on the long needle and the soft ropes in the falling process, and then automatic threading is achieved. The machine has the effect of being high in automation degree.

Owner:陈振波

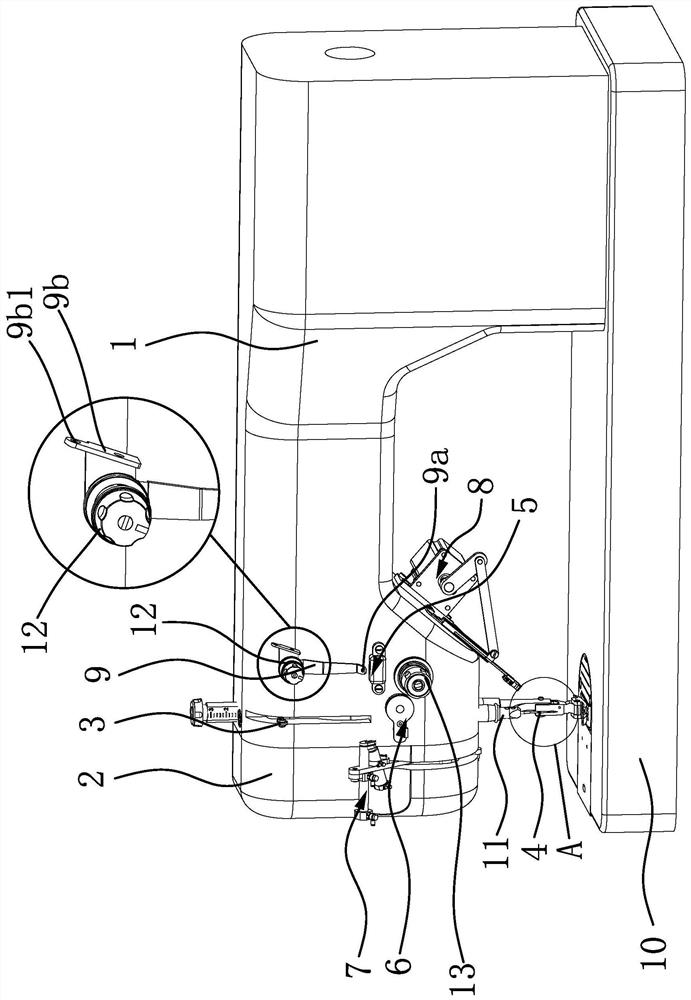

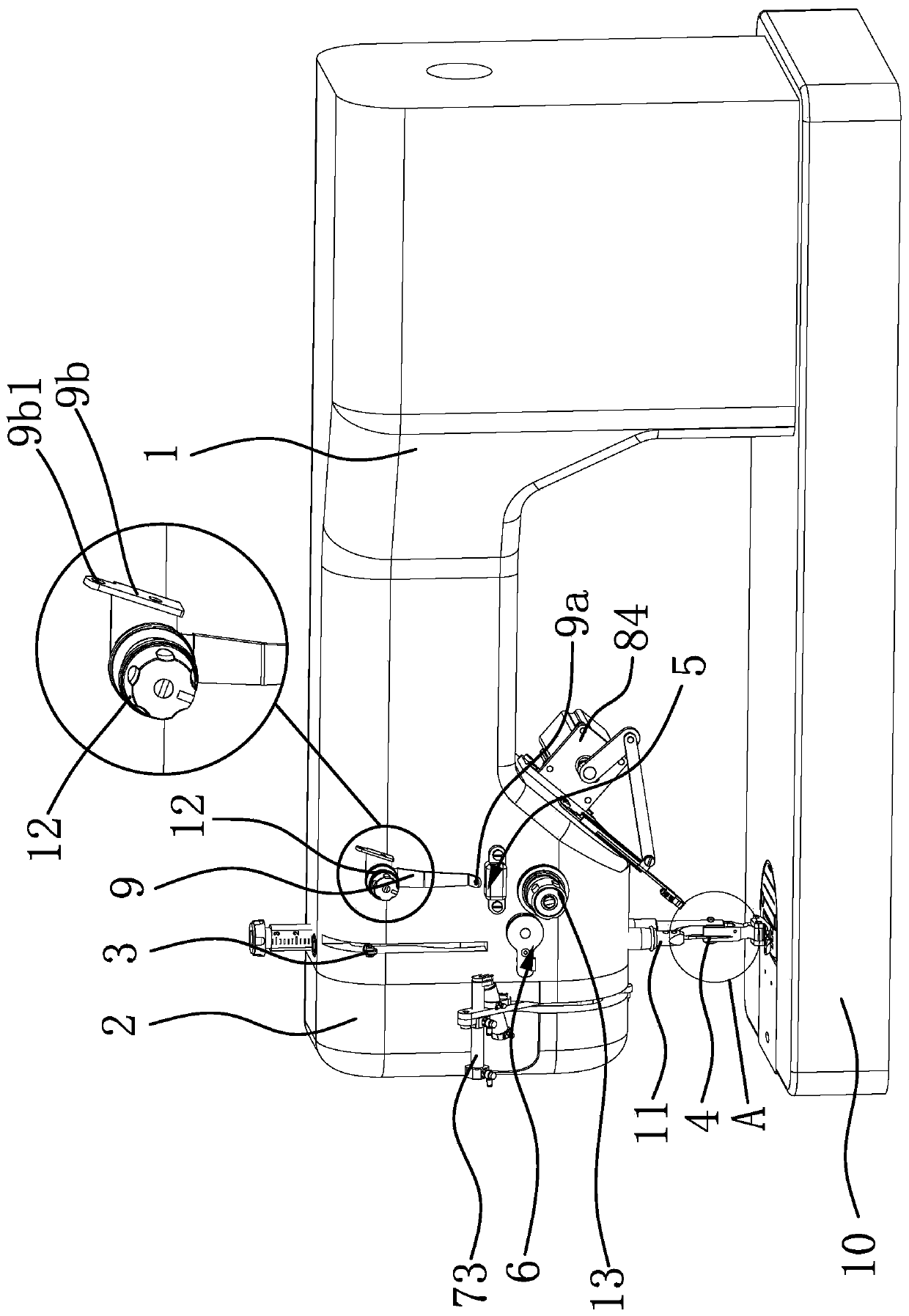

An automatic button-threading machine and its application in shoe-making

ActiveCN110950066BRealize automatic threadingSave human effortConveyor partsReciprocating motionStructural engineering

The invention discloses an automatic pin buckle wearing machine and application thereof in shoemaking production. A pin buckle fixed at the output end of an input mechanism is moved by a translation and clamping mechanism, a pin of the pin buckle is placed vertically upward, and then the pin buckle is enabled to do horizontal reciprocating motion between the lower portion of a pin buckle wearing mechanism and the output end of the input mechanism; when the pin of the pin buckle can achieve station switching, the orientation of the pin is adjusted, and the pin buckle wearing mechanism can be more convenient to use during pin buckle wearing; moreover, by the cooperation of a strip coiling mechanism and a moving mechanism, a strip required for pin buckle wearing can be continuously and automatically cut into sections and supplied to the pin buckle wearing mechanism for operation. According to the scheme, automatic pin buckle wearing is achieved, manpower is saved, and the production efficiency is improved.

Owner:吉庆禹

A sewing machine with automatic threading function

ActiveCN111560714BRealize automatic threadingHigh degree of automationNeedle severing devicesThread-break detectorsPhysicsWire breakage

The invention provides a sewing machine with automatic threading function, which belongs to the technical field of sewing machines. It solves the technical problems such as the low degree of automation of sewing machine threading. The sewing machine includes a casing, a side cover, a thread take-up lever and a machine needle. The needle has a threading hole, and the outer surface of the casing is located between the thread take-up lever and the needle with a thread break detection device; the outer surface of the casing is also A thread clamping structure for thread clamping and thread cutting is fixed, and a thread release structure is provided on the side cover. The thread release structure includes a rotating link and a driving member that drives the rotating link to swing to the side of the threading hole of the needle; the rotating link One end of the clamping cylinder and the top line cylinder are fixed, the outer end of the output shaft of the clamping cylinder is fixed with a clamping plate, the clamping plate has an open groove, and the output shaft of the top line cylinder is fixed with an opening groove The ejector rod; the casing is provided with a threading structure capable of clamping the suture at the clamping plate and passing through the threading hole of the needle. The sewing machine of the invention improves the automation degree of threading of the existing sewing machines.

Owner:TAIZHOU UNIV

Automatic paper threading device at the operating side of the reel

InactiveCN105129474BRealize automatic threadingHigh degree of automationWebs handlingWinding machinePaper tape

The invention relates to the field of papermaking machines, in particular to an automatic paper leading device used on the operating side of a paper winding machine. The automatic paper leading device comprises a guiding tensioning wheel, an idle pulley and a paper leading belt. Paper leading through grooves are evenly distributed in the middle of the paper leading belt in the length direction of the belt. The automatic paper leading device further comprises a paper leading belt engagement and disengagement mechanism which is coaxial with a paper winding roller of the paper winding machine. The paper leading belt surrounds the guiding tensioning wheel. The idler wheel and the paper leading belt engagement and disengagement mechanism rotate cyclically. According to the automatic paper leading device used on the operating side of the paper winding machine, paper tape can be led to the position nearby the paper winding roller from one end of the paper leading belt by controlling a cylinder to stretch out and draw back at a long distance, full-automatic paper leading is achieved, and the automation degree is greatly improved; meanwhile, safety accidents which are easily caused by manual paper leading are avoided, and safe production is quite greatly promoted; and one worker can completely finish paper leading operation, manual investment in a factory is reduced, manpower is saved, and production cost is reduced for enterprises.

Owner:程黔

Threading mechanism for automatic winding machine

The invention relates to a threading mechanism for an automatic winding machine. The threading mechanism comprises a wire taking device, a fixing device and a wire fixing device. The wire taking device and the wire fixing device are arranged on the two sides of the fixing device respectively. The wire fixing device comprises a guide rail and a wire fixing clamp, the guide rail is assembled on thefixing device, and the wire fixing clamp is movably assembled on the guide rail. The fixing device comprises a clamping jaw, a base part, a shaping device and a driving device, the clamping jaw is movably assembled on the base part, the shaping device is connected to the base part, the wire taking device and the clamping jaw are arranged on the same side of the base part, the wire fixing device and the shaping device are arranged on the same side of the base part, and the driving device penetrates through the base part. The wire taking device clamps a copper wire to the fixing device, the wirefixing clamp of the wire fixing device can clamp the copper wire, the wire fixing clamp moves along the guide rail to enable the copper wire to penetrate through the fixing device, and the automaticwire threading is achieved.

Owner:东电化电子(珠海)有限公司

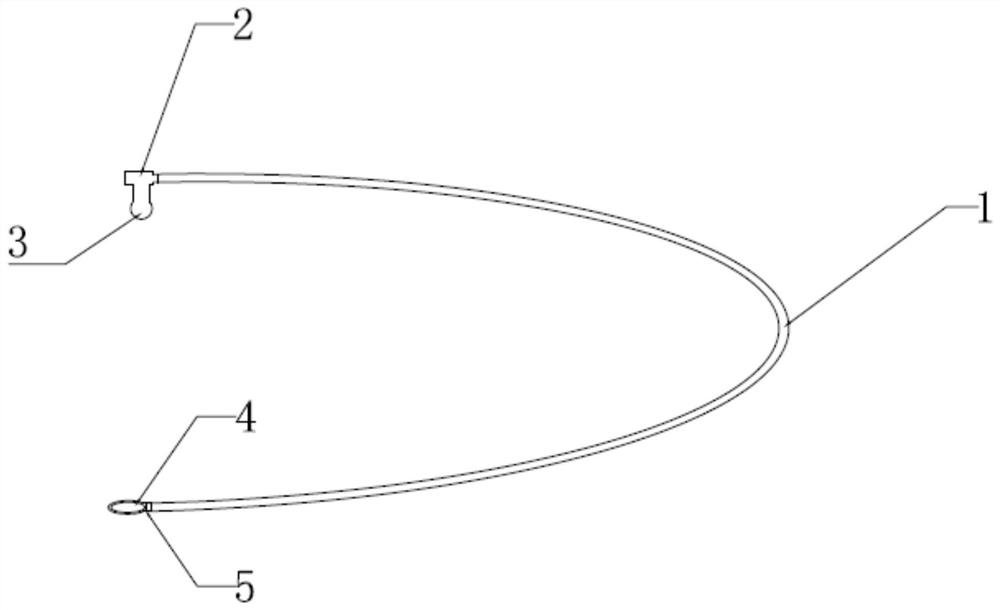

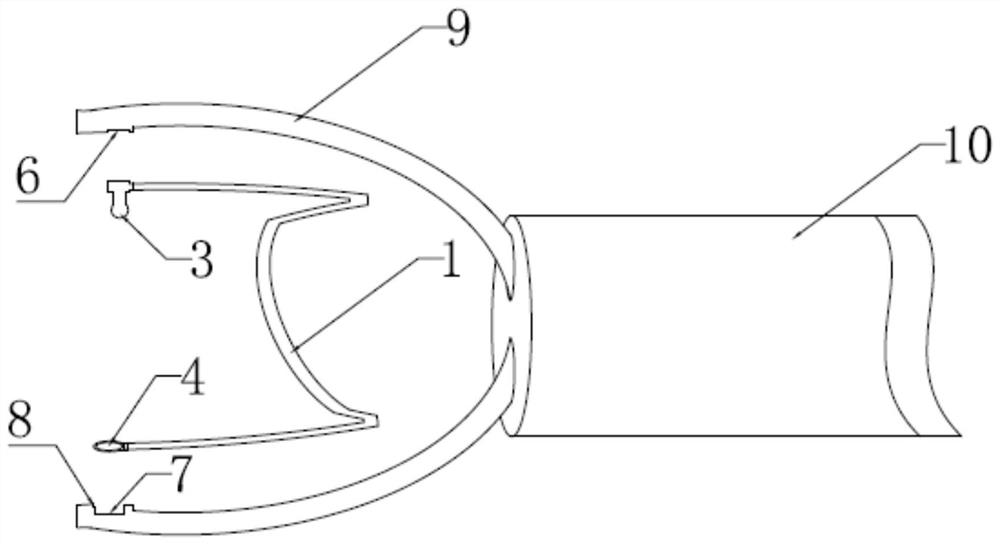

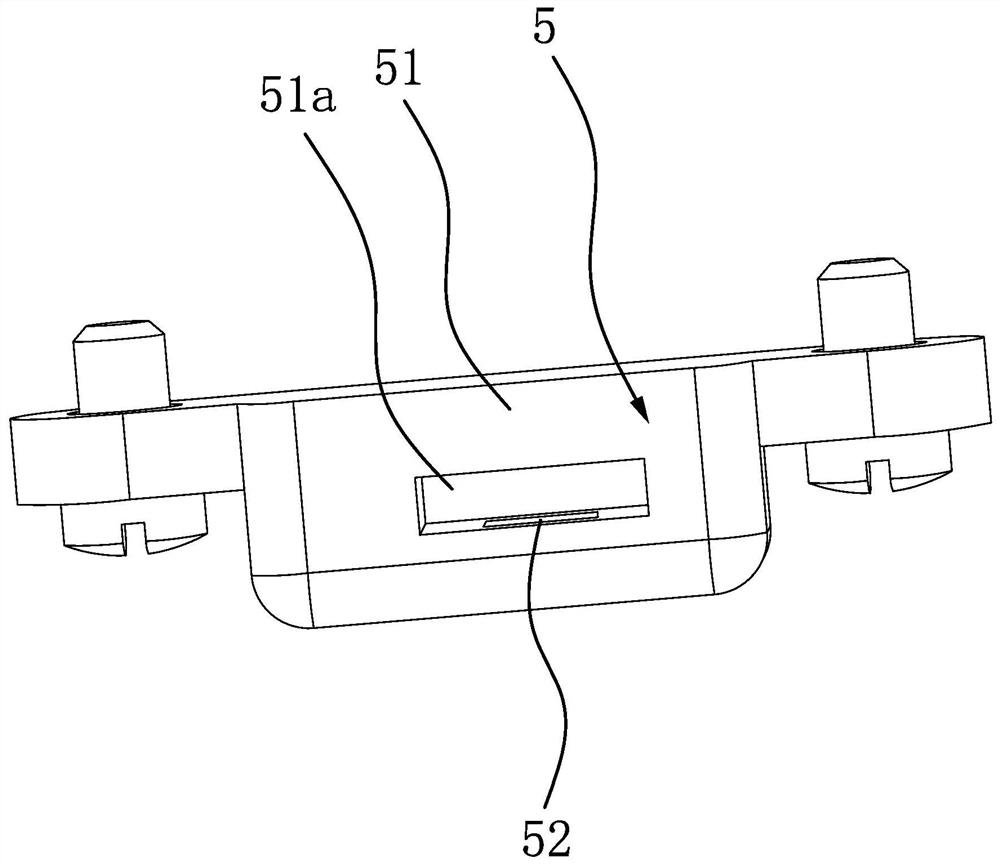

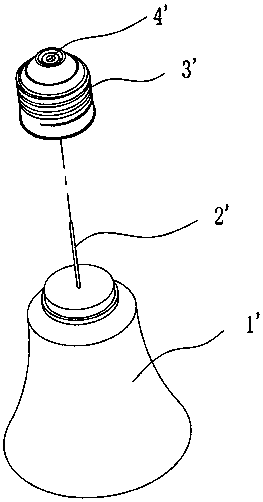

Disposable blood vessel suspension device

PendingCN113729812AAutomatic and efficient suspension operationSurgical safetySurgeryDiagnostic markersLaparoscopic surgeryBiomedical engineering

The invention discloses a disposable blood vessel suspension device, and belongs to the technical field of medical supplies, the disposable blood vessel suspension device comprises a flexible male and female buckle suspension device and an automatic buckle clamp matched with the flexible male and female buckle suspension device for use, the flexible male and female buckle suspension device comprises a suspension rubber belt, a male buckle base body, a male buckle, a female buckle and a female buckle base body, the male buckle base body and the female buckle base body are fixed to the two ends of the suspension rubber belt in a press fit mode respectively, and the male buckle is buckled in the female buckle in a press fit mode. Through the flexible red, blue and yellow single-color suspension rubber belt, two ends of the flexible red, blue and yellow single-color suspension rubber belt are provided with male and female buckles matched with each other, automatic buckling is achieved through matched automatic buckling pincers, and the device is automatic, convenient, efficient, standard and clear in identification, so that effective suspension of important pipelines such as blood vessels under the laparoscopic surgery is achieved, clear pipeline identification is guaranteed, and the surgery is safely and efficiently completed.

Owner:THE FIFTH AFFILIATED HOSPITAL SUN YAT SEN UNIV

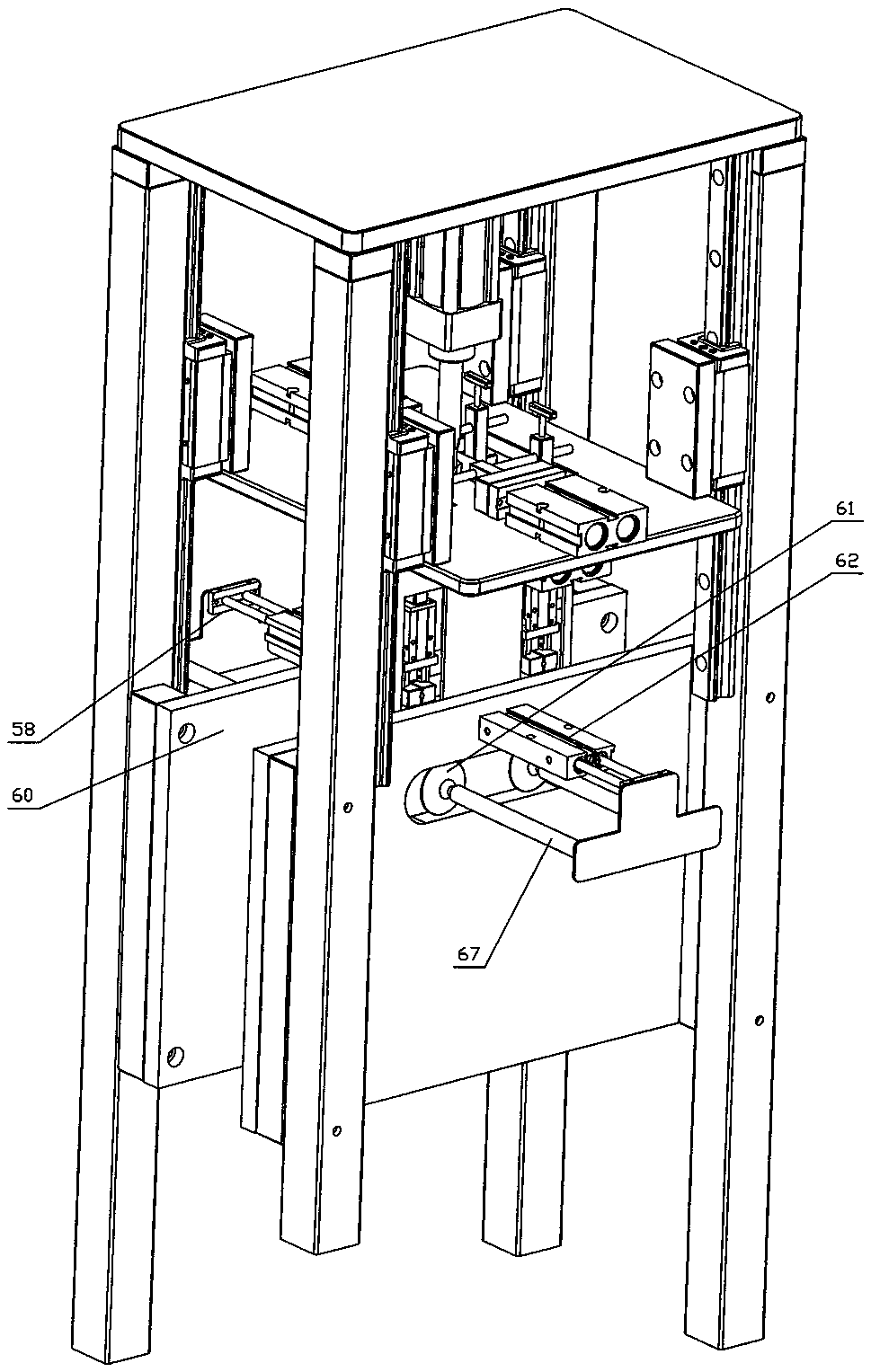

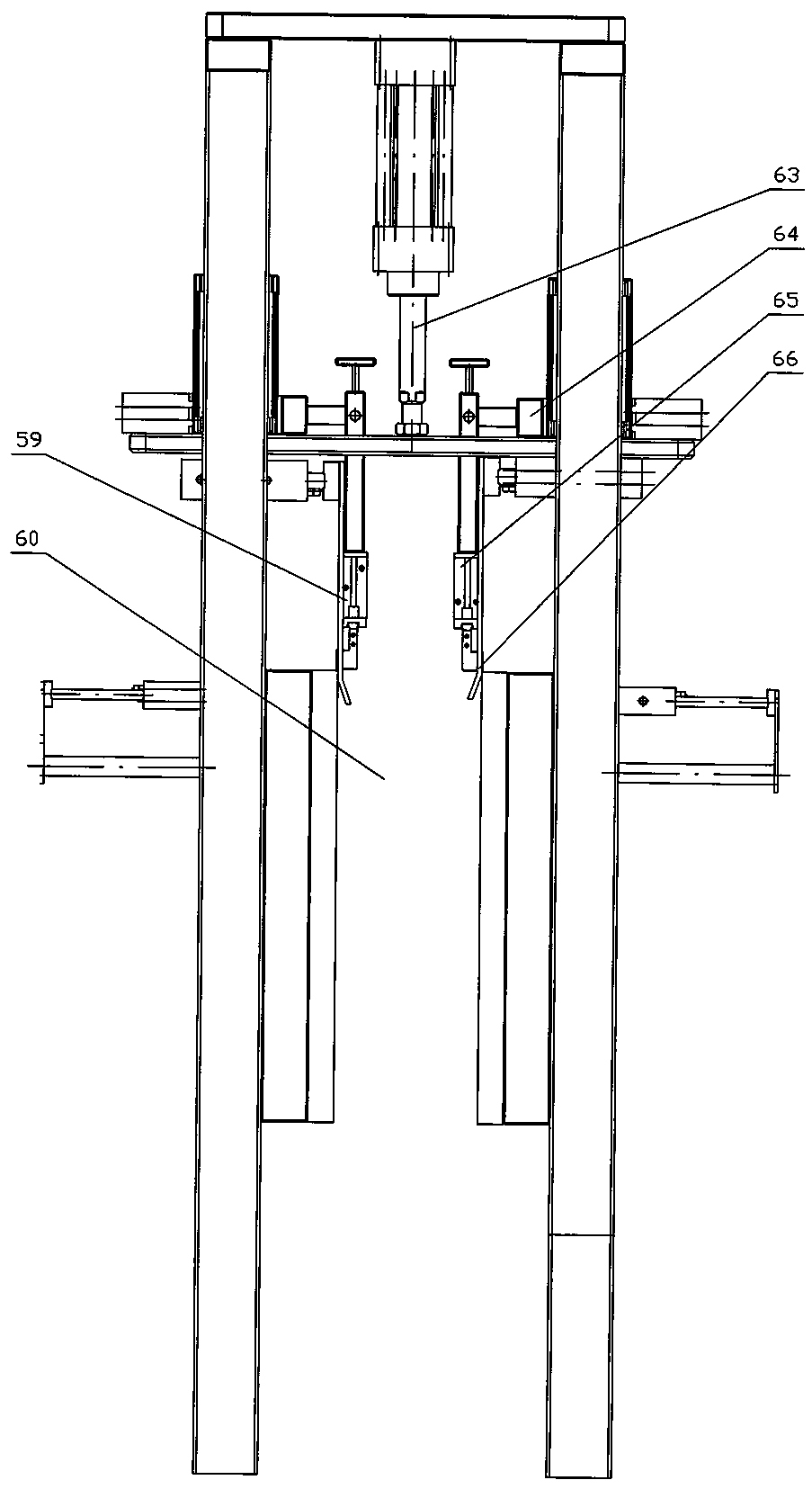

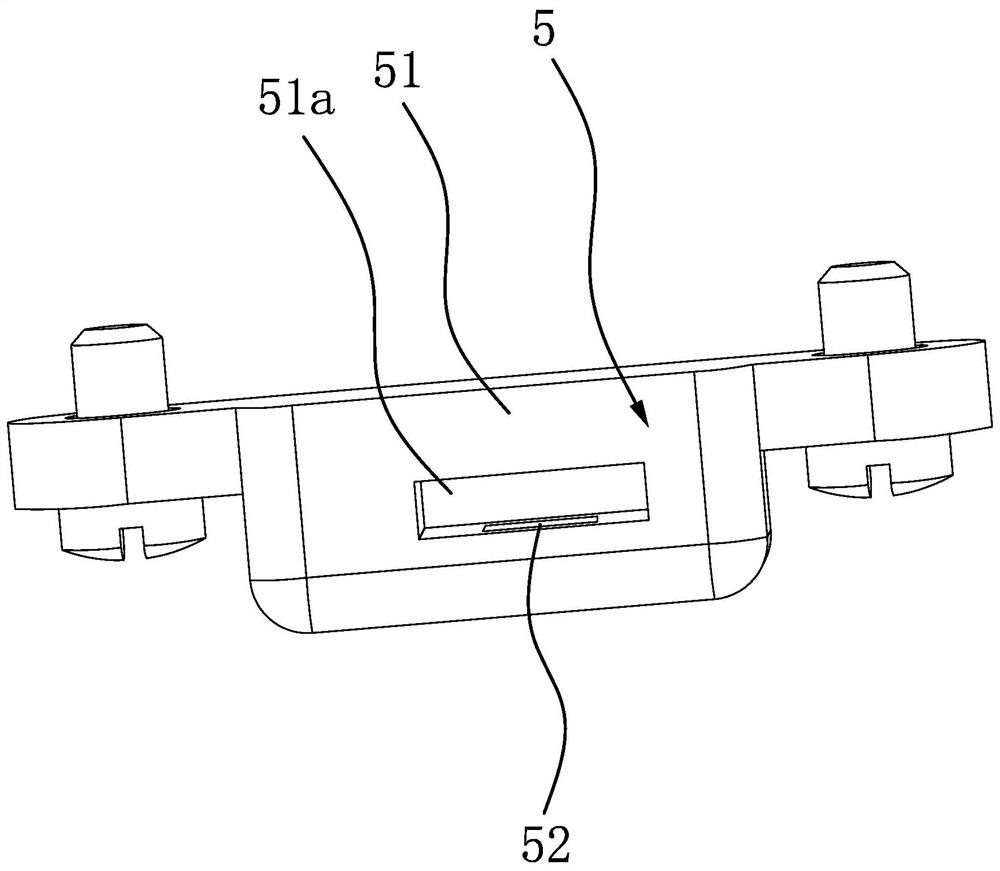

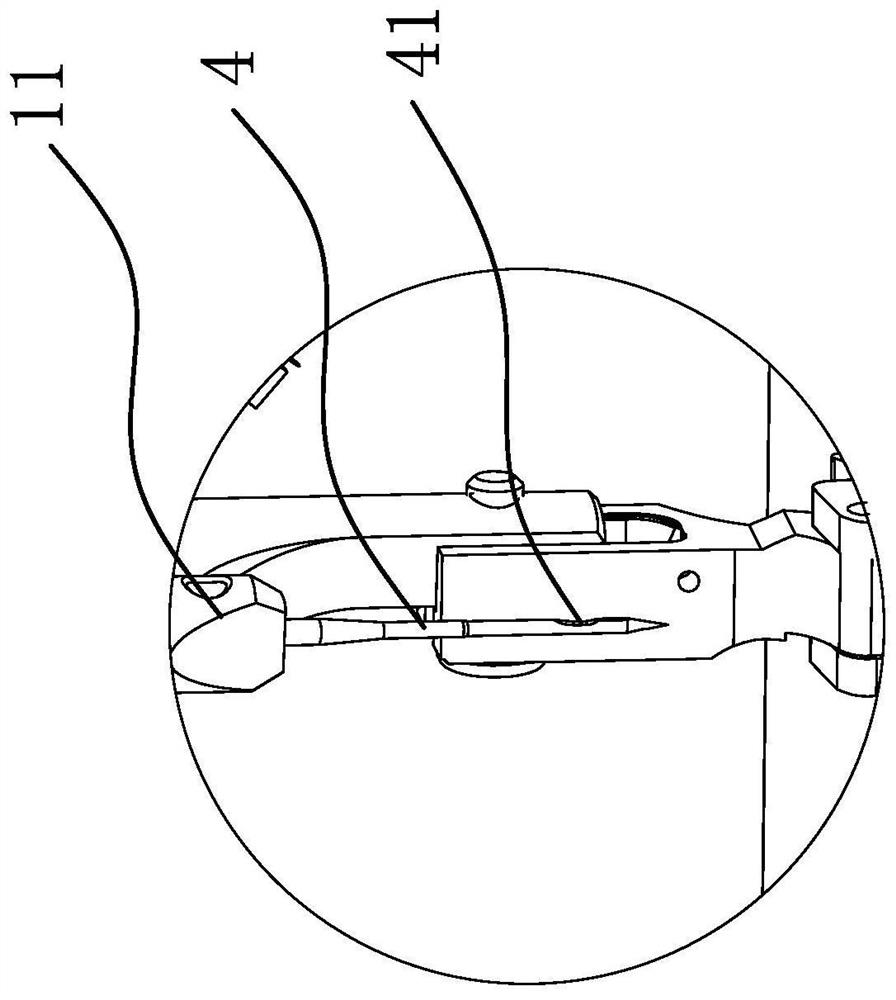

Guiding and threading structure in automatic threading device of industrial sewing machine

ActiveCN111560715ARealize automatic threadingHigh degree of automationNeedle severing devicesThread-break detectorsEngineeringIndustrial sewing machine

The invention provides a guiding and threading structure in an automatic threading device of an industrial sewing machine, and belongs to the technical field of sewing. The technical problem that theautomation degree of threading of existing industrial sewing machines is low is solved. The industrial sewing machine comprises a shell, a side cover fixedly arranged at one end of the shell, a take-up lever and a frame needle. The frame needle is provided with a threading hole. The guiding and threading structure comprises a rotary connecting rod, a driving piece, a guide plate and a threading connecting rod. One end of the rotary connecting rod is fixedly provided with a silk clamping air cylinder and a silk ejecting air cylinder. The outer end of an output shaft of the silk clamping air cylinder is fixedly provided with a silk clamping plate. The silk clamping plate is provided with an open slot. An output shaft of the silk ejecting air cylinder is fixedly provided with an ejecting rodfacing the open slot. The rotary connecting rod and the guide plate are arranged on the two sides of the frame needle respectively. The threading connecting rod is slidably arranged on the guide plate. The end, facing the frame needle, of the threading connecting rod is fixedly provided with a flexible threading hook. By means of the guiding and threading structure, the automation degree of threading of the existing industrial sewing machines is greatly improved.

Owner:TAIZHOU UNIV

Full-automatic shoulder belt sewing machine

InactiveCN102605562BReasonable structural designEasy to useWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention relates to a full-automatic shoulder belt sewing machine which consists of a front processing machine and a rear processing machine which are spliced and fastened together by a front processing machine connecting plate and a rear processing machine connecting plate; the front processing machine mainly comprises a belt conveying device, a belt pushing device, a belt cutting device, an eight-button conveying device, a nine-button conveying device or a zero-button conveying device, a belt threading device, a rotary button turning device, a belt drawing device and a sewing device; the belt pushing device is connected with the belt conveying device; the belt threading device is connected with the belt drawing device, the eight-button conveying device, the nine-button conveying device or the zero-button conveying device; and the rear processing machine mainly comprises a belt connecting device, a rear processing belt drawing device, a belt protecting device, a secondary rotary button turning device, a belt head clamping device, a tensioning device and a belt connecting button pushing device. By the design of the shoulder belt sewing machine, the automatic button threading of eight buttons and nine buttons on the shoulder belt can be realized; and the front processing machine and the rear processing machine are assembled independently, thereby facilitating the conveying safety.

Owner:尤文聘

Bra steel ring penetrating and connecting system

InactiveCN113080534ARealize automatic threadingReduce work intensityBrassieresCorsetsElectric machineryEngineering

A supporting top plate is arranged at the top end of a supporting base, an electric telescopic rod is arranged in the middle of the supporting top plate, a pressing plate is arranged at the bottom end of the electric telescopic rod, a guide rail is arranged at one end of the bottom of the supporting top plate, and a first electric push rod, a second electric push rod and a second fixing clamping sleeve are arranged at the bottom end of the guide rail; a rotating shaft is arranged in the fixed clamping sleeve II; the first electric push rod is of a rotatable structure, and the rotation angle of the first electric push rod is 180 degrees. The first electric push rod is connected with the guide rail in a matched mode through a lead screw transmission structure, the lead screw transmission structure is composed of a lead screw and a fourth driving motor, and the fourth driving motor is located at one end of the guide rail and connected with the lead screw in a matched mode. The bra steel ring threading machine has the beneficial effects that automatic threading of bra steel rings can be realized, multi-angle conversion can be realized according to the shapes of the steel rings during threading, the threading accuracy is improved, automatic feeding of the steel rings and automatic discharging of finished products can be realized, the production efficiency is effectively improved, and the working intensity of workers is reduced.

Owner:重庆知翔科技有限公司

Automatic threading device for bolt

The invention relates to an automatic threading device for a bolt. The automatic threading device comprises a bracket, a bolt fixing device, screw dies, a lead screw, a belt pulley, a motor and a reducer, wherein the bolt fixing device, the belt pulley and the lead screw are fixed on the bracket; the screw dies are arranged on the side part of the bolt fixing device and fixed at the end part of the lead screw; the motor and the reducer are connected with the belt pulley; and the lead screw is driven by the belt pulley to move. The automatic threading device for the bolt is easy to operate and maintain, low in failure rate, safe and reliable, and can realize automatic threading of the bolt.

Owner:山东华宁矿业集团有限公司

Laminated steel fixed-direction heating and continuous cleaning and drying equipment

ActiveCN112659540ARealize automatic threadingEliminate hanging phenomenonDrying gas arrangementsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses laminated steel fixed-direction heating and continuous cleaning and drying equipment. The equipment comprises a frame structure, a laminated steel conveying component, fixed-direction heating components, continuous cleaning components and a drying component, wherein the laminated steel conveying component is installed in the frame structure and penetrates through a whole frame; the fixed-direction heating components are installed on the front portion of the inner side of the frame structure; the fixed-direction heating components are symmetrically distributed on the two sides of the laminated steel with the conveyed laminated steel as the center; the continuous cleaning components are installed behind the fixed-direction heating components and also symmetrically distributed on the two sides of the laminated steel with the laminated steel as the center; the drying component is located behind the continuous cleaning components and installed at the side edge of the rear of the frame structure; and the laminated steel penetrates through the middle of the drying component. All the components cooperate to realize efficient and environment-friendly rust-proof oil removal on the laminated steel.

Owner:江阴卓普新型包装材料有限公司

A portable paper bag stringing machine and its stringing method

InactiveCN109648919BRealize automatic threadingImprove work efficiencyBag making operationsPaper-makingPunchingFully automated

The invention relates to full-automatic portable paper bag processing equipment, in particular to a threading machine for a portable paper bag. The threading machine comprises a processing platform, afeeding mechanism, a bag opening mechanism, a punching mechanism, a bag expanding turnover mechanism, threading mechanisms and a discharging mechanism, the processing platform is composed of two flatplates which are horizontally arranged at intervals, in the conveying direction of the paper bag, the feeding mechanism is arranged above the front end of the processing platform, the bag opening mechanism is arranged at the position, below the feeding mechanism, of the processing platform, the punching mechanism is arranged at the position, behind the bag opening mechanism, of the processing platform, the bag expanding turnover mechanism is arranged at the interval between the two flat plates of the processing platform, and is arranged behind the bag opening mechanism, the number of the threading mechanisms is two, the two threading mechanisms are correspondingly arranged on the two sides of the upper end of the bag expanding turnover mechanism, and the discharging mechanism is arrangedat the position, behind the bag supporting turnover mechanism, of the processing platform. The threading machine for the portable paper bag combines a threading method so that the threading work of the portable paper bag can be rapidly completed.

Owner:射阳县农牧渔业总公司

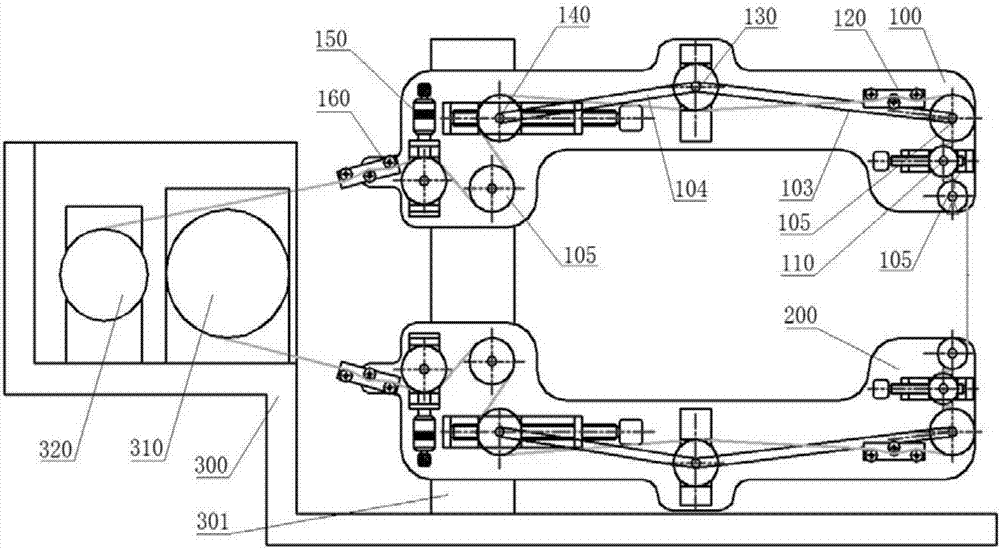

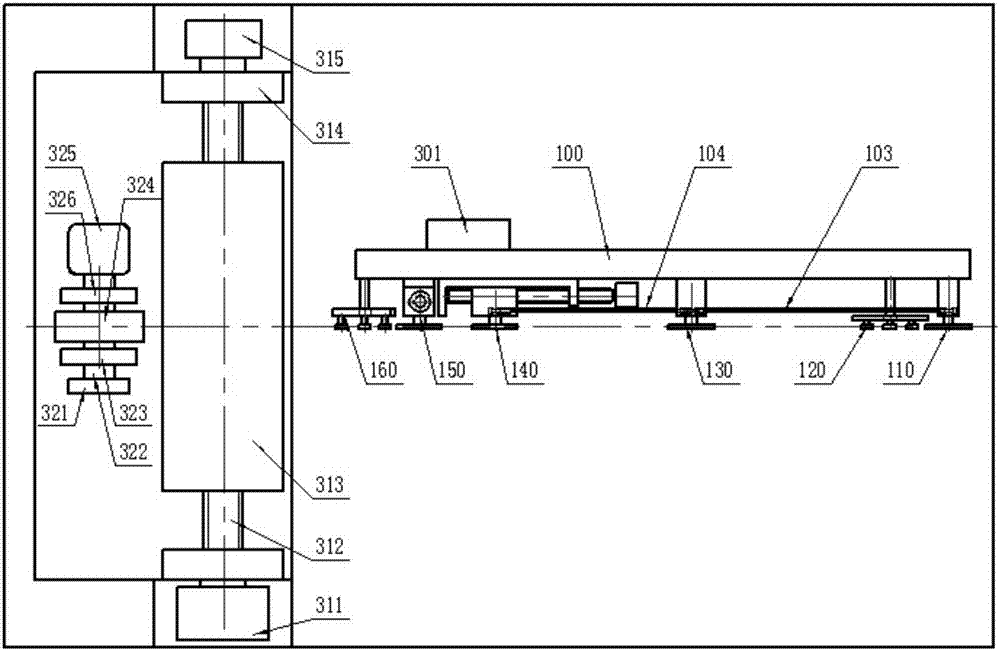

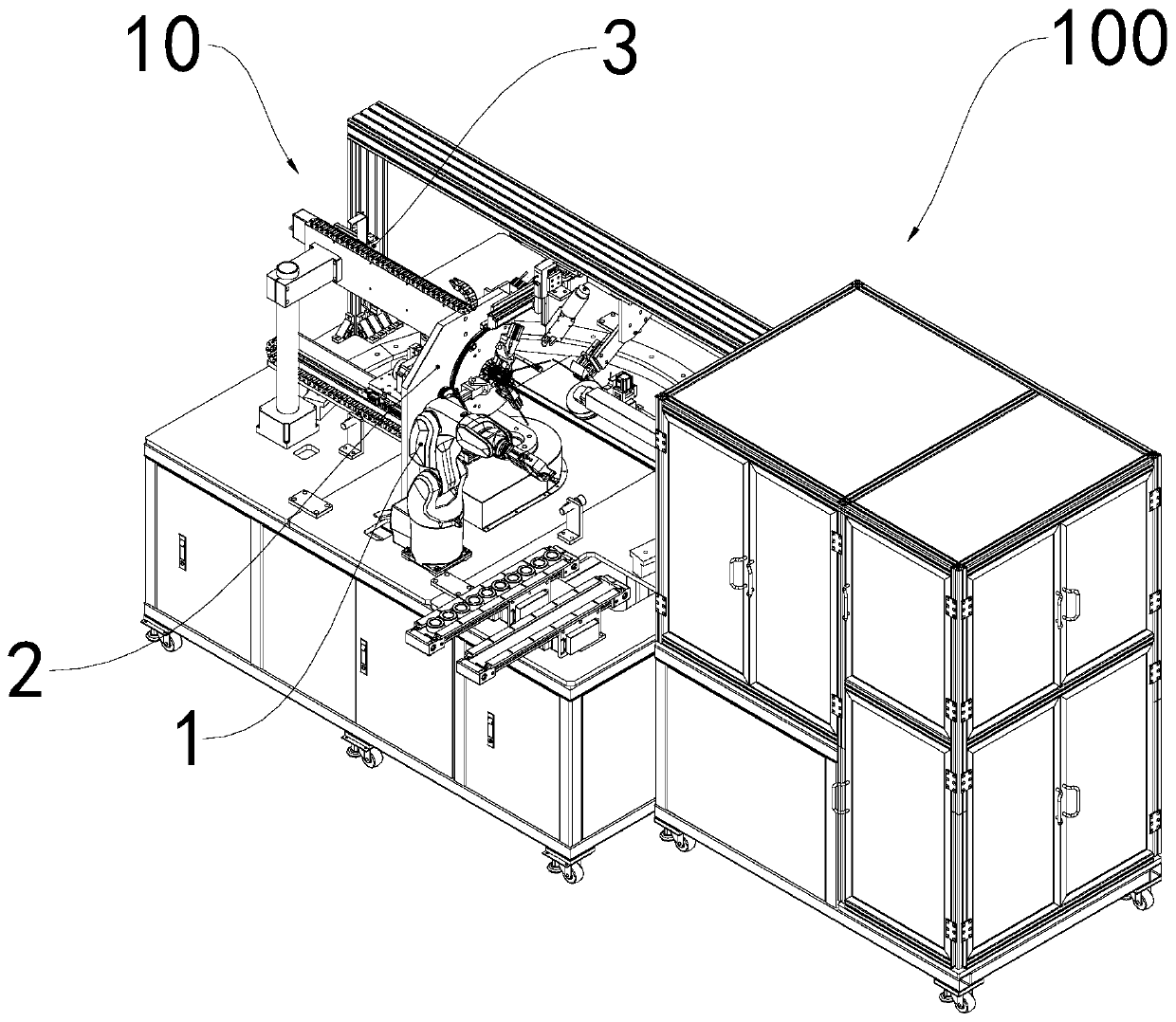

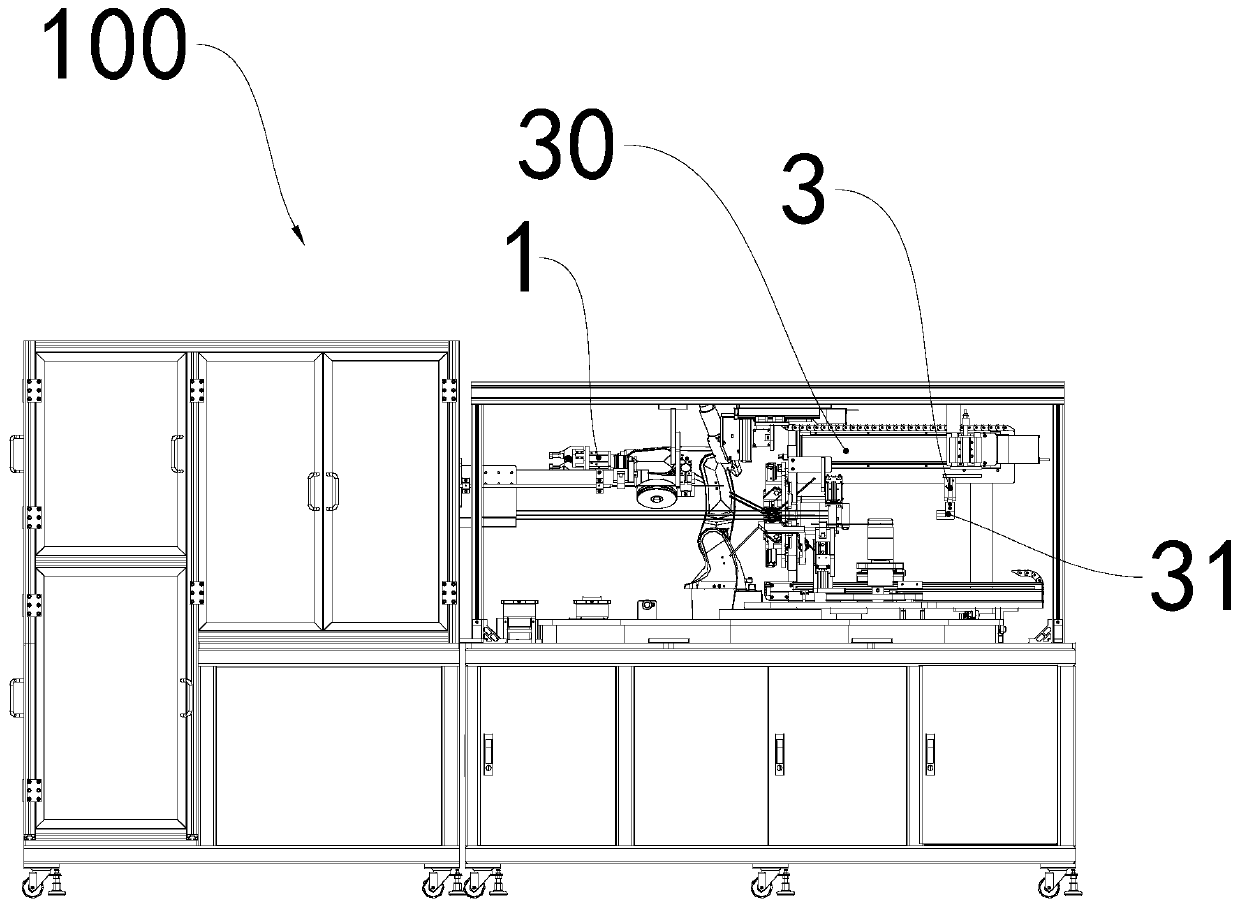

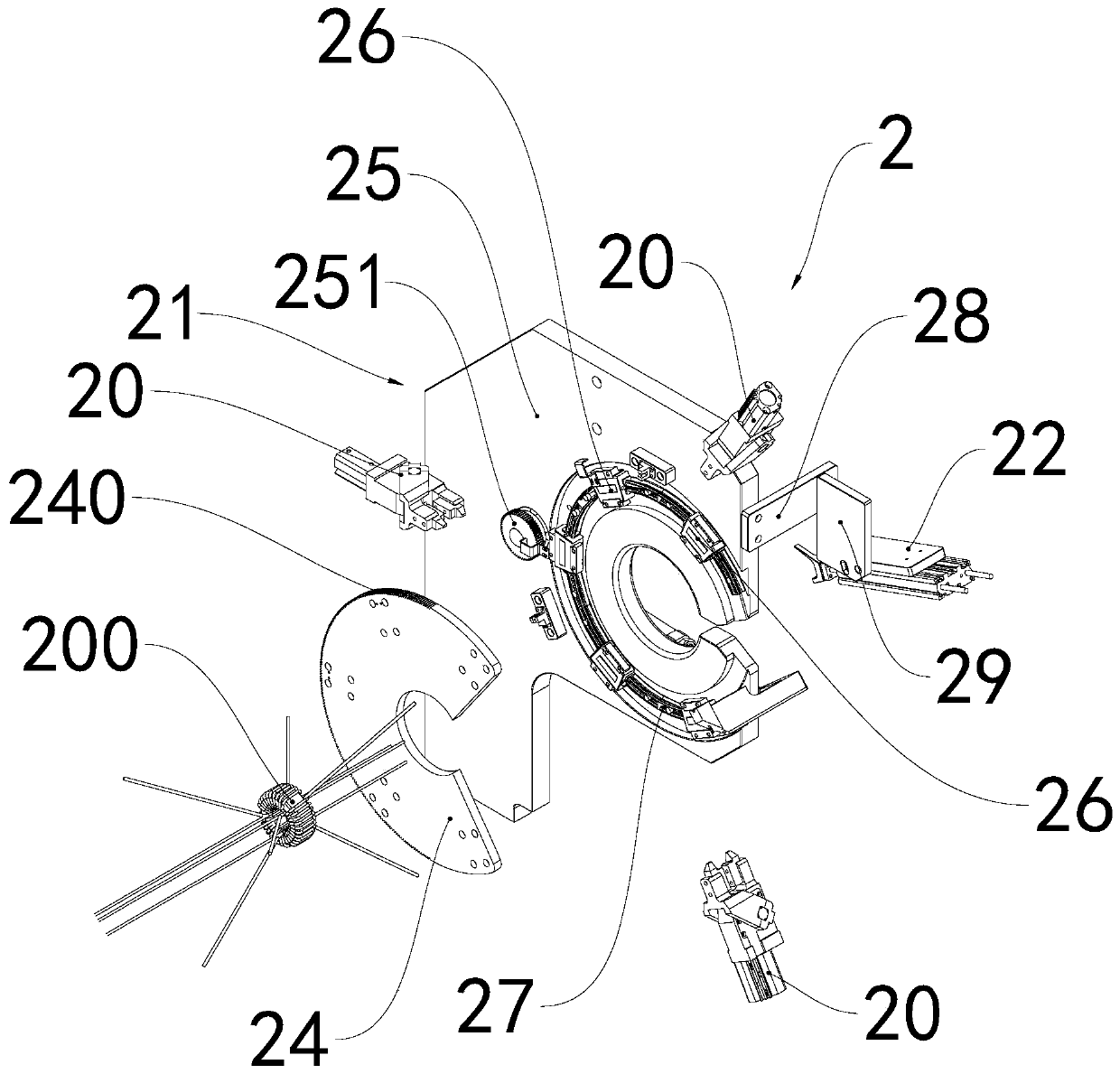

System and method for processing steel wire rope components

ActiveCN105033122BEasy to produceReduce participationMaterial strength using tensile/compressive forcesMachining systemMachining process

Owner:CMCU ENG

Guiding and threading structure in an automatic threading device of an industrial sewing machine

ActiveCN111560715BRealize automatic threadingHigh degree of automationNeedle severing devicesThread-break detectorsIndustrial sewing machineIndustrial engineering

Owner:TAIZHOU UNIV

Automatic monofilament ingot feeding and raw silk cohesion detection device

InactiveCN114544489ARealize automatic opening and closingImprove the efficiency of cohesion detectionUsing mechanical meansMaterial analysisElectric machineryIngot

The invention discloses an automatic monofilament ingot feeding and raw silk cohesion detection device which comprises an automatic feeding mechanism, a tool rest lifting mechanism and a tool rest reciprocating friction mechanism. A silk winding shaft in the automatic silk feeding mechanism is used for fixing one end of raw silk, a first direct-current gear motor at the tail end pulls a tension sensor to control tension, and automatic silk feeding is achieved. And the knife rest reciprocating friction mechanism enables the knife to rub the raw silk, and after the specified number of times is reached, friction is stopped, the state of the raw silk is observed, and the cohesion score is recorded. According to the device, automatic silk feeding for raw silk cohesion detection and automatic opening and closing of the tool rest can be achieved, the problems that the labor input in the silk feeding step is reduced, and efficiency is low are solved, and the cohesion detection efficiency is improved.

Owner:CHINA JILIANG UNIV

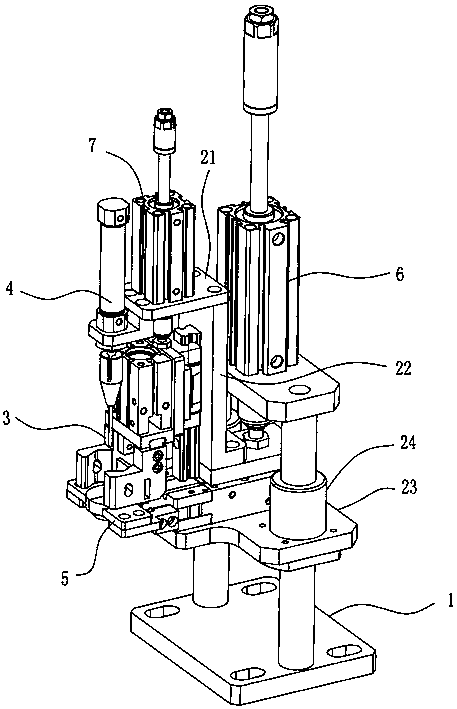

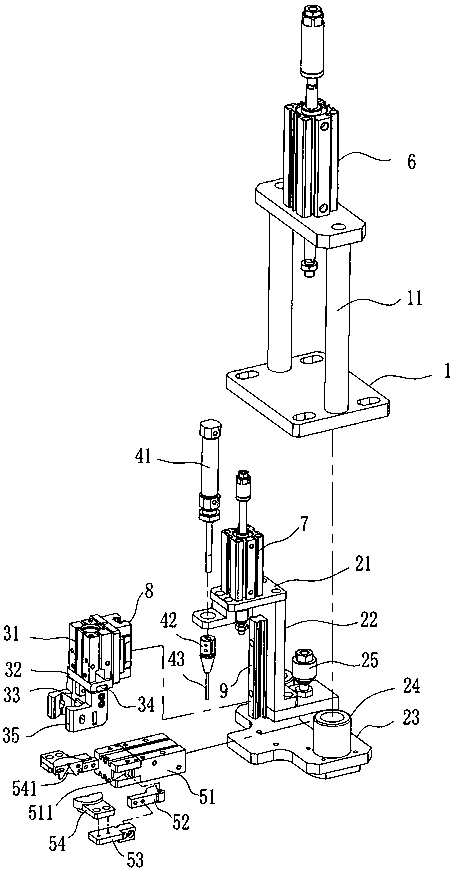

Lampholder threading assembling equipment

PendingCN108466041ARealize automatic threadingIncrease the level of automationMetal working apparatusProduction lineEngineering

The invention discloses lampholder threading assembling equipment which comprises a rack, a lamp pressing module, a clamping claw mechanism, a wire-fixing module and a lampholder placing mechanism, wherein a main air cylinder is mounted on the rack; the lamp pressing module is movably mounted on the rack and is connected to the main air cylinder; a lamp pressing air cylinder is mounted on the lamppressing module, and the clamping claw mechanism is movably mounted on the lamp pressing module; the wire-fixing module is mounted on the lamp pressing module, and is arranged above the clamping clawmechanism, and the wire-fixing module comprises a wire-fixing air cylinder, a hollow pipe sleeve and a hollow pipe; and the lamp holder placing mechanism arranged below the clamping claw mechanism comprises a rotary control air cylinder, two rotary arm assemblies and two lamp placing plates, wherein the rotary control air cylinder controls the two rotary arm assemblies to rotate; the lamp placingplate is fixedly connected to the rotary arm assemblies; threading grooves are formed in the two lamp placing plates, and are arranged right below the hollow tube. The lampholder threading assemblingequipment is simple in structure, and the lampholder can be threaded and assembled to a lamp cup automatically, so that the automatic level of an LED production line is improved, and the labor intensity of workers is alleviated.

Owner:厦门市先创鹭为自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com