Threading machine and threading method for portable paper bag

A paper bag and rope machine technology, applied in papermaking, bag making, paper/cardboard containers, etc., can solve the problems of low production efficiency, low efficiency, long residence time, etc., to improve production efficiency, improve work efficiency, and facilitate positioning and the effect of grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

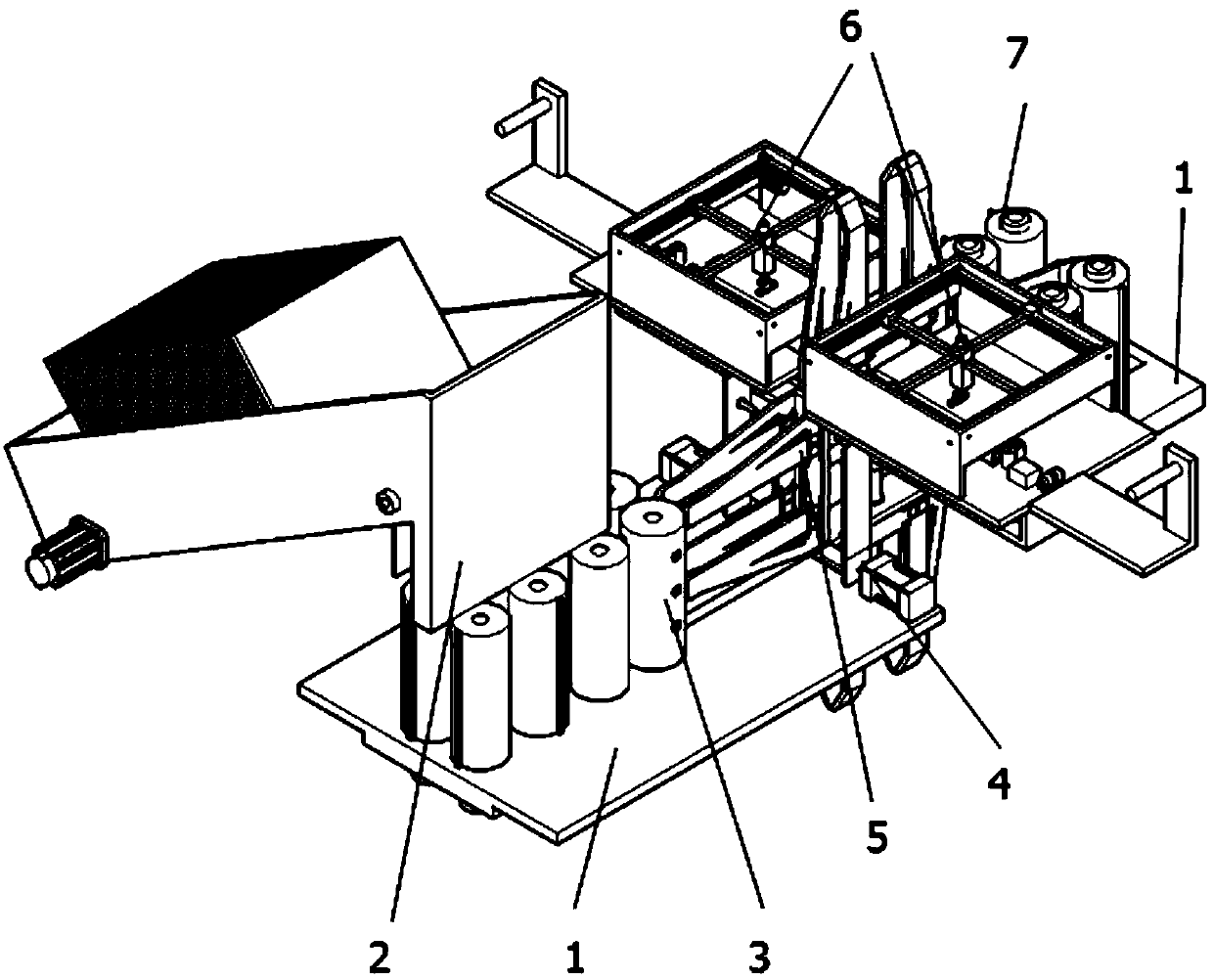

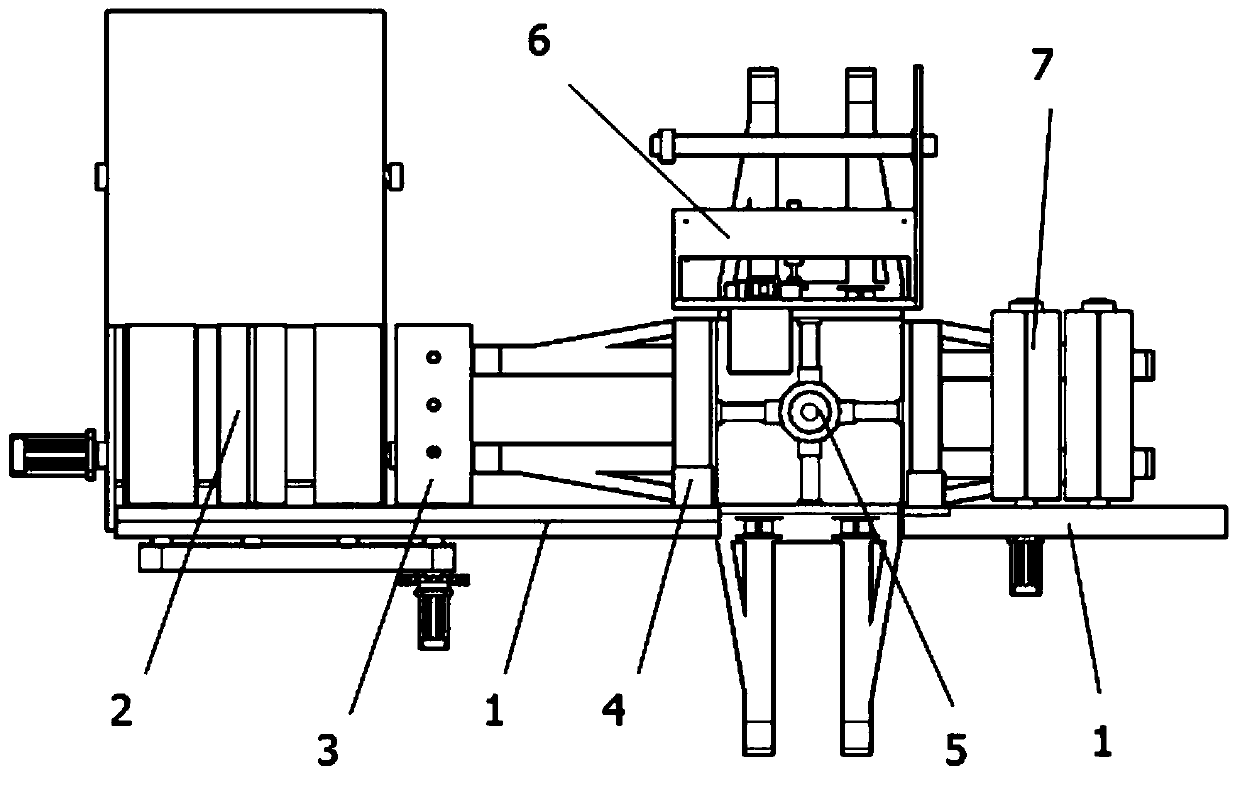

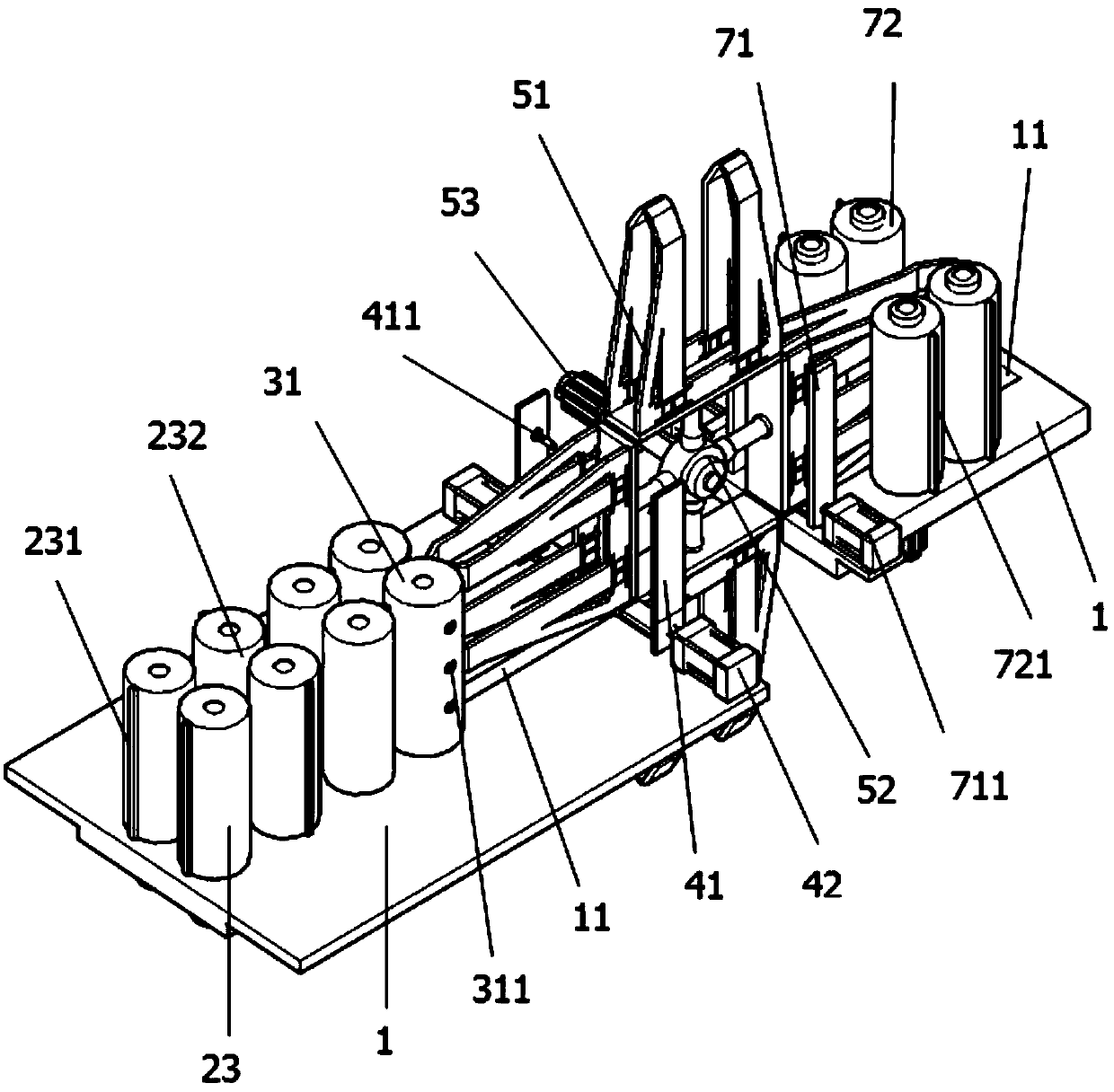

[0057] Such as figure 1 , figure 2 As shown, a portable paper bag stringing machine includes: a processing platform 1, a feeding mechanism 2, a bag opening mechanism 3, a punching mechanism 4, a bag supporting and turning mechanism 5, a rope threading mechanism 6, and a feeding mechanism 7;

[0058] The processing platform 1 is composed of two horizontally spaced flat plates, the feeding mechanism 2 is arranged above the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com