Automatic paper threading device at the operating side of the reel

A paper winding machine and operation side technology, which is applied in the field of papermaking machinery, can solve the problems of worker injury and too many people occupied by paper threading, and achieve the effects of avoiding safety accidents, saving manpower, and promoting safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

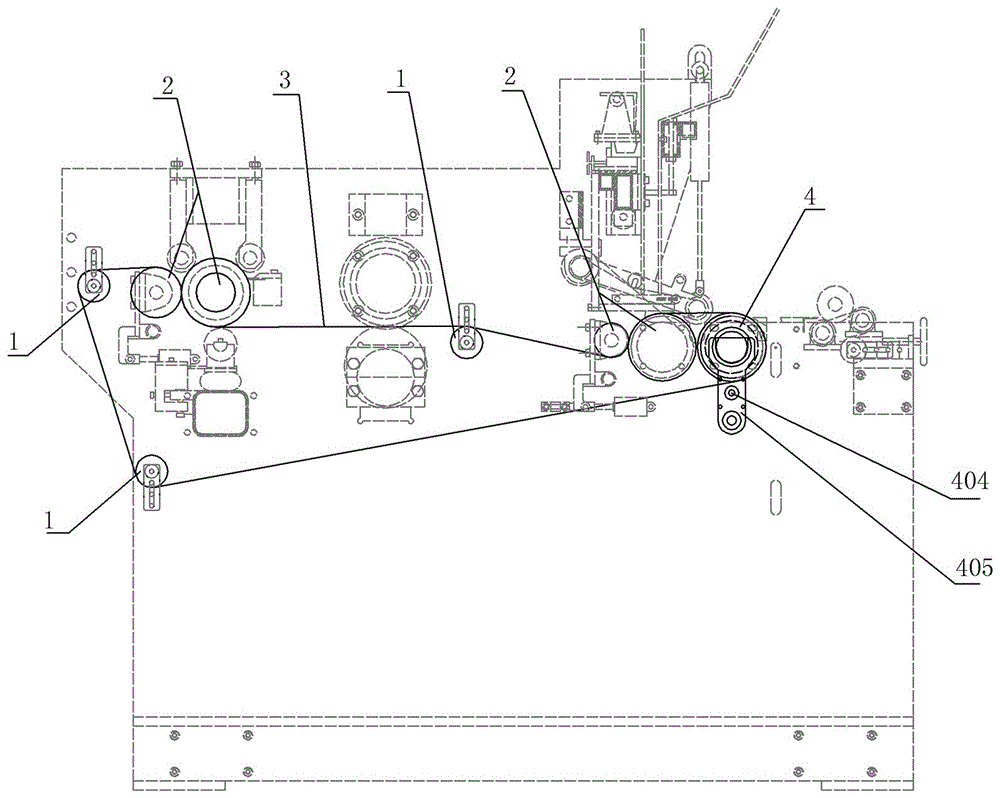

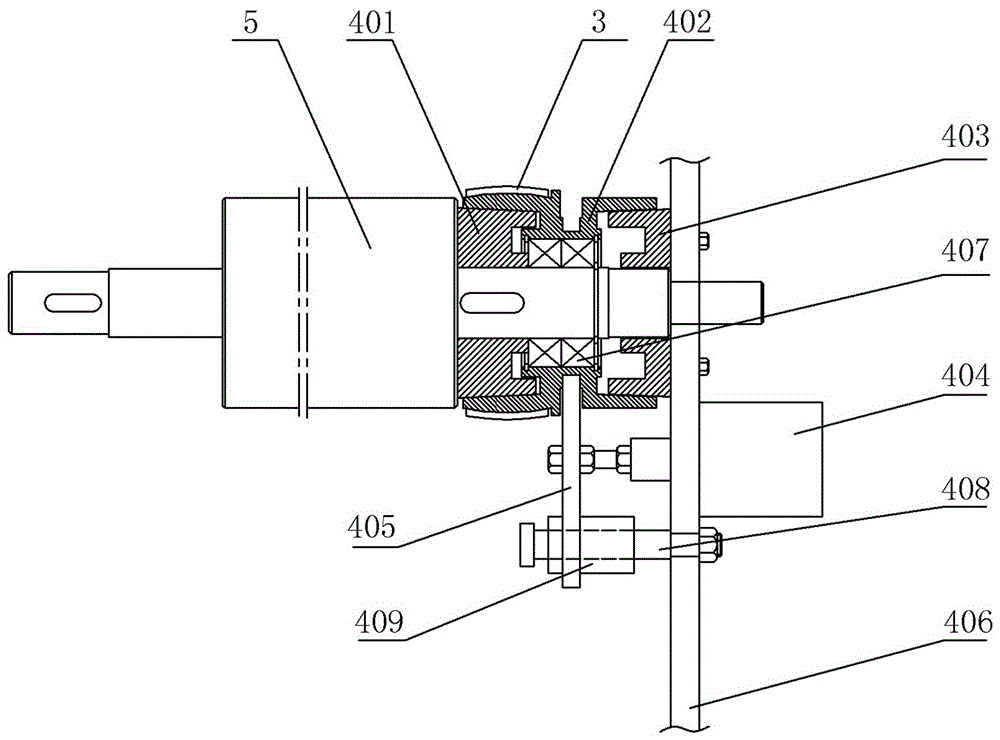

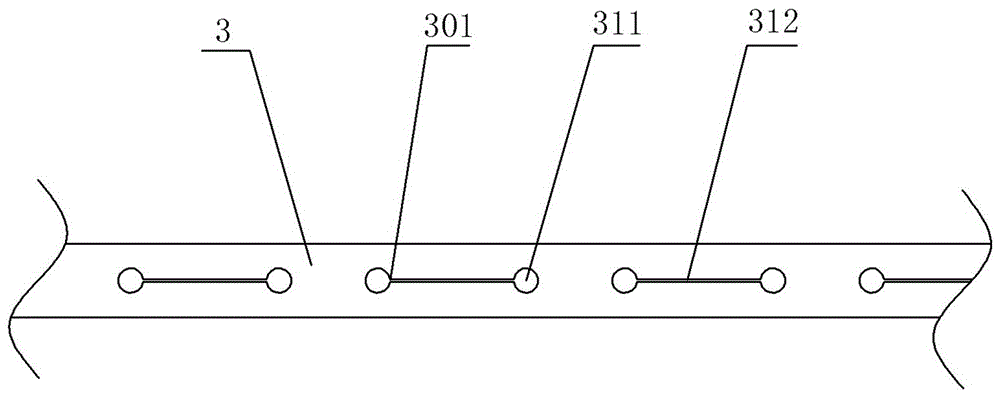

[0017] The automatic paper threading device on the operation side of the paper reel of the present invention includes a guide tension wheel 1, a passing wheel 2 and a paper threading belt 3, and the guide tension wheel 1 is arranged around the operation side of the paper winder, so that the paper threading belt 3 To avoid the mechanical equipment near the winder, the passing wheel 2 is arranged on the operating side of the winder, and the middle part of the paper-leading belt 3 is uniformly arranged with paper-leading slots 301 along the belt length direction; the paper-leading device also It includes the paper delivery belt clutch mechanism 4, the paper delivery belt clutch mechanism 4 is coaxially arranged with the winding roller 5 of the winder, and the paper delivery belt 3 surrounds the guide tension wheel 1, the passing wheel 2 and the paper delivery belt clutch mechanism 4 Loop rotation.

[0018] The paper-leading belt clutch mechanism 4 includes the internal friction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com