System and method for processing steel wire rope components

A technology of wire rope assembly and processing system, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of low operation safety performance, low production efficiency, safety accidents, etc., to liberate labor productivity, improve production efficiency and improve production efficiency. The effect of production quality and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

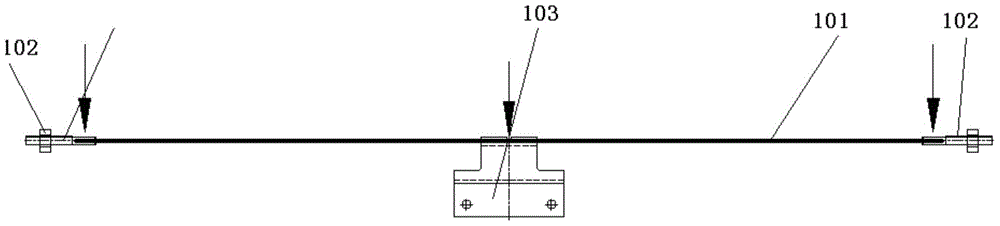

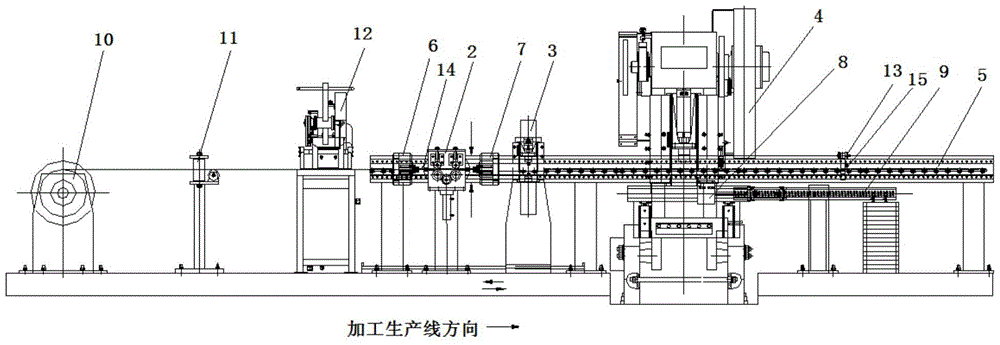

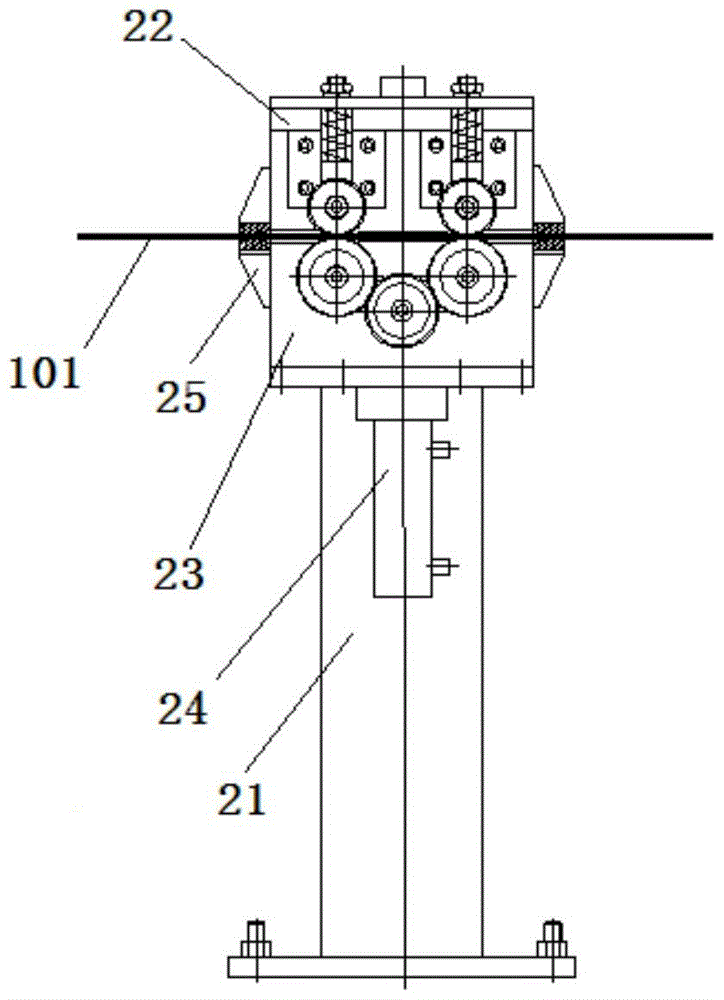

[0036] Such as figure 2 As shown, a steel wire rope assembly processing system, wherein, the steel wire rope assembly 1 includes a steel wire rope 101, a screw 102 arranged at both ends of the steel wire rope 101, and a connecting plate 103 arranged in the middle of the steel wire rope 101, and the processing system includes sequentially arranged for The feeding device 2 for pinching the steel wire rope 101, the first riveting press 3 for riveting the steel wire rope 101 and the screw 102, the second riveting press 4 for riveting the steel wire rope 101 and the connecting plate 103, and the connecting feeding device 2 , the production guide rail 5 of the first riveting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com