Patents

Literature

43results about How to "Liberate labor productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

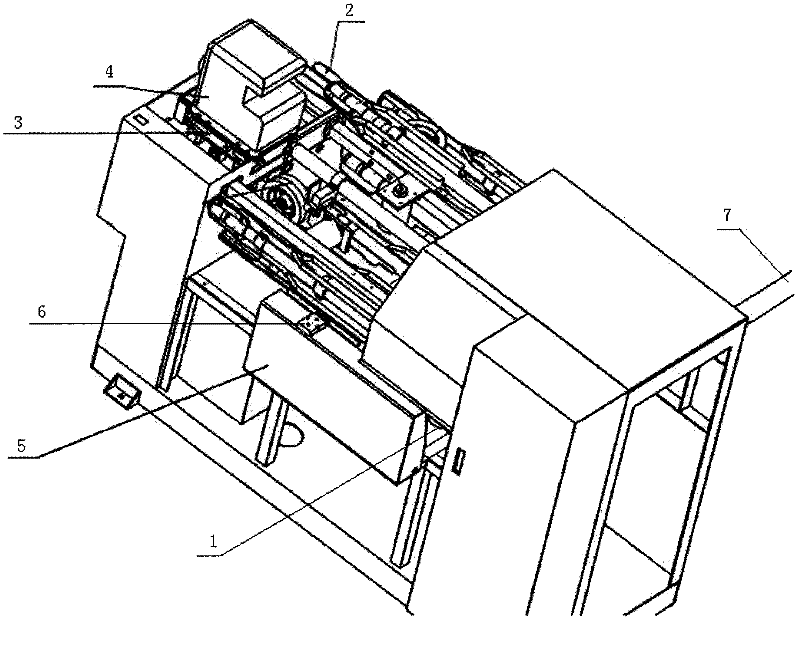

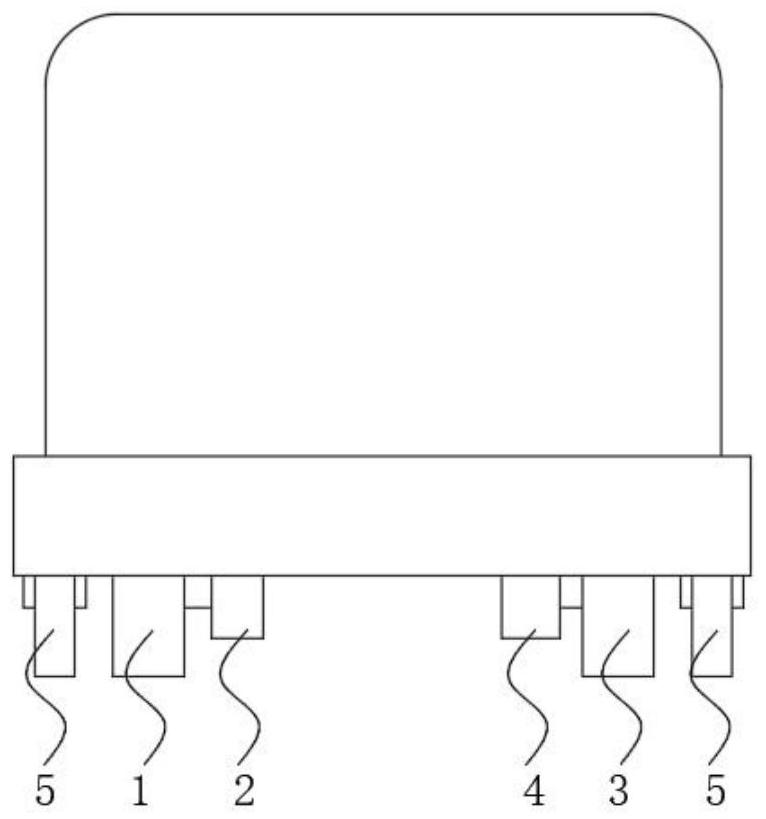

Automatic silk stocking toe sewing machine and use method thereof

InactiveCN102433689ANo missing stitchesDoes not produce uniformityWorkpiece carriersWork-feeding meansMan machineCrowds

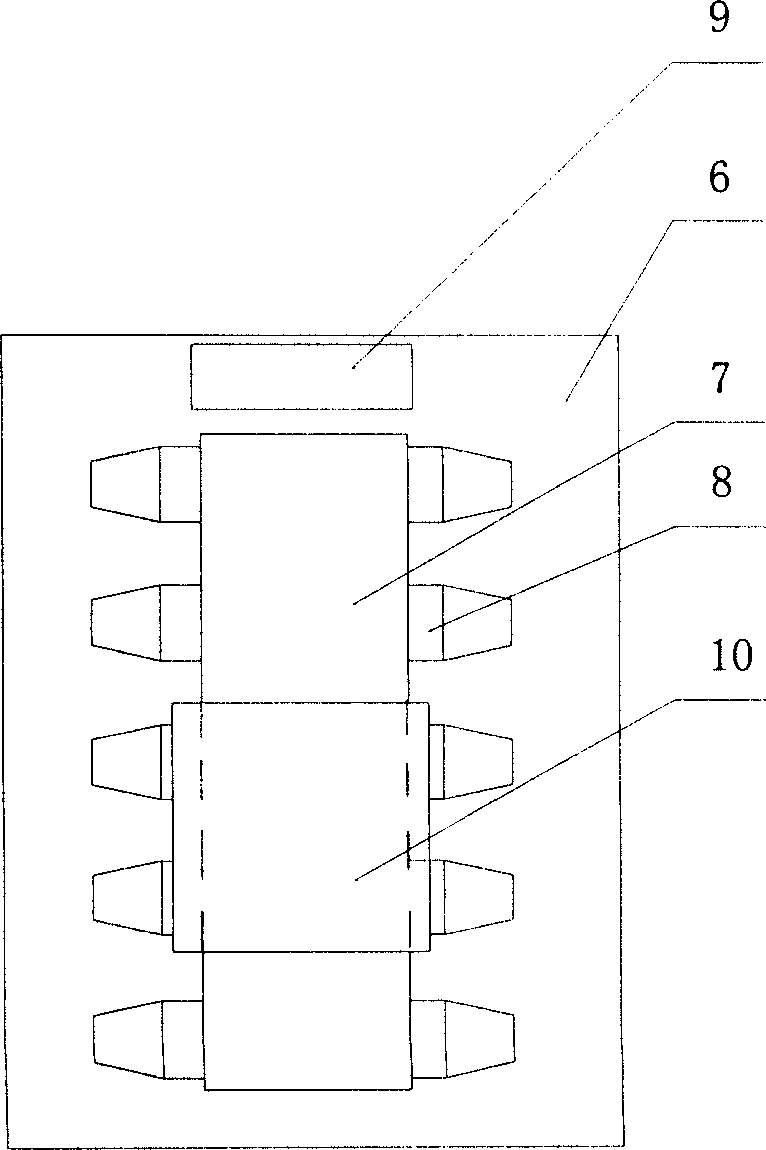

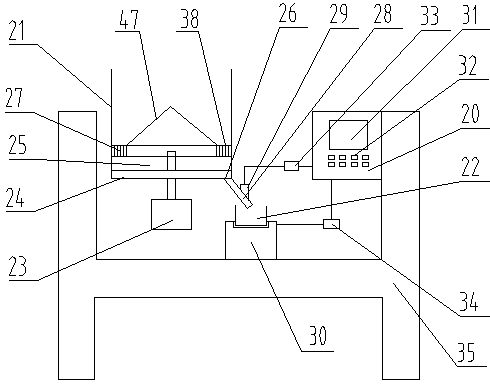

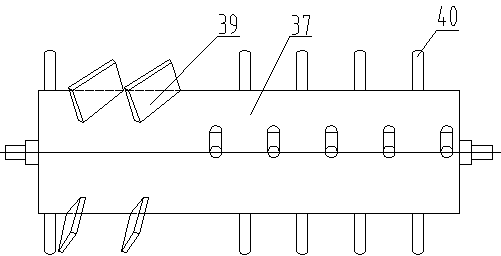

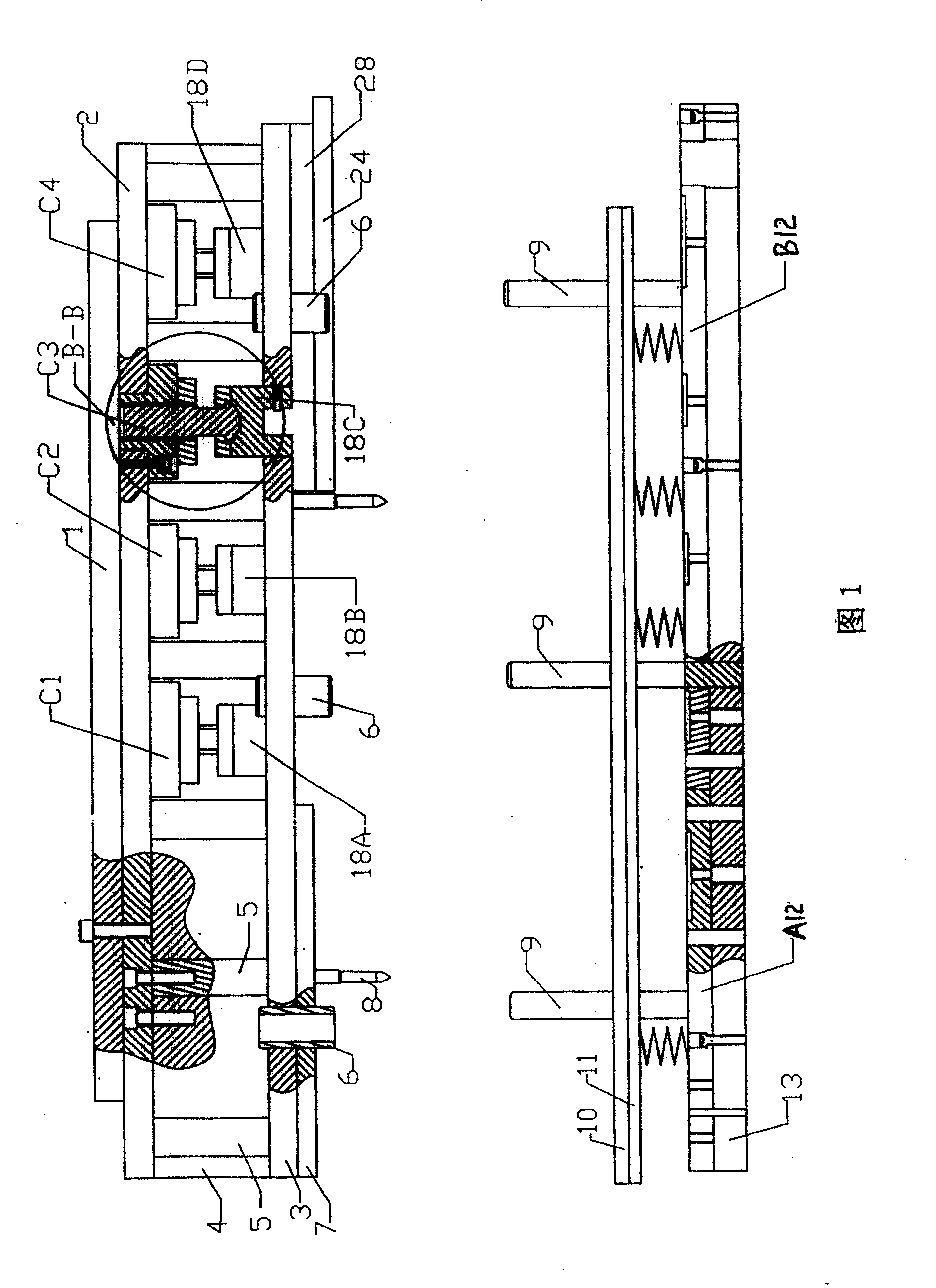

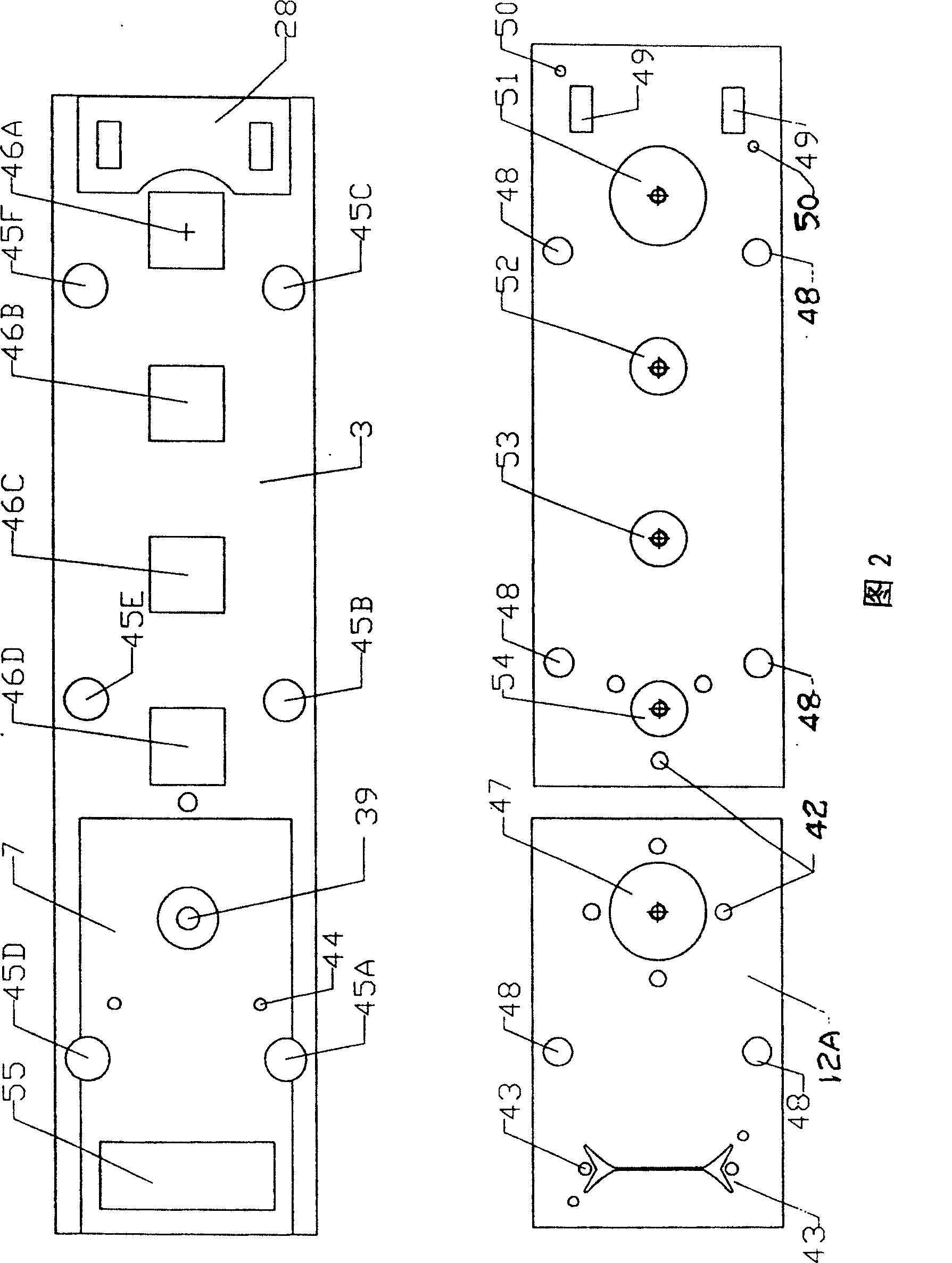

The invention discloses an automatic silk stocking toe sewing machine and a use method thereof. The automatic silk stocking toe sewing machine comprises a host machine, a movable socking plate, a machine head support, a machine head, a crotch cutting system, a stocking clamping system and the like, wherein the machine head support is independently driven by a lead screw motor, and the machine head support drives the machine head to change the sewing track; because the stocking casing is stationary when the stocking toe is sewn, a movable support drives the machine head to adopt an active sewing mode, thus the rotation speed of the machine head is reduced; and the stocking clamping system is used for clamping the stocking casing, so that the crotch cutting system carries out crotch cutting on the sewn stocking casing. In the invention, through simple man-machine conversation, multiple processes and multiple persons required by stocking toe sewing are changed into one-person operation; when ultra-thin or ultra-thick stockings are sewn, the problems of missed sewing, nonuniform spacing and the like are not generated, and the sewn stockings can accord with the toe arc lines of different crowds; and the crotch cutting is carried out under the state of clamping and tightening the stocking casing, thus the cut is straight and accurate, the artificial crotch cutting error is reduced, the working efficiency is greatly improved, the product quality is guaranteed and the raw materials are saved.

Owner:韶关市新时韵针织有限公司

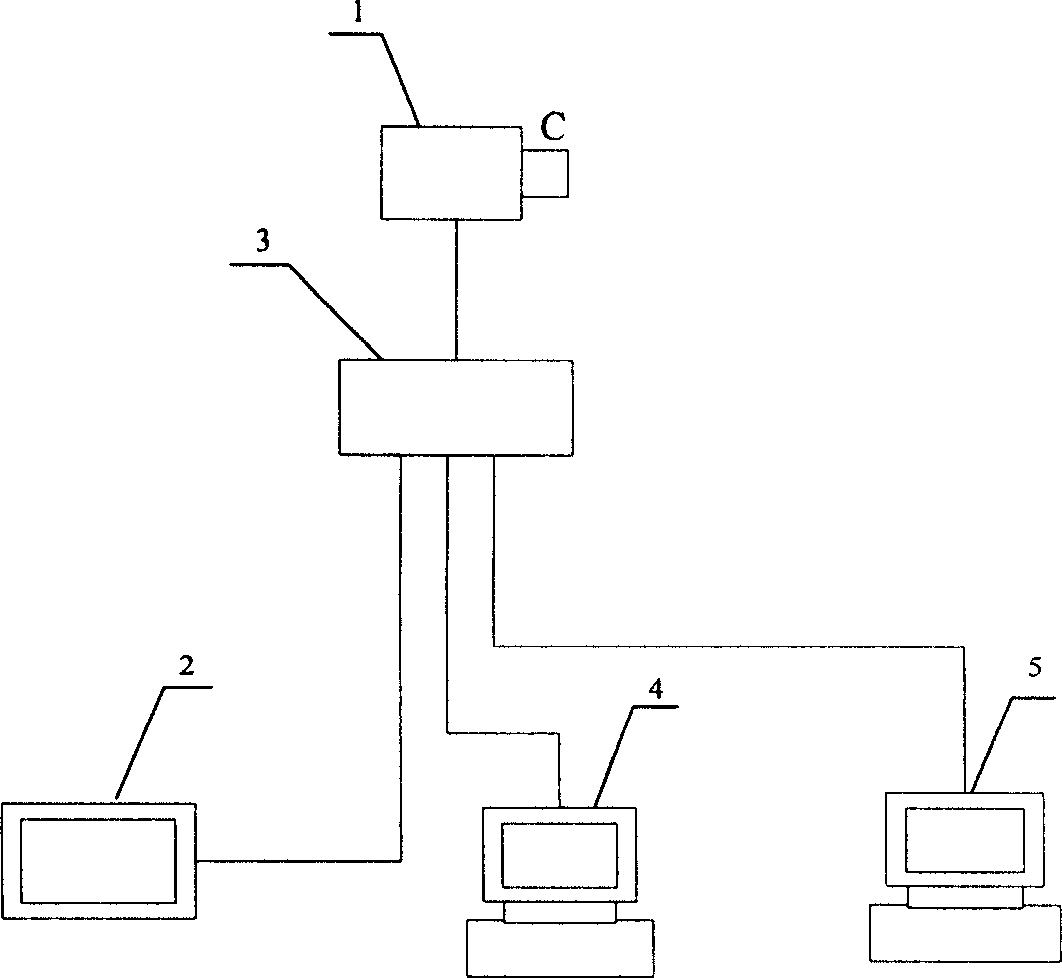

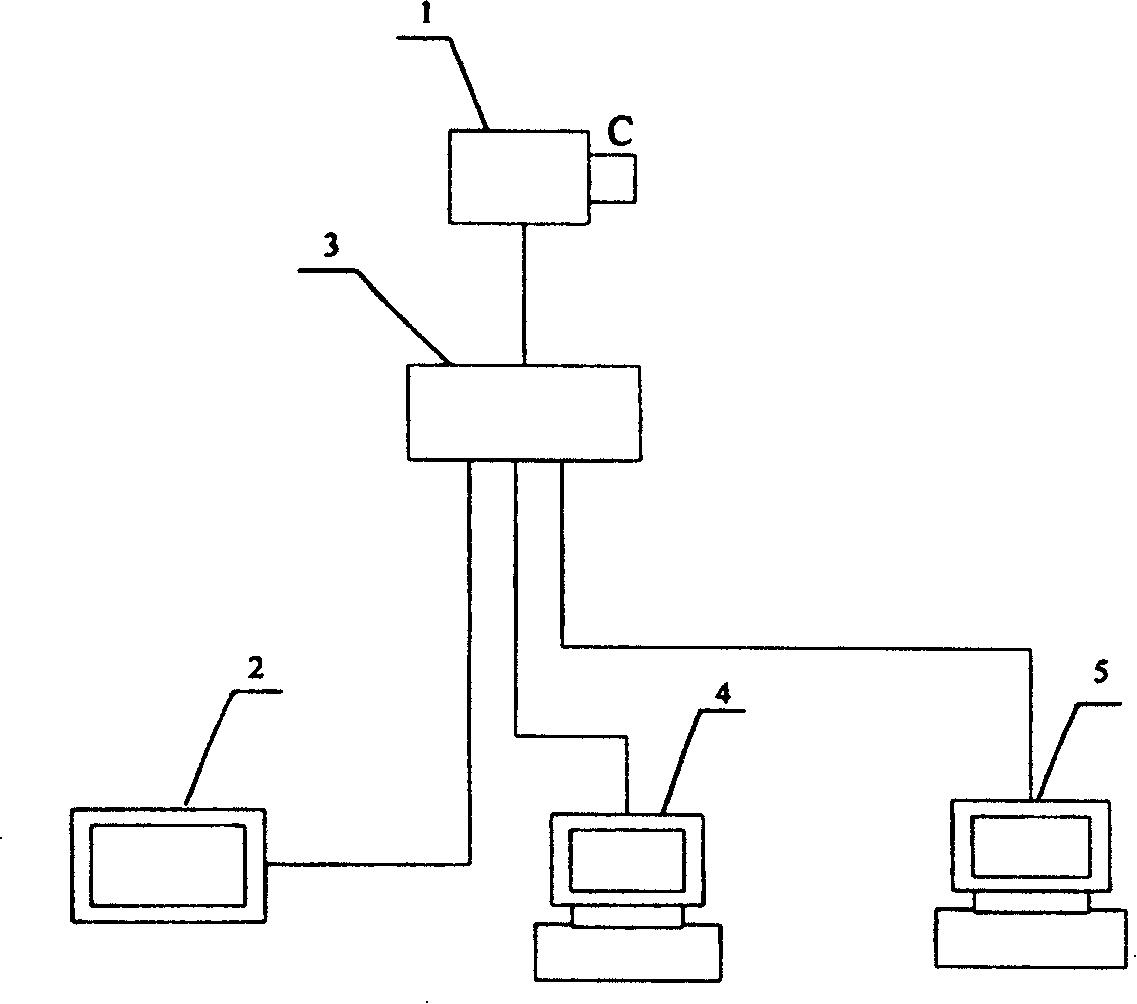

Method of automatically distinguishing band steel running aside in continuous annealing furnace

ActiveCN1904090ALess investmentThe alarm information is accurateImage analysisUsing electrical meansMonitoring systemStrip steel

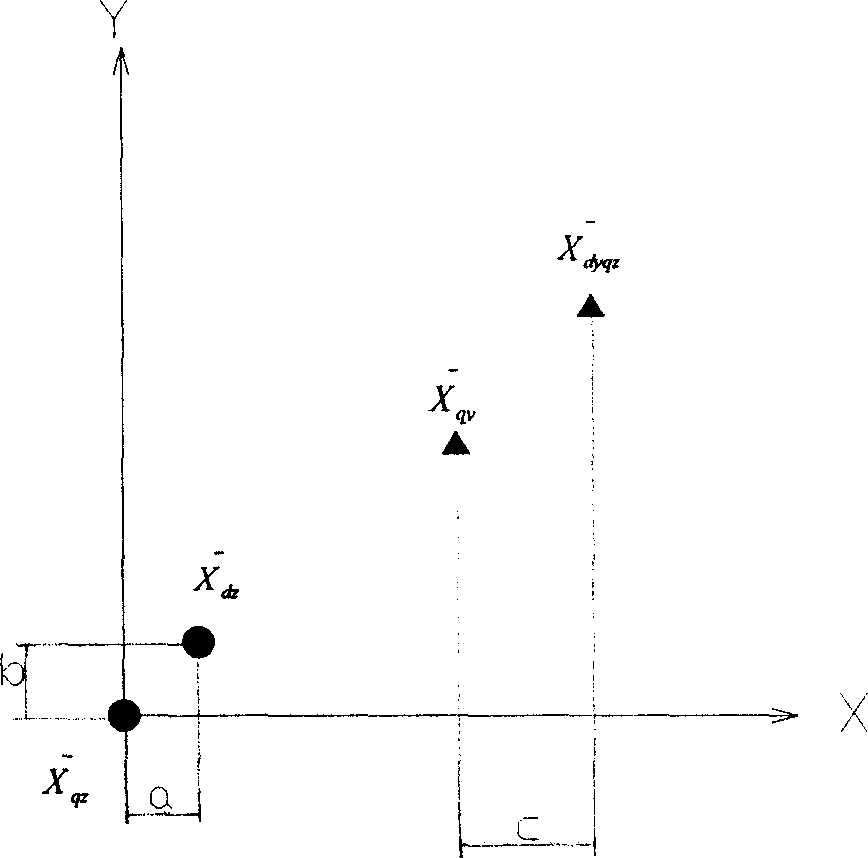

The present invention belongs to the field of image identification technology, in particular it relates to an image identification method for identifying running-off strip steel in continuous annealing furnace. Said method includes the following steps: converting the image shot by industrial TV set mounted in the continuous annealing furnace into digital signal, then calculating and sampling the transverse displacement change of image gray median point, utilizing the image median point displacement extent to automatically judge that the strip steel in the continuous annealing furnace is run off or not.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Macroscopic defect cold etching visualizing reagent

InactiveCN101587040ASolve environmental problemsSimple and fast operationPreparing sample for investigationSurface finishSulfite salt

The invention relates to a macroscopic defect cold etching visualizing reagent for the billet macroscopic structure defect quick detection in the steel production enterprise, which solves the problem at present that the reagent for detecting the macroscopic structure and internal defect of the billet is not easy to be stored and unable to be produced into the products with high danger and easy explosion; the harmful gas discharged in the process of etching with a heat acid method influences the human body and pollutes the environment; and a great deal of auxiliary machinery is invested. The invention is characterized by adding 5-30 ml of analytically pure nitric acid with the concentration of 65.0-68.0% into 100 ml water; or adding 3-15 g of anhydrous sodium sulfite or sodium sulphite in the above reagent. One of the using method of the invention is that: processing the sample billet to be detected to that of which the surface finish is smaller than 15 mum; pouring the mixed liquid prepared according to the above proportion on the sample surface for etching, waiting for about 30s, then washing with water, drying, repeating the operation until the casting billet structure presents clearly if there is an uncorruptible steel.

Owner:黄楠

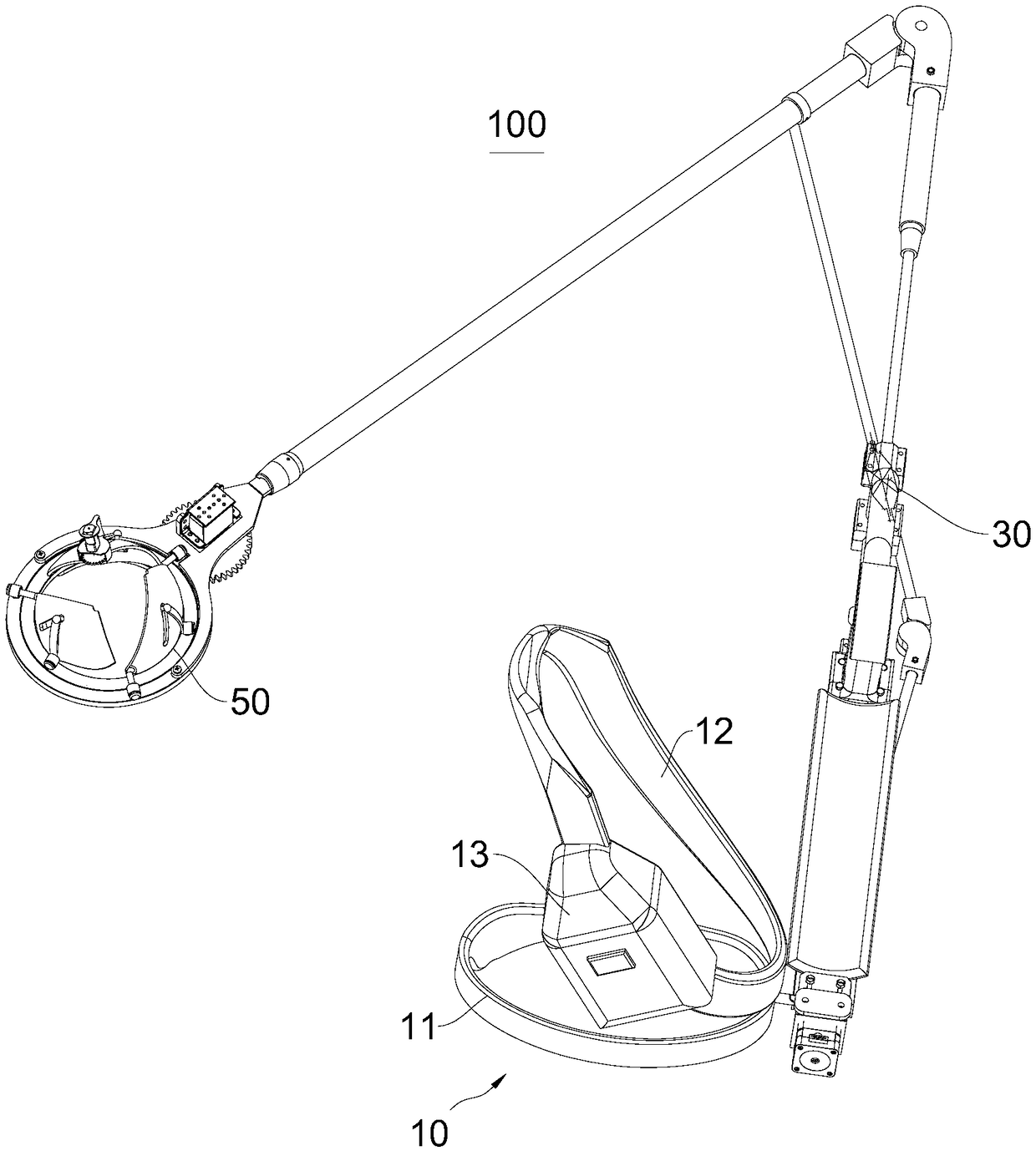

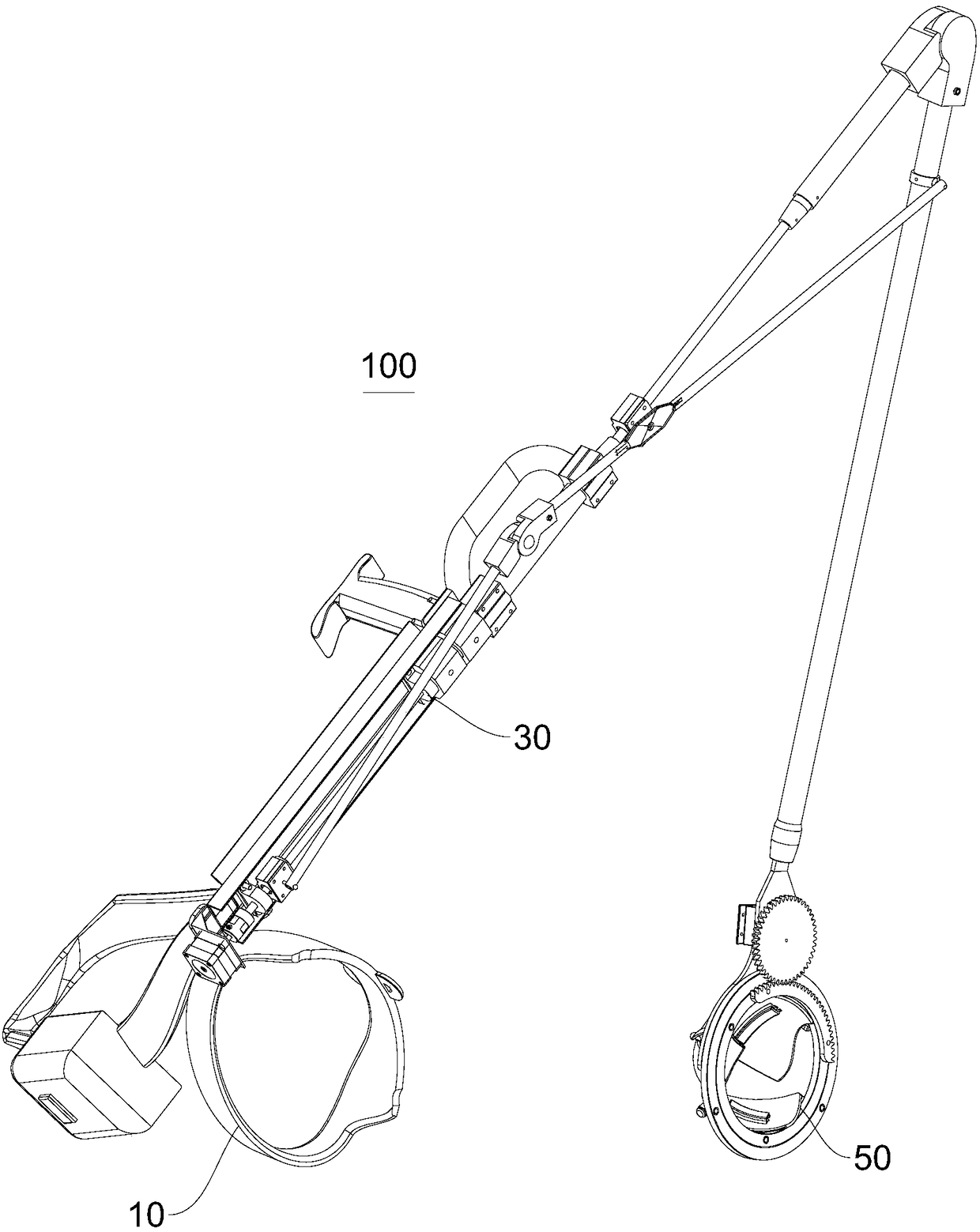

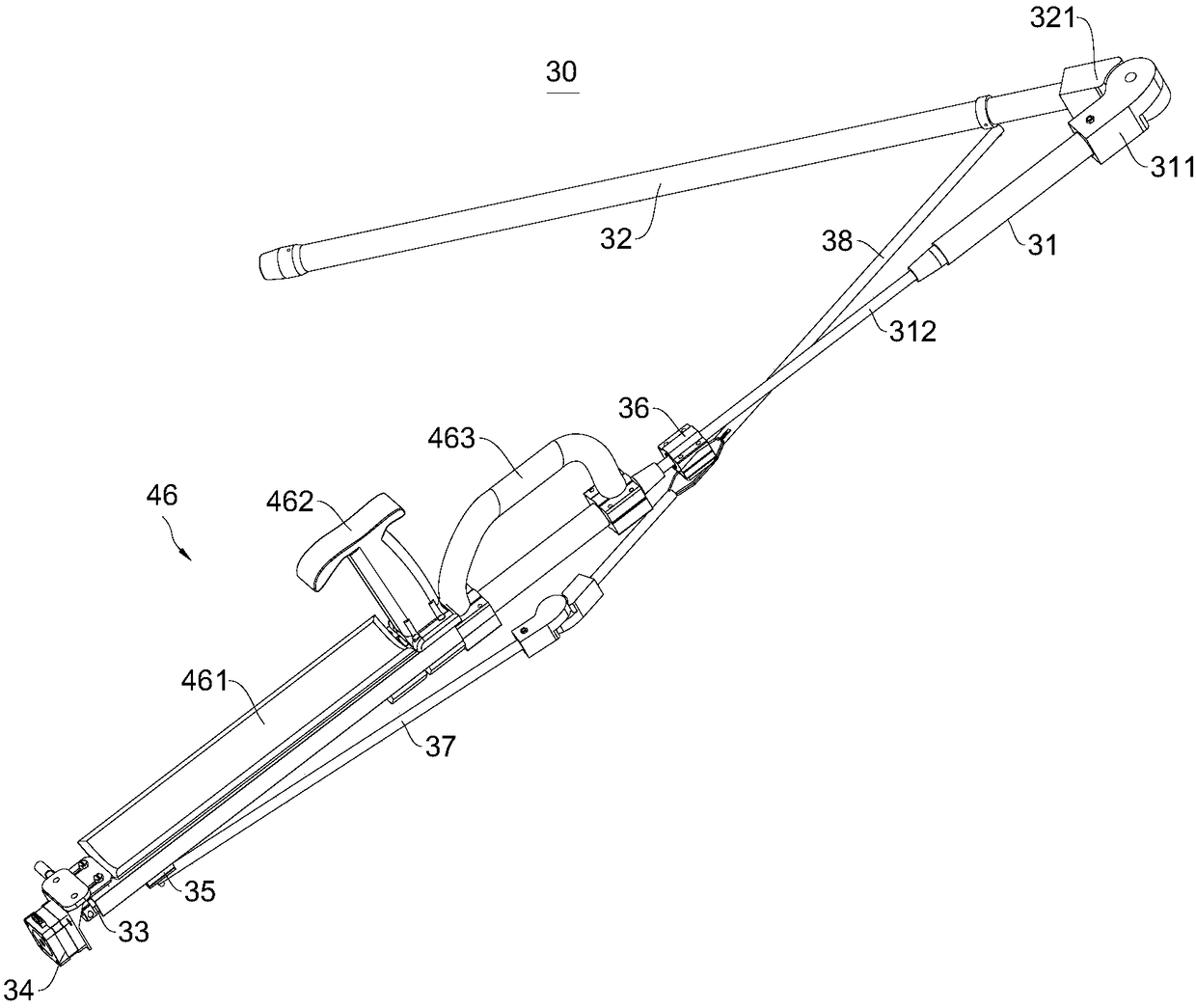

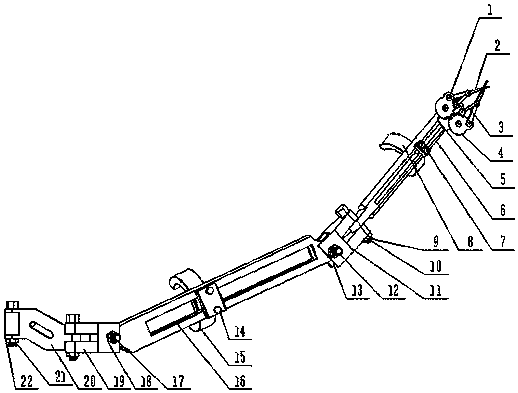

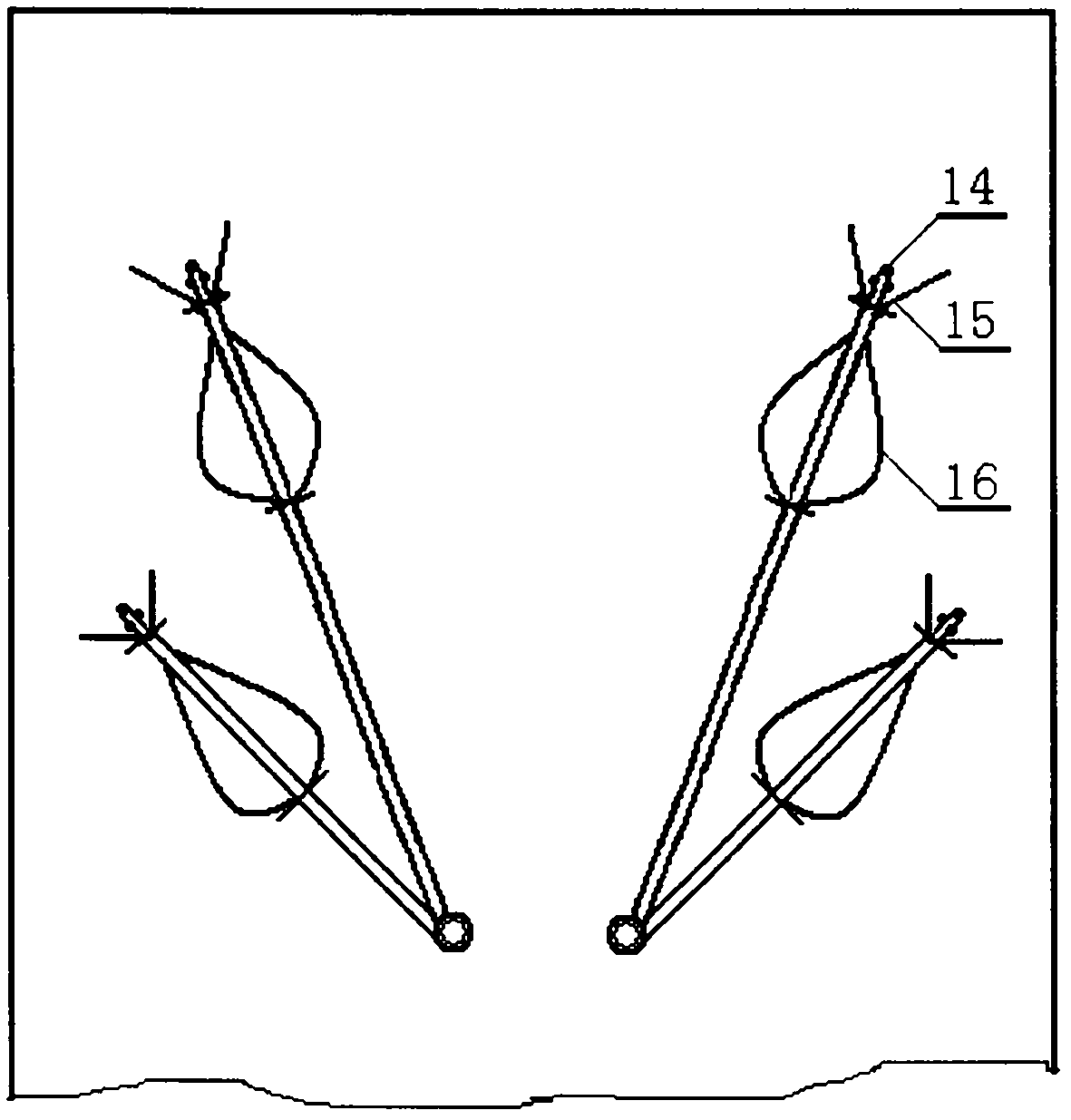

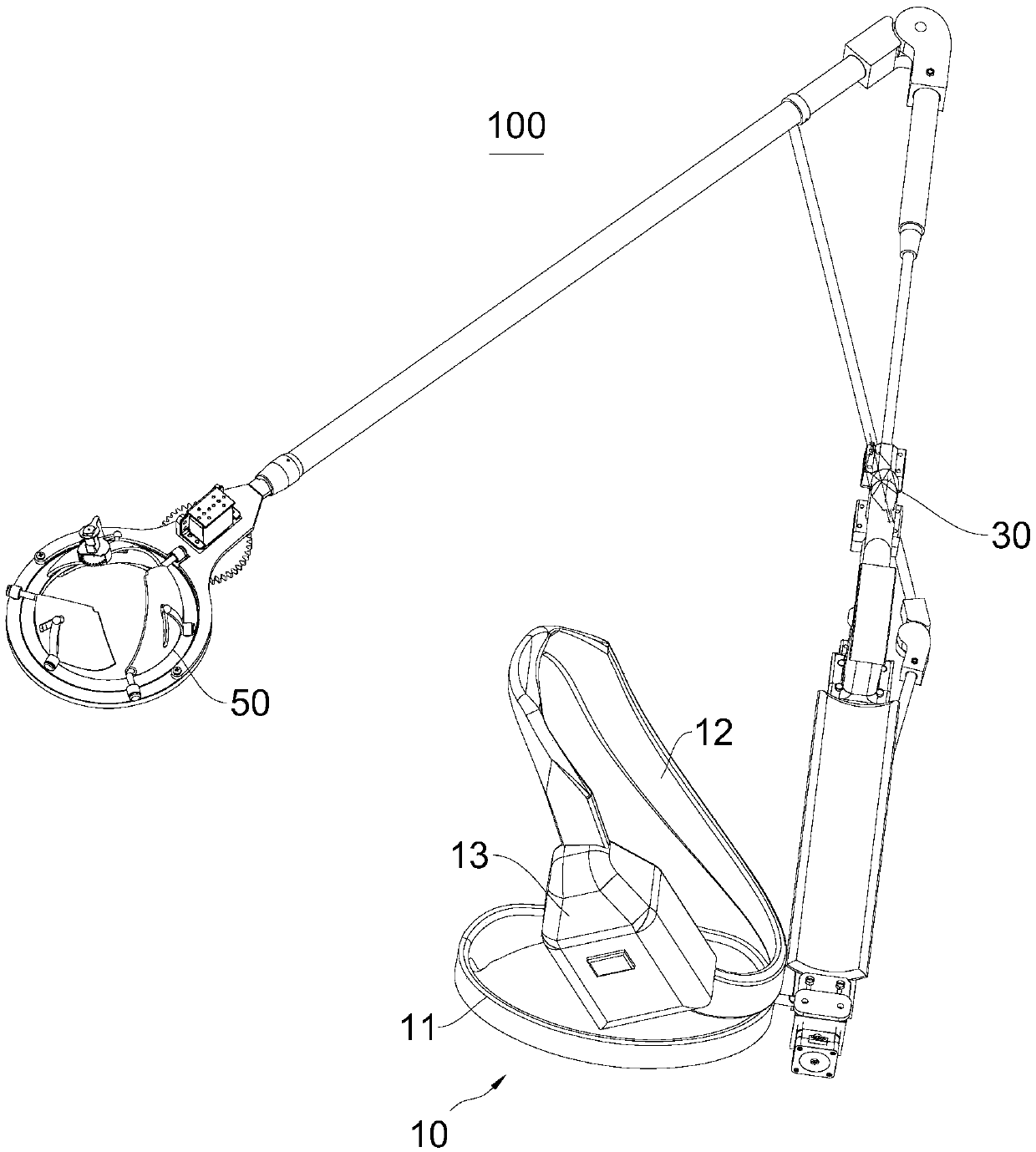

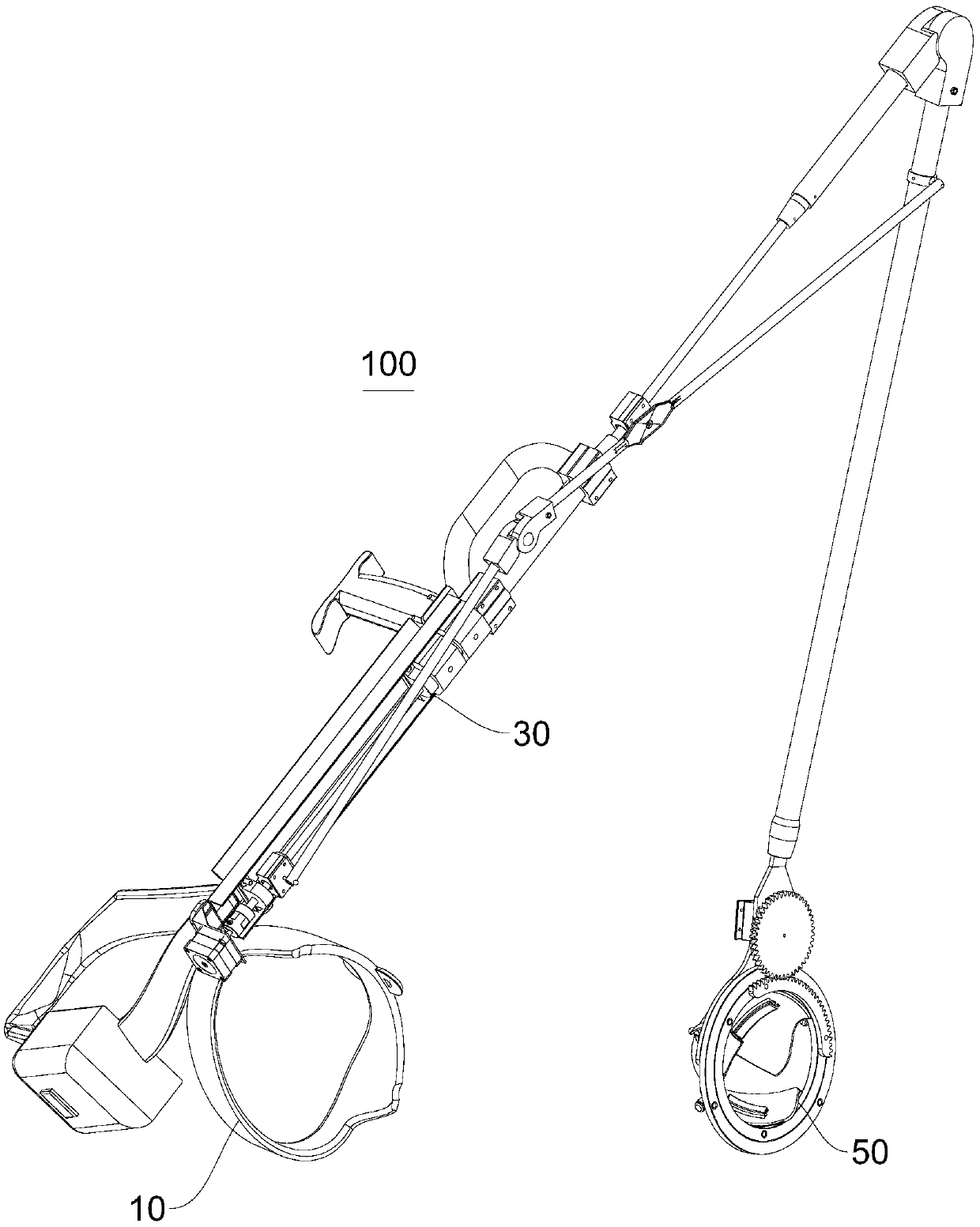

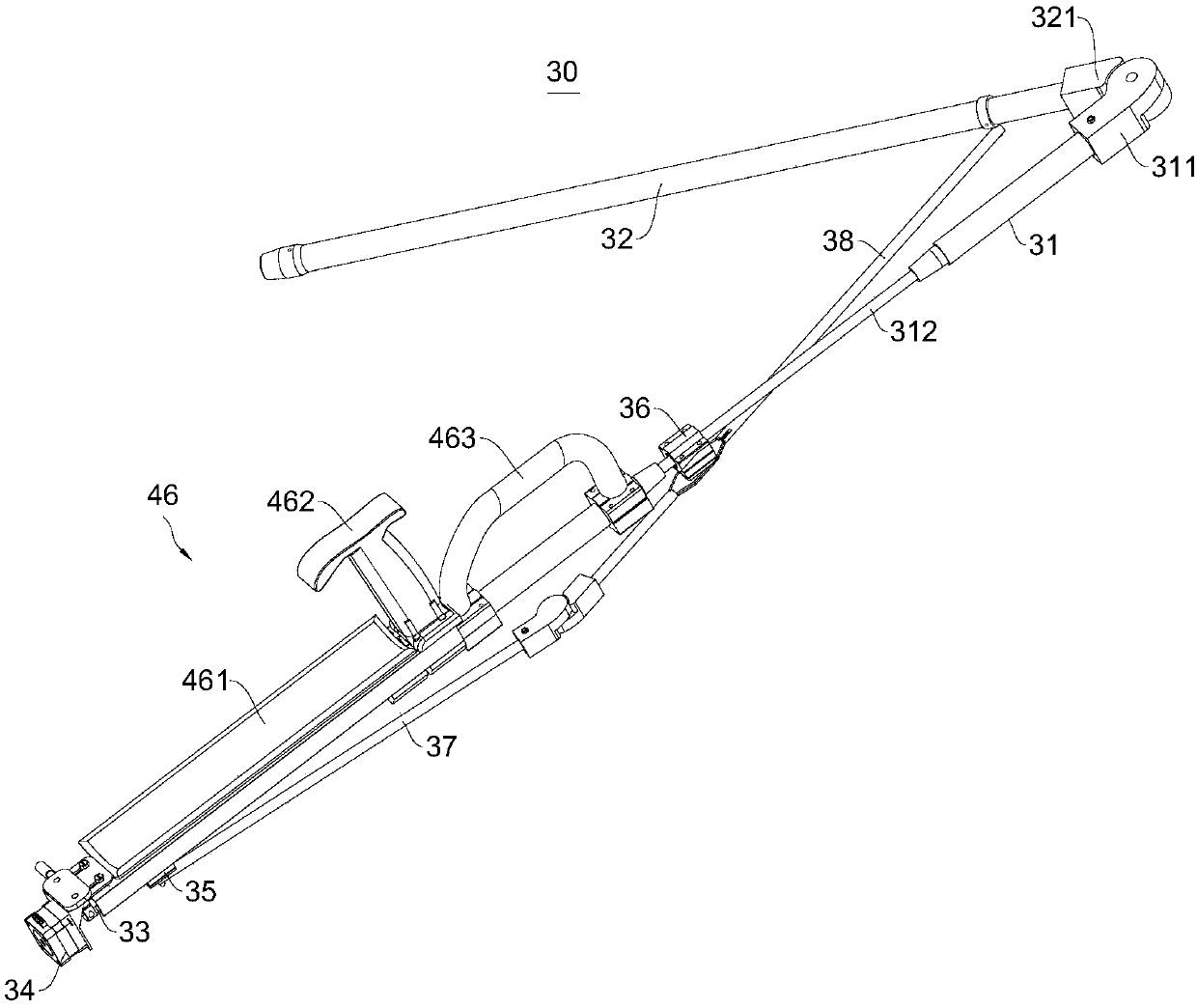

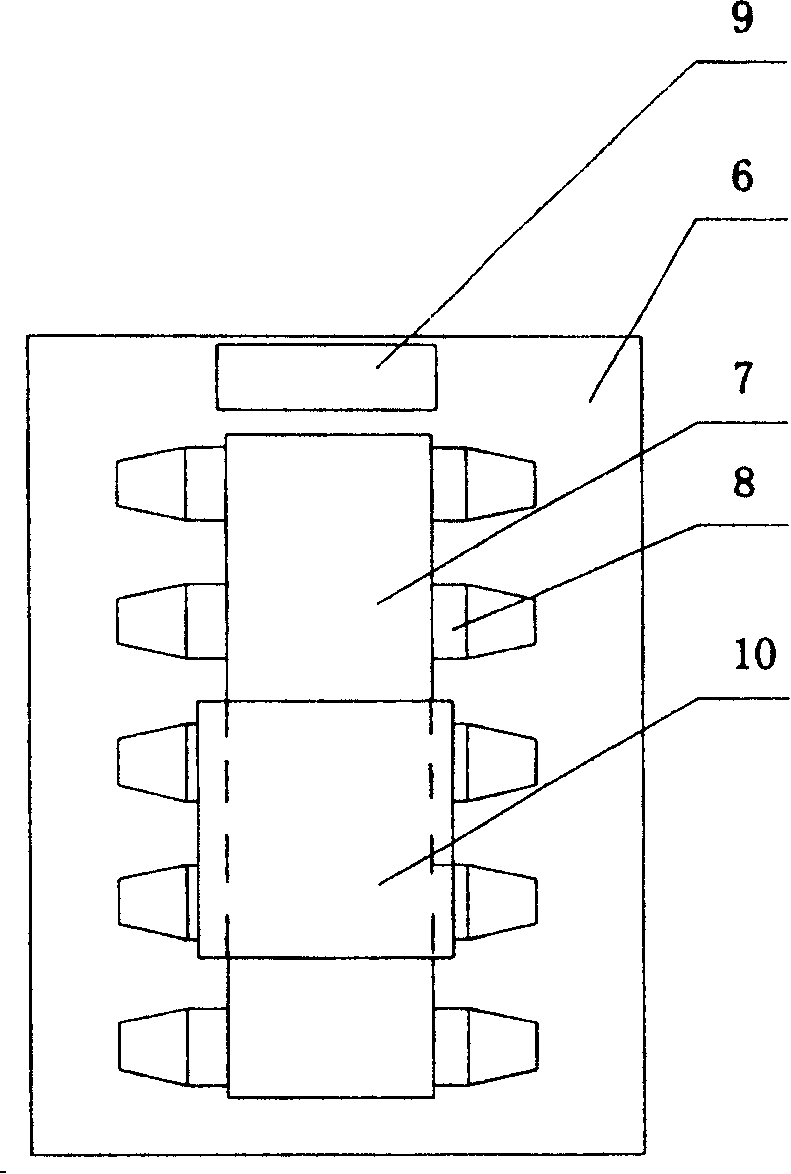

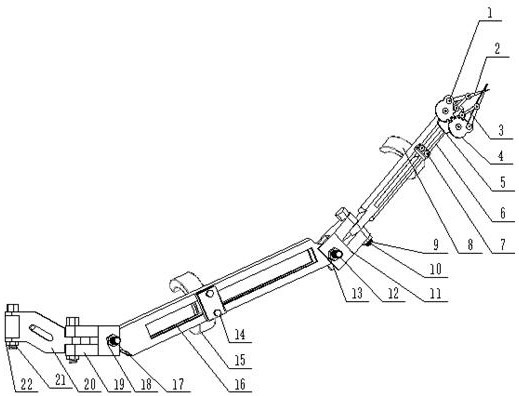

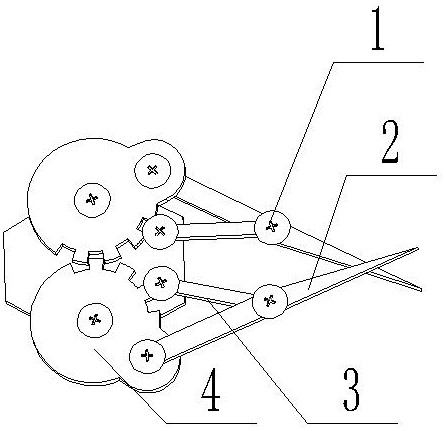

Fruit picker and picking equipment

ActiveCN108566831AAdjustable sizeEasy to operateRenewable energy machinesPicking devicesHuman bodyElectric machinery

The invention provides a fruit picker and picking equipment, and belongs to the technical field of fruit picking. The fruit picker comprises a wearing device, a positioning device and a picking device, wherein the wearing device is adaptive to a waist and shoulders of a human body; the positioning device comprises a first supporting rod, a second supporting rod, a lead screw, a first drive motor,a first slide block, a second slide block, a first drive rod and a second drive rod; and the picking device comprises a frame body, a rotary part, a second drive motor, a third slide block, a connecting rod, a cutting motor and at least two petal parts. The fruit picker is adjustable in dimension, is greatly convenient for a use, is simple in operation, improves picking efficiency, is reasonable in structural design and is high in practicability. The picking equipment comprises the fruit picker which has all functions of the fruit picker.

Owner:WUHAN POLYTECHNIC UNIVERSITY

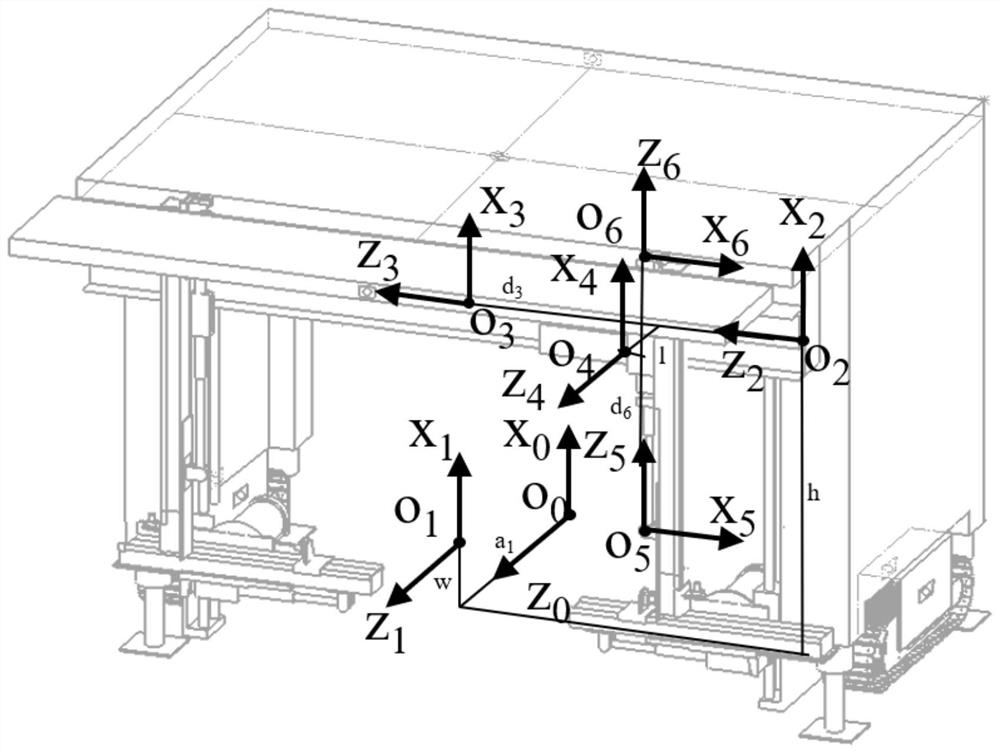

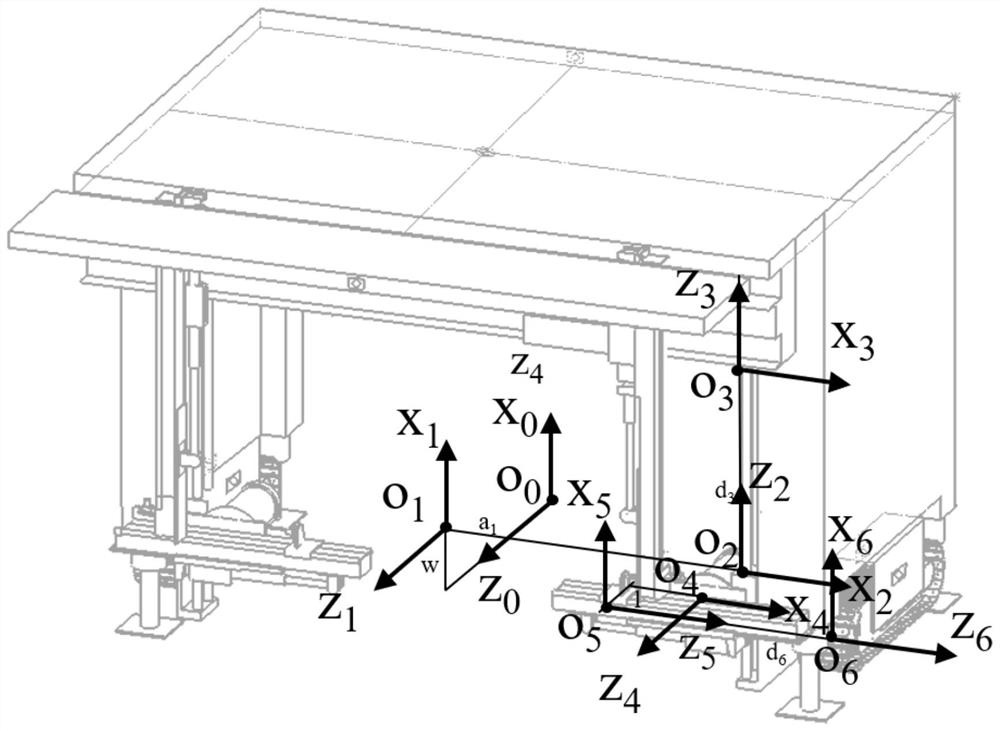

Coal mine drilling and anchoring robot drilling accurate positioning method based on visual calibration

PendingCN112068543AAdjust in timeSmooth Drilling and Anchor OperationPosition/course control in two dimensionsTotal factory controlLoop controlControl system

The invention discloses a coal mine drilling and anchoring robot drilling accurate positioning method based on visual calibration. A distributed radar ranging sensor is adopted to collect distance information of a front side, a rear side, an inner side and an outer side of a drilling and anchoring robot, and the drilling and anchoring robot is ensured to advance along the center line of a roadwaywithout offset through a program design; a photoelectric encoder and an angular displacement sensor are adopted to form a semi-closed-loop control system for a translation distance and a rotation angle of a drilling machine on a drilling and anchoring platform; an inclination angle sensor is adopted to collect ground inclination angle information of the drilling and anchoring robot, and posture adjustment of the drilling machine platform is achieved to compensate errors caused by ground inclination angles; and a tail end of the drilling machine is intelligently aligned with an anchor mesh to complete an accurate drilling target in a vision-based mode, and accurate positioning of the drilling machine is achieved. The accurate positioning method is simple and complete, the problems that manual drilling operation wastes time and labor, a danger coefficient is high and so on are solved, the accuracy and real-time performance of drilling and anchor rod operation are improved, and wide application prospects are achieved.

Owner:XIAN UNIV OF SCI & TECH

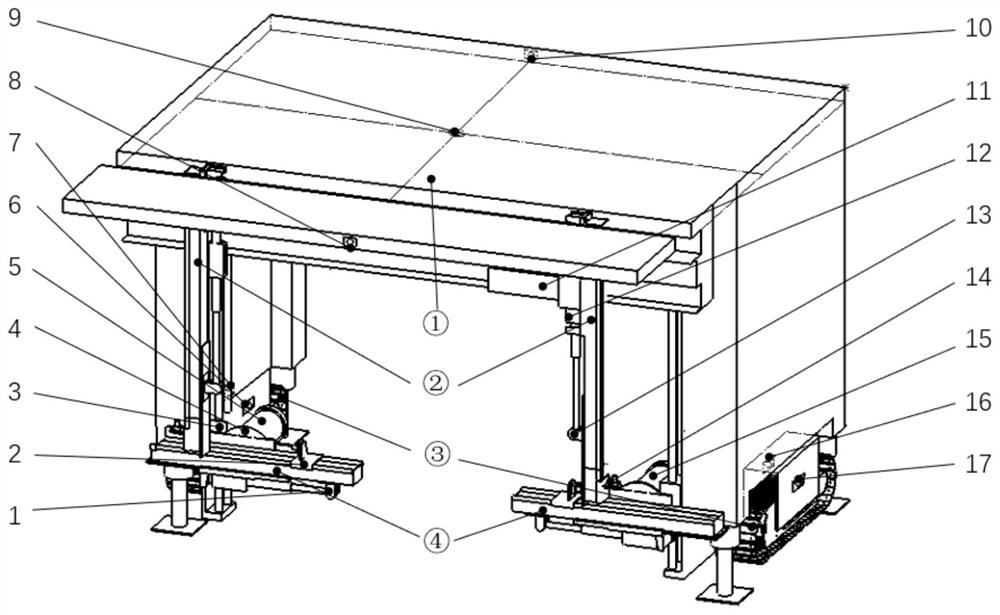

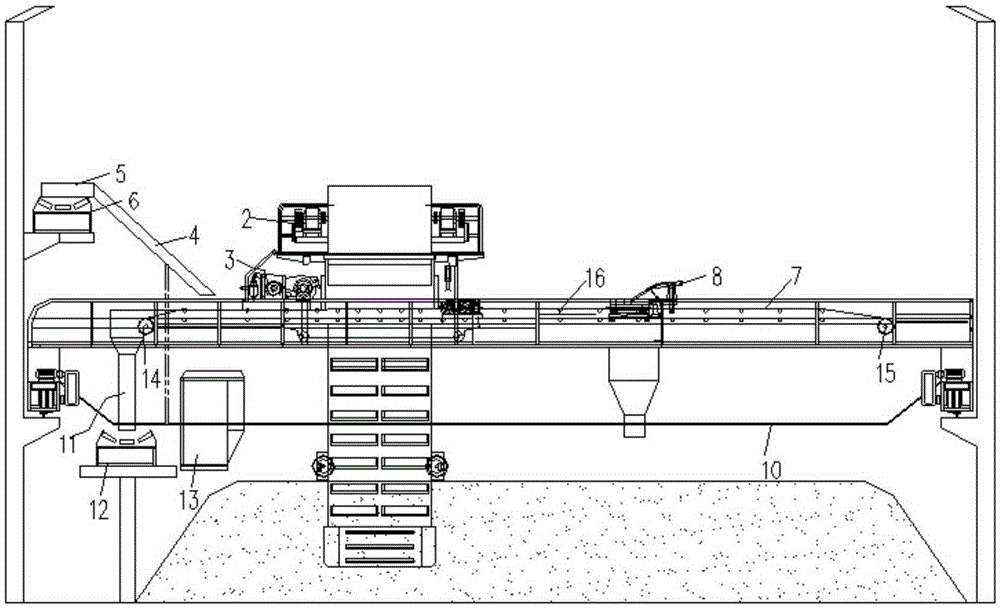

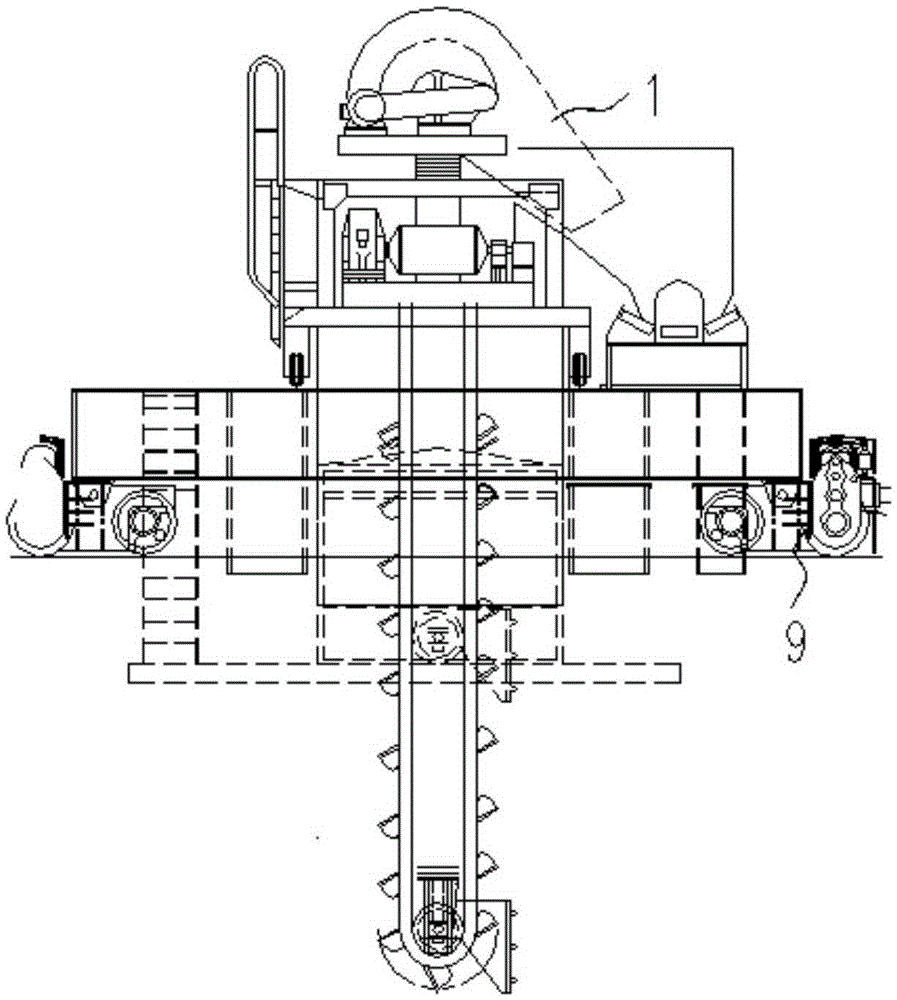

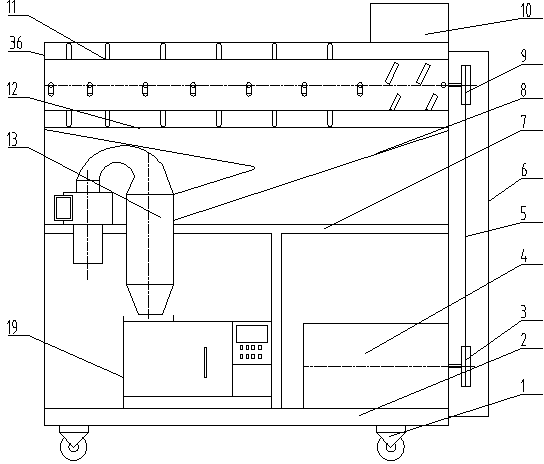

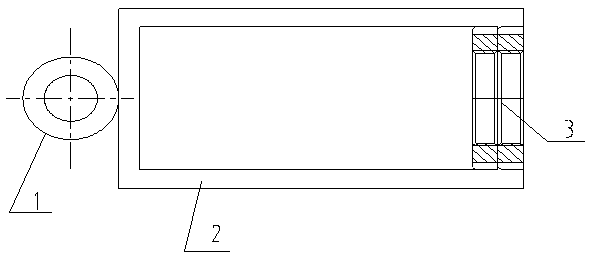

Bridge type chain bucket car unloader

InactiveCN105253648ALiberate labor productivityIncrease production levelsLoading/unloadingCartEngineering

The invention provides a bridge type chain bucket car unloader. Skip bucket mechanisms are arranged on the two sides of a sliding bucket box, and an ascending mechanism is arranged at the bottoms of the skip bucket mechanisms; a material conveying frame is arranged on one side of the ascending mechanism, and a moving material throwing trolley is arranged at the top end of the material conveying frame; a first main belt conveyor is arranged at the bottom of the moving material throwing trolley, and an equipment belt conveyor is arranged at the bottom end of the material conveying frame; a moving plough unloader is arranged at the top end of the equipment belt conveyor, and a cart running mechanism is arranged on the side edge of the equipment belt conveyor; a metal support is arranged at the bottom of the equipment belt conveyor, and a material spilling bucket is arranged at the bottom of the metal support; and a second main belt conveyor is arranged at the bottom of the material spilling bucket, and a cab is arranged on one side of the second main belt conveyor. Semiautomatic material distributing and material taking functions are achieved, the labor force is liberated, the production level is improved, the whole unloader is reasonable in design and convenient to use, and the working efficiency is improved.

Owner:WUXI ZHONGJI MACHINERY MFG CO LTD

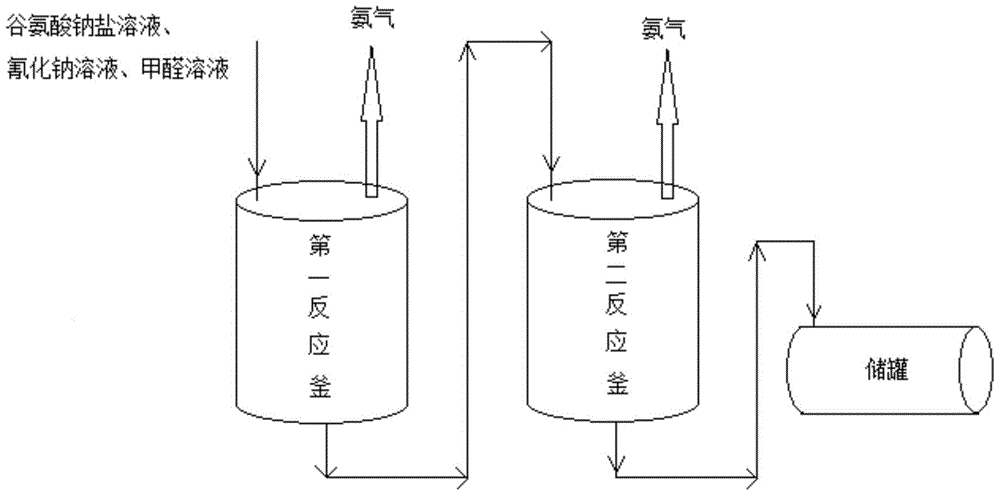

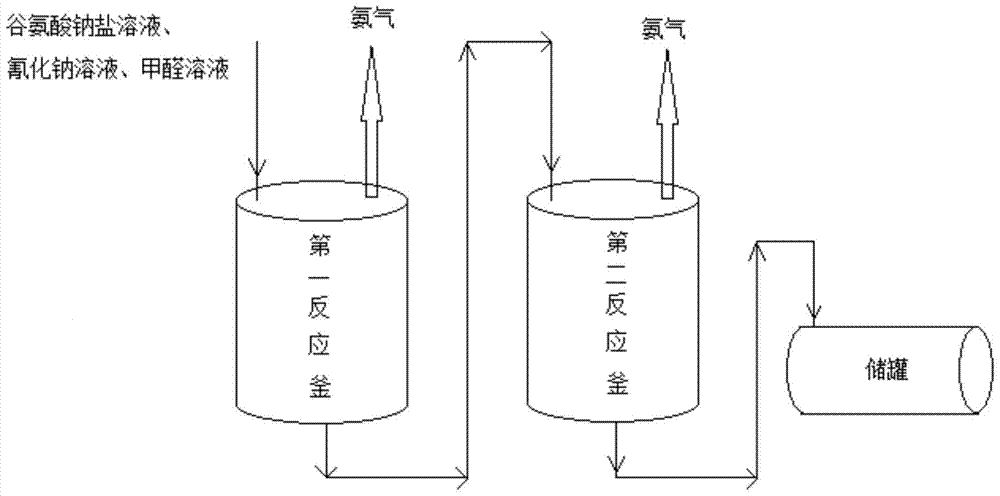

Process for producing tetrasodium glutamate diacetate through continuous method

ActiveCN105732408AHigh yieldHigh purityOrganic compound preparationAmino-carboxyl compound preparationFiltrationSodium cyanide

The invention provides a process for producing tetrasodium glutamate diacetate through a continuous method.Production is conducted through a continuous reactor.The process includes the following steps that A, a sodium glutamate saline solution, a sodium cyanide solution and a formaldehyde solution are used as raw materials and fed into a first reaction kettle to react through a heat exchange system according to the flow speed, and generated ammonia gas is collected at the same time; B, feed liquid generated after reaction in the first reaction kettle is discharged from the bottom of the kettle and directly enters a second reaction kettle to continue to react, and ammonia gas generated in the second reaction kettle is collected at the same time; C, feed liquid reacting in the second reaction kettle is discharged from the bottom of the kettle and enters a storage tank to be subjected to decoloration, filtration and concentration regulation so that a tetrasodium glutamate diacetate solution can be obtained.By means of the process, tetrasodium glutamate diacetate can be continuously produced, the quality of the obtained product is good, the production stability is good, control is easy, and by-products generated by kettle type reaction can be avoided.

Owner:HEBEI CHENGXIN

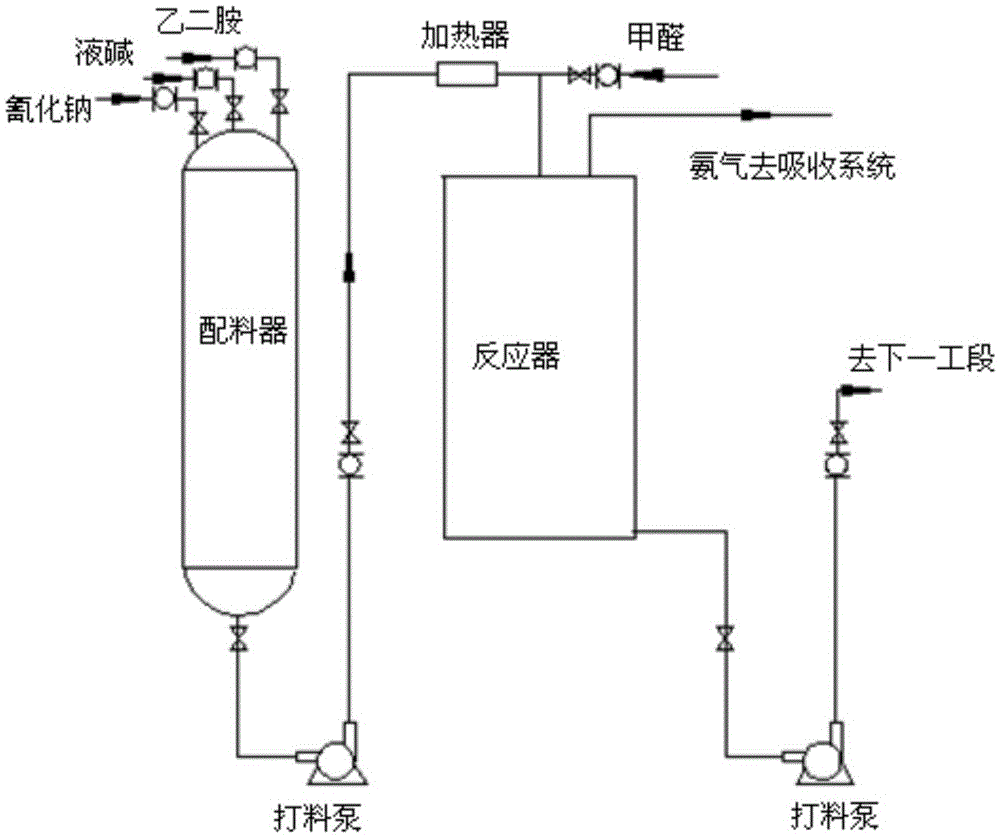

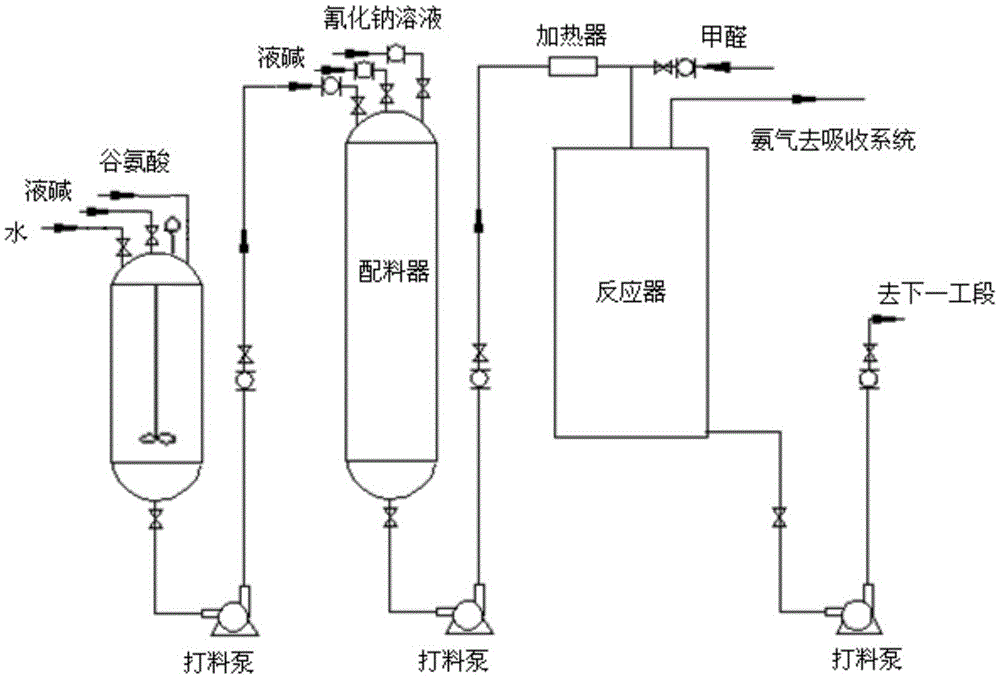

Novel continuous automated reaction process for preparing aminopolycarboxylic acids chelating agent

ActiveCN105646254AImprove qualityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationContinuous reactorAfter treatment

The invention discloses a novel continuous automated reaction process for preparing an aminopolycarboxylic acids chelating agent and belongs to the technical field of aminopolycarboxylic acids chelating agents. Production is conducted through a flow reactor, a whole reaction system is under DCS automation control, and the process comprises the following steps: 1, material blending and mixing, wherein raw materials are continuously and stably pumped into a batcher for mixing, so that a liquid mixture is obtained; 2, preheating treatment, wherein the liquid mixture is pumped out of the batcher through a material delivering pump, and the liquid mixture which is pump out is subjected to heating treatment through a heater; 3, reaction and generation, wherein heated liquid materials and formaldehyde or heated liquid materials and a glycolonitrile solution are added into the reactor for a reaction, ammonia gas generated through the reaction is discharged through the top of the reactor and collected, and a reaction solution is drained through the bottom of the reactor and delivered to the acidification procedure for after-treatment through the material delivering pump, so that the aminopolycarboxylic acids chelating agent is obtained. By means of the process, the aminopolycarboxylic acids chelating agent can be produced in a continuous and automated mode, and stability of the reaction process is improved.

Owner:石家庄杰克化工有限公司

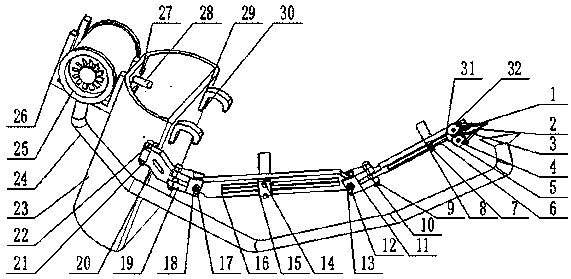

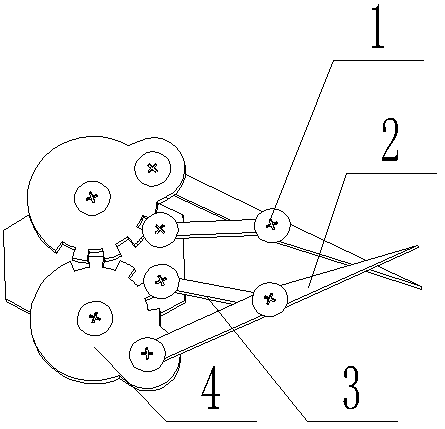

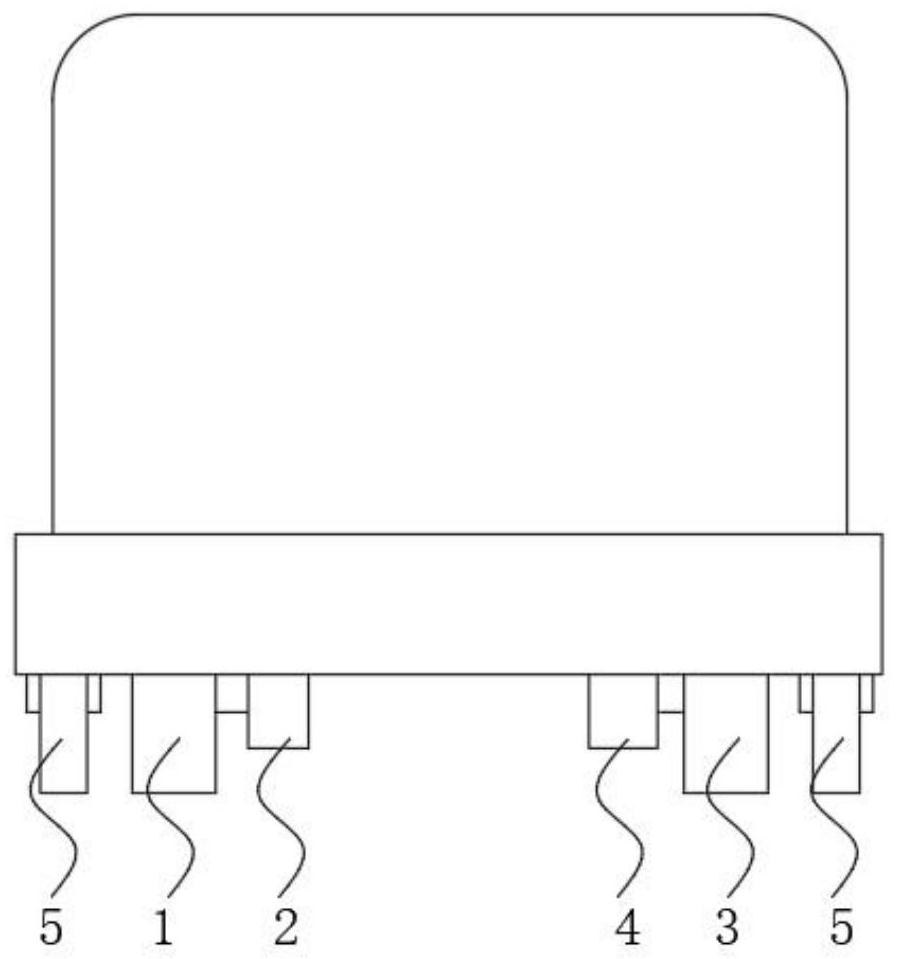

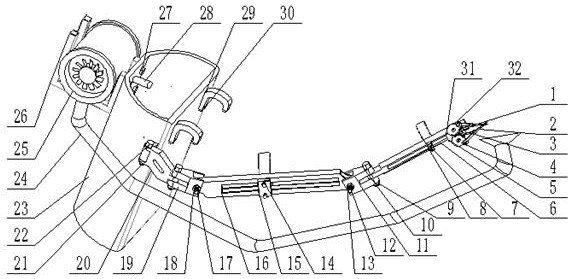

Exoskeleton wolfberry picking mechanism

ActiveCN108161897AMeet supply problemsLiberate labor productivityProgramme-controlled manipulatorPicking devicesLycium barbarum fruitEngineering

The invention relates to an exoskeleton wolfberry picking mechanism and belongs to the technical field of agricultural machinery. The exoskeleton wolfberry picking mechanism comprises a shearing mechanism, a forearm manipulator mechanism, an upper arm manipulator mechanism, a middle connecting part and a fruit collecting part, wherein the shearing mechanism is used for picking wolfberry fresh fruit; the forearm manipulator mechanism is used for carrying out picking work in cooperation with the fore arm of a worker; the upper arm manipulator mechanism is used for carrying out picking work in cooperation with the upper arm of the worker; the middle connecting part is used for connecting the upper arm manipulator mechanism and the fruit collecting part and used for fitting the movement of a shoulder joint in the working process of the worker; and the fruit collecting part is used for collecting the fresh fruit picked by an exoskeleton picking mechanical arm part. The wolfberry fresh fruitmanipulator picking mechanism related to the invention has great significance in increasing the wolfberry picking efficiency, reducing manual picking operation intensity, reducing economical cost inthe picking process and increasing the labor productivity.

Owner:KUNMING UNIV OF SCI & TECH

Automatic metering type single-plant soybean thresher

An automatic metering type single-plant soybean thresher comprises a machine frame. An automatic metering device and a power driving device are arranged on the bottom of the machine frame. A threshing device is arranged on the upper portion of the machine frame. A power output end of the power driving device is in transmission connection with a power input end of the threshing device. A feeding opening is formed in the top of the threshing device. A concave plate screen is arranged below the threshing device. A cyclone separation device which is placed between the threshing device and the automatic metering device is arranged on the machine frame. An inlet of the cyclone separation device is connected with a flow guiding structure placed below the concave plate screen. An outlet of the cyclone separation device is connected with an inlet of the automatic metering device. According to the automatic metering type single-plant soybean thresher, threshing is clean and complete, grains cannot be damaged, no residues exist in the thresher, sorting is clean, mixing is avoided, automatic counting and weighing are quick and accurate, a memory storing function is achieved, and after-test checking and processing are convenient.

Owner:HENAN AGRICULTURAL UNIVERSITY

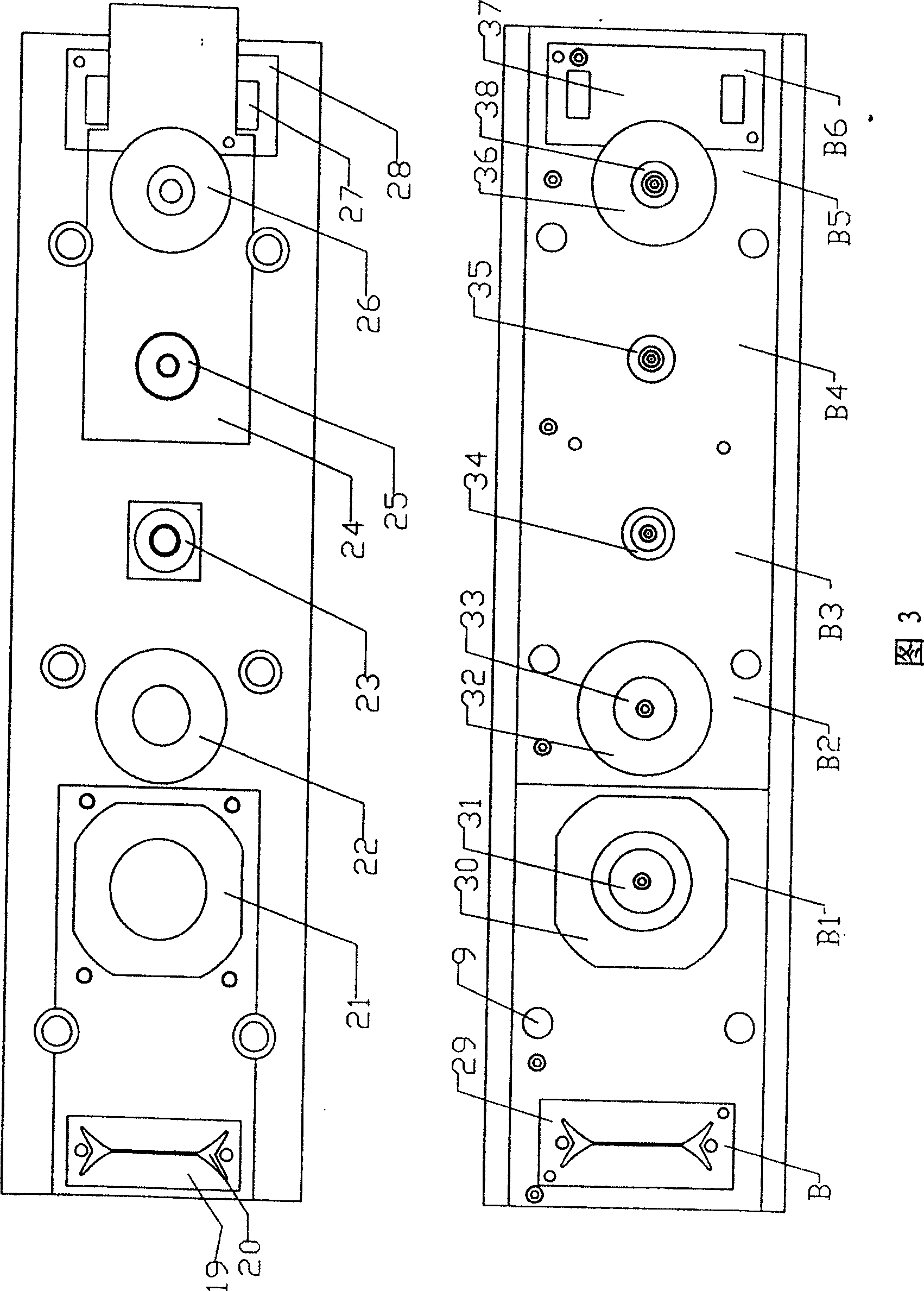

Full automatic compounding process and mould for household motor shell

InactiveCN100462157CReasonable designGuaranteed lifeShaping toolsManufacturing dynamo-electric machinesPunch pressEngineering

This invention discloses an automatic complex technology and dies for motor shell of family appliances, in which, the complex technology includes a punch technology characterizing in setting 7 steps: a first step of cut station, a second step of stretch station etc. along the transmission direction of a feed-in device on a punch, and an automatic compound die, up and down die base composed of up and down templates, a guiding device in the die and up and down dies characterizing in the up and down die base composed of up and down templates, in which, the upper base includes an upper template fixed on the punch of a punch machine tool.

Owner:佛山市南海里水中兴五金电器厂

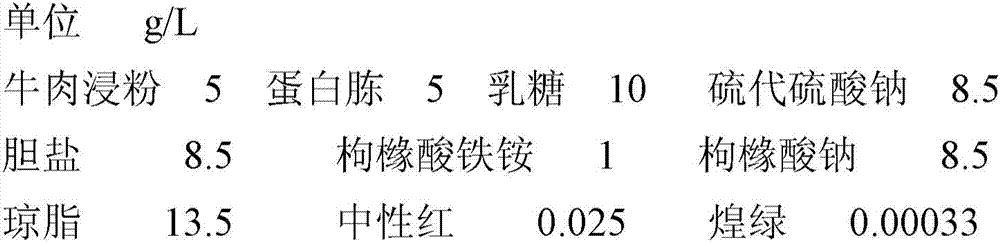

Culture medium, culture medium composition, and preparation methods of culture medium and culture medium composition

PendingCN107354095AReduce consumptionLiberate labor productivityMicroorganismsBiotechnologyMicroorganism

The invention relates to a culture medium, a culture medium composition, and preparation methods of the culture medium and the culture medium composition. The culture medium composition comprises: a first component, wherein the first component is the structure support component of the culture medium composition, and is a gel; a second component, wherein the second component is the remaining component excluding the first component and a third component in the culture medium composition; and the third component, wherein the third component is the component unstable to room temperature, illumination or solutions, or complete animal living cells, or the component capable of producing denaturation during high temperature and high pressure sterilization, and is required to be separately stored and transported by considering the specific property of the component. According to the present invention, during the preparation of the culture medium, only the first component is required to be heated to dissolve the gel, and then the heated first component is mixed with the second component and the third component so as to complete the preparation of the culture medium; the preparation time before the experiment is saved, the method is suitable for industrial production, the standardization degree of the microbiological detection is improved, the solid mixing mode of the traditional dry powder culture medium is replaced with the liquid mixing mode, the components of the culture medium are uniform, and the inter-assay stability and the quality reliability of the microbial culture medium are improved.

Owner:BEIJING JUNLIKANG BIOTECHNOLOGY CO LTD

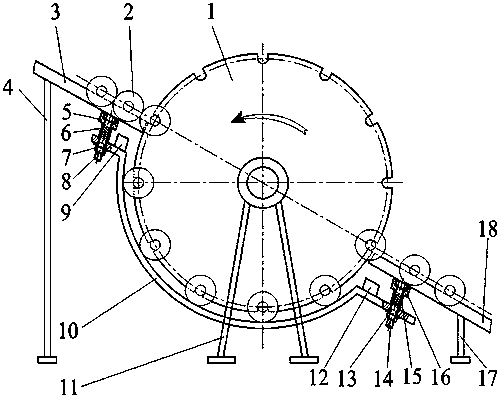

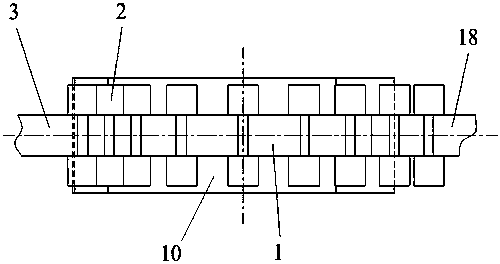

Grooved wheel type intermittent feeding and discharging automatic gluing device

ActiveCN111439555ASimple structureEasy to manufactureLiquid surface applicatorsCoatingsYarnEngineering

The invention provides a grooved wheel type intermittent feeding and discharging automatic gluing device. The grooved wheel type intermittent feeding and discharging automatic gluing device comprisesa grooved wheel type turntable (1), a single-rail rolling feeding channel (3), a single-rail rolling discharging channel (18), a feeding channel support (4), a discharging channel support (17), a gluedripping device (9), an arc-shaped gluing plate (10), a turntable support (11), a glue collector (12), an upper distance adjusting mechanism and a lower distance adjusting mechanism; a plurality of uniformly arranged shaped grooves are formed in the circumference of the grooved wheel type turntable (1); the single-rail rolling feeding channel (3) and the single-rail rolling discharging channel (18) form a certain inclination; and the distance between the inner surface of the arc-shaped gluing plate and the outer circumferential surface of the grooved wheel type turntable can be adjusted through the upper distance adjusting mechanism and the lower distance adjusting mechanism. Yarn guide leather rollers sliding into the shaped grooves roll one by one for multiple times along the inner surface of the arc-shaped gluing plate in a self-rotating mode, the gluing is uniform and consistent, and the yarn guide leather rollers after being subjected to gluing are discharged intermittently at acertain distance in sequence without mutual interference. According to the grooved wheel type intermittent feeding and discharging automatic gluing device, the manual gluing is replaced by a machine,therefore, the gluing quality is controllable, the operation is simple, the efficiency is high, and the grooved wheel type intermittent feeding and discharging automatic gluing device has good application prospects in the technical field of repair of the yarn guide rollers of spinning machines.

Owner:CHANGZHOU UNIV

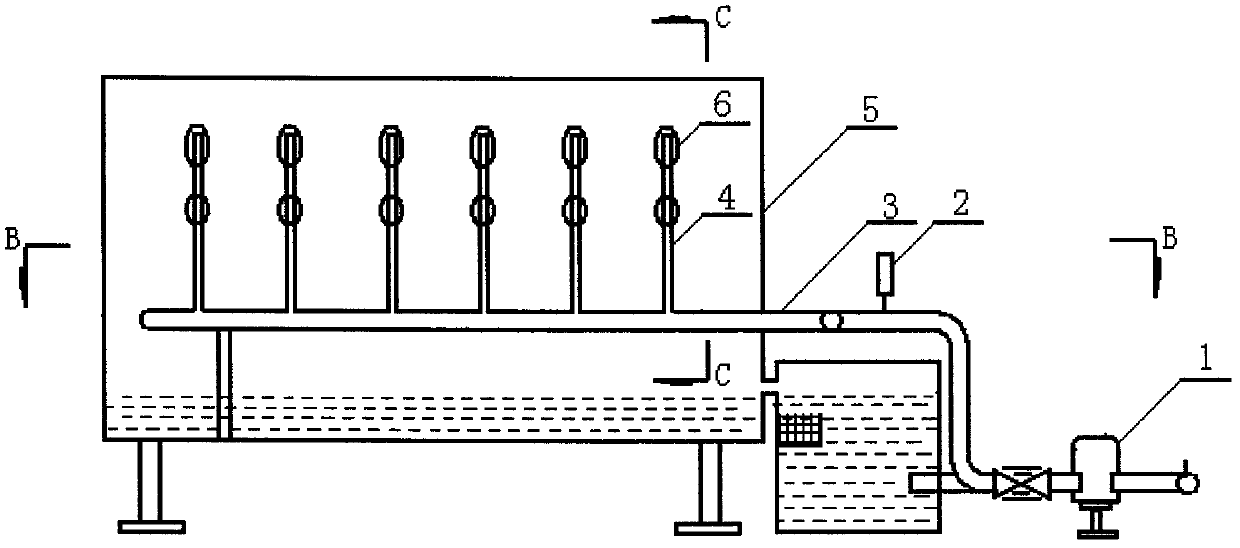

Automatic rain boot cleaning machine

InactiveCN103371790ALiberate labor productivityReduce labor intensityFootwear cleanersWater dischargeElectrical control

Disclosed is an automatic rain boot cleaning machine aiming at solving the problem of difficulty in large-batch manual cleaning of rain boots for labor protection. The automatic rain boot cleaning machine is characterized in that the automatic rain boot cleaning machine comprises a water tank, a water pump, a water pipe, a valve, cleaning heads, a spraying chamber and an electrical control system, a water incoming end of the water pump is connected with the water tank, a water outgoing end of the water pump is communicated into the spraying chamber, a main water pipe in the spraying chamber is divided into a plurality of branches, each branch is connected with one cleaning head which is formed by a spraying head, and a sole rack and a boot barrel support which are arranged around the spraying head, and the spraying chamber is provided with a water discharging port. The automatic rain boot cleaning machine depends on the quincuncial spraying heads to spray large-coverage-area and high-impact-force water flow to wash and brush inner cavities of boots, and dirt and sweat in the rain boots can be quickly washed and cleaned while no detergent is needed. Cleaning can be completed in only 1-3 minutes, and 15-35 pairs of the rain boots can be cleaned simultaneously. The automatic rain boot cleaning machine is short in cleaning cycle, high in working efficiency, good in cleaning effect and suitable for all walks of life like coal mines, all places needing the rain boots to be worn for operation and all units needing large-batch cleaning of the rain boots.

Owner:张勤

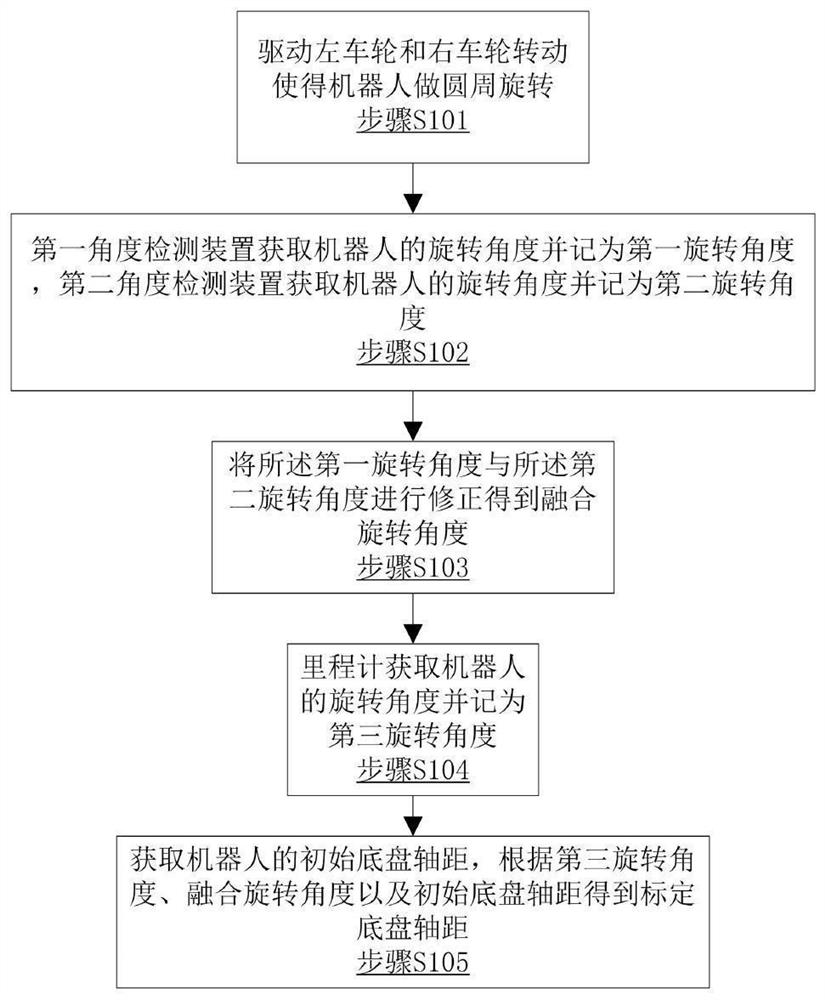

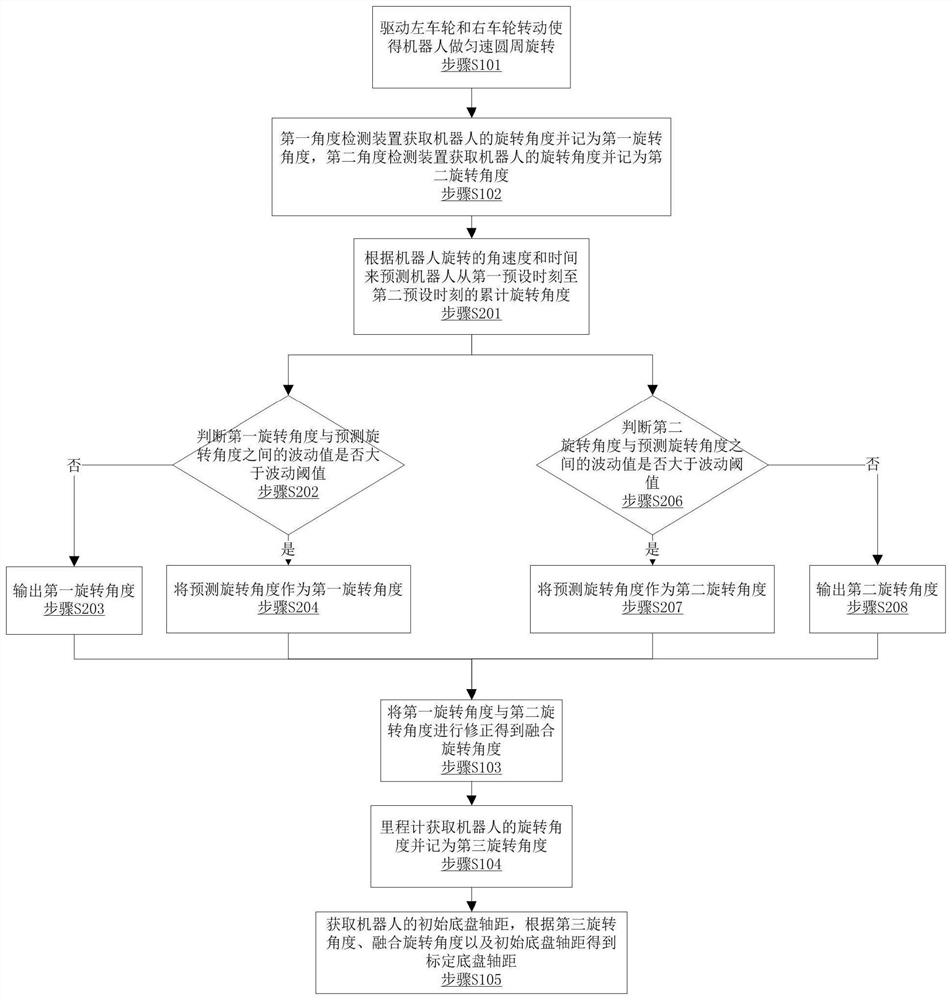

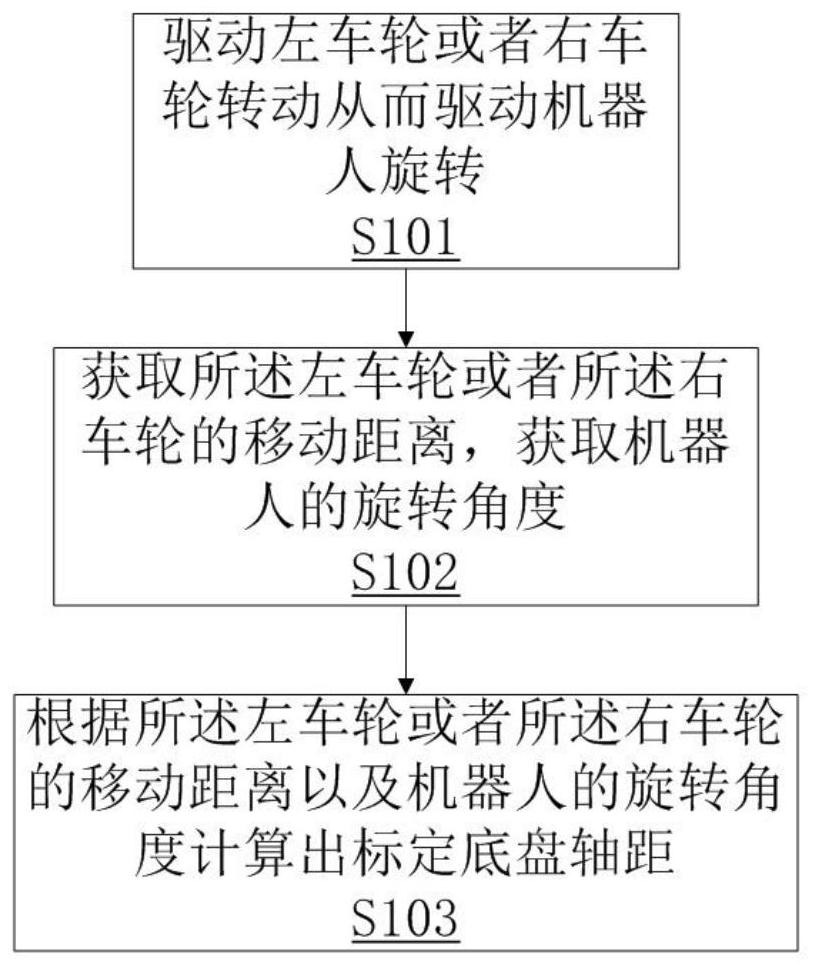

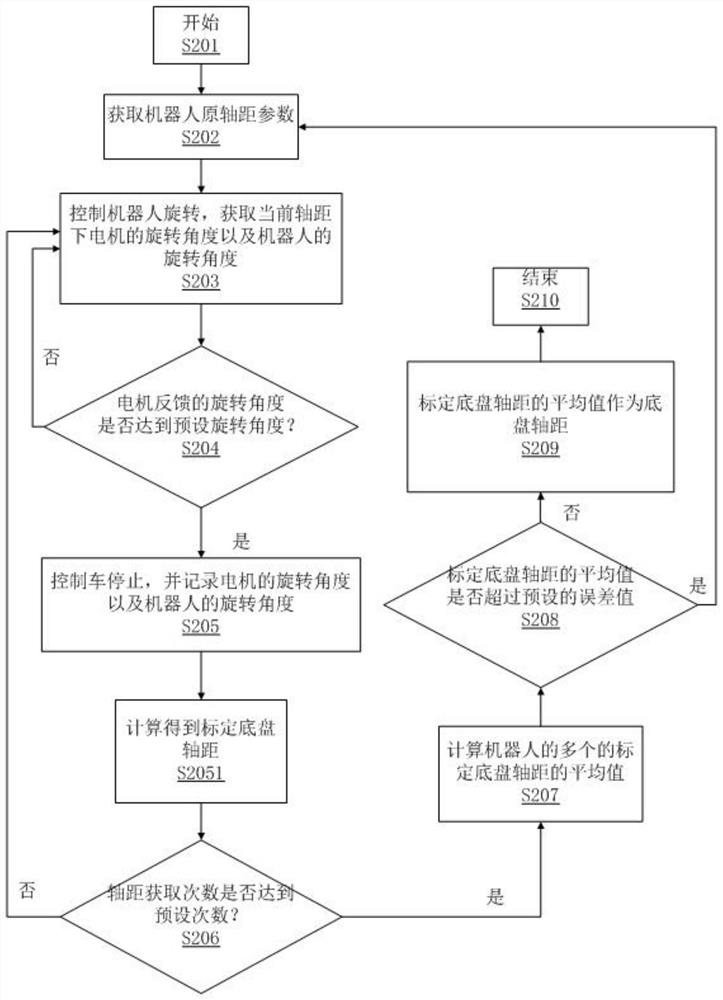

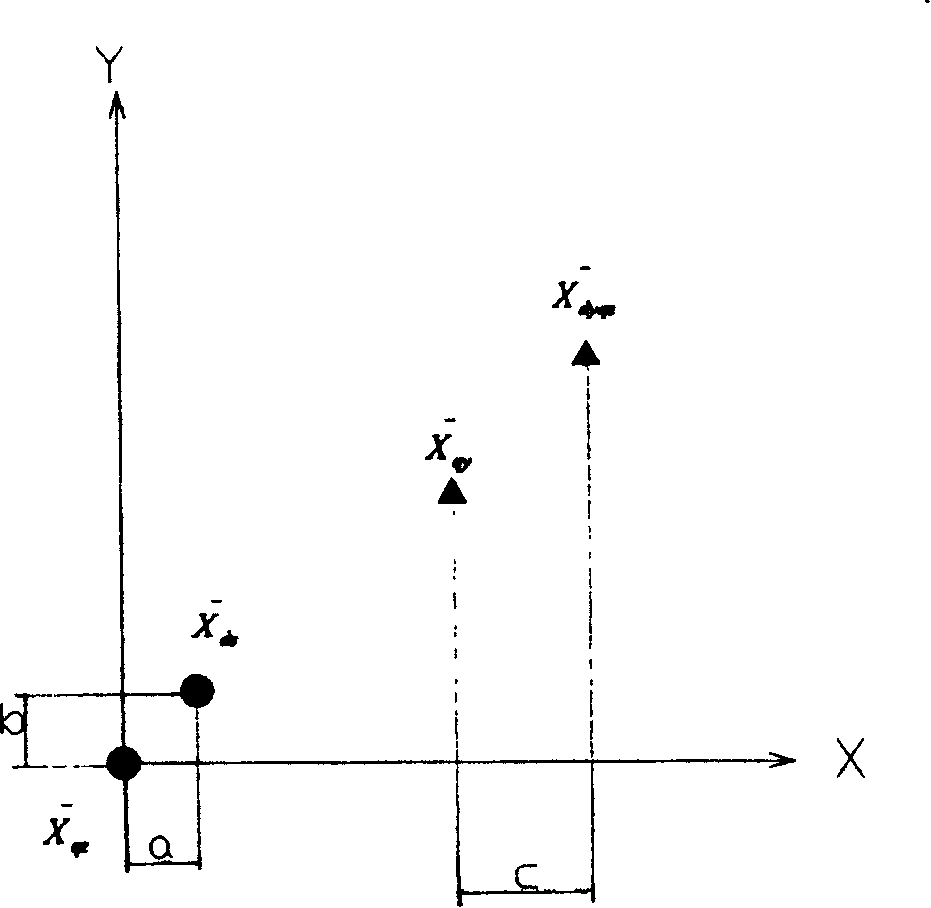

Shaft distance calibration method and system for robot chassis

The invention discloses a wheelbase calibration method and system for a robot chassis. The wheelbase calibration method comprises the following steps that a left wheel and a right wheel are driven to rotate, so that a robot rotates circumferentially; the first angle detection device obtains the rotation angle of the robot and records the rotation angle as a first rotation angle, and the second angle detection device obtains the rotation angle of the robot and records the rotation angle as a second rotation angle; correcting the first rotation angle and the second rotation angle to obtain a fusion rotation angle; the speedometer obtains the rotation angle of the robot and records the rotation angle as a third rotation angle; and an initial chassis axle distance of the robot is obtained, and a calibrated chassis axle distance is obtained according to the third rotation angle, the fused rotation angle and the initial chassis axle distance. According to the technical scheme, the speed of calibrating the chassis wheelbase is far higher than that of manual wheelbase calibration, the problem of complexity of manual wheelbase calibration can be effectively solved, and labor productivity is liberated.

Owner:福建汉特云智能科技有限公司

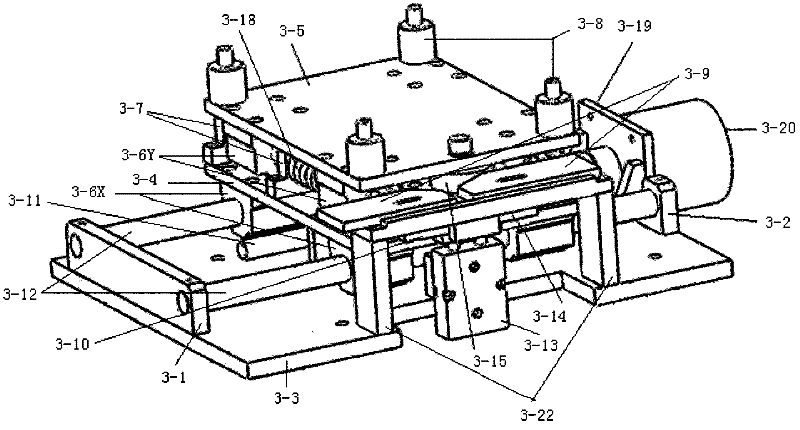

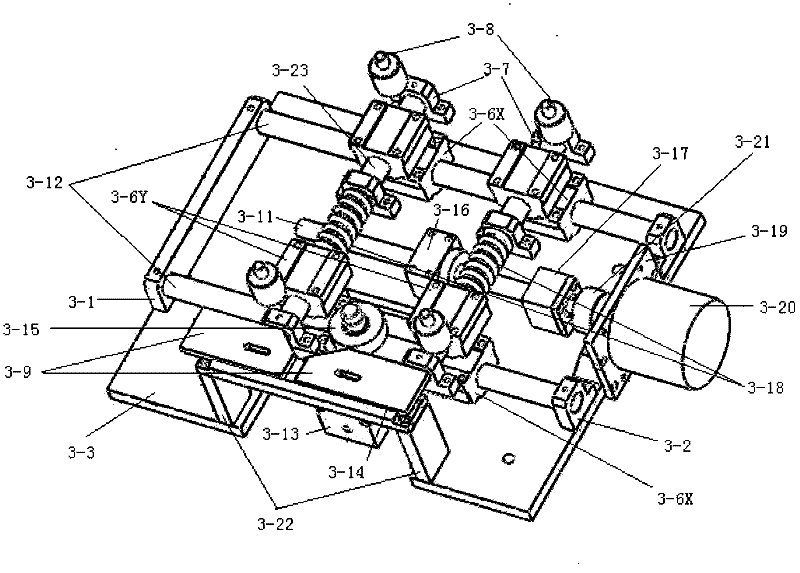

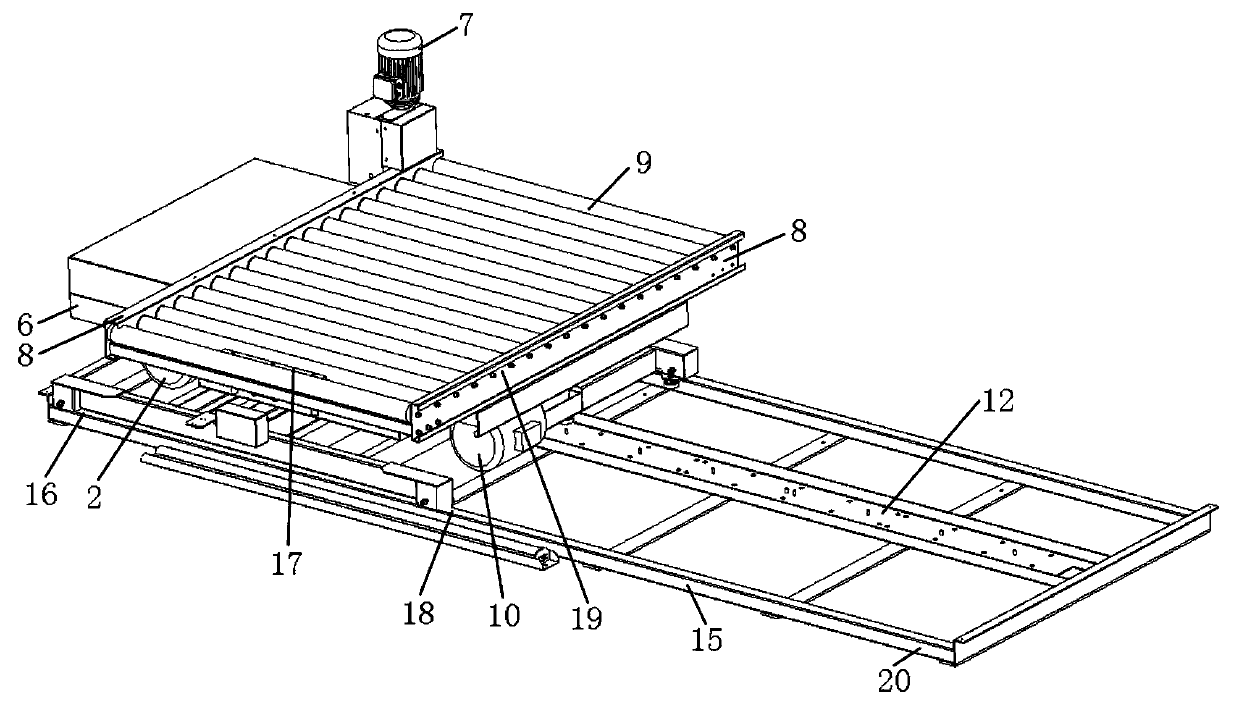

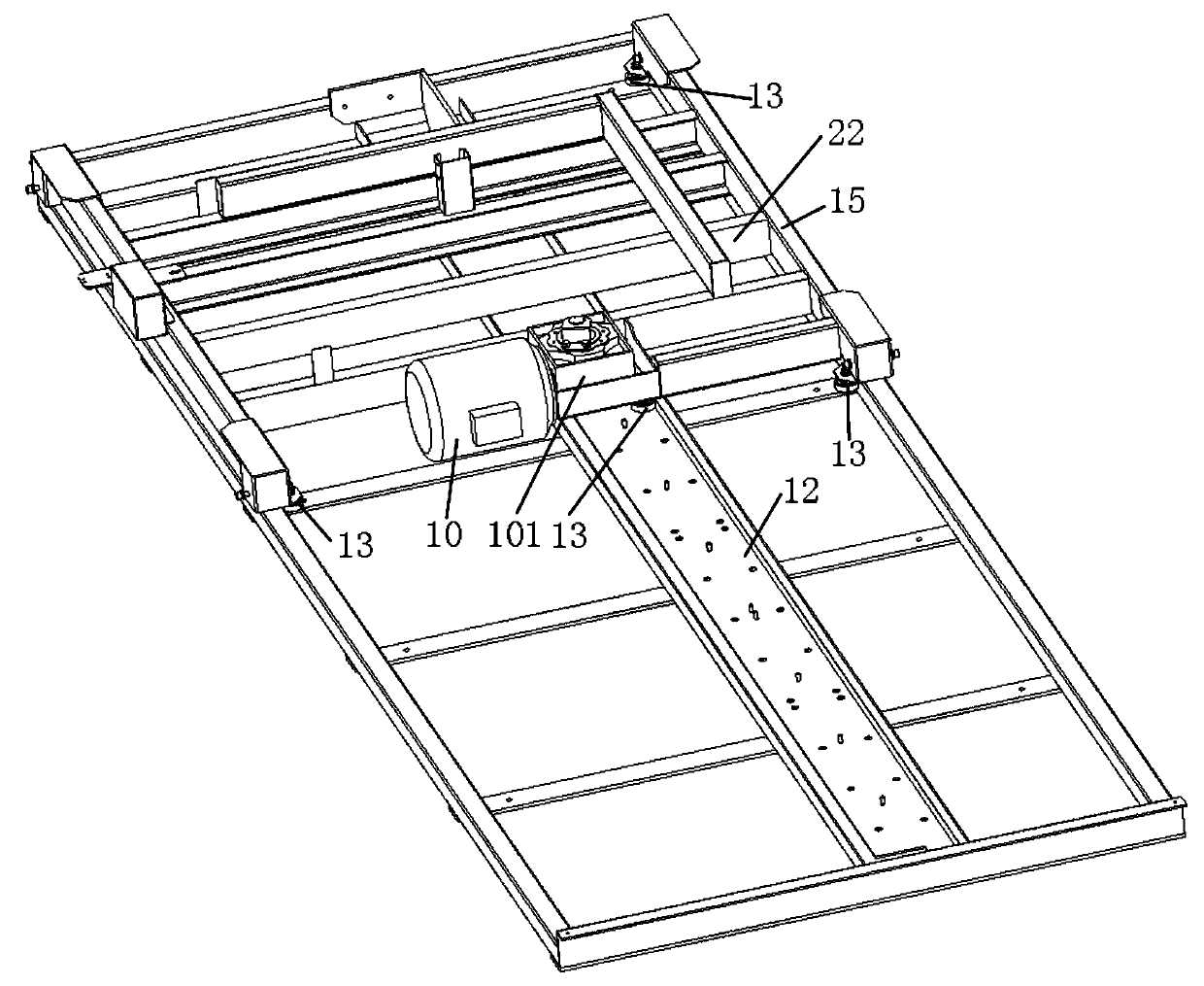

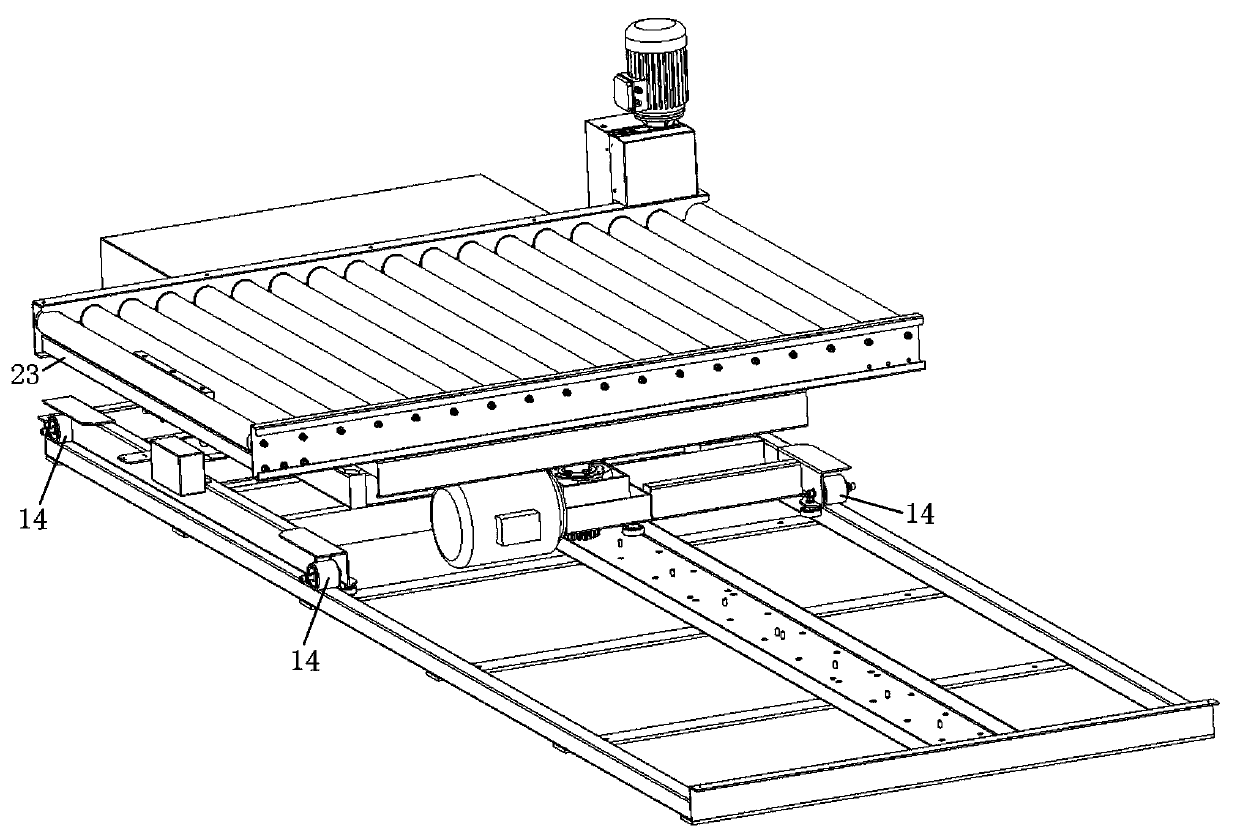

Horizontal rotating and transplanting mechanism

InactiveCN110606238AFast, precise and efficientLiberate labor productivityPackaging automatic controlBundling machine detailsEngineeringMoving parts

The invention discloses a horizontal rotating and transplanting mechanism. The mechanism comprises a first conveying device for conveying products in a first linear direction, a rotating device for rotating the products on a plane, and a second conveying device for conveying the products in a second linear direction; the first conveying device is mounted on a rotating part of the rotating device;the rotating device is mounted on a moving part of the second conveying device; and the first linear direction is perpendicular to the second linear direction. The horizontal rotating and transplanting mechanism can repeat packing actions by multiple times; and in particle, for high-mass products, the horizontal rotating and transplanting mechanism can be matched with a standard tape punch for useto quickly, precisely and effectively finish the rotating and transplanting work, so that the labor productivity is liberated, and the work is finished with low cost and high efficiency.

Owner:中电九天智能科技有限公司

Positioning device and fruit-picking device

The invention provides a positioning device and fruit-picking device, pertaining to the technical field of fruit picking. The positioning device comprises a first support rod, a second support rod, alead screw, a first driving motor, a first sliding block, a second sliding block, a first driving rod and a second driving rod. One end of the first support rod is equipped with a first rotary part. One end of the second support rod is equipped with a second rotary part. The first rotary part can be rotatably connected to the second rotary part. The lead screw is rotatably connected to the first support rod. The length and direction of the lead screw are the same as those of the first support rod. The first driving motor is connected with the first support rod and used for driving the lead screw. The first sliding block is provided with an internal screw thread matching the lead screw. The positioning device is size-adjustable. The positioning device greatly facilitates a user and is simple to operate. Meanwhile, the picking efficiency is increased. The structure is reasonably designed and highly pratical. The fruit picking device comprises the positioning device and has all functionsof the positioning device.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Robot chassis axle distance calibration method and system

ActiveCN113970310AImprove stabilityHigh speedMeasurement devicesElectric energy managementControl theoryWheelbase

The invention discloses a robot chassis wheelbase calibration method and system. The calibration method comprises the following steps that a left wheel or a right wheel is driven to rotate so as to drive a robot to rotate; the moving distance of the left wheel or the right wheel is obtained, and the rotating angle of the robot is obtained; and according to the moving distance of the left wheel or the right wheel and the rotating angle of the robot, the calibrated chassis wheelbase is calculated. According to the technical scheme, the robot can obtain the calibrated chassis wheelbase of the robot according to the moving distances of the left wheel and the right wheel and the rotating angle of the robot, and the inaccurate wheelbase of the robot is replaced, so that the accurate wheelbase is obtained in real time, and the advancing stability of the robot is improved. Moreover, the speed of calibrating the chassis wheelbase is far higher than the speed of manual wheelbase calibration, the complexity of manual wheelbase calibration can be effectively solved, and the labor productivity is liberated.

Owner:福建汉特云智能科技有限公司

Method of automatically distinguishing band steel running aside in continuous annealing furnace

ActiveCN100398675CLess investmentThe alarm information is accurateImage analysisUsing electrical meansMonitoring systemStrip steel

Owner:BAOSHAN IRON & STEEL CO LTD +1

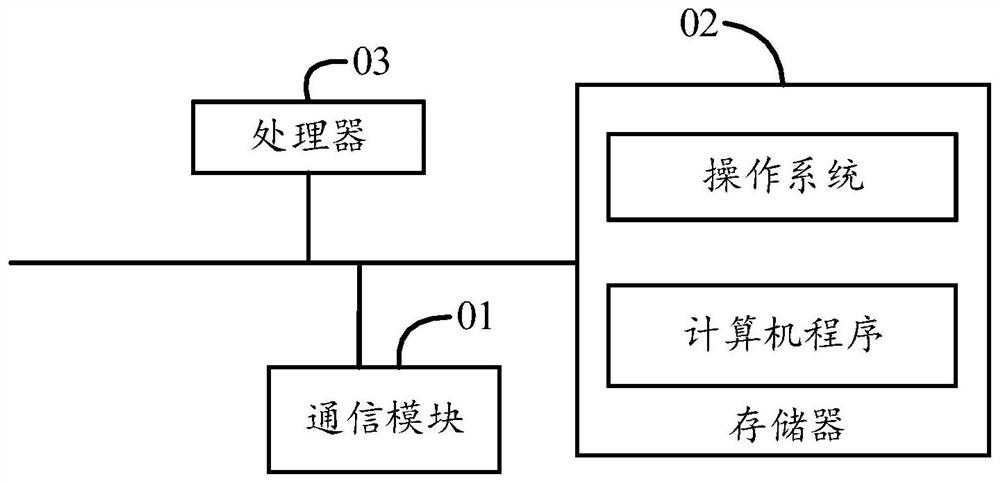

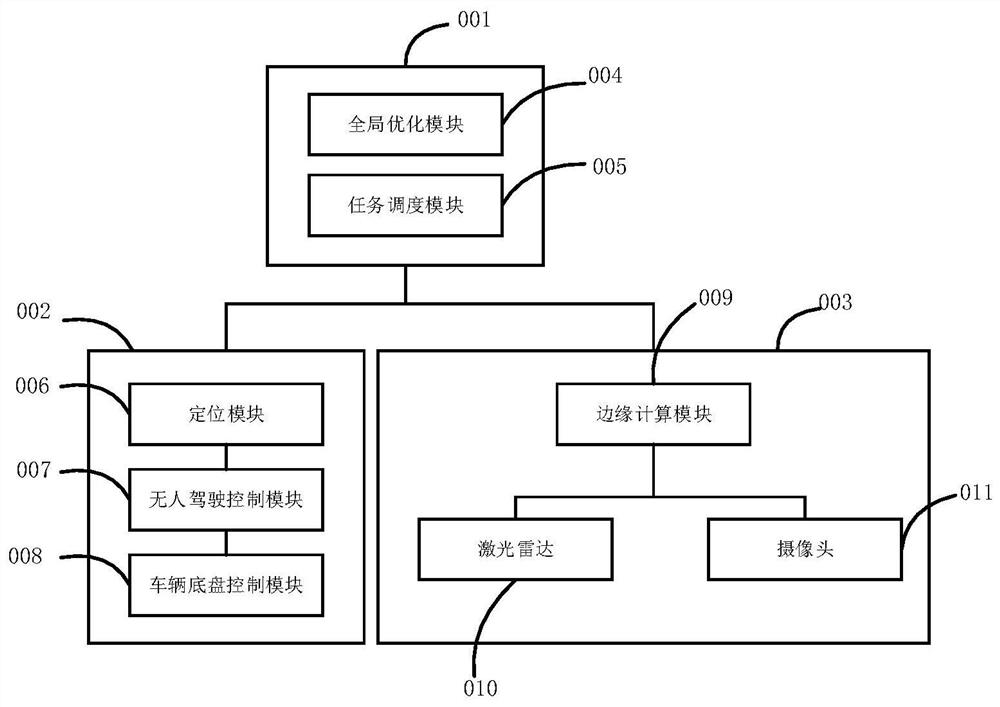

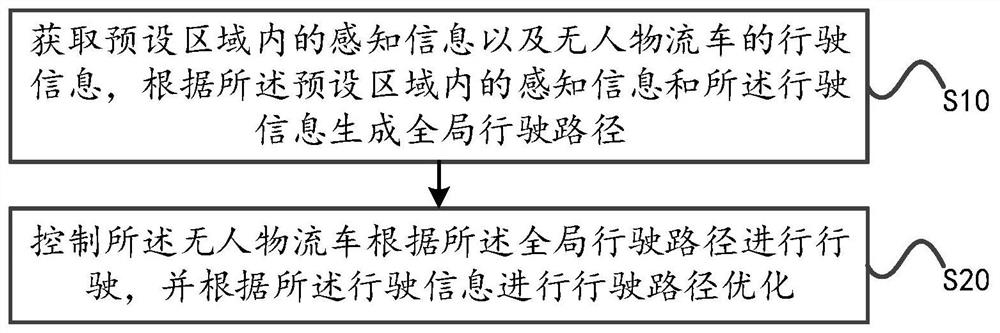

Vehicle control system, vehicle control method, vehicle control apparatus, and storage medium

InactiveCN113851003AExpand the scope of information accessReduce manufacturing costDetection of traffic movementLogisticsLogistics managementControl system

The invention discloses a vehicle control system, a vehicle control method, vehicle control equipment and a storage medium. The vehicle control system comprises roadside sensing equipment, an unmanned logistics vehicle and a cloud control platform, wherein the roadside sensing equipment and the unmanned logistics vehicle are in mutual communication connection, and the cloud control platform is in communication connection with the unmanned logistics vehicle and the roadside sensing equipment; the roadside sensing equipment is arranged on a roadside and comprises a laser radar, a camera and an edge calculation unit which is in communication connection with the laser radar and the camera; the unmanned logistics vehicle comprises a positioning module, an unmanned driving control module and a vehicle chassis control module which are connected in sequence; and the cloud control platform comprises a global optimization module and a task scheduling module which are connected with each other. According to the invention, the use experience of unmanned logistics is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

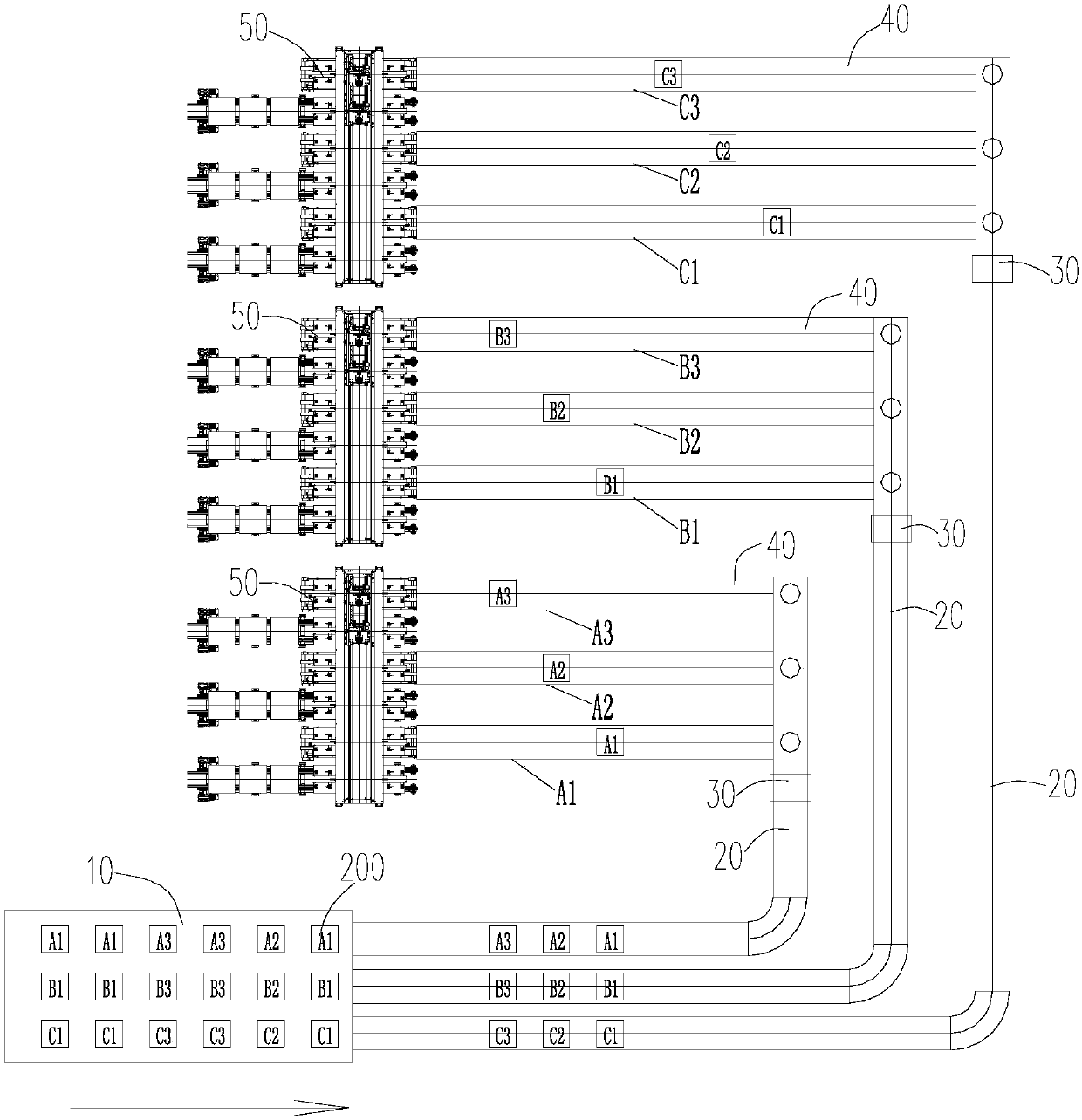

Environment-friendly automatic classification production method for ceramic tile

ActiveCN109650016AReduce pollutionReduce energy consumptionConveyor partsEnvironmental resistanceBrick

The invention discloses an environment-friendly automatic classification production method for ceramic tiles. The method comprises the following steps of discharging bricks out of a kiln and conveyingthe bricks, identification and flow dividing and stacking, wherein the plurality of conveying lines are arranged at tile outlets of the kiln and are parallel to the tile outlet direction of the kiln,each conveying line corresponds to a green tile of one kiln position, and the function of dividing the kiln positions is achieved; identification and flow dividing is provided, the types of green tiles are recognized through a recognition system, the green tiles on each conveying line are divided to different flow dividing conveying lines according to the recognition result; and stacking is provided, each flow dividing conveying line corresponds to a different tile sorting machine, the tile sorting machine is used for stacking green tiles on the flow dividing conveying line on a support or aconveying chain, each conveying line corresponds to a green tile with a serial number or a pattern, the function of dividing the number or the pattern is achieved, and the procedure of dividing the number in the rear section in a traditional process is avoided. The green tiles are automatically recognized in the flow dividing step, classified storage is carried out, the labor productivity is liberated, the production efficiency and accuracy are improved, dust pollution and energy consumption are reduced, and environment protection is facilitated.

Owner:GUANGDONG EDING IND

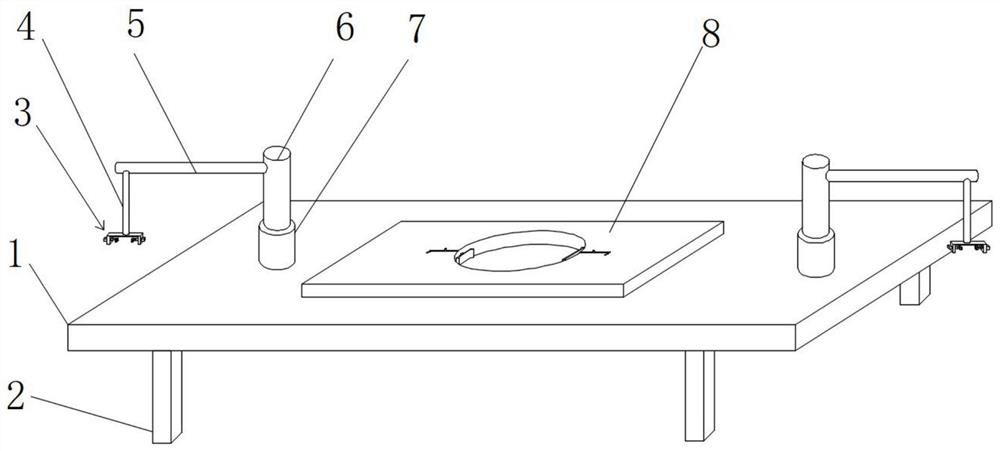

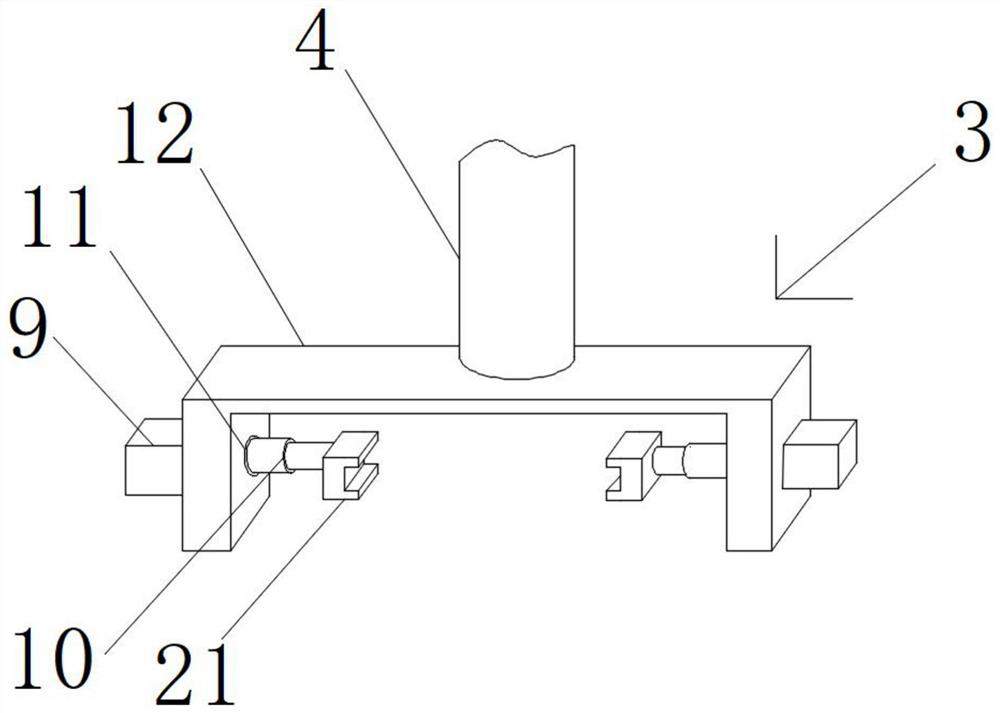

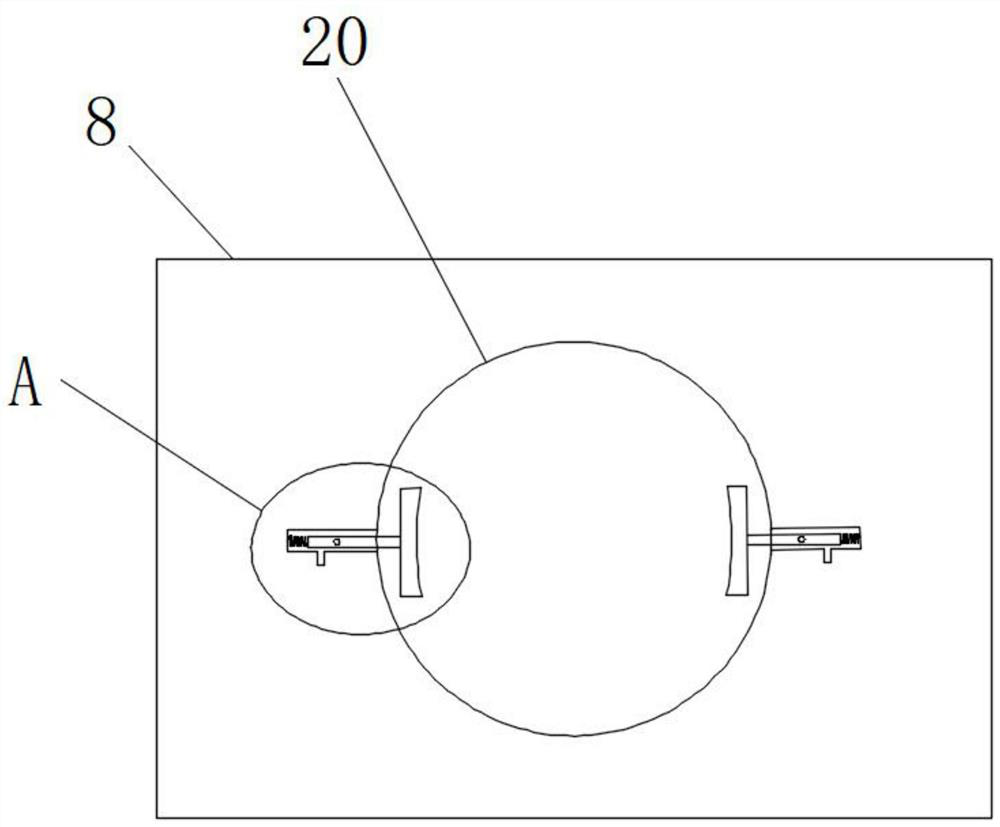

Automatic positioning and assembling equipment for telephone receiver production

InactiveCN111702700AReduce workloadLiberate labor productivityElectrical transducersMetal-working hand toolsHydraulic cylinderElectric machinery

The invention discloses automatic positioning and assembling equipment for telephone receiver production. The equipment comprises a workbench, wherein supporting legs are installed at the corners of the bottom end of the workbench correspondingly, motors are arranged on the two sides of the bottom end of the workbench correspondingly, transmission columns are fixedly connected to the upper ends ofthe motors correspondingly, and the in-between positions of the motors and the transmission columns are sleeved with limiting columns correspondingly. According to the automatic positioning and assembling equipment for telephone receiver production, the motors are arranged on the two sides of the bottom end of the workbench and can drive the transmission columns to rotate left and right, so thatconnecting columns are driven to rotate left and right, then clamping mechanisms at the bottom ends of supporting columns are driven to rotate, the two ends of U-shaped plates of the clamping mechanisms are provided with hydraulic cylinders correspondingly, telescopic rods connected with the hydraulic cylinders can stretch out and draw back left and right, clamps on the two sides are driven to move towards the middle, then a part is placed on a mounting plate through cooperation of the transmission columns and the clamping mechanisms, the working amount of workers is reduced, the labor productivity is liberated, and then the production cost is saved.

Owner:嘉兴则盈电子科技有限公司

A kind of technique for continuous production of tetrasodium glutamic acid diacetate

ActiveCN105732408BHigh yieldHigh purityOrganic compound preparationAmino-carboxyl compound preparationFiltrationFORMALDEHYDE SOLUTION

The invention provides a process for producing tetrasodium glutamate diacetate through a continuous method.Production is conducted through a continuous reactor.The process includes the following steps that A, a sodium glutamate saline solution, a sodium cyanide solution and a formaldehyde solution are used as raw materials and fed into a first reaction kettle to react through a heat exchange system according to the flow speed, and generated ammonia gas is collected at the same time; B, feed liquid generated after reaction in the first reaction kettle is discharged from the bottom of the kettle and directly enters a second reaction kettle to continue to react, and ammonia gas generated in the second reaction kettle is collected at the same time; C, feed liquid reacting in the second reaction kettle is discharged from the bottom of the kettle and enters a storage tank to be subjected to decoloration, filtration and concentration regulation so that a tetrasodium glutamate diacetate solution can be obtained.By means of the process, tetrasodium glutamate diacetate can be continuously produced, the quality of the obtained product is good, the production stability is good, control is easy, and by-products generated by kettle type reaction can be avoided.

Owner:HEBEI CHENGXIN

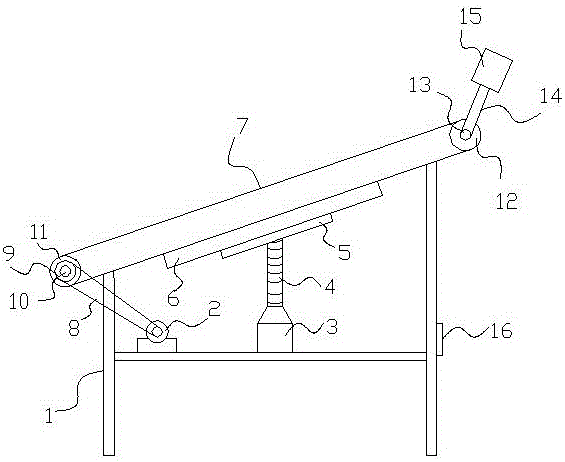

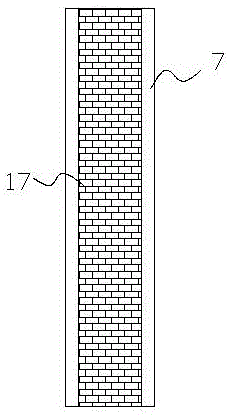

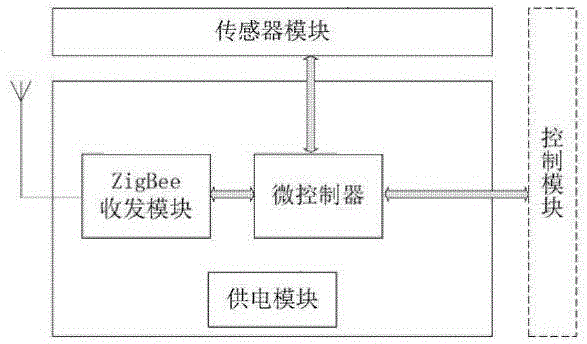

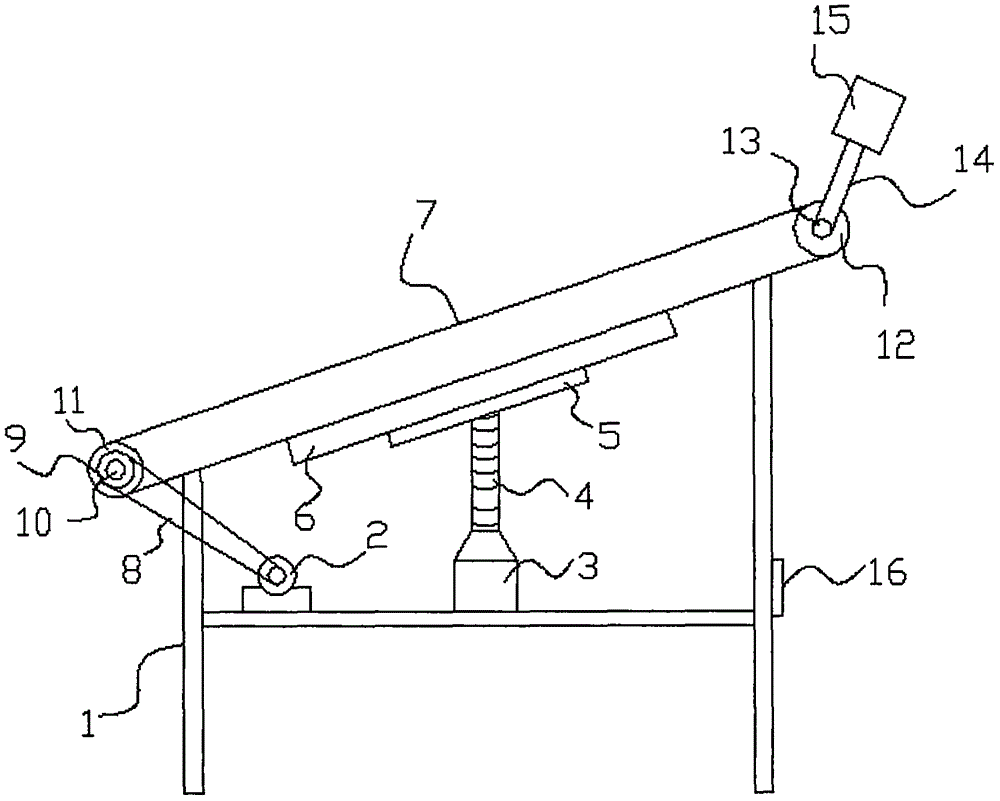

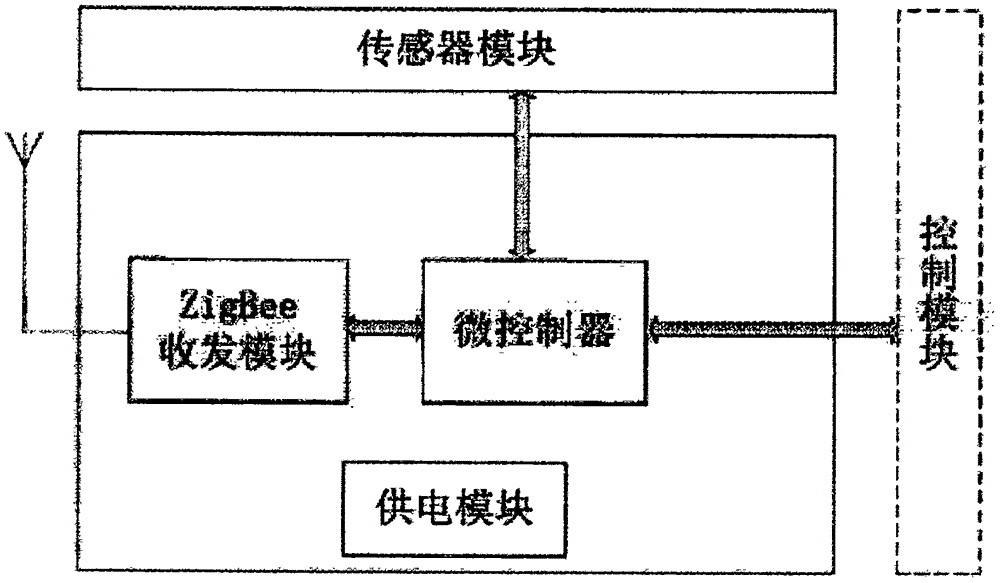

Sweet potato pulverizer conveying device based on Zigbee technology

InactiveCN106185173AFast deliveryReal-time monitoring of delivery conditionsConveyorsControl devices for conveyorsDrive shaftEngineering

The invention discloses a sweet potato pulverizer conveying device based on the Zigbee technology. The sweet potato pulverizer conveying device comprises a base which is internally provided with a conveying motor and a lifting motor; the top end of the lifting motor is provided with a lifting rod; the top end of the lifting rod is provided with a fixing plate; the top end of the fixing plate is provided with a friction rubber block; the top of the friction rubber block is provided with a conveying belt; the conveying motor is connected with a belt wheel through a belt; the belt wheel is arranged at one end of a conveying driving shaft; a conveying driving roller is connected to the conveying driving shaft in a sleeving mode and connected with a conveying driven roller through the conveying belt; the conveying driven roller is connected to a conveying driven shaft in a sleeving mode; and a bracket is arranged on the conveying driven shaft and provided with an electric charge replenisher. According to the sweet potato pulverizer conveying device based on the Zigbee technology, sweet potatoes can be quickly conveyed by arranging the friction rubber block and fur and are prevented from being thrown out of the conveying device; the labor productivity is liberated; the production efficiency is improved; and the whole device is simple in structure and suitable for sweet potato manufacturers.

Owner:LIUZHOU SHOUGUANG TECH

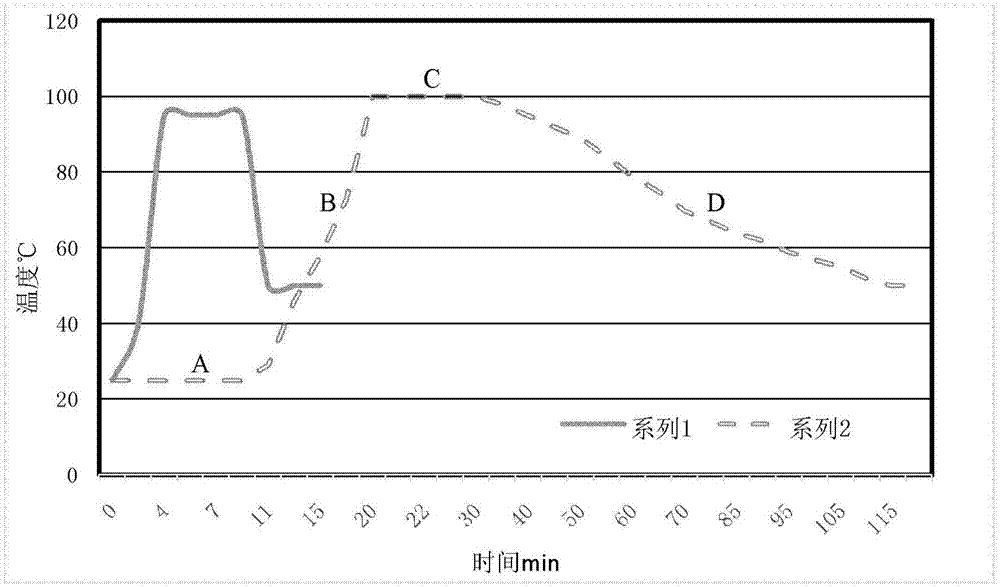

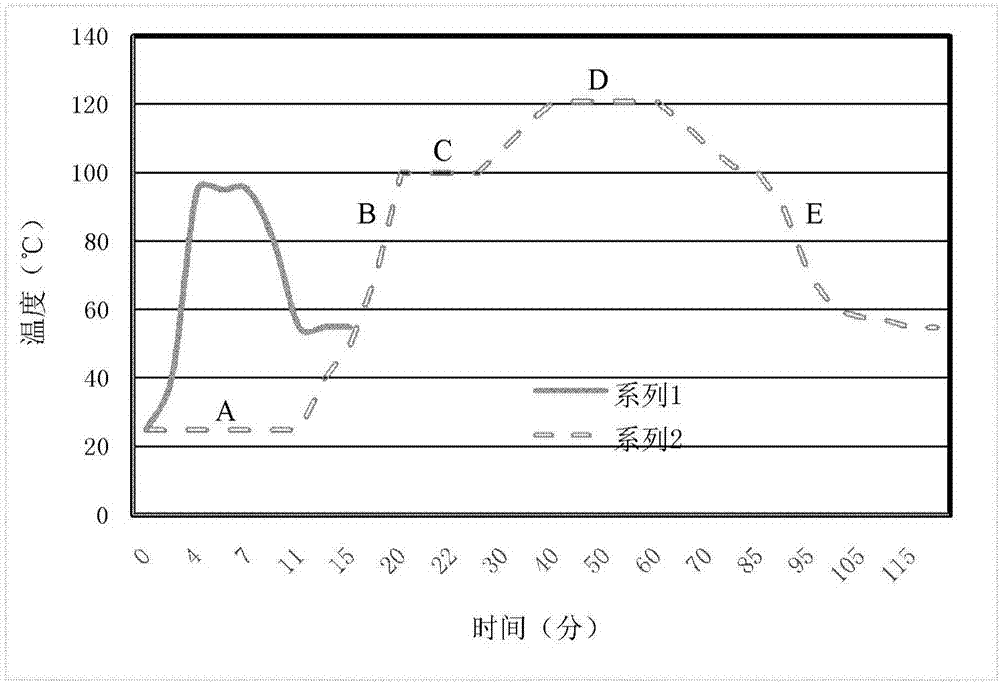

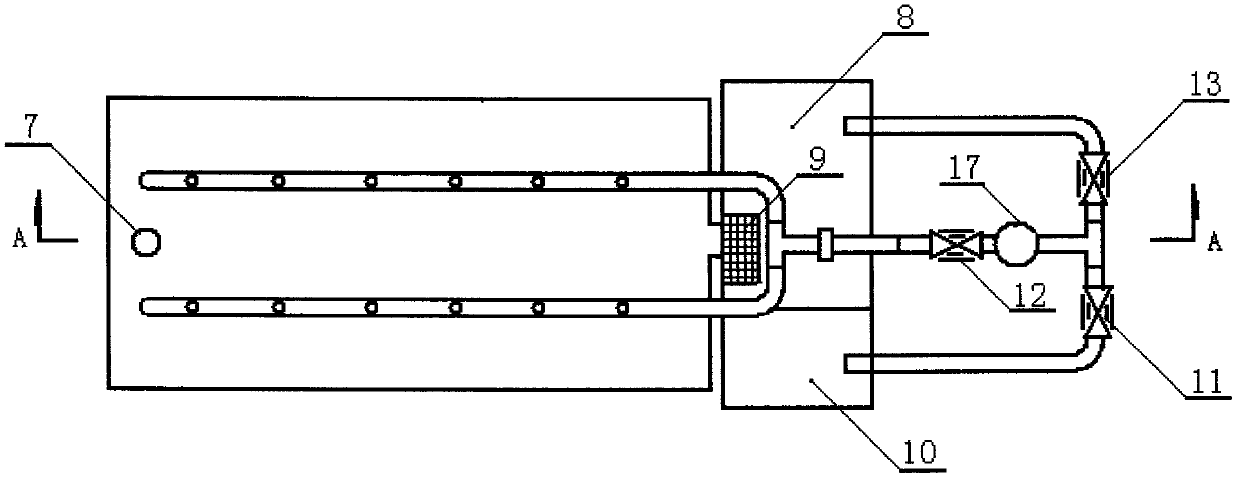

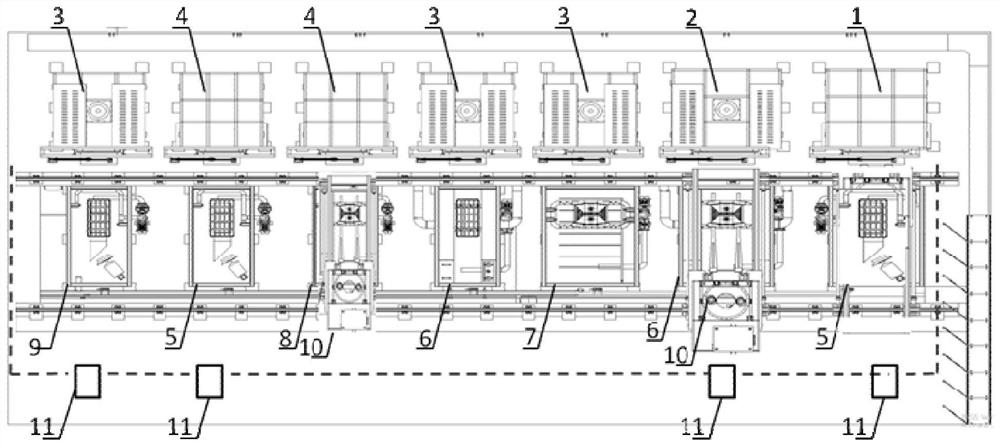

Large flexible heat treatment automatic production line with protective atmosphere and production method

PendingCN114045383AImprove quality consistencyFully automatedFurnace typesHeat treatment process controlTemperingClean water

The invention provides a large flexible heat treatment automatic production line with protective atmosphere and a process thereof. The heat treatment automatic production line can use a computer integrated control management system to realize automatic loading and unloading of a material taking vehicle, automatic execution of heat treatment process parameters, online monitoring and real-time regulation and control. The heat treatment automatic production line comprises: a set of high-temperature quenching heating unit, which is composed of three high-temperature quenching heating furnaces; a tempering heating unit which is composed of four tempering heating furnaces, wherein the heat treatment furnaces are sequentially arranged from right to left as follows: a large high-temperature quenching heating furnace, a large tempering heating furnace, a small tempering heating furnace, a small tempering heating furnace, a small high-temperature quenching heating furnace, a small high-temperature quenching heating furnace and a small tempering heating furnace; and a set of matched high-precision cooling unit which is composed of cooling tanks with different specifications, wherein the cooling tanks are sequentially a clear water tank, an oil tank, a cleaning tank, an oil tank, a saline water tank, a clear water tank and an organic solvent tank from right to left.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Concrete vibrator conveying device based on ZigBee technology

InactiveCN106335741AFast deliveryReal-time monitoring of delivery conditionsConveyorsControl devices for conveyorsDrive shaftEngineering

The invention discloses a concrete vibrator conveying device based on the ZigBee technology. The concrete vibrator conveying device comprises a base; a conveying motor and a lifting motor are arranged inside the base; a lifting rod is arranged at the top end of the lifting motor; a fixed plate is arranged at the top end of the lifting rod; a friction rubber block is arranged at the top end of the fixed plate; a conveyor belt is arranged on the top of the friction rubber block; the conveying motor is connected with a belt wheel through a belt; the belt wheel is arranged at one end of a conveying drive shaft; a conveying drive roller is arranged on the conveying drive shaft in a sleeved mode; the conveying drive roller is connected with a conveying driven roller through the conveyor belt; the conveying driven roller is arranged on the conveying driven shaft in the sleeved mode; a bracket is arranged on the conveying driven shaft; and an electric charge complementer is arranged on the bracket. According to the concrete vibrator conveying device disclosed by the invention, the friction rubber block and furs are arranged, so that concrete can be quickly conveyed, materials are prevented from being thrown out of the conveying device, labor power is liberated and production efficiency is improved; and the whole device is relatively simple in structure, and is relatively suitable for manufacturers which easily produce concrete.

Owner:WUXI CHUANGNENG POWER TECH CO LTD

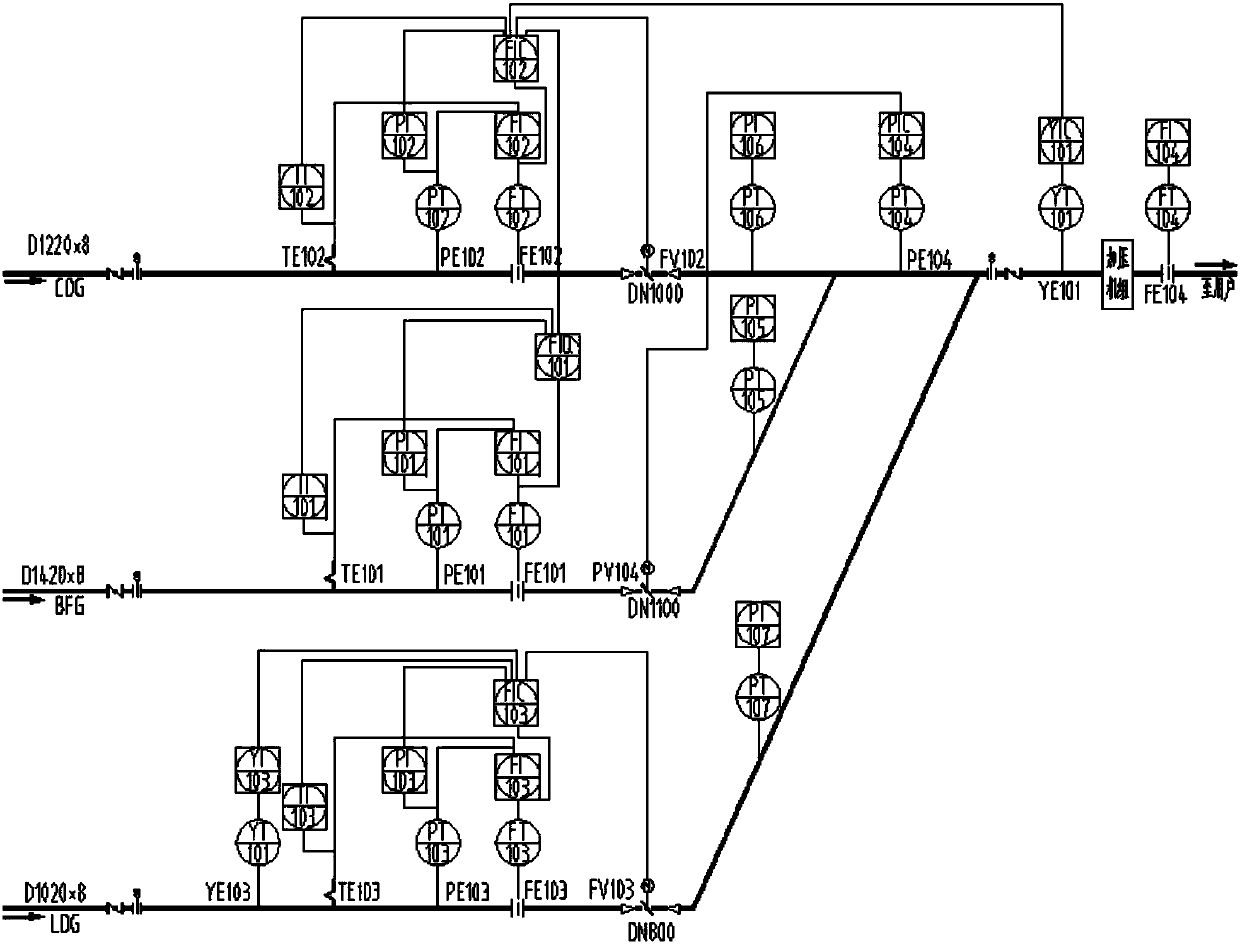

Blast furnace gas, coke oven gas and converter gas mixing control method and system

ActiveCN105955373BStable supplyHigh degree of automationSimultaneous control of multiple variablesCombustionControl system

Owner:MCC HUATIAN NANJING AUTOMATION ENG

Edible mushroom culturing method

InactiveCN102550284BNot easy to inactivateInoculum size can be adjustedHorticultureFertilizer mixturesBiotechnologyEdible mushroom

The invention discloses an edible mushroom culturing method which comprises the following steps: inoculating edible mushroom strains to a solid medium and culturing for 25-40 days at the temperature of 20-26 DEG C, thus obtaining solid strains; adding a stabilizing agent into water or a PDA Potato Dextrose Agar fluid nutrient medium and mixing, thus obtaining a liquefying agent; adding the solid strains into the liquefying agent, stirring, filtering and taking filtrate, thus obtaining liquid strains; and inoculating the liquid strains into the production culture medium for production and cultivation, thus obtaining the edible mushroom. During the edible mushroom culturing process, the liquefying agent is utilized for liquefying the solid strains which are then inoculated for production and cultivation, the edible mushroom is produced for use, the operation is simple and convenient, the labor intensity can be lightened, the strain quantity can be well controlled, and standardized production is benefited; the product quality of scattered growers is stable, and regional scaled production can be formed; and simultaneously pollution can be effectively controlled, labor and material wastes can be reduced, and the product benefit and the product quality can be improved.

Owner:ZHEJIANG UNIV

An exoskeleton wolfberry picking mechanism

ActiveCN108161897BMeet supply problemsLiberate labor productivityProgramme-controlled manipulatorPicking devicesAgricultural scienceAgricultural engineering

The invention relates to an exoskeleton wolfberry picking mechanism and belongs to the technical field of agricultural machinery. The exoskeleton wolfberry picking mechanism comprises a shearing mechanism, a forearm manipulator mechanism, an upper arm manipulator mechanism, a middle connecting part and a fruit collecting part, wherein the shearing mechanism is used for picking wolfberry fresh fruit; the forearm manipulator mechanism is used for carrying out picking work in cooperation with the fore arm of a worker; the upper arm manipulator mechanism is used for carrying out picking work in cooperation with the upper arm of the worker; the middle connecting part is used for connecting the upper arm manipulator mechanism and the fruit collecting part and used for fitting the movement of a shoulder joint in the working process of the worker; and the fruit collecting part is used for collecting the fresh fruit picked by an exoskeleton picking mechanical arm part. The wolfberry fresh fruitmanipulator picking mechanism related to the invention has great significance in increasing the wolfberry picking efficiency, reducing manual picking operation intensity, reducing economical cost inthe picking process and increasing the labor productivity.

Owner:KUNMING UNIV OF SCI & TECH

A lifting and transporting device of an electric motor rotor

InactiveCN109217582AAvoid bruisesEnsure personal safetyManufacturing stator/rotor bodiesLoad-engaging elementsHigh risk factorsEngineering

The invention relates to a hoisting and transporting device of an electric motor rotor, which relates to a device for hoisting and transporting the electric motor rotor during assembly. It mainly solves the problem that the laminated rotor needs to be press-fitted and dynamically balanced in the assembly process. At present, these processes are carried out by two people working together to lift the rotor to the target position and press-fit or dynamically balance the rotor. High labor intensity, low working efficiency and high risk factor are solved. The lifting device of the invention is thata lifting ring is arranged on the sealing end of a circular steel pipe with one end sealed and one end opened, and a round nut is fixed in one end of the circular steel pipe opening. Two round nuts are screwed on the matching thread of the rotor rotating shaft, the lifting ring is hung on the lifting hook of the sling, and the motor rotor can be lifted and transported through the sling. The invention can be operated by only one person, has high working efficiency, low labor intensity, safety and reliability, and ensures that the rotor is not damaged in the handling process.

Owner:襄阳中车电机技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com