A lifting and transporting device of an electric motor rotor

A technology for handling devices and motor rotors, which is used in transportation and packaging, manufacturing stator/rotor bodies, load hanging components, etc., can solve the problems of high labor intensity, easy to bruise the rotor, and high risk factors, and achieve the liberation of labor productivity, The effect of avoiding the risk of falling and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

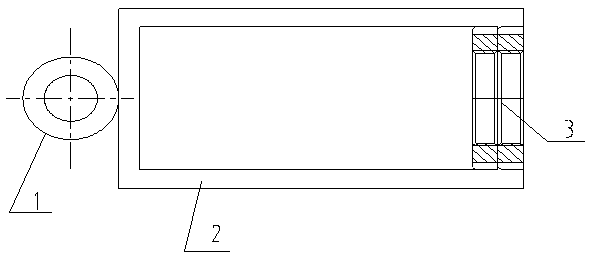

[0008] Such as figure 1 As shown, the motor rotor lifting and handling device of the present invention includes a round steel pipe 2 with one end sealed and one end open, and one end of the round steel pipe 2 sealed is provided with a lifting ring 1, and the size of the lifting ring 1 matches the size of the hanger hook; One end of the opening of the steel pipe 2 is fixed with a round nut 3, and there are two round nuts 3 (to ensure that there is enough contact surface when mating with the rotating shaft, and the firmness of the device can also be improved), and the size of the inner thread of the round nut 3 is the same as The size of the screw thread on the motor rotor shaft to be lifted matches; the length of the round steel pipe 2 is, when the rotor shaft to be lifted is connected to the round steel pipe 2 of the present invention, the shaft end of the rotor to be lifted that is located in the round steel pipe 2 and the round steel pipe There is a certain gap between 2; wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com