Automatic silk stocking toe sewing machine and use method thereof

A technology for sewing head machine and stockings, which is applied to sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of narrow application surface, pulling out holes, and missing needles, etc., to improve work efficiency, uniform force, and guarantee quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

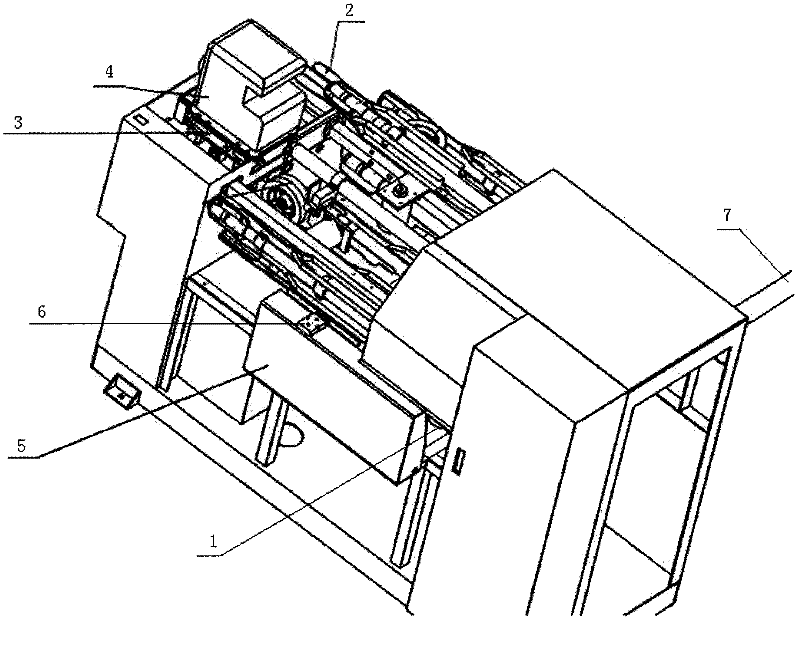

[0025] The automatic silk stockings sewing machine of the present invention is mainly made up of five parts: the sock inlet part, the host part, the machine head part, the crotch cutting part and the sock outlet part, such as figure 1 As shown, ten hollow movable sock boards are evenly distributed on the main machine, and each hollow movable sock board is sequentially pressed into the sock→machine head sewing→cut the crotch→out the sock→in the sock...progressive work, automatic stocking cut crotch The head sewing machine is equipped with an independent small fan. Since the ten moving sock boards in the oval shape of the main machine are hollow, the suction port of the fan automatically stops at these two stations. The tail end of the hollow movable sock plate on the station is connected so that the socks are sucked into the hollow tube of the movable sock plate. Every time the main engine stops normally, it is a station. The tail of the movable sock plate is connected with the...

Embodiment 2

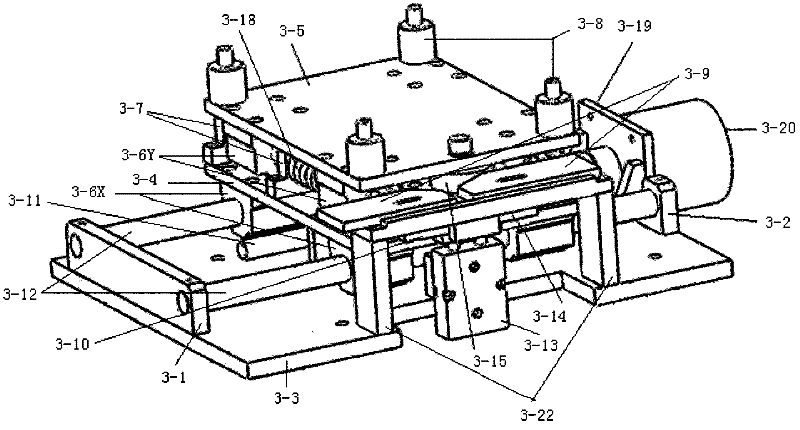

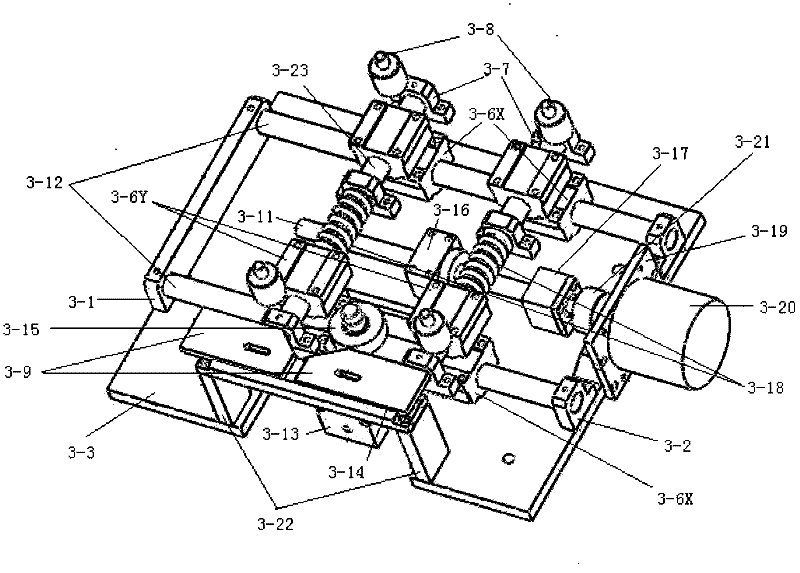

[0027] The present embodiment is the working process of the machine head support 3 of the present invention driving the machine head 2, such as figure 2 , image 3 shown, where image 3 Connecting plate 3-4 not shown: according to the width of the sock toe to be sewn, pre-adjust the length of the lower side of the isosceles trapezoid formed between the two movable guide rails 3-9, such as when sewing adult socks, the lower side It can be adjusted within the range of 80-105mm, 70-80mm when sewing children's socks, and 105-120mm when sewing European-style oversized socks; after adjustment, the operator only needs to place the The tubular stockings that have been knitted on the hosiery machine are placed one by one on the automatic sewing head cutting system and evenly distributed on the ten movable sock boards 2 connected to the main machine 1. It is out of operation, so the movable sock plate 2 is also out of operation at this time. Under this condition, the screw motor 3-20...

Embodiment 3

[0029] The present embodiment is the workflow of the crotch cutting system 5 and the sock clamping system of the present invention, as Figure 4 , Figure 5 Shown: According to the crotch length of different pantyhose, adjust the installation position of the right limit sensor in advance. For example, when producing children's stockings, adjust the installation position of the right limit sensor of scissors 5-1 to 300- 310mm; if producing adult stockings, adjust the installation position of the scissors 5-1 right limit sensor to 310-330mm from the original position of the scissors; The installation position of the limit sensor is adjusted to 330-350mm away from the original position of the scissors; when the crotch cutting scissors are in the original position and receive the work order that there are socks that need to be cut from the detection signal, the sock clamping plate 6-2 is placed on the sock clamping cylinder Under the action of 6-1, it is pushed horizontally to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com