Method for opening seamless knitted underwear

A technology of seamless knitted underwear and seamless underwear, which is applied in the field of pretreatment, dyeing and weaving to achieve the effect of generous style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material composition: 57.3% 70D / 68F elastic yarn, 40.5% 20 / 40-36F air core-spun yarn, 1.9% 140 / 70 elastic, 0.3% heat-melt yarn (model: Mobilon R-LL)

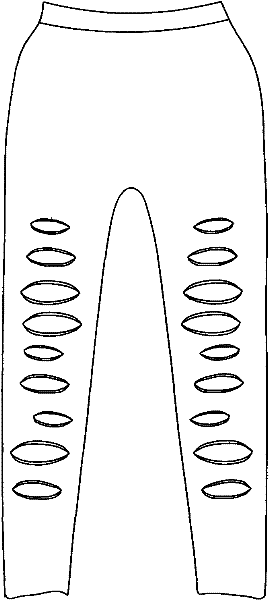

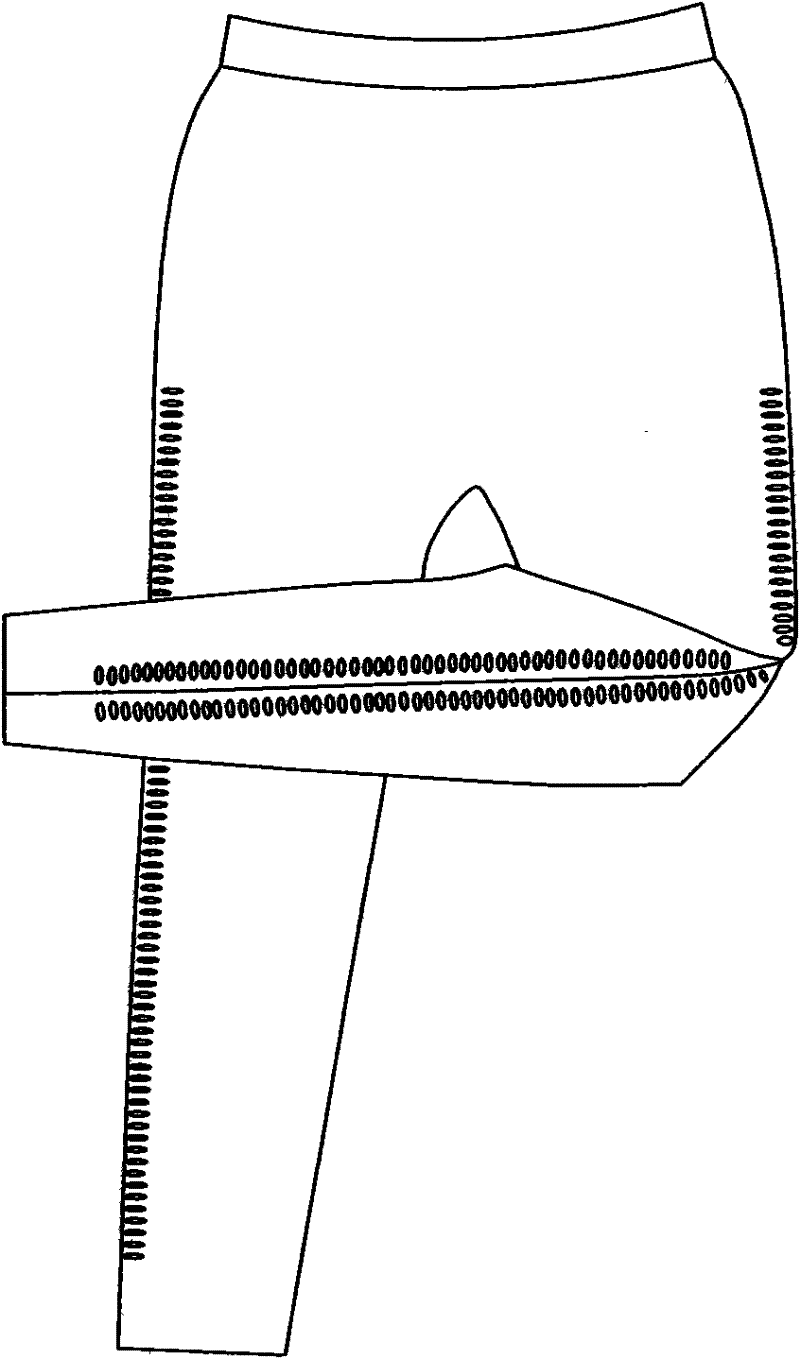

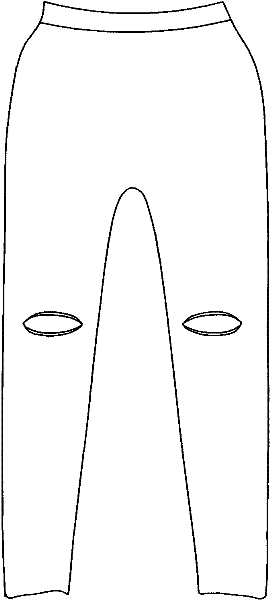

[0033] Product: Open trousers for women, with 4 holes of different sizes in front of each trouser leg

[0034] Knitting machine: fully formed seamless underwear machine made in Italy, TOP2 model

[0035] Colour: Black

[0036] Technological process: weaving, weaving, weaving, weaving, hanging, steaming, scouring and dyeing, washing, soaping, washing, color fixing, washing, softening, dehydration and drying

[0037] (1) Weaving: 8 roads of 20 / 40-36F core-spun yarn are fed from No. 2 yarn feeder, the 1st, 3rd, 5th, and 7th roads are "S" twisted core-spun yarns, and the 2nd, 4th, 6th, and 8th roads It is "Z" twisted core yarn, 70D / 68F elastic yarn is fed in 8 ways from the No. 5 yarn feeder, the 1st, 3rd, 5th and 7th way is "Z" twisted elastic yarn, and the 2nd, 4th, 6th and 8th way For "S" twisted elastic yarn, heat-...

Embodiment 2

[0048] Adopt identical weaving, different steaming and dyeing process with the same product in embodiment 1, wherein,

[0049] (1) Steaming: heat up to 85°C at 1°C / min, vacuumize to 200bar, keep warm for 10 minutes, then heat up to 95°C at 1°C / min, then vacuumize to 300bar, keep warm for 10 minutes, and then exhaust the steam.

[0050] (2) Dyeing formula:

[0051] Degreaser FT-128 1g / L

[0052] Scouring agent L-271 0.5g / L

[0053] Ellinier A-MR Black 3.5%

[0054] Glacial acetic acid 1g / L

[0055] Leveling agent 0.5g / L

[0056] Steps:

[0057] Put the product into the dye vat → heat up to 75°C, add degreasing agent and scouring agent for refining and degreasing → add glacial acetic acid, leveling agent and Ellinier A-MR black, adjust the pH value to 7, turn for 5 minutes → set at 1.5°C / min Raise the temperature to 90°C and keep it for 65 minutes, then cool down to 60°C and drain → hot water washing → 80°C soaping → water washing → 80°C color fixation → water washing → add...

Embodiment 3

[0059] Adopt identical weaving, different steaming and dyeing process with the same product in embodiment 1, wherein,

[0060] (1) Steaming: heat up to 85°C at 1.5°C / min, vacuumize to 200bar, hold for 8 minutes, then heat up to 100°C at 1.5°C / min, then vacuumize to 280bar, hold for 8 minutes, and then discharge the steam out of the pot.

[0061] (2) Dyeing formula:

[0062] Degreaser FT-128 1g / L

[0063] Scouring agent L-271 0.5g / L

[0064] Ellinier A-MR Black 3.5%

[0065] Glacial acetic acid 1g / L

[0066] Leveling agent 0.5g / L

[0067] Steps:

[0068] Put the product into the dye vat → raise the temperature to 90°C, add degreasing agent and scouring agent for refining and degreasing → add glacial acetic acid, leveling agent and Ellinier A-MR black, adjust the pH value to 6, turn for 5 minutes → set at 1°C / min Raise the temperature to 100°C and keep it for 55 minutes, then cool down to 60°C and drain → hot water washing → 80°C soaping → water washing → 80°C color fixat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com