Method of automatically distinguishing band steel running aside in continuous annealing furnace

A continuous annealing furnace and strip deviation technology, applied in the field of image recognition, can solve the problems of no video storage, inconvenient accident analysis, and no time to judge production accidents, so as to achieve less equipment investment, reduce video space and time, and prevent further accidents. The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

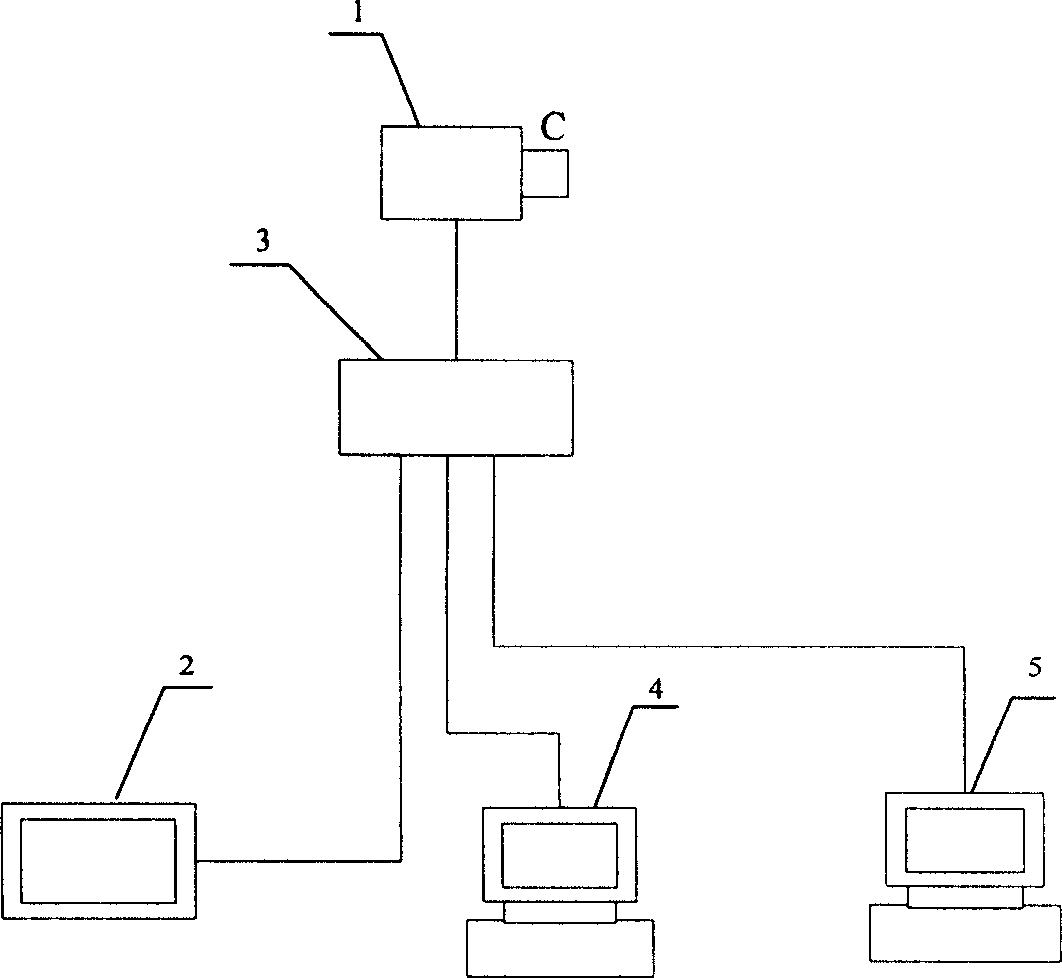

[0017] see figure 1 , The system for automatically identifying the strip deviation in the continuous annealing furnace is composed of an industrial camera 1, a monitor 2, a frequency divider 3, a first industrial computer 4, and a second industrial computer 5. The industrial camera 1 is installed in the continuous annealing furnace, and is used to record the running conditions of the steel strip in the furnace. The monitor 2, the frequency divider 3, the first industrial computer 4 and the second industrial computer 5 are all installed in the control room. The image optical signal captured by the industrial camera is sent to the control room through the signal cable, and then the signal is amplified by a frequency divider 3 with signal amplification function, and then sent to the monitor 2, the first industrial computer 4 and the second industrial computer 5 respectively. The first industrial computer 4 is equipped with an image acquisition card, which is used to convert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com