Process for producing tetrasodium glutamate diacetate through continuous method

A technology of tetrasodium glutamic acid diacetate and sodium glutamate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low production efficiency and lack of research, and achieve easy control and liberation. The effect of labor productivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

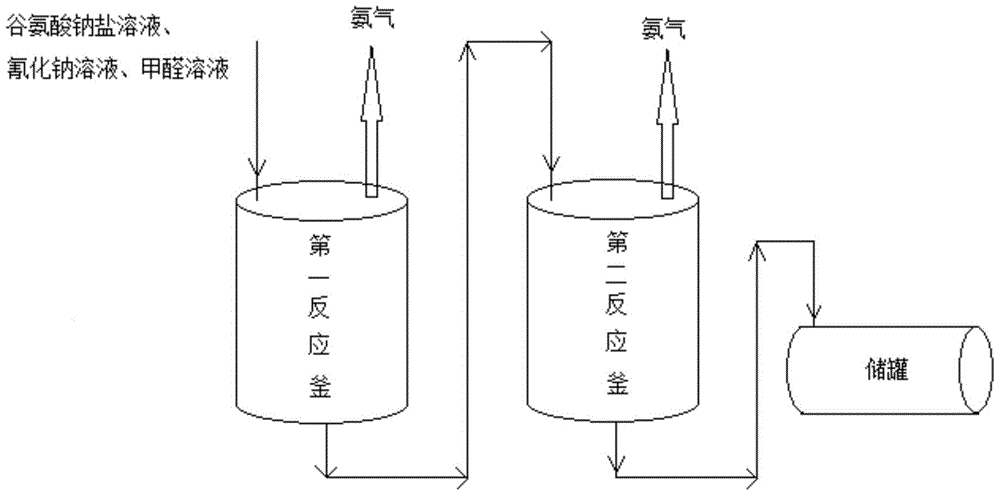

Embodiment 1

[0022] First adjust the temperature of the first reaction kettle to be controlled at 100°C. Under the action of the pump, the 30% sodium cyanide aqueous solution after the heat exchange treatment of the heat exchange system will be used at a flow rate of 327kg / h, and the 37% formaldehyde solution at a flow rate of 327kg / h. The flow velocity of 162kg / h and 40% glutamic acid sodium salt solution are fed into the first reactor at a flow velocity of 422kg / h, and under strong stirring, act rapidly, and simultaneously, the ammonia gas that hydrolysis generates from the first reactor The top of the reactor is discharged and collected, and the feed liquid stays in the first reactor for 15 minutes. After the first stage reaction is completed, the feed liquid enters the second reactor. Stay in the second reactor for 8 minutes, and at the same time, the ammonia gas generated by the further reaction is further discharged from the top of the second reactor and collected, thereby completing ...

Embodiment 2

[0024] First adjust the temperature of the first reaction kettle to be controlled at 100°C. Under the action of the pump, the 30% sodium cyanide aqueous solution after the heat exchange treatment of the heat exchange system will be used at a flow rate of 350kg / h, and the 37% formaldehyde solution at a flow rate of 350kg / h. The flow rate of 175kg / h and 40% sodium glutamate solution are fed into the first reactor at a flow rate of 422kg / h, and under strong stirring, they act rapidly. The top of the reactor is discharged from the entire system and collected. The feed liquid stays in the first reactor for 20 minutes. After the first stage reaction is completed, the feed liquid enters the second reactor. Stay in the second reactor for 10 minutes. At the same time, the ammonia gas generated by the further reaction is further discharged from the top of the second reactor, thereby completing the entire reaction. After the reaction, the feed liquid enters the storage tank for the next s...

Embodiment 3

[0026] First adjust the temperature of the first reaction kettle to be controlled at 90°C. Under the action of the pump, the 30% sodium cyanide aqueous solution after the heat exchange treatment of the heat exchange system will be used at a flow rate of 327kg / h, and the 37% formaldehyde solution at a flow rate of 327kg / h. The flow rate of 162kg / h and 40% sodium glutamate solution enter the first reaction kettle at a flow rate of 422kg / h, and act rapidly under strong stirring. At the same time, the ammonia gas generated by hydrolysis flows from the top of the first reaction kettle It is discharged from the whole system, and the feed liquid stays in the first reactor for 30 minutes. After the first-stage reaction is completed, the feed liquid enters the second reactor, and the temperature of the second reactor is controlled at 110 ° C. The feed liquid stays in the second reactor for 5 minutes. At the same time, the ammonia gas generated by the further reaction is further discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com